设计简介

光学磨床主轴设计及三维建模

摘 要

现代机床的发展日益趋向高效率和高精度,这对机床的设计提出了更高的要求,需要采用更先进和合理的设计方法来完成机床设计优化。对于磨床而言,主轴组件是磨床极为重要的组成部分,其性能的好坏对磨床的性能有着重要的影响。本文具体研究分析了磨床发展的现状,磨床主轴组件的发展状况和发展趋势;在总结前人研究成果的基础上,结合当前的技术发展趋势,对主轴组件进行了受力分析计算,同时对该类立轴圆台平面磨削的磨削力进行了分析。利用轴承静刚度的有效经验计算公式,结合该磨床的实际情况对轴承的刚度状况进行了分析。

关键词:光学磨床;主轴设计;三维建模;Solid Edge

Optical design and three-dimensional modeling ogrinding spindle

Abstract

The growing tendency of the development of modern machine tools with high efficiency and precision, the design of this machine a higher requirements, the need to adopt more advanced and reasonable design method to complete the machine design optimization. For the grinding, the grinding spindle is a very important component part of, the performance is good or bad performance on the grinding machine has a significant impact. This detailed analysis of the development status grinder, grinding machine spindle component of development conditions and trends; In conclusion, based on the results of previous studies, combined with current technology trends, force analysis of spindle components were calculated at the same time that type of spindle and round table surface grinding of the grinding force is analyzed. STIFFNESS OF EXTERNALLY effective use of axis empirical formula, combined with the grinding reality of the bearing stiffness conditions were analyzed.

KeyWords: optical grinder; Spindle Design; three-dimensional modeling; Solid Edget

摘 要

现代机床的发展日益趋向高效率和高精度,这对机床的设计提出了更高的要求,需要采用更先进和合理的设计方法来完成机床设计优化。对于磨床而言,主轴组件是磨床极为重要的组成部分,其性能的好坏对磨床的性能有着重要的影响。本文具体研究分析了磨床发展的现状,磨床主轴组件的发展状况和发展趋势;在总结前人研究成果的基础上,结合当前的技术发展趋势,对主轴组件进行了受力分析计算,同时对该类立轴圆台平面磨削的磨削力进行了分析。利用轴承静刚度的有效经验计算公式,结合该磨床的实际情况对轴承的刚度状况进行了分析。

关键词:光学磨床;主轴设计;三维建模;Solid Edge

Optical design and three-dimensional modeling ogrinding spindle

Abstract

The growing tendency of the development of modern machine tools with high efficiency and precision, the design of this machine a higher requirements, the need to adopt more advanced and reasonable design method to complete the machine design optimization. For the grinding, the grinding spindle is a very important component part of, the performance is good or bad performance on the grinding machine has a significant impact. This detailed analysis of the development status grinder, grinding machine spindle component of development conditions and trends; In conclusion, based on the results of previous studies, combined with current technology trends, force analysis of spindle components were calculated at the same time that type of spindle and round table surface grinding of the grinding force is analyzed. STIFFNESS OF EXTERNALLY effective use of axis empirical formula, combined with the grinding reality of the bearing stiffness conditions were analyzed.

KeyWords: optical grinder; Spindle Design; three-dimensional modeling; Solid Edget

