设计简介

摘 要

焊接变位机也已成为制造业的一种不可缺少的设备,在焊接领域把它划为焊接辅助机。就型式系列和品种规格而言,已问世的,约有十余个系列,百余个品种规格,正在形成一个新兴行业。但是,有关焊接变位机的基本概念、型式与分类、主要技术参数等,存在不统一的问题。

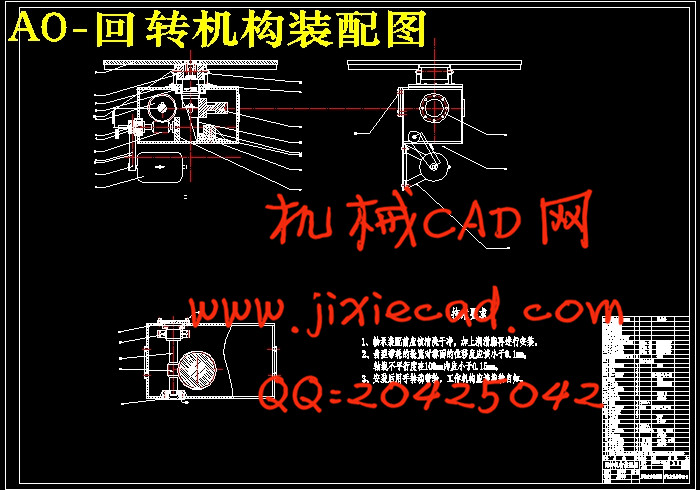

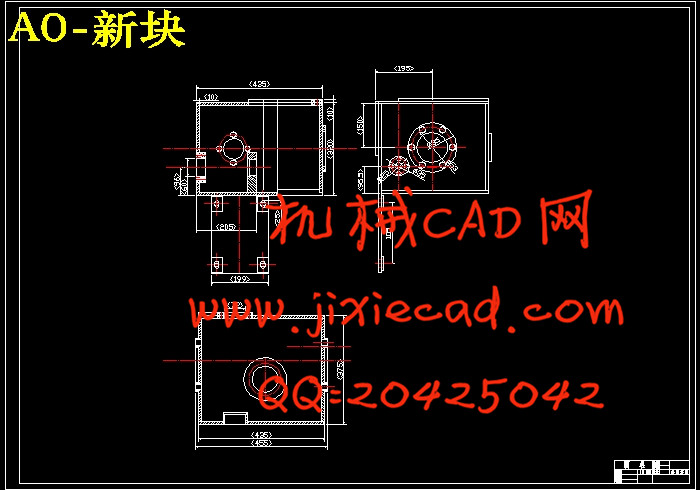

本题目是设计能载重1.0t工件,进行全位置焊接的变位机械。主要内容是关于焊接时机械的回转翻转的控制、电机选择、减速器的选择、各个轴和齿轮轴承的确定以及校核等等。

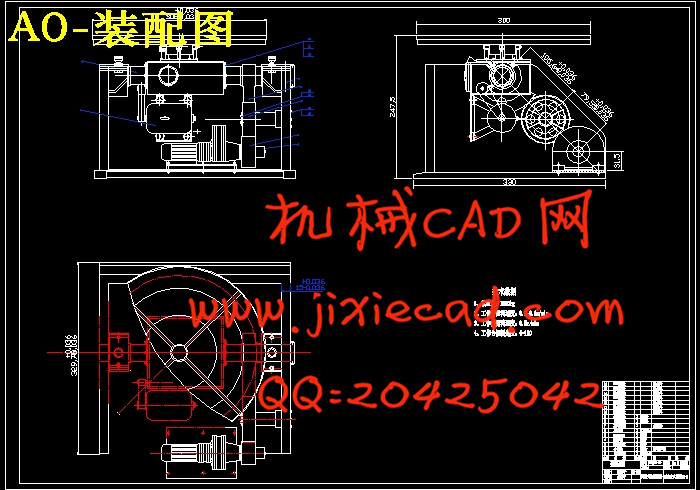

设计的具体过程是根据预定的载荷和要求的焊接速度从而确定设备所需要的电机类型,包括:电机的转速、额定功率、电压电流等,在此基础上计算轴的尺寸和相应配件的型号,并且对其进行相关的强度、使用寿命等的校核,然后对一些外购件也进行选择。最后使用CAD软件将相关的零件图。总装图绘制出来。

选用的方法主要是机械设计的相关知识,使用到的有材料力学、金属工艺学、Autocad等。

关键词:焊接变位机;机械设计

Abstract

Welding conjugation plane has become an indispensable manufacturing equipment , which is zoned welding assistant engine in the welding area. Patterns and varieties of specifications on the series, has been developed, some over 10 series, more than 100 varieties of specifications, a newly emerging industries. However, the welding machine conjugation basic concepts, patterns and classification, the main technical parameters, there are not uniform.

