设计简介

摘要

设计一台玻璃钢成型机,玻璃钢在引拔张力下连续成型,可充分发挥增强材料连续性和定向强度高的特点,制品质量高,劳动条件好,易于实现自动化。根据参考有关书籍。我们设计生产的玻璃钢管主要技术参数如下:外径D=22mm,内径d=6mm,螺距p=10mm,生产速率v=20m/h。参与设计的共四人,分为总体设计、成型部设计、牵引部设计和切割部分设计四部分内容。本人负责切割部分设计。传统的玻璃钢切割系统以及市场上销售的成品几乎都是依靠纯粹的机械传动来实现其功能,它们通过带轮,齿轮,齿条等机械零件将动力进行输出,从而达到切割的目的。而我在这次设计中,尤其是传动系统的设计中采用了大胆的创新。我在设计中巧妙地运用了电子技术,将原本纯粹的机械传动变成了轻巧的机电传动,这样不仅为机械设计人员在设计中减轻了工作量,为机械加工降低了成本,与此同时也在自动化技术日益渗入机械工程领域的今天,使得该机械系统变得更加智能化,从而更加方便控制与管理。因此,在这次毕业设计中,我根据自己装置的工作原理分别进行了机械设计与电路设计两部分构思,并且取得了很好的效果。

关键词:玻璃钢;切割部分;机电传动;机械设计

设计一台玻璃钢成型机,玻璃钢在引拔张力下连续成型,可充分发挥增强材料连续性和定向强度高的特点,制品质量高,劳动条件好,易于实现自动化。根据参考有关书籍。我们设计生产的玻璃钢管主要技术参数如下:外径D=22mm,内径d=6mm,螺距p=10mm,生产速率v=20m/h。参与设计的共四人,分为总体设计、成型部设计、牵引部设计和切割部分设计四部分内容。本人负责切割部分设计。传统的玻璃钢切割系统以及市场上销售的成品几乎都是依靠纯粹的机械传动来实现其功能,它们通过带轮,齿轮,齿条等机械零件将动力进行输出,从而达到切割的目的。而我在这次设计中,尤其是传动系统的设计中采用了大胆的创新。我在设计中巧妙地运用了电子技术,将原本纯粹的机械传动变成了轻巧的机电传动,这样不仅为机械设计人员在设计中减轻了工作量,为机械加工降低了成本,与此同时也在自动化技术日益渗入机械工程领域的今天,使得该机械系统变得更加智能化,从而更加方便控制与管理。因此,在这次毕业设计中,我根据自己装置的工作原理分别进行了机械设计与电路设计两部分构思,并且取得了很好的效果。

关键词:玻璃钢;切割部分;机电传动;机械设计

Abstract

Design of a glass fiber reinforced plastic molding machine, glass steel in drawing tension for continuous molding, can give full play to enhance material continuity and directional characteristics of high strength, high quality products, good labor condition, easy realization of automation. According to the reference books. We design and production of glass steel tube main technical parameters are as follows: the diameter D = 22mm, d = 6mm, P = 10mm pitch, the rate of production of V =20m / h. In the design of the four, divided into the overall design, molding part design, traction of the design and cutting section design of four parts. I am responsible for the cutting part of the design. The traditional glass steel cutting system and market sales of finished products are almost pure mechanical transmission to realize its function, they pass through a belt wheel, gear, rack and other mechanical parts of the power output, thereby achieving the purpose of cutting. And I'm in this design, especially the transmission system used in the design of bold innovation. I design and clever use of the electronic technology, the original pure mechanical transmission into a light transmission, so that not only the mechanical design personnel in the design to reduce the workload, machinery processing reduces the cost, at the same time also in the field of mechanical engineering automation technology into today, the mechanical system becomes more intelligent, thus more convenient control and management. Therefore, in this graduation design, according to their working principle of the device are carried out respectively in mechanical design and circuit design two part design, and achieved very good results.

Key words: glass steel; cutting parts; electric drive; mechanical design

目录Design of a glass fiber reinforced plastic molding machine, glass steel in drawing tension for continuous molding, can give full play to enhance material continuity and directional characteristics of high strength, high quality products, good labor condition, easy realization of automation. According to the reference books. We design and production of glass steel tube main technical parameters are as follows: the diameter D = 22mm, d = 6mm, P = 10mm pitch, the rate of production of V =20m / h. In the design of the four, divided into the overall design, molding part design, traction of the design and cutting section design of four parts. I am responsible for the cutting part of the design. The traditional glass steel cutting system and market sales of finished products are almost pure mechanical transmission to realize its function, they pass through a belt wheel, gear, rack and other mechanical parts of the power output, thereby achieving the purpose of cutting. And I'm in this design, especially the transmission system used in the design of bold innovation. I design and clever use of the electronic technology, the original pure mechanical transmission into a light transmission, so that not only the mechanical design personnel in the design to reduce the workload, machinery processing reduces the cost, at the same time also in the field of mechanical engineering automation technology into today, the mechanical system becomes more intelligent, thus more convenient control and management. Therefore, in this graduation design, according to their working principle of the device are carried out respectively in mechanical design and circuit design two part design, and achieved very good results.