目 录

1 绪 论 1

1.1课题研究的背景和意义 1

1.2磨削精度和表面质量 2

1.3国内外平磨设备的发展 2

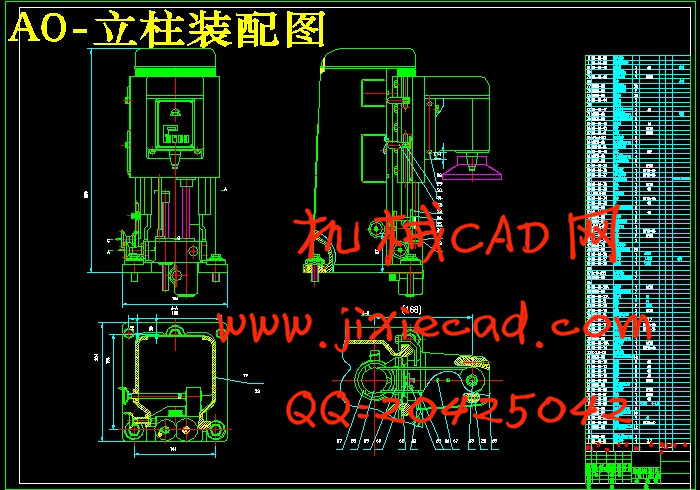

1.4 PM500平面磨床的工作原理 3

1.5PM5OO传动系统 4

1.6磨头机构及其主轴组件的研究现状 4

2 主轴组件的受力与支承轴承刚度 6

2.1主轴组件的受力分析 6

2.1.1动力及工况简介 6

2.1.2带传动产生的轴压力 6

2.2主轴支承轴承的刚度分析 7

2.2.1轴承刚度计算理论 7

2.2.2轴承预紧 8

2.3主轴支承轴承的刚度计算 10

2.3.1下支承刚度 10

2.3.2中支承刚度 10

2.3.3上支承刚度 11

2.3.4推力球轴承 11

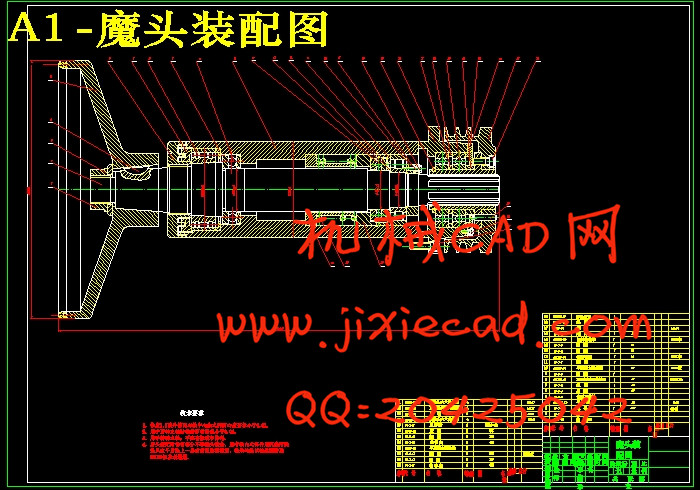

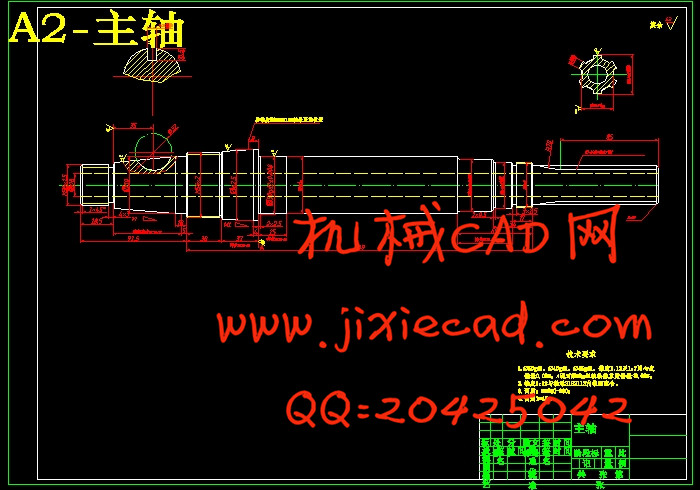

3 主轴部分的设计 12

3.1主轴设计的主要内容 12

