设计简介

摘 要

随着信息技术的进步和全球化制造技术的进步,企业为了提高自身的竞争力,要求配置效率更高成本更低的加工设备,而传统机床在未来的加工业中会遇到难以克服的困难,例如在高速加工中(轨迹速度达到50m/min)和高效空间曲面加工及机床的通用性方面将无法满足现代加工技术的要求。因此探索和研究一种现代化机床具有十分重要的意义。

虚拟轴机床与传统的串联式数控机床相比具有很多优越性。传统数控机床各自由度是串联相接的,呈悬臂结构,且层叠嵌套致使传动链长,传动系统复杂,累计误差大,而精度低,成本昂贵,至今多数机床只是4轴联动,极少5轴。而虚拟轴机床的并联式加工中心结构特别简单,传动链极短,刚度大、质量轻、切削效率高、响应快,特别是很容易实现六轴联动,因而,能加工更复杂的三维曲面,且其加工精度和加工粗糙度都直接由控制程序来保证,因此,硬件成本低,而软件附加值高,是一种技术附加值极高的机电一体化产品。

此研究课题针对现今的机加工趋向,制定了设计一部并联机床实验台的任务,作者与合作人共同设计。其中的并联部分分配给了合作者,作者主要负责并联机床实验台的总体框架结构设计。

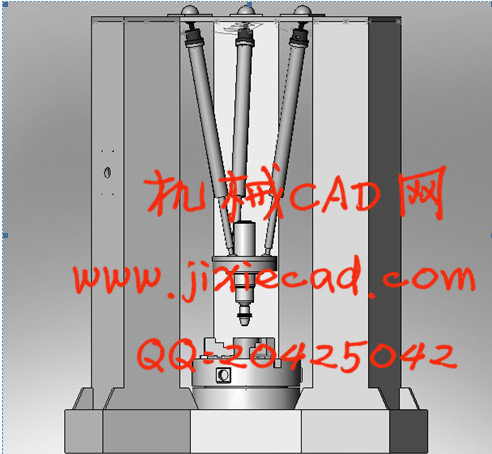

平台大致由并联机构——三根并联丝杠(驱动电机)、铸铁机架、装卡平台和电主轴以及弹簧铣夹头组成。

关键词:并联机构、虚轴加工、雅可比矩阵、正解算法

Abstract

With the progress of the information technology and the development of the global manufacturing techniques, enterprises require more efficient and lower cost machines by reason of enhancing their competitive ability. But conventional machine tools will encounter many difficulties which are hard to overcome in the future, for instance of high-speed machining ( path speed exceeding 50m/min)and high efficient space curved surfacing machining as well as flexibility of machines. Thus, it is very important to explore and study kind of modern machines.

Be compared to the normal numerical control machine tool, it has larger rigidity, stronger carrying capacity, smaller error, higher precision, smaller ratio of self-weight and load, better dynamical capacity, less investment of hardware, but stronger function of software. All of these show its high additional technical valve.

This research topic for the current trend of the processing machine, developed a design of a parallel machine test-bed task, which the Author co-design and a partner. Some of them parallel to the allocation of the partner, the author mainly responsible for the PMT test-bed framework of the overall structural design.

Platform from roughly parallel bodies - three parallel screw (motor driven), cast iron rack, with card platform and Spindle and milling chucks of spring.

Key words: parallel instruction, virtual axis processing, Jacobian Matrix, positive solution algorithm