Key words: glass steel; cutting parts; electric drive; mechanical design

1.绪论 …………………………………………………………………1

2.整机传动方案的初步确定及工作原理 ……………………………2

2.1机械传动系统总体设计 ………………………………………………2

2.1.1传动方案的拟定 …………………………………………………2

2.1.2电动机的选择 ………………………………………………………2

2.2玻璃钢成型机切割系统传动部分工作原理………………………………4

3.传动装置运动和动力参数的计算 …………………………………4

3.1传动比分配 ………………………………………………………4

3.2各轴的转速计算 …………………………………………………4

3.3各轴输入功率计算 …………………………………………………4

3.4各轴输入扭矩计算 …………………………………………………5

4.零、部件的设计 ………………………………………………6

4.1.V带传动的设计计算 ……………………………………………7

4.2.齿轮传动的设计计算 ………………………………………………8

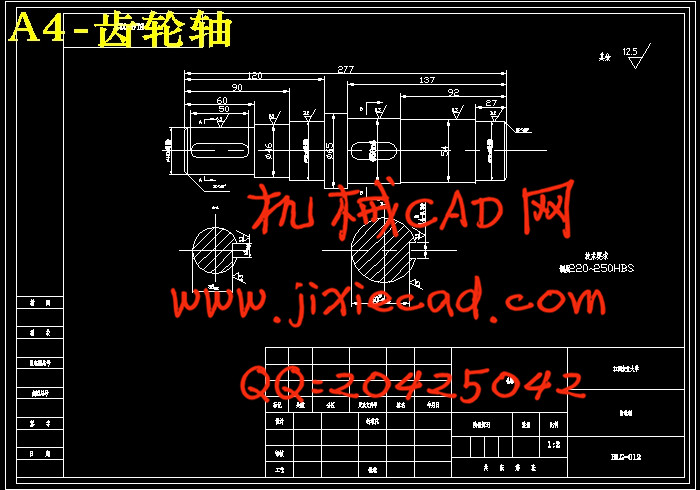

4.3.轴系零件的设计计算 ………………………………………………9

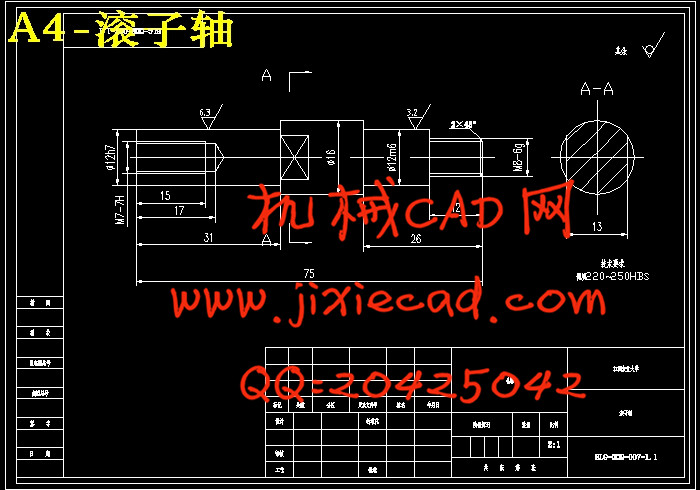

4.3.1.初算轴径d ………………………………………………………10

4.3.2.计算轴上载荷 …………………………………………………11

4.3.3绘制轴的弯扭矩图,对危险截面进行校核 …………………………12