This topic is designed to load 1.0t working, welding locations throughout the conjugation machinery. Mainly on the subject of welding, mechanical rotation turnover of control, the electrical options, reducer selection, various axle and the wheel bearings and determine accuracy, and so on.

The design process is based on specific target load and speed requirements of welding equipment to determine the type of electrical needs, including : the rotational speed electrical, rated power, voltage, current and on the basis of the calculation of axle size and corresponding accessories models, and their associated intensity, and the useful life of accuracy, then for some purchases were also chosen. Finally related to the use of CAD software components map. GAD mapping out.

The method chosen mainly mechanical design relevant knowledge, the use of the material mechanics, metal crafts science, Autocad.

Keyword : welding conjugation machines, mechanical design.

目录

第1章 绪论 1

1.1关于焊接变位机的几个定义和基本的要求 1

1.2 几种常见的焊接变位机的特点 3

1.3焊接变位机的变位 5

1.4变位机械中的机械传动机构的选择 5

1.5变位机的额定载荷 6

1.6焊接变位机械应具备的性能 7

1.7国际和国内焊接变位机的发展 8

1.8任务的提出 10

第2章 焊接变位机的总体方案设计 11

2.1焊接变位机的总体设计和适用范围 11

2.2焊接变位机的自由度 11

2.3设计方案的确定 12

第3章 设计与校核 15

3.1传动比的假定和确定 15

3.2传动装置总效率的确定 16

3.3工作台阻力矩的计算 17

3.4电动机额定功率的确定 18

3.5电动机转速的确定 19

3.6电机类型的确定 20

3.7蜗轮蜗杆的设计 21

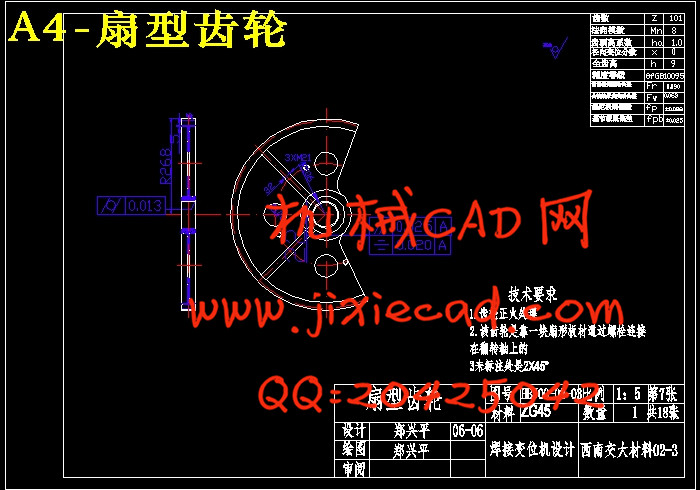

3.8 齿轮的设计与较核 24

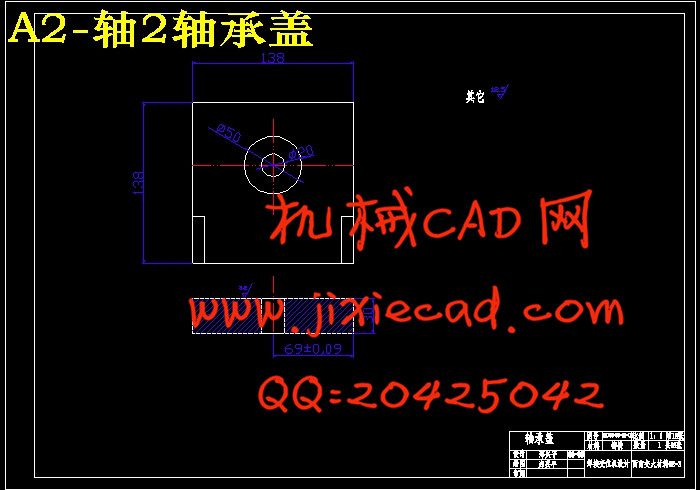

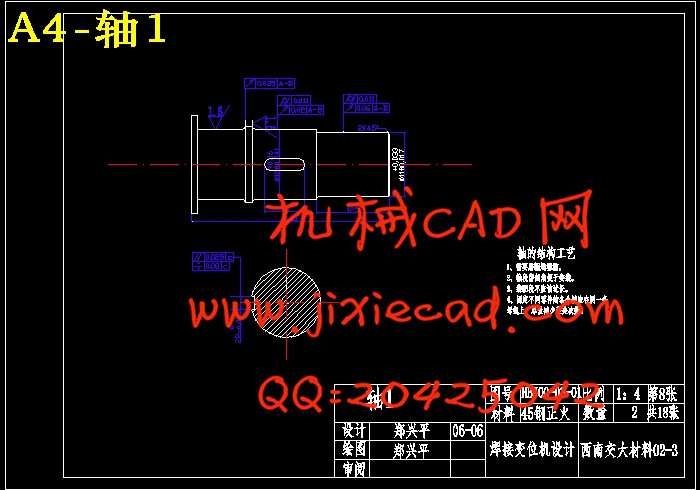

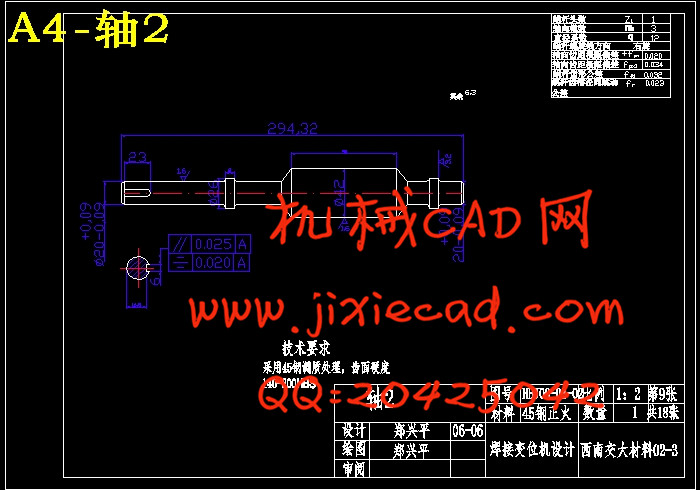

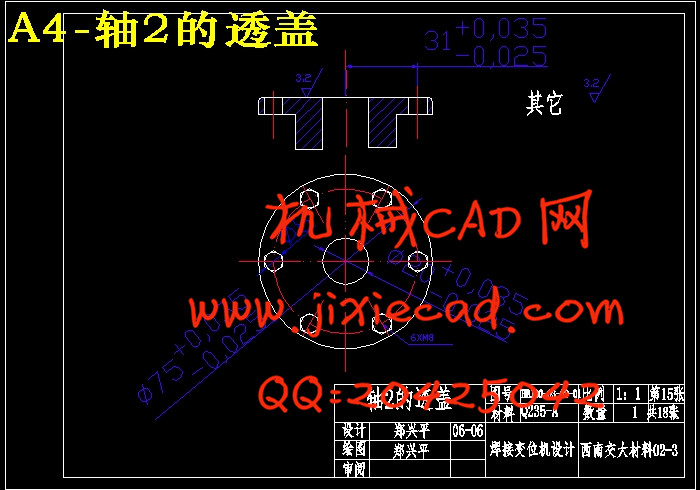

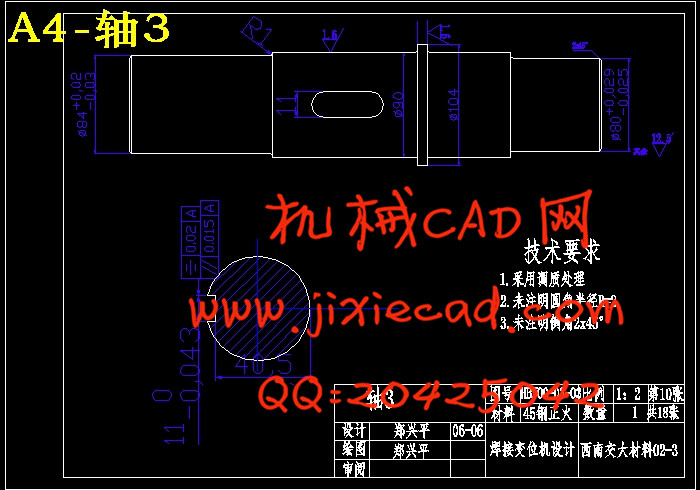

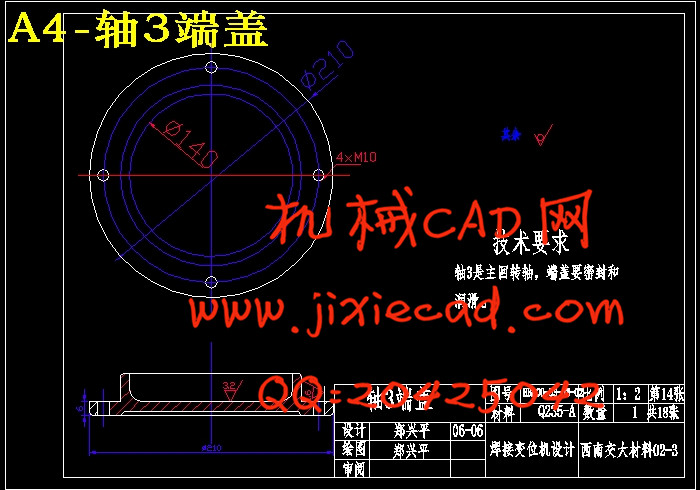

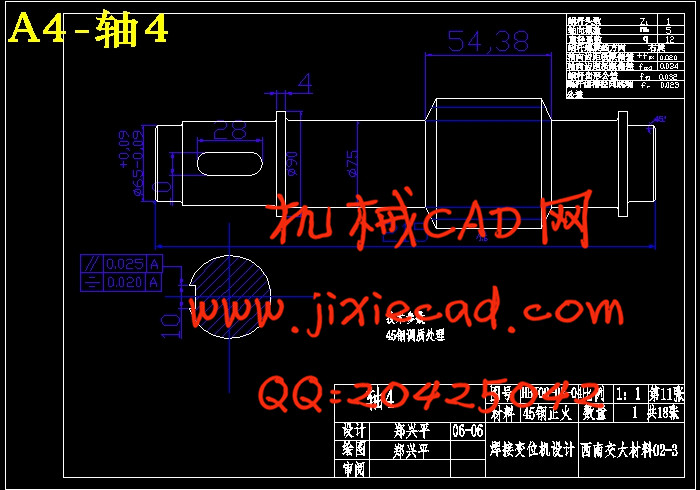

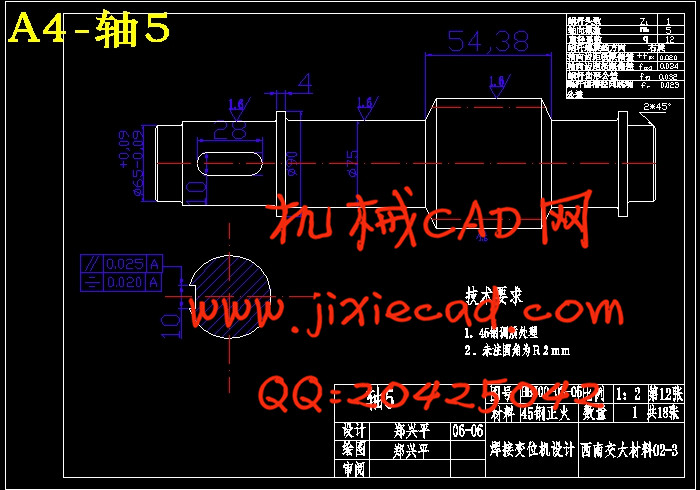

3.9轴的设计 26

3.10轴的强度的校核[5] 28

3.11轴承的选择和较核 29

3.12机架的设计 33

3.13 导电装置的设计 34

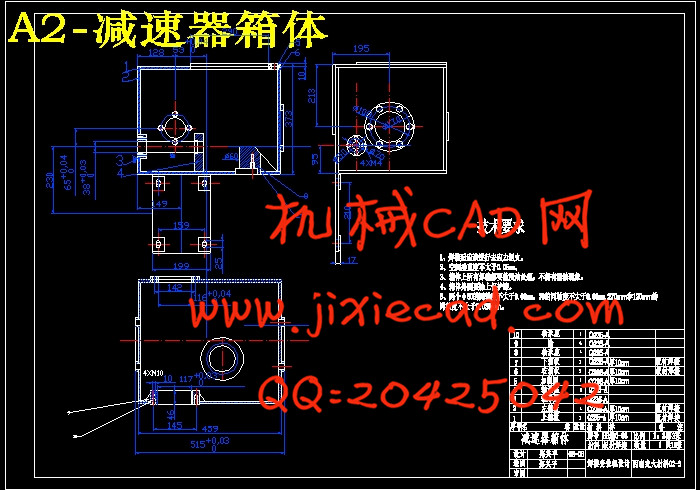

3.14 减速器箱体 34

3.15其他外购件的选择 36

结论 38

致谢 39

参考文献 40

焊接变位机也已成为制造业的一种不可缺少的设备,在焊接领域把它划为焊接辅助机。就型式系列和品种规格而言,已问世的,约有十余个系列,百余个品种规格,正在形成一个新兴行业。但是,有关焊接变位机的基本概念、型式与分类、主要技术参数等,存在不统一的问题。

本题目是设计能载重1.0t工件,进行全位置焊接的变位机械。主要内容是关于焊接时机械的回转翻转的控制、电机选择、减速器的选择、各个轴和齿轮轴承的确定以及校核等等。

