设计简介

摘要

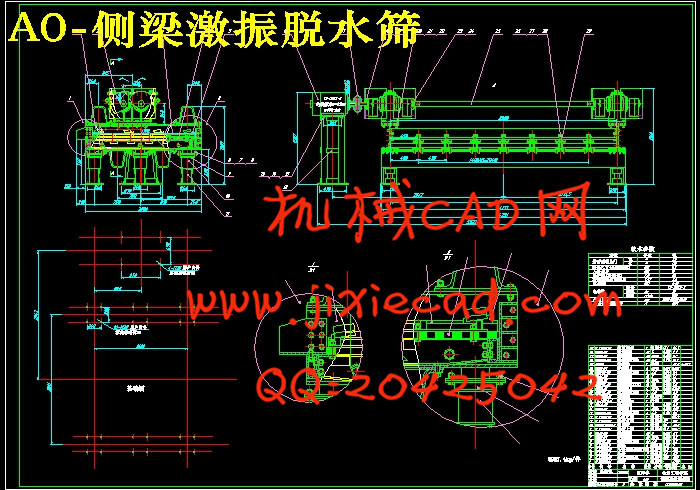

侧梁激振脱水筛是直线振动筛的一种,主要用于煤泥脱水,是选煤厂的重要设备之一。

传统的直线振动脱水筛,一般结构较复杂,机体较笨重,而且能耗高,为此研制了一种新型的脱水筛。侧梁激振脱水筛与其它振动筛相比具有如下结构优点:

(1)单位面积处理量是普通振动筛的2倍以上;

(2)抛射角度合适,抛射强度高,振幅大,单位处理能力的能耗较小,与同面积的筛子相比,成本可降低20%;

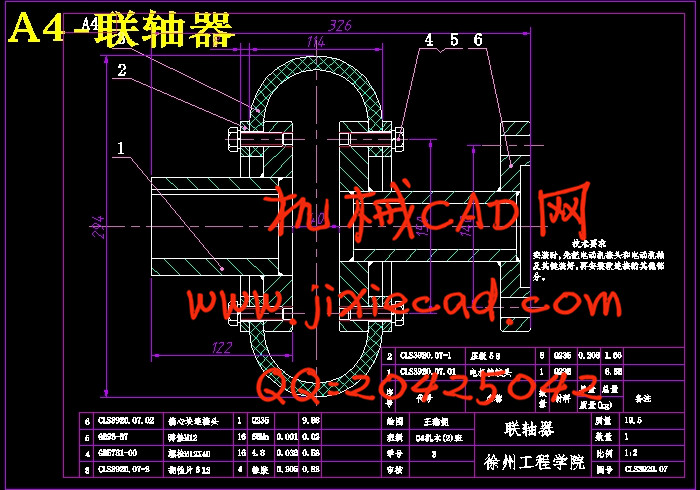

(3)电动机与箱式激振器激振轴采用橡胶联轴器(即挠性联接或软联接),可补偿电机轴线与偏心轴轴线不同心造成的误差。

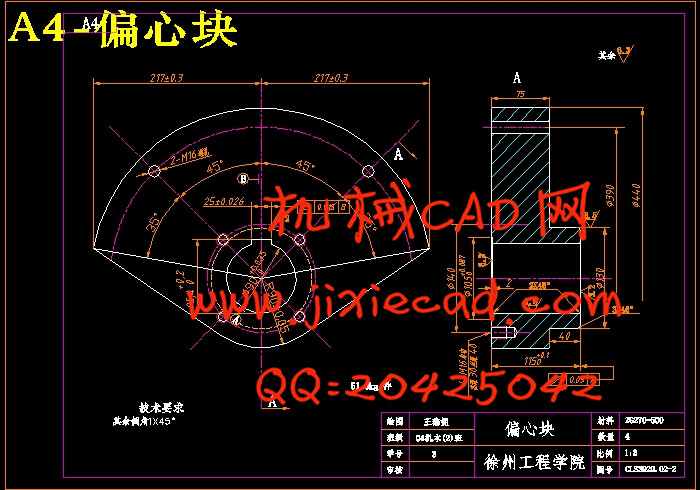

(4)偏心块为轴偏心结构,轴承采用干油润滑,不存在漏油问题;

(5)依靠箱式激振器长短轴上键槽相互位置,使得两偏心块之间成60°,保证激振力始终与水平成60°夹角,使得物料以合适的速度向出料槽前进;

(6)可通过增减副偏心块质量调节筛子振幅,在物料水分和粘度的变化时,仍能保证激振力要求。

本设计论述了振动筛的基本理论,对侧梁激振脱水筛主要的零部件进行了选择、设计和校核计算。对其安装、调试和常见的故障也作了简要的介绍。

关键词 脱水筛;侧梁;激振器;偏心块

Abstract

Lateral excitation beam dehydration screen is a straight line, mainly for dehydration slime, coal preparation plant is one of the key equipment.