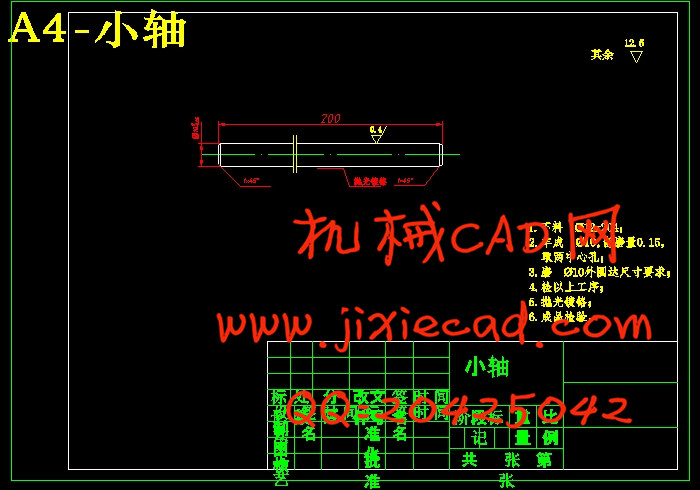

3.2轴材料的选择 12

3.3主轴结构分析 13

3.4主轴结构的改进 13

3.5主轴的结构设计 13

4 Solid Edge三维建模 16

4.1三维设计软件的简介 16

4.2 特征建模技术的特点 16

4.3 Solid Edge建模的操作方法 17

4.3.1 简单三维实体建模技术 18

4.3.2 复杂三维实体建模技术 18

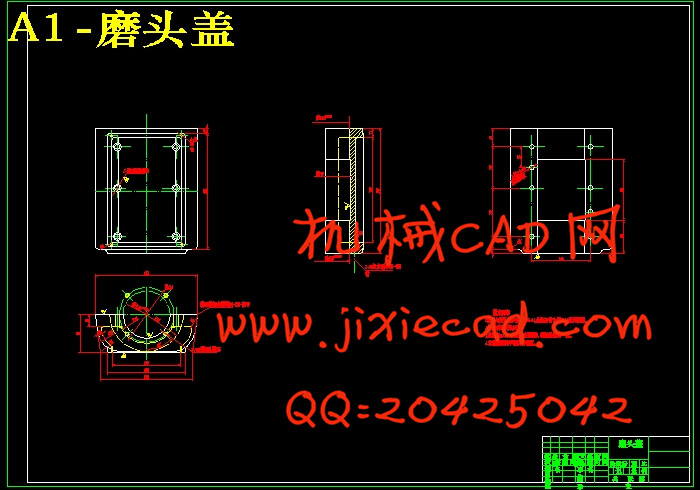

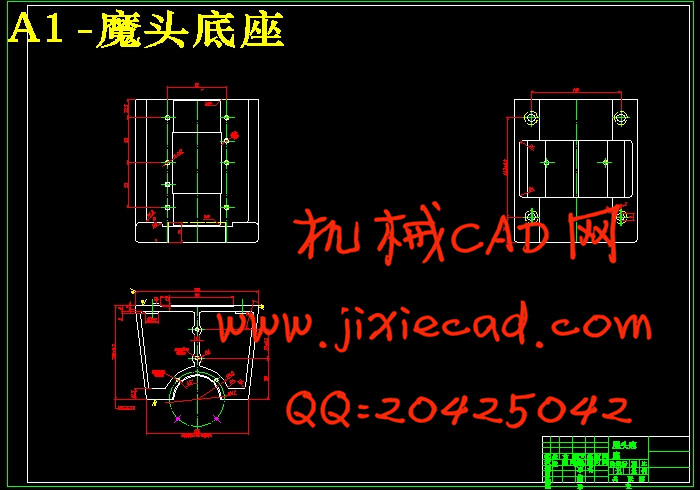

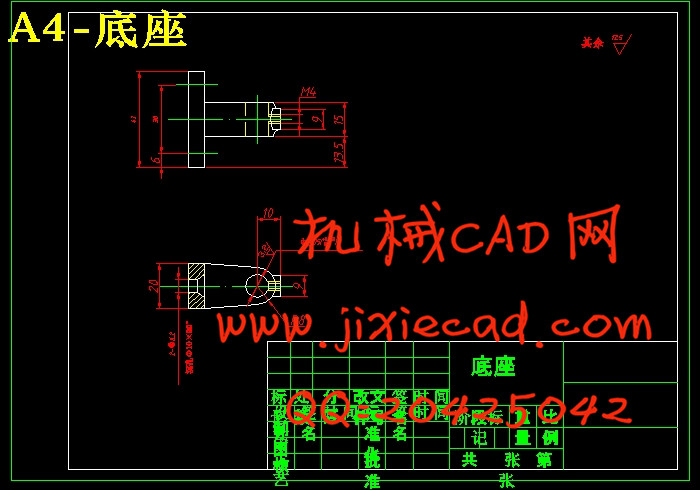

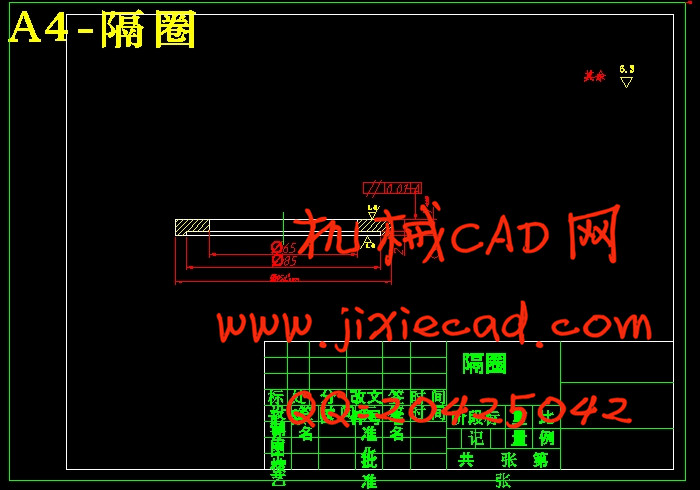

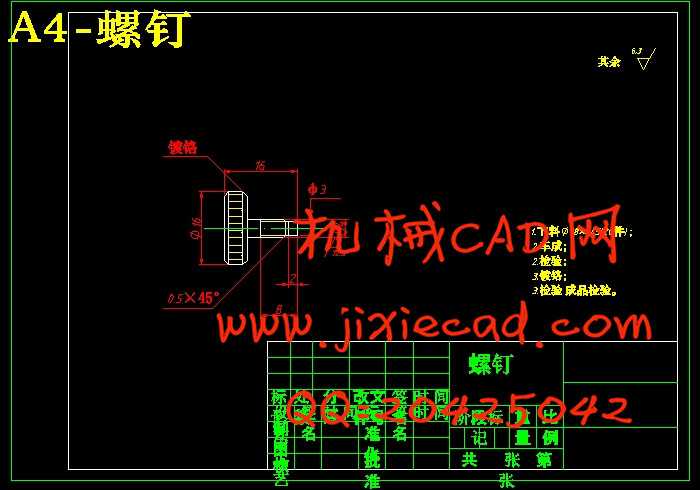

4.4主轴系统部分零部件建模 19

5.磨床主轴的模型装配 23

6结论 25

致 谢 27