设计简介

摘 要

由于现代科学工作者技术的迅猛发展,机械工业,电子工业,航空航天工业,化学工等,要求尖端科学技术产品向高精度、高速度、大功率、小型化方向发展,以及在高温、高压、重载荷或腐蚀环境下长期可靠地工作。为了适应这些要求,各种新结构、新材料和复杂形状的精密零件大量出现,其结构和形状越来越复杂,材料的性能越来越强韧,对精度要求越来越高,对加工表面粗糙度和完整性要求越来越严格,使机械制造面临着一系列严峻的任务。

1) 解决各种难切削材料的加工问题。如硬质合金、钛合金、耐热钢、不锈钢、锗等各种高硬度、高韧性、高脆性的金属材料的加工。

2) 解决各种特殊复杂型面的加工问题。如喷气涡轮机叶片、整体涡轮、发动机机匣、锻压模等的立体成型表面。

要解决上述一系列的问题,传统的切削加紧工方法很难实现,有些根本无法实现。在生产的迫切需求下,人们不断研究和探索新的加工方法。精密电火花加工就是在这种环境下产生和发展起来的。

关键词:机械;精密;加工;电火花

Abstract

Thanks to modern technology rapid development of scientific workers,Mechanical industry, electronic industry, the aerospace industry, chemical etc and more,Request advanced science and technology to the high precision, high speed products, power, miniaturization,

direction, And in high temperature, high pressure, heavy load or corrosive environment long-term working reliably. In order to adapt to the requirements of the new structure, and new materials and complex shape precision components, its structure and shape is more and more complicated, the properties of materials and fortitude, accuracy, completeness of surface roughness and more stringent requirements, mechanical manufacturing is facing a series of serious tasks.

1) to solve all kinds of difficult problems of cutting materials processing. Hard alloy, titanium alloy, such as heat resistant steel, stainless steel, high hardness etc. Various ge, high toughness, high brittle metal material processing.

2) to solve the problem of various special factors. As the jet turbine blade, turbine, blast, forging the magazine etc. Stero-prototyping surface,

To solve these problems, a series of traditional cutting to work hard to achieve, some basic method can achieve. In urgent need of the production, research and exploration for new people. Precision edm is in this kind of environment and development.

Key words:Machinery;precision;processing;edm

目 录

摘 要 IAbstract II

1 引言 1

1.1 电火花加工的背景 1

1.2电火花加工的意义及特点 1

1.3 电火花加工机的现状及发展前景 2

2 电火花原理和总体方案拟定 3

2.1 电火花加工机的原理 3

2.2拟定总体设计方案 3

3 电火花Z轴的设计计算 8

3.1概述 8

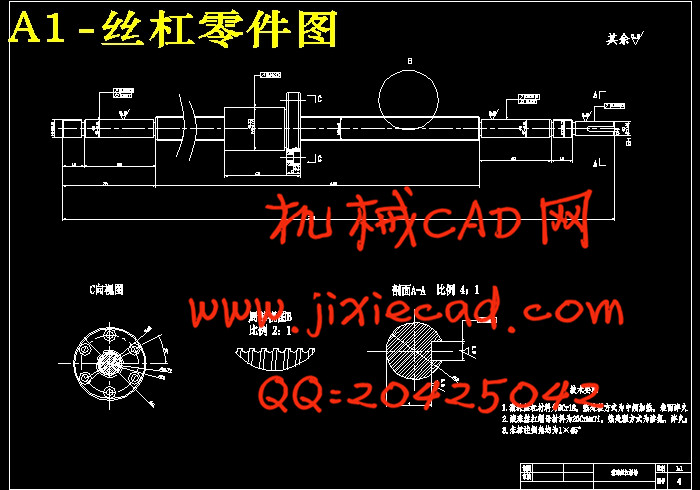

3.2丝杠的计算和选择 8

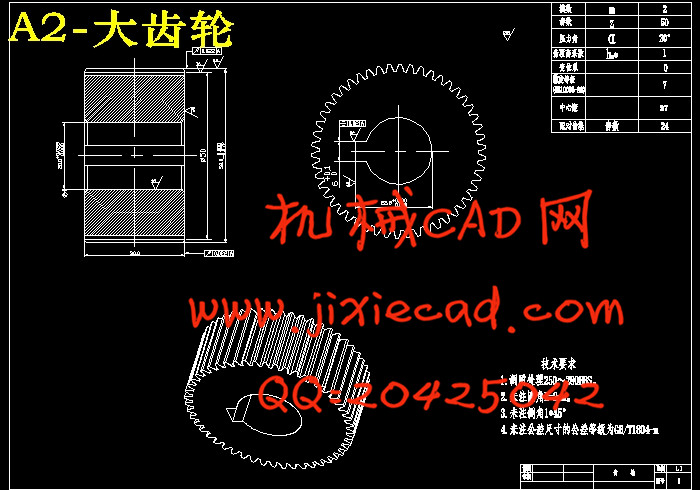

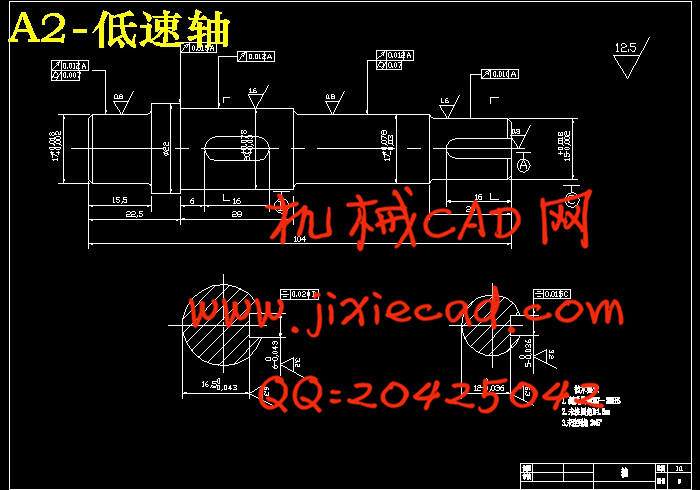

3.3减速器的设计与计算 11

3.4步进电机的计算与选择 14

4 步进电机PLC控制设计 21

4.1 步进电机控制器的选择 21

4.2 步进电机的控制原理 21

4.3 控制器的总体设计 22

总结 24

致谢 25

参考文献 26

附录 26