设计的具体过程是根据预定的载荷和要求的焊接速度从而确定设备所需要的电机类型,包括:电机的转速、额定功率、电压电流等,在此基础上计算轴的尺寸和相应配件的型号,并且对其进行相关的强度、使用寿命等的校核,然后对一些外购件也进行选择。最后使用CAD软件将相关的零件图。总装图绘制出来。

选用的方法主要是机械设计的相关知识,使用到的有材料力学、金属工艺学、Autocad等。

关键词:焊接变位机;机械设计

Abstract

Welding conjugation plane has become an indispensable manufacturing equipment , which is zoned welding assistant engine in the welding area. Patterns and varieties of specifications on the series, has been developed, some over 10 series, more than 100 varieties of specifications, a newly emerging industries. However, the welding machine conjugation basic concepts, patterns and classification, the main technical parameters, there are not uniform.

This topic is designed to load 1.0t working, welding locations throughout the conjugation machinery. Mainly on the subject of welding, mechanical rotation turnover of control, the electrical options, reducer selection, various axle and the wheel bearings and determine accuracy, and so on.

The design process is based on specific target load and speed requirements of welding equipment to determine the type of electrical needs, including : the rotational speed electrical, rated power, voltage, current and on the basis of the calculation of axle size and corresponding accessories models, and their associated intensity, and the useful life of accuracy, then for some purchases were also chosen. Finally related to the use of CAD software components map. GAD mapping out.

The method chosen mainly mechanical design relevant knowledge, the use of the material mechanics, metal crafts science, Autocad.

Keyword : welding conjugation machines, mechanical design.

目录

第1章 绪论 1

1.1关于焊接变位机的几个定义和基本的要求 1

1.2 几种常见的焊接变位机的特点 3

1.3焊接变位机的变位 5

1.4变位机械中的机械传动机构的选择 5

1.5变位机的额定载荷 6

1.6焊接变位机械应具备的性能 7

1.7国际和国内焊接变位机的发展 8

1.8任务的提出 10

第2章 焊接变位机的总体方案设计 11

2.1焊接变位机的总体设计和适用范围 11

2.2焊接变位机的自由度 11

2.3设计方案的确定 12

第3章 设计与校核 15

3.1传动比的假定和确定 15

3.2传动装置总效率的确定 16

3.3工作台阻力矩的计算 17

3.4电动机额定功率的确定 18

3.5电动机转速的确定 19

3.6电机类型的确定 20

3.7蜗轮蜗杆的设计 21

3.8 齿轮的设计与较核 24

3.9轴的设计 26

3.10轴的强度的校核[5] 28

3.11轴承的选择和较核 29

3.12机架的设计 33

3.13 导电装置的设计 34

3.14 减速器箱体 34

3.15其他外购件的选择 36

结论 38

致谢 39

参考文献 40