The traditional linear vibration sieve dehydration, the general structure of the more complex, more cumbersome body, and high energy consumption, for which developed a new type of dehydration sieve. Lateral excitation beam dehydration sieve shaker compared with other structures have the following advantages:

(1) per unit area is the capacity of ordinary shaker of more than two times;

(2) projectile point of view appropriate, projectile high intensity, amplitude, and the unit energy consumption of smaller capacity, and compared with the size of the sieve, the cost can be reduced by 20%;

(3) the box-type motor shaft vibration excitation using rubber couplings (that is, flexible connectivity or soft link) that can compensate for the electrical axis and the eccentric shaft axis different heart of the error;

(4) eccentric block is the structure of Axis eccentric, by dry-lubricated bearings, and there is no oil spills;

(5) rely on me-length shaft keyway Exciter each other location, making the two blocks between the eccentric into 60 °, always exciting force and guarantee a level of 60 ° angle, making materials to the appropriate speed to the local materials Forward;

(6) can increase or decrease in the quality of eccentric block amplitude adjustment sieve, water and materials in the viscosity of the changes, can guarantee exciting force requirements.

The design of the shaker on the basic theory, dehydration screen opposite the main beam exciting parts for the selection, design verification and calculation. Its installation, commissioning and common failure also made a brief introduction.

Keywords dehydration screen side beam vibrator eccentric block

侧梁激振脱水筛是直线振动筛的一种,主要用于煤泥脱水,是选煤厂的重要设备之一。

传统的直线振动脱水筛,一般结构较复杂,机体较笨重,而且能耗高,为此研制了一种新型的脱水筛。侧梁激振脱水筛与其它振动筛相比具有如下结构优点:

(1)单位面积处理量是普通振动筛的2倍以上;

(2)抛射角度合适,抛射强度高,振幅大,单位处理能力的能耗较小,与同面积的筛子相比,成本可降低20%;

(3)电动机与箱式激振器激振轴采用橡胶联轴器(即挠性联接或软联接),可补偿电机轴线与偏心轴轴线不同心造成的误差。

(4)偏心块为轴偏心结构,轴承采用干油润滑,不存在漏油问题;

(5)依靠箱式激振器长短轴上键槽相互位置,使得两偏心块之间成60°,保证激振力始终与水平成60°夹角,使得物料以合适的速度向出料槽前进;

(6)可通过增减副偏心块质量调节筛子振幅,在物料水分和粘度的变化时,仍能保证激振力要求。

本设计论述了振动筛的基本理论,对侧梁激振脱水筛主要的零部件进行了选择、设计和校核计算。对其安装、调试和常见的故障也作了简要的介绍。

关键词 脱水筛;侧梁;激振器;偏心块

Abstract

Lateral excitation beam dehydration screen is a straight line, mainly for dehydration slime, coal preparation plant is one of the key equipment.

The traditional linear vibration sieve dehydration, the general structure of the more complex, more cumbersome body, and high energy consumption, for which developed a new type of dehydration sieve. Lateral excitation beam dehydration sieve shaker compared with other structures have the following advantages:

(1) per unit area is the capacity of ordinary shaker of more than two times;

(2) projectile point of view appropriate, projectile high intensity, amplitude, and the unit energy consumption of smaller capacity, and compared with the size of the sieve, the cost can be reduced by 20%;

(3) the box-type motor shaft vibration excitation using rubber couplings (that is, flexible connectivity or soft link) that can compensate for the electrical axis and the eccentric shaft axis different heart of the error;

(4) eccentric block is the structure of Axis eccentric, by dry-lubricated bearings, and there is no oil spills;

(5) rely on me-length shaft keyway Exciter each other location, making the two blocks between the eccentric into 60 °, always exciting force and guarantee a level of 60 ° angle, making materials to the appropriate speed to the local materials Forward;

(6) can increase or decrease in the quality of eccentric block amplitude adjustment sieve, water and materials in the viscosity of the changes, can guarantee exciting force requirements.

