设计简介

摘 要

槽轮机构是一种步进间歇运动机构,由于结构简单、制造容易、工作可靠,能准确地控制转角, 机械效率高, 所以在自动和半自动生产线中得到广泛的应用;但槽轮在销轴进出槽轮槽口时加速度大,机构产生较大的冲击,而且随着转速的增加和槽轮槽数的减少冲击加剧,因而不适用于高速运转的情况。

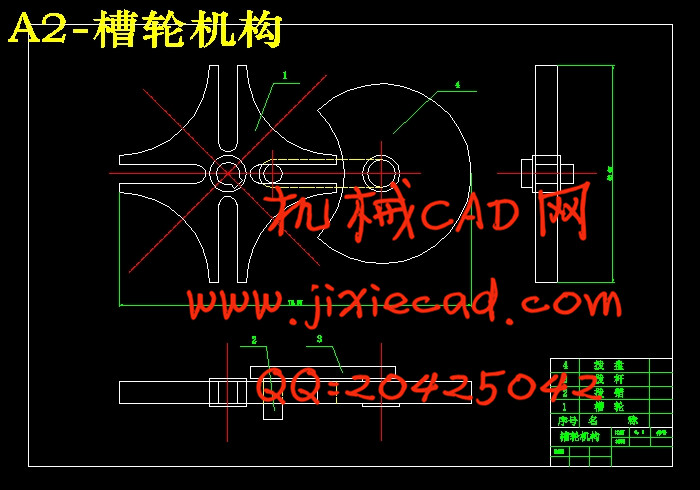

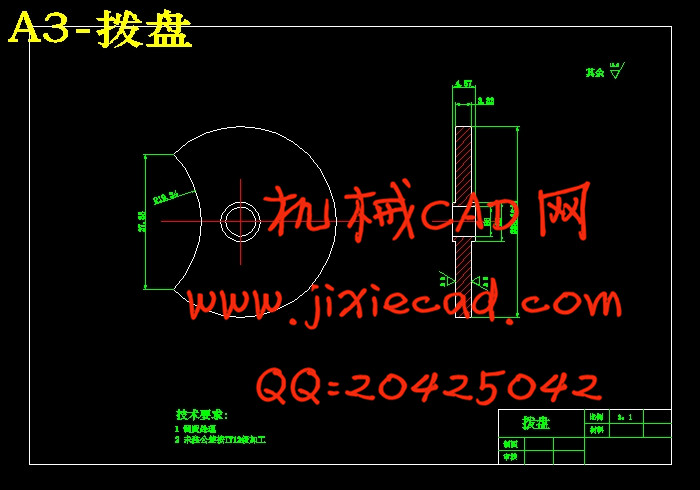

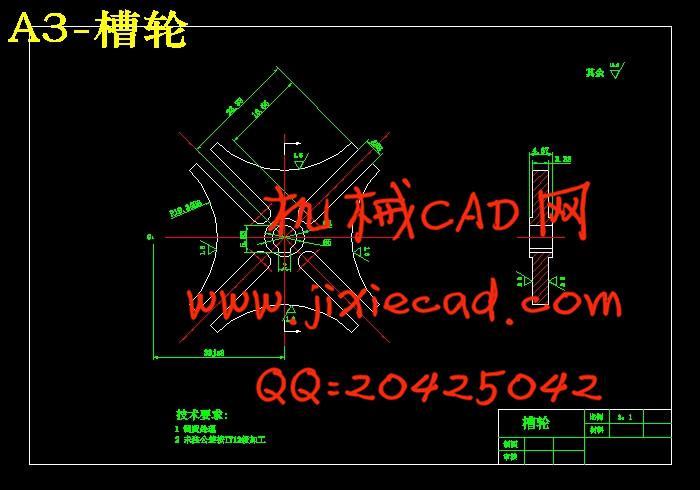

本设计以槽数4 、销轮和槽轮中心距33 mm、销轴半径2 mm、铣刀半径2mm 为例,设计槽槽轮机构,并对槽轮的运动特性进行分析。采用CAM技术对槽轮和拨盘进行数控编程,对零件进行工艺分析,确定刀具和切削用量,最后形成NC指令。

关键词:槽轮机构 工艺 数控编程 NC

Abstract

Geneva agencies is stepping intermittent movement,because of Simple structure、manufacturing easy、reliable,Can accurately control angle, High mechanical efficiency,Therefore, automatic and semi-automatic production line is widely used; But trough round slot in the round pin and out of the acceleration when Passage,Institutions have a greater impact,moreover, with the speed and the increase in the number of slot groove round of intensified to reduce the impact,Thus does not apply to high-speed operation

My Design is take 4 to trough, and trough round pin round of 33 mm center distance, pin radius of 2 mm, 2 mm radius cutter for example, Design groove grooved wheel agencies, and the movement of tank rounds analysis. Using CAM technology to dial tank round and NC Programming, Process analysis of the parts, Cutting Tool and determine the amount, finally formed NC order.

