设计简介

摘要

本次设计的题目是设计一种基于单片机控制的玻璃横切机。主要设计内容为:设计玻璃横切机的机械结构及人机界面系统。机械结构部分的设计确定为步进电动机带动的同步带传动系统。控制系统采用AT89C51为CPU。由矩阵键盘和RT12864M汉字图形点阵液晶显示模块组成人机界面系统。

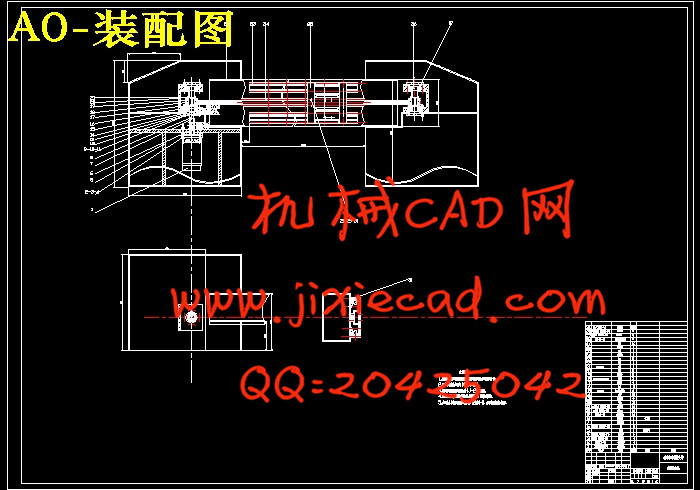

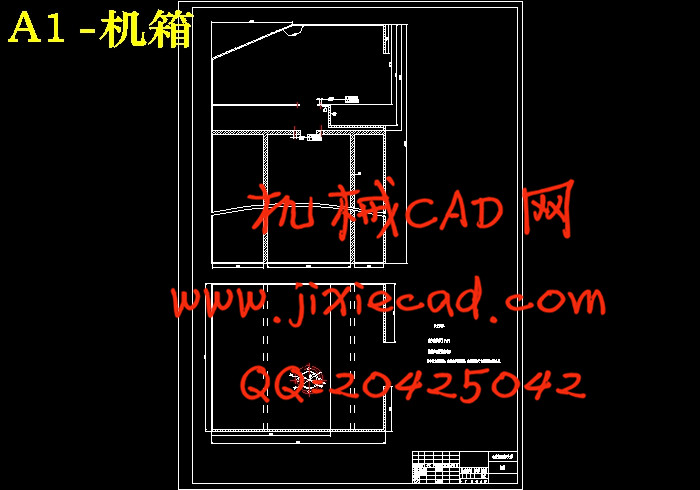

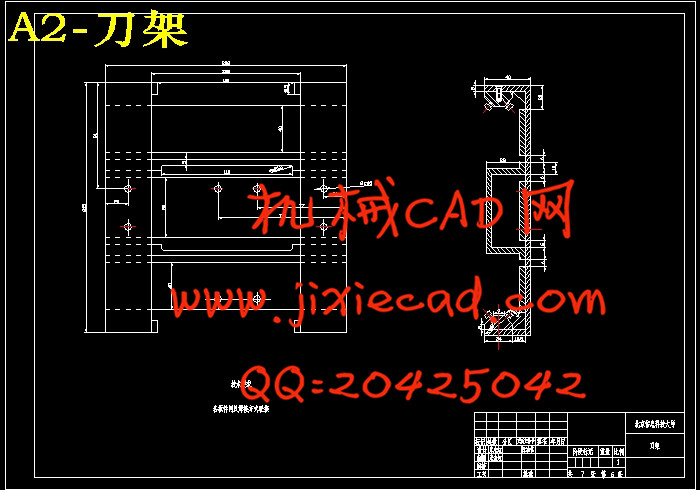

首先,分析了玻璃横切机的市场前景及其在玻璃生产中的重要作用。然后,确定机械结构。根据现有的玻璃横切机的结构将其分类,并归纳出每一类玻璃横切机的机械机构特征、运行特征、切割原理等。本设计最终选用了其中的斜置、速度控制式的机械结构。基于这种机械结构,对步进电动机、同步带进行了选型和计算。绘制了机械结构装配图及部分零件图。