The design of the shaker on the basic theory, dehydration screen opposite the main beam exciting parts for the selection, design verification and calculation. Its installation, commissioning and common failure also made a brief introduction.

Keywords dehydration screen side beam vibrator eccentric block

目 录

1 绪论 1

1.1 课题背景及前言 1

1.2 脱水筛分概述 2

1.2.1 筛分作业分类 2

1.2.2 筛分过程的基本概念 3

1.2.3 脱水目的 4

1.2.4 水在煤中的存在状态 4

1.2.5 物料性质与脱水难易的关系 4

1.2.6常用的脱水方法与脱水设备 5

1.3 筛分机械的类型及其主要特点 6

1.4 影响筛分效率的因素 8

1.5 筛分技术及筛分机械在国内外发展情况 9

1.5.1 我国筛分机械的现状 9

1.5.2 我国筛分设备的基本情况 9

1.5.3 筛分机械的发展方向 10

1.5.4结论 10

2 振动原理 12

2.1 直线振动筛 12

2.1.1 振动筛的分类 12

2.1.2 直线振动筛的工作原理 12

2.2 侧梁激振脱水筛原理方案设计 15

2.2.1 设计任务书 15

2.2.2 原理方案确定 16

2.3 侧梁减振脱水筛结构方案设计 16

2.3.1 筛框 16

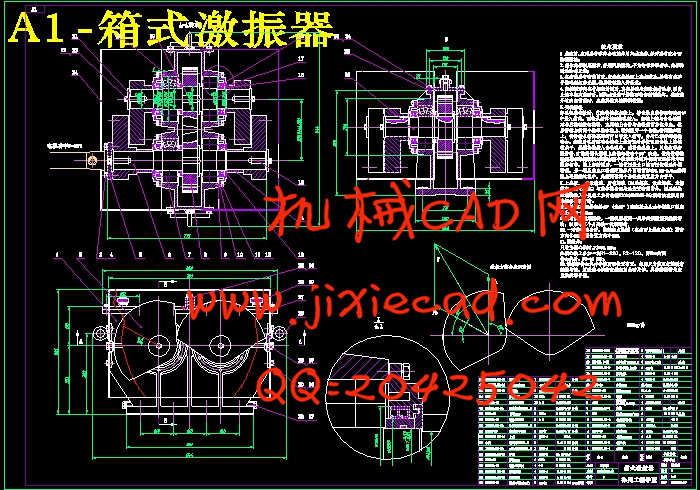

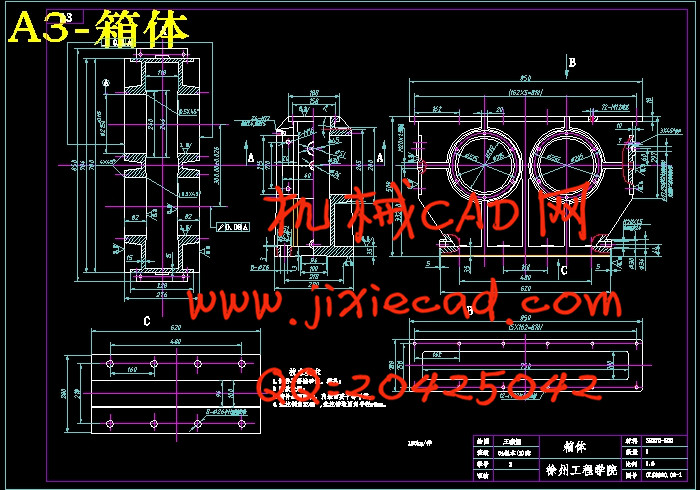

2.3.2 激振器 17

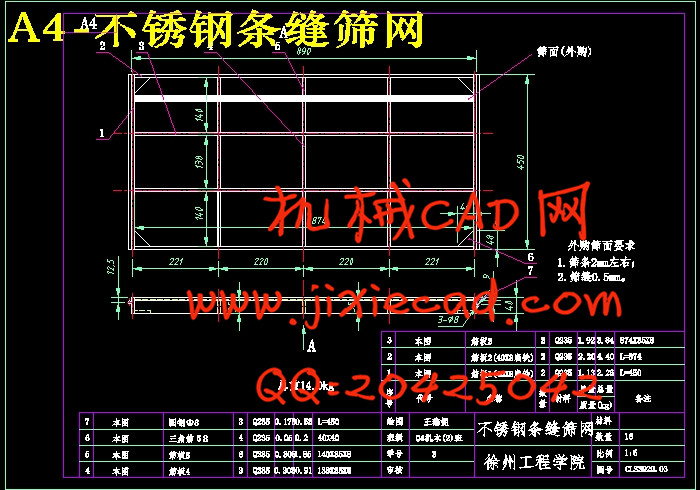

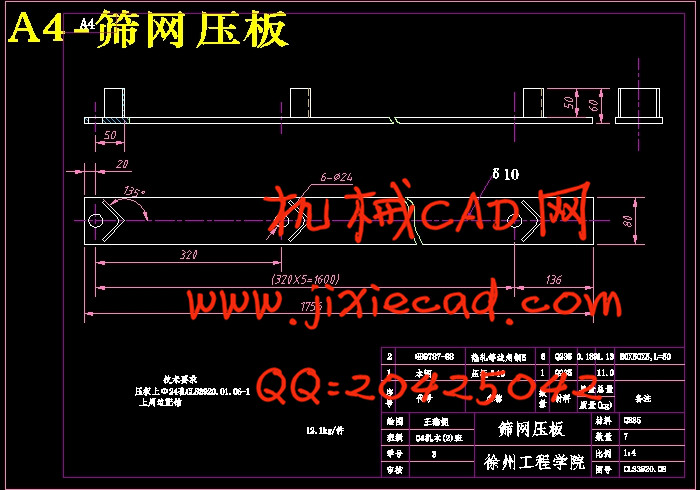

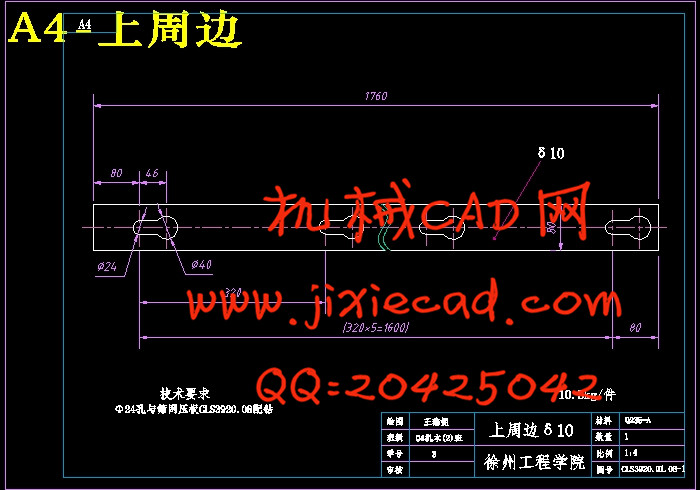

2.3.3 筛面及其固定装置 19

2.3.4 支承装置 20

2.3.5 传动装置 20

3 物料的运动分析和工艺参数的选择 22

3.1 物料的运动分析 22

3.1.1 筛面的运动方程 22

3.1.2 筛面物料的运动分析22

3.1.3 抛掷指数Kv和跳跃系数iD 24

3.2 工艺参数的选择计算 25

3.2.1 筛面的长和宽 25

3.2.2 筛面的倾角 25

3.2.3 振幅和频率 26

3.2.4 振动方向角β 26

3.2.5 抛掷指数Kv和振动强度K 26

3.2.6 物料运动速度 26

3.2.7 处理能力 27

4 动力学分析及参数的计算 28

4.1 动力学分析 28

4.1.1 力学模型的建立 28

4.1.2 振动方程的建立 29

4.2 振动频幅曲线和工作状态分析 30

4.3 动力学参数的计算 31

4.3.1 隔振弹簧的确定 31

4.3.2 隔振弹簧的选择与验算 33