目 录

第1章 绪论 1

1.1课题背景与意义 1

1.2 并联机床发展历史及现状 2

1.3本文主要研究内容 5

第2章 重要零部件选型 6

2.1依照主轴功率确定电主轴型号 6

2.2 选择主轴下部刀具夹头 7

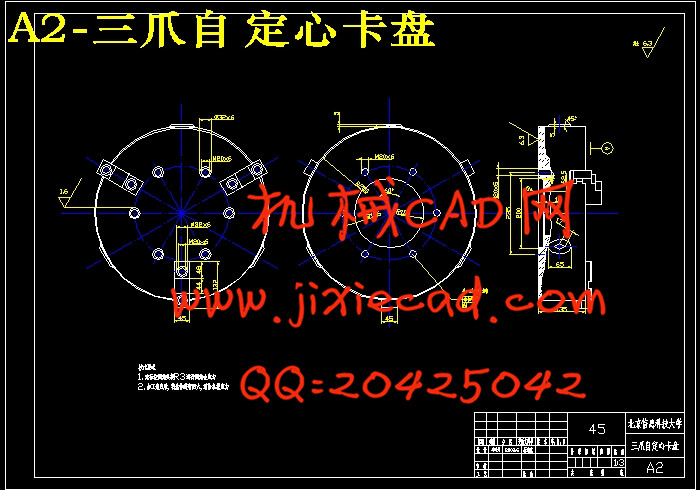

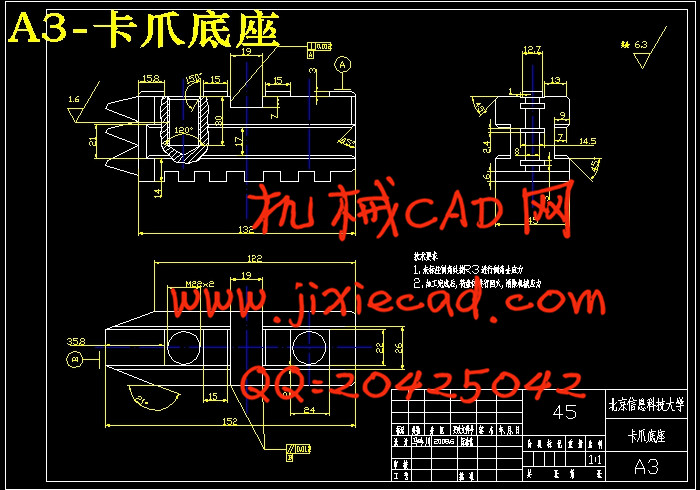

2.3选择工件的装卡方式 8

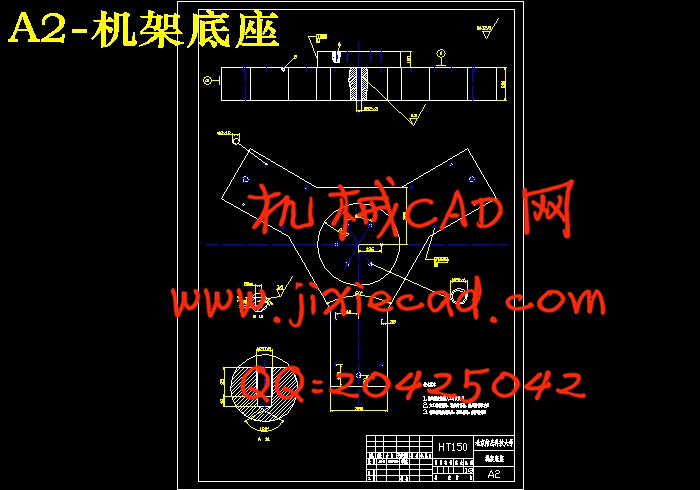

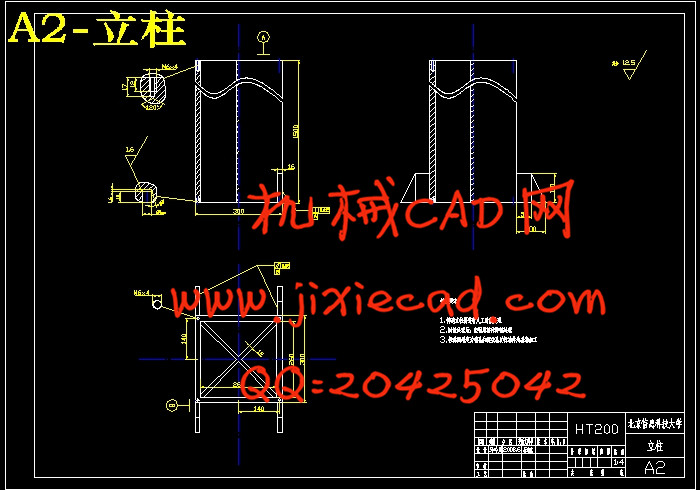

第3章 实验台支承部分及其连接的方案 11

3.1机架的设计方案 11

3.2铸造机架的材料及热处理 14

3.3机架的截面形状、壁厚及周边筋的布置 14

3.4立柱与底座的连接方式 16

3.5底座的造型 16

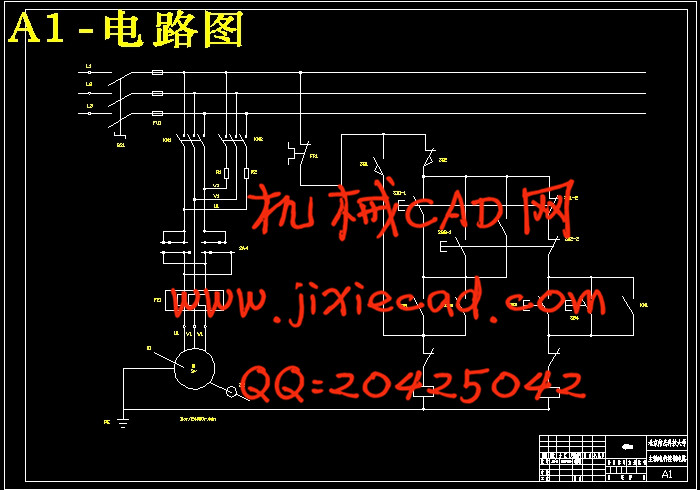

第4章 实验台驱动电路 17

4.1 电路布线方案 17

4.2 电路控制要求 17

4.3电路控制连线原理图 17

第5章 实验结果及三维建模 18

5.1 设计并联实验台结果 18

5.2 实验台solidworks建模 18

第6章总结与展望 19

参考文献 20

致 谢 20

随着信息技术的进步和全球化制造技术的进步,企业为了提高自身的竞争力,要求配置效率更高成本更低的加工设备,而传统机床在未来的加工业中会遇到难以克服的困难,例如在高速加工中(轨迹速度达到50m/min)和高效空间曲面加工及机床的通用性方面将无法满足现代加工技术的要求。因此探索和研究一种现代化机床具有十分重要的意义。

虚拟轴机床与传统的串联式数控机床相比具有很多优越性。传统数控机床各自由度是串联相接的,呈悬臂结构,且层叠嵌套致使传动链长,传动系统复杂,累计误差大,而精度低,成本昂贵,至今多数机床只是4轴联动,极少5轴。而虚拟轴机床的并联式加工中心结构特别简单,传动链极短,刚度大、质量轻、切削效率高、响应快,特别是很容易实现六轴联动,因而,能加工更复杂的三维曲面,且其加工精度和加工粗糙度都直接由控制程序来保证,因此,硬件成本低,而软件附加值高,是一种技术附加值极高的机电一体化产品。

此研究课题针对现今的机加工趋向,制定了设计一部并联机床实验台的任务,作者与合作人共同设计。其中的并联部分分配给了合作者,作者主要负责并联机床实验台的总体框架结构设计。

平台大致由并联机构——三根并联丝杠(驱动电机)、铸铁机架、装卡平台和电主轴以及弹簧铣夹头组成。

关键词:并联机构、虚轴加工、雅可比矩阵、正解算法

Abstract

With the progress of the information technology and the development of the global manufacturing techniques, enterprises require more efficient and lower cost machines by reason of enhancing their competitive ability. But conventional machine tools will encounter many difficulties which are hard to overcome in the future, for instance of high-speed machining ( path speed exceeding 50m/min)and high efficient space curved surfacing machining as well as flexibility of machines. Thus, it is very important to explore and study kind of modern machines.