4.3.4轴承的校核 ………………………………………………………14

4.3.5轴上键连接的选择及校核 …………………………………………14

4.3.6轴上螺母的选择 …………………………………………………15

5.轴系零件的设计、选择与校核 …………………………………15

5.1轴承的选择、校核 …………………………………………………16

5.2齿轮连接键的选择及校核 …………………………………………17

5.3轴上螺母选择 ……………………………………………………18

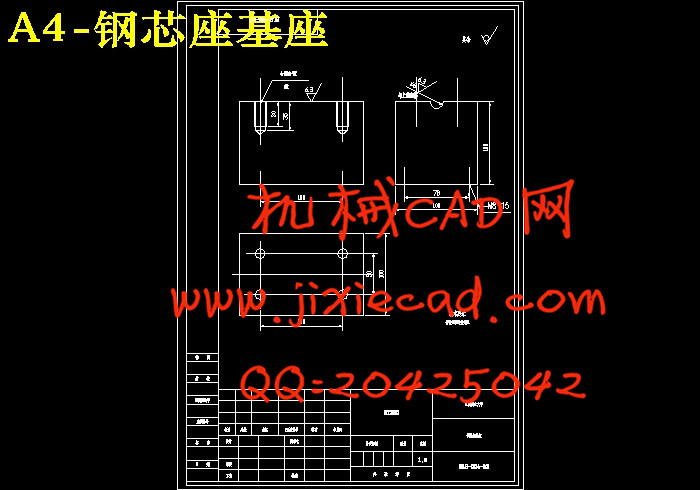

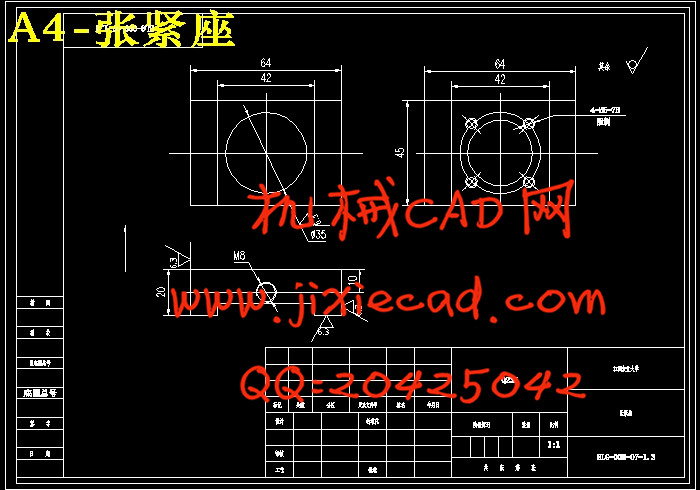

5.4.轴承座、端盖的结构设计 ………………………………………19

5.4.1轴承座的选材 ……………………………………………………19

5.4.2轴承座的固定方式 …………………………………………………19

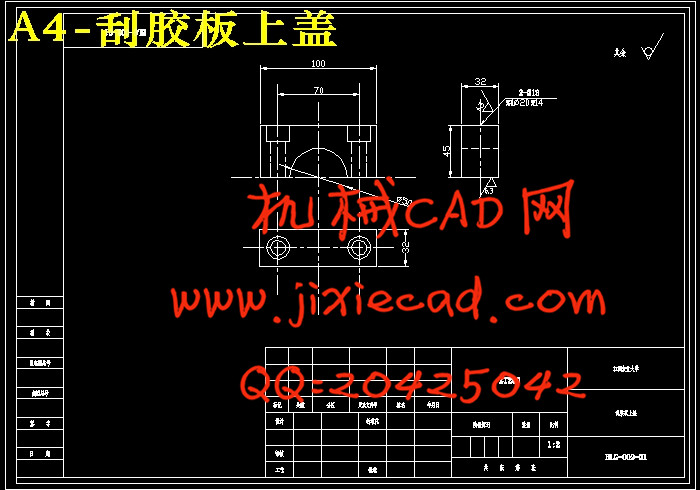

5.4.3轴承座的结构设计 …………………………………………………20

5.4.4轴承座端盖选材、结构设计…………………………………………20

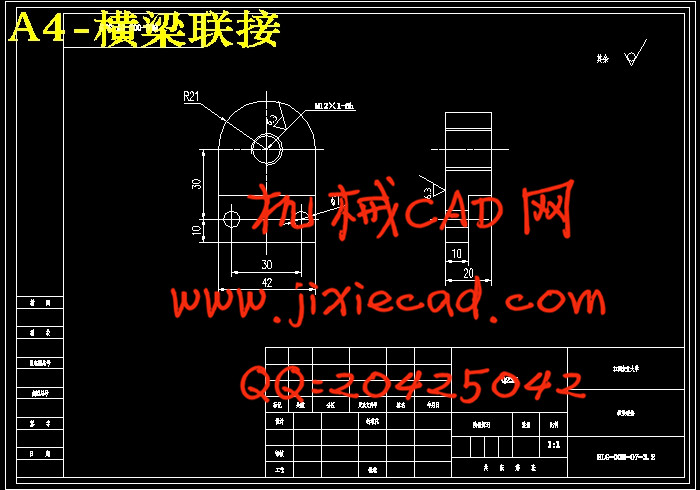

5.5.轴承座联接用螺栓的设计计算 ……………………………………………20

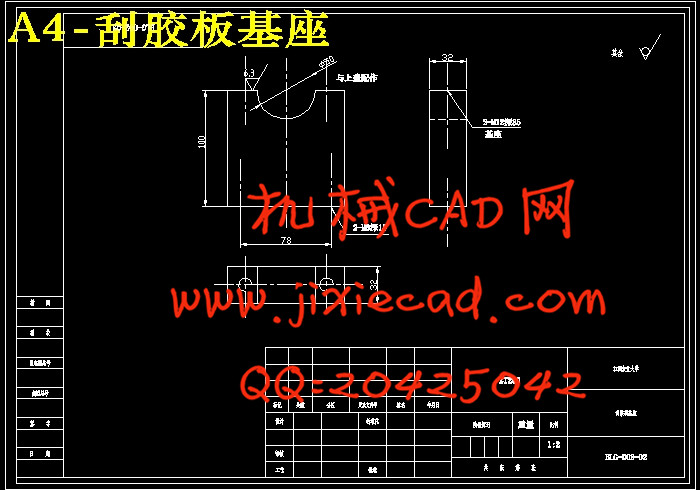

5.6.机架的结构设计 ………………………………………………………20

6.电路的设计…………………………………………………………21

设计小结 …………………………………………………………21

参考资料 …………………………………………………………21