4.3.3 隔振弹簧减轻能力的分析 35

4.3.4 参振质量的计算 36

4.3.5 电机功率的计算和选择 37

5 主要零部件的选择设计与校核 38

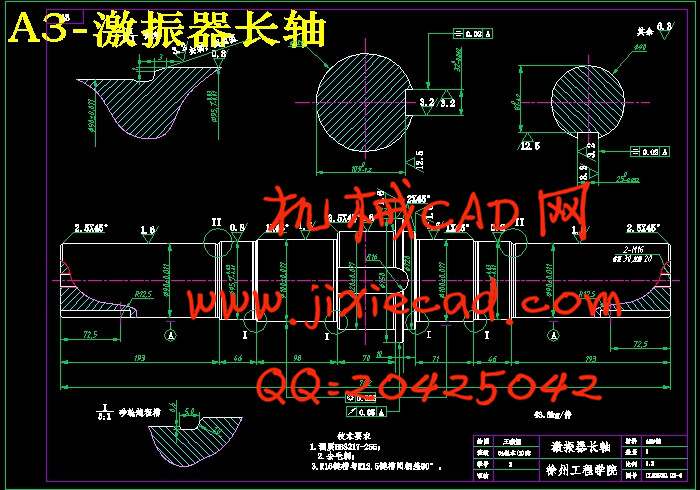

5.1 激振器主要零件的设计与校核 38

5.1.1 偏心块的设计 38

5.1.2 齿轮的设计与校核 41

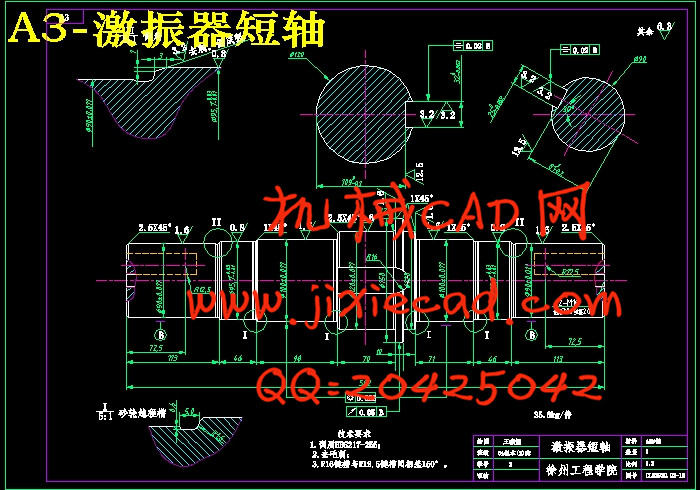

5.1.3 激振器轴的设计 46

5.1.4 激振器长轴的校核 47

5.1.5 轴承的选择与校核 52

5.1.6 键的校核 54

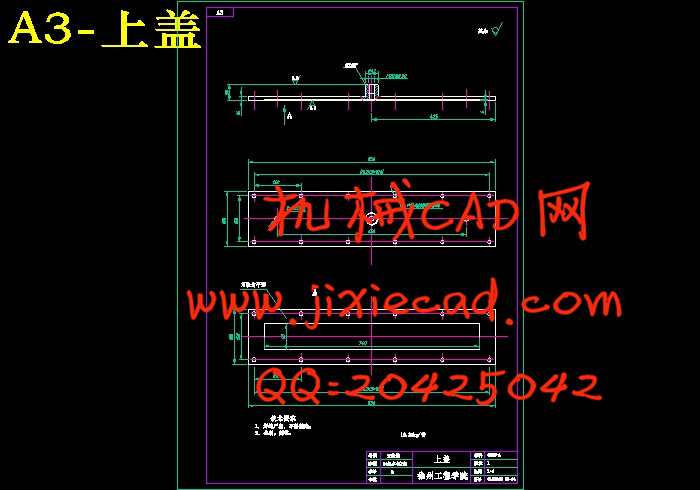

5.2 侧梁激振脱水筛专业零部件的设计 55

5.2.1 筛面 55

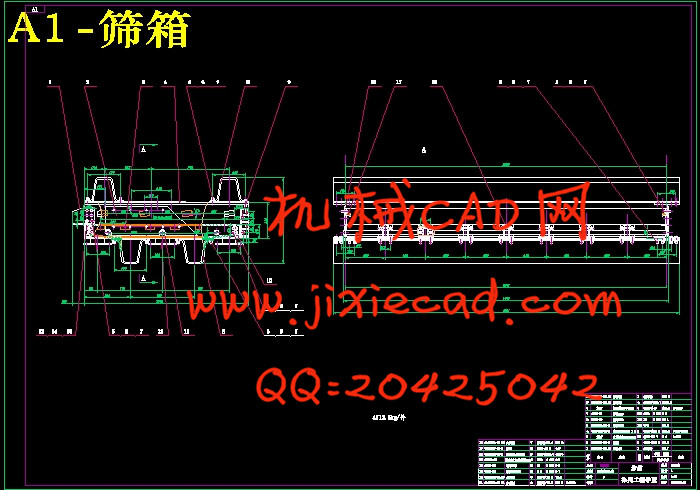

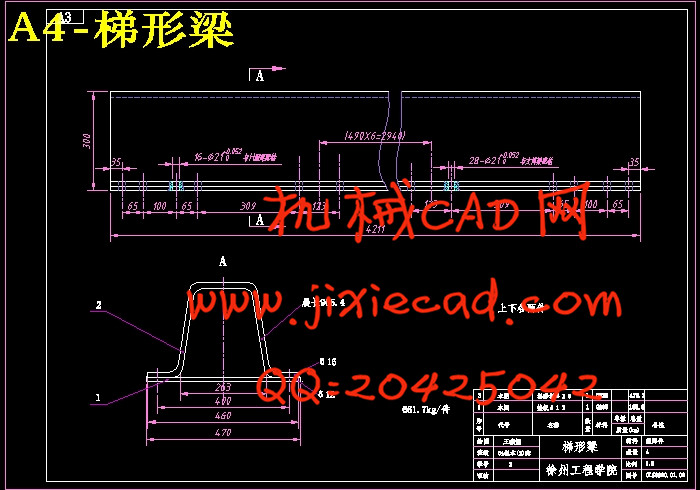

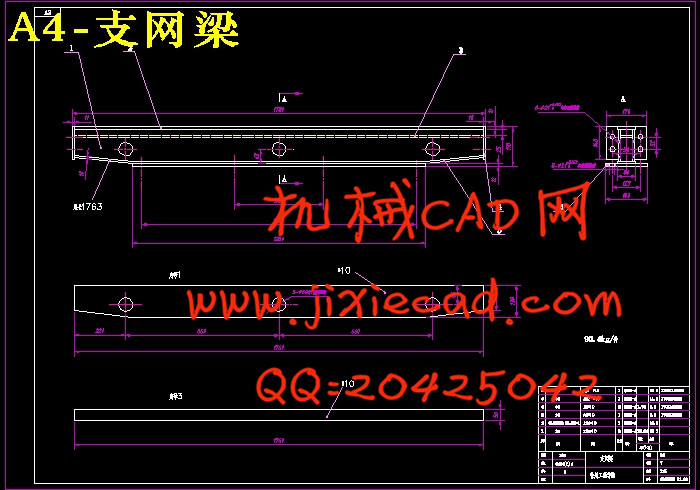

5.2.2 筛框 57

6 侧梁激振脱水筛的安装、试运转和常见故障 61

6.1 侧梁激振脱水筛的安装、试运转 61

6.1.1 脱水筛的安装 61

6.1.2 脱水筛的试运转 61

6.2 侧梁激振脱水筛的异常振动及常见故障 62

6.2.1 脱水筛的异常振动 62

6.2.2 脱水筛的常见故障及消除措施 62

结论 64

致谢 65

参考文献 66

3.2 工艺参数的选择计算 25