Keywords: Geneva agencies Technology NC Pro

目 录

第一章 概述························································1

第一节槽轮机构概述············································1

一、 槽轮机构简介·········································1

二、 槽轮机构的应用和研究现状··························2

第二节机械CAD技术概述········································2

一、机械CAD技术简述·····································2

二、 机械CAD技术的研究现状和发展方向·················3

第三节智能CAD 概述··········································· 5

第二章 槽轮机构的设计与分析·······························6

第一节槽轮机构的工作原理···································6

一、 槽轮机构的工作原理··································6

二、 外槽轮机构角速度和角加速度的分析················6

三、 内槽轮机构的角速度和角加速度规律················7

四、主要几何尺寸的设计··································8

五、本设计的主要几何尺寸的设计························9

第三章 数控加工技术概述·······································11

一、 数控加工技术的发展··························11

二、 数控加工工艺的特点······························11

三、 数控机床与普通机床相比具有的优越性···········12

第四章 槽轮和拨盘的工艺规程设计·························13

一、机械加工工艺规程的作用···························13

二、机械加工工艺规程的制定程序······················13

三、毛坯的选择··········································13

四、定位基准的选择····································14

五、加工顺序的安排····································15

六、本零件工艺规程设计····································15

结论·································································28

参考文献····························································29

致谢·································································30

附录·································································31

槽轮机构是一种步进间歇运动机构,由于结构简单、制造容易、工作可靠,能准确地控制转角, 机械效率高, 所以在自动和半自动生产线中得到广泛的应用;但槽轮在销轴进出槽轮槽口时加速度大,机构产生较大的冲击,而且随着转速的增加和槽轮槽数的减少冲击加剧,因而不适用于高速运转的情况。

本设计以槽数4 、销轮和槽轮中心距33 mm、销轴半径2 mm、铣刀半径2mm 为例,设计槽槽轮机构,并对槽轮的运动特性进行分析。采用CAM技术对槽轮和拨盘进行数控编程,对零件进行工艺分析,确定刀具和切削用量,最后形成NC指令。

关键词:槽轮机构 工艺 数控编程 NC

Abstract

Geneva agencies is stepping intermittent movement,because of Simple structure、manufacturing easy、reliable,Can accurately control angle, High mechanical efficiency,Therefore, automatic and semi-automatic production line is widely used; But trough round slot in the round pin and out of the acceleration when Passage,Institutions have a greater impact,moreover, with the speed and the increase in the number of slot groove round of intensified to reduce the impact,Thus does not apply to high-speed operation

My Design is take 4 to trough, and trough round pin round of 33 mm center distance, pin radius of 2 mm, 2 mm radius cutter for example, Design groove grooved wheel agencies, and the movement of tank rounds analysis. Using CAM technology to dial tank round and NC Programming, Process analysis of the parts, Cutting Tool and determine the amount, finally formed NC order.

Keywords: Geneva agencies Technology NC Pro

目 录

第一章 概述························································1

第一节槽轮机构概述············································1

一、 槽轮机构简介·········································1

二、 槽轮机构的应用和研究现状··························2

第二节机械CAD技术概述········································2

一、机械CAD技术简述·····································2

二、 机械CAD技术的研究现状和发展方向·················3

第三节智能CAD 概述··········································· 5

第二章 槽轮机构的设计与分析·······························6

第一节槽轮机构的工作原理···································6

一、 槽轮机构的工作原理··································6

二、 外槽轮机构角速度和角加速度的分析················6

三、 内槽轮机构的角速度和角加速度规律················7

四、主要几何尺寸的设计··································8

五、本设计的主要几何尺寸的设计························9

第三章 数控加工技术概述·······································11

一、 数控加工技术的发展··························11

二、 数控加工工艺的特点······························11

三、 数控机床与普通机床相比具有的优越性···········12

第四章 槽轮和拨盘的工艺规程设计·························13

一、机械加工工艺规程的作用···························13

二、机械加工工艺规程的制定程序······················13

三、毛坯的选择··········································13

四、定位基准的选择····································14

五、加工顺序的安排····································15

六、本零件工艺规程设计····································15

结论·································································28

参考文献····························································29

致谢·································································30

附录·································································31