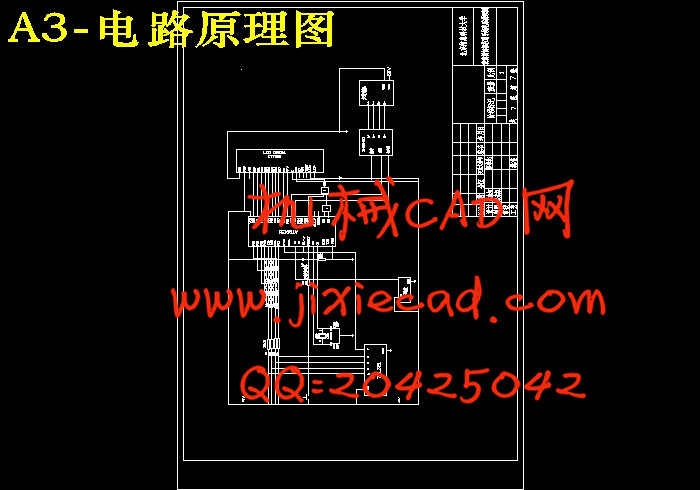

对于玻璃横切机的人机界面系统,本设计主要大致完成其程序的编写。即液晶显示四组控制参数,并可以通过键盘修改这些参数。本文中包括了各级程序流程图及其对应的说明。大致包括LCD驱动、键盘监控、液晶显示三个程序块。详见正文。

关键字 玻璃横切机; 步进电动机; 同步带; 单片机; 人机界面系统 ;液晶

Abstract

This graduation project's topic is the design of one kind of the auto glass-cutter which controls based on the Microcontroller. The main content of the design is: the machine mechanism and man-machine contact surface system of the glass-cutter’s design .The mechanism part's design I determined it as that Pulse motor gives the power and the Transmission system transfer the power to the Ambulacrum.The control system uses AT89C51 as CPU. Forms the man-machine contact surface department of the matrix keyboard and the RT12864M Chinese character graph lattice liquid crystal display module.

First, has analyzed the glass-cutter’s market prospect and its influential role in the glass production. Then, determination of the machine mechanism. According to the existing glass-cutter’s structure I staple then to same types, and then concluded the mechanism character, sport character, cutting principle of each of the types. And so on.

This design finally has selected the tilts, speed control-like mechanism. Based on this kind of mechanism, I did the choice of the Pulse motor, ambulacrum’s and the count, checkout of them. I had drawn up the drawing of mechanism assembly and some part drawings.

Regarding the glass-cutter’s man-machine contact surface system, this design mainly completes its program’s compilation. Namely the liquid crystal display shows the four groups of controlled variables, and may revise these parameters through the keyboard. This article has included all levels of program flow diagram and the corresponding explanation. Includes the LCD actuation, the keyboard monitoring, and the liquid crystal display three blocks approximately. For details sees the main text.

Key-words glass-cutter ; Pulse motor ;ambulacrum ; Microcontroller ; man-machine contact surface system ; liquid crystal display module