Be compared to the normal numerical control machine tool, it has larger rigidity, stronger carrying capacity, smaller error, higher precision, smaller ratio of self-weight and load, better dynamical capacity, less investment of hardware, but stronger function of software. All of these show its high additional technical valve.

This research topic for the current trend of the processing machine, developed a design of a parallel machine test-bed task, which the Author co-design and a partner. Some of them parallel to the allocation of the partner, the author mainly responsible for the PMT test-bed framework of the overall structural design.

Platform from roughly parallel bodies - three parallel screw (motor driven), cast iron rack, with card platform and Spindle and milling chucks of spring.

Key words: parallel instruction, virtual axis processing, Jacobian Matrix, positive solution algorithm

目 录

第1章 绪论 1

1.1课题背景与意义 1

1.2 并联机床发展历史及现状 2

1.3本文主要研究内容 5

第2章 重要零部件选型 6

2.1依照主轴功率确定电主轴型号 6

2.2 选择主轴下部刀具夹头 7

2.3选择工件的装卡方式 8

第3章 实验台支承部分及其连接的方案 11

3.1机架的设计方案 11

3.2铸造机架的材料及热处理 14

3.3机架的截面形状、壁厚及周边筋的布置 14

3.4立柱与底座的连接方式 16

3.5底座的造型 16

第4章 实验台驱动电路 17

4.1 电路布线方案 17

4.2 电路控制要求 17

4.3电路控制连线原理图 17

第5章 实验结果及三维建模 18

5.1 设计并联实验台结果 18

5.2 实验台solidworks建模 18

第6章总结与展望 19

参考文献 20

致 谢 20