3.2.1 筛面的长和宽 25

3.2.2 筛面的倾角 25

3.2.3 振幅和频率 26

3.2.4 振动方向角β 26

3.2.5 抛掷指数Kv和振动强度K 26

3.2.6 物料运动速度 26

3.2.7 处理能力 27

4 动力学分析及参数的计算 28

4.1 动力学分析 28

4.1.1 力学模型的建立 28

4.1.2 振动方程的建立 29

4.2 振动频幅曲线和工作状态分析 30

4.3 动力学参数的计算 31

4.3.1 隔振弹簧的确定 31

4.3.2 隔振弹簧的选择与验算 33

4.3.3 隔振弹簧减轻能力的分析 35

4.3.4 参振质量的计算 36

4.3.5 电机功率的计算和选择 37

5 主要零部件的选择设计与校核 38

5.1 激振器主要零件的设计与校核 38

5.1.1 偏心块的设计 38

5.1.2 齿轮的设计与校核 41

5.1.3 激振器轴的设计 46

5.1.4 激振器长轴的校核 47

5.1.5 轴承的选择与校核 52

5.1.6 键的校核 54

5.2 侧梁激振脱水筛专业零部件的设计 55

5.2.1 筛面 55

5.2.2 筛框 57

6 侧梁激振脱水筛的安装、试运转和常见故障 61

6.1 侧梁激振脱水筛的安装、试运转 61

6.1.1 脱水筛的安装 61

6.1.2 脱水筛的试运转 61

6.2 侧梁激振脱水筛的异常振动及常见故障 62

6.2.1 脱水筛的异常振动 62

6.2.2 脱水筛的常见故障及消除措施 62

结论 64

致谢 65

参考文献 66