目录

摘要(中文)…………………………………………………………………………………І

(英文)…………………………………………………………………………………П

第一章概述……………………………………………………………………………………1

1.1我国玻璃市场现状………………………………………………………………………………………1

1.2 我国浮法玻璃技术与国际先进水平的差距…………………………………………………………1

1.3 高精度玻璃切割的必要………………………………………………………………………………1

1.4 玻璃横切机的分类……………………………………………………………………………………1

第二章 设计方案……………………………………………………………………………7

2.1研究内容………………………………………………………………………………………………7

2.2实现方法…………………………………………………………………………………………………7

2.3设计任务…………………………………………………………………………………………………9

2.4 总体方案的确定………………………………………………………………………………………10

第三章 机械部分设计计算…………………………………………………………………11

3.1 机械传动部件的计算与选型…………………………………………………………………………11

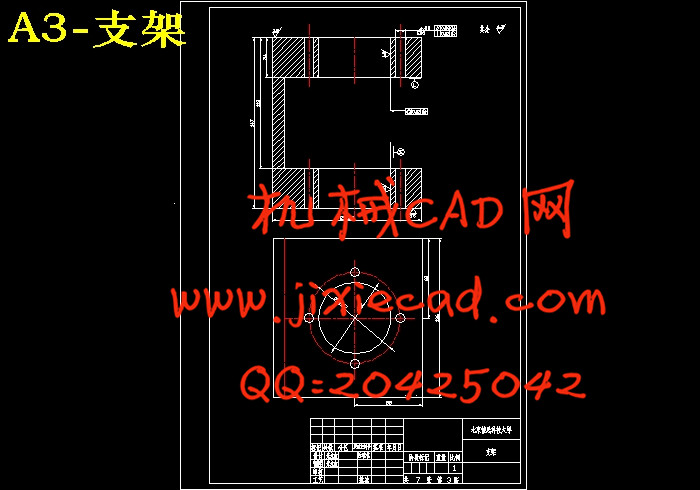

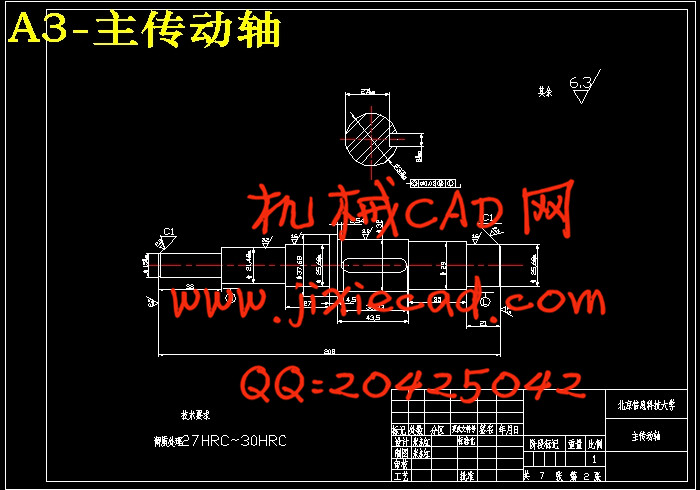

3.2 机械装配图的绘制……………………………………………………………………………………17

第四章 控制系统设计、编程………………………………………………………………19

4.1控制系统硬件电路设计………………………………………………………………………………19

4.2 人机界面的软件设计…………………………………………………………………………………19

结束语………………………………………………………………………………………36

参考文献……………………………………………………………………………………37

本次设计的题目是设计一种基于单片机控制的玻璃横切机。主要设计内容为:设计玻璃横切机的机械结构及人机界面系统。机械结构部分的设计确定为步进电动机带动的同步带传动系统。控制系统采用AT89C51为CPU。由矩阵键盘和RT12864M汉字图形点阵液晶显示模块组成人机界面系统。

首先,分析了玻璃横切机的市场前景及其在玻璃生产中的重要作用。然后,确定机械结构。根据现有的玻璃横切机的结构将其分类,并归纳出每一类玻璃横切机的机械机构特征、运行特征、切割原理等。本设计最终选用了其中的斜置、速度控制式的机械结构。基于这种机械结构,对步进电动机、同步带进行了选型和计算。绘制了机械结构装配图及部分零件图。

对于玻璃横切机的人机界面系统,本设计主要大致完成其程序的编写。即液晶显示四组控制参数,并可以通过键盘修改这些参数。本文中包括了各级程序流程图及其对应的说明。大致包括LCD驱动、键盘监控、液晶显示三个程序块。详见正文。

关键字 玻璃横切机; 步进电动机; 同步带; 单片机; 人机界面系统 ;液晶

Abstract

This graduation project's topic is the design of one kind of the auto glass-cutter which controls based on the Microcontroller. The main content of the design is: the machine mechanism and man-machine contact surface system of the glass-cutter’s design .The mechanism part's design I determined it as that Pulse motor gives the power and the Transmission system transfer the power to the Ambulacrum.The control system uses AT89C51 as CPU. Forms the man-machine contact surface department of the matrix keyboard and the RT12864M Chinese character graph lattice liquid crystal display module.

First, has analyzed the glass-cutter’s market prospect and its influential role in the glass production. Then, determination of the machine mechanism. According to the existing glass-cutter’s structure I staple then to same types, and then concluded the mechanism character, sport character, cutting principle of each of the types. And so on.

This design finally has selected the tilts, speed control-like mechanism. Based on this kind of mechanism, I did the choice of the Pulse motor, ambulacrum’s and the count, checkout of them. I had drawn up the drawing of mechanism assembly and some part drawings.

Regarding the glass-cutter’s man-machine contact surface system, this design mainly completes its program’s compilation. Namely the liquid crystal display shows the four groups of controlled variables, and may revise these parameters through the keyboard. This article has included all levels of program flow diagram and the corresponding explanation. Includes the LCD actuation, the keyboard monitoring, and the liquid crystal display three blocks approximately. For details sees the main text.

Key-words glass-cutter ; Pulse motor ;ambulacrum ; Microcontroller ; man-machine contact surface system ; liquid crystal display module

目录

摘要(中文)…………………………………………………………………………………І

(英文)…………………………………………………………………………………П

第一章概述……………………………………………………………………………………1

1.1我国玻璃市场现状………………………………………………………………………………………1

1.2 我国浮法玻璃技术与国际先进水平的差距…………………………………………………………1

1.3 高精度玻璃切割的必要………………………………………………………………………………1

1.4 玻璃横切机的分类……………………………………………………………………………………1

第二章 设计方案……………………………………………………………………………7

2.1研究内容………………………………………………………………………………………………7

2.2实现方法…………………………………………………………………………………………………7

2.3设计任务…………………………………………………………………………………………………9

2.4 总体方案的确定………………………………………………………………………………………10

第三章 机械部分设计计算…………………………………………………………………11

3.1 机械传动部件的计算与选型…………………………………………………………………………11

3.2 机械装配图的绘制……………………………………………………………………………………17

第四章 控制系统设计、编程………………………………………………………………19

4.1控制系统硬件电路设计………………………………………………………………………………19

4.2 人机界面的软件设计…………………………………………………………………………………19

结束语………………………………………………………………………………………36

参考文献……………………………………………………………………………………37