设计简介

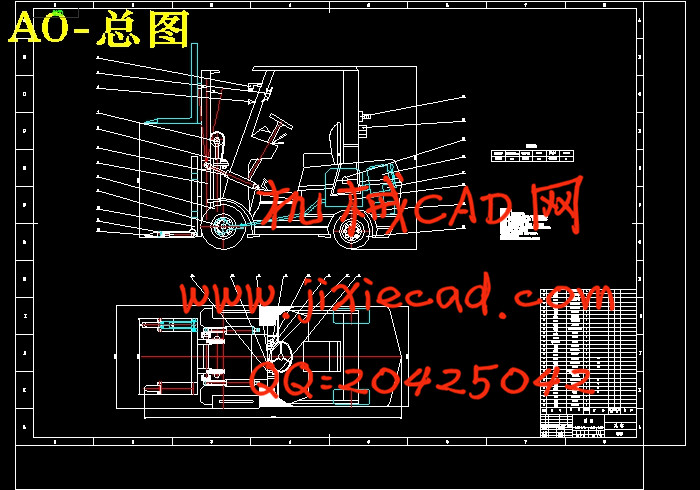

叉车载重量为10吨,发动机功率112kw,

最高车速为20km/h,最大爬坡角25°。

摘 要

叉车具有装卸和搬运功能,机动灵活,能适应多变的装卸搬运要求,普遍适用于港口、车站、货场、车间、仓库、油田及机场等处,还可以进入船舱和集装箱内进行装卸作业,除此之外,还广泛应用于军事部门和特殊防爆部门,有的车辆可无人驾驶,到人员不断接近的地方工作适用于柔性加工系统,总之,随着物流技术的不断发展和工业化水平的提高,叉车使用范围将日益扩大,成为一种产量与品种很多的装卸搬运机械。

本叉车是参照市场上已有产品大连6113BG型10吨叉车设计,基本参数与相近,最大载重量也为10吨,本设计主要设计了变速箱、起降油缸、差速器、货叉前端,其中货叉前端档块为创新点。

现代叉车技术发展的主要趋势是充分考虑舒适性、安全可靠性和可维护性 ,产品专业化、系列多样化,大量应用新技术,完善操控系统,重视节能和环保 ,全面提升产品的性能和品质。

通过对国际国内叉车造型设计的现状分析,运用工业设计的理论和方法,研究了叉车造型设计的要素及设计原则:造型要求简洁明快、线条流畅,以体现车身的力度感与坚实稳重的感;色彩.力求单纯,给人以轻松、愉悦的感觉,主色调以明度较高的黄 色、橙色为宜;车身前后左右要求有宽大的玻璃,仪表具有良好的可读性。研究结果对叉车设计具有重要的实际指导意义。

关键词:叉车; 三轴式; 滑移直齿轮变速; 紧凑

Forklifts can do handing works,and can flexibility to adapt to changing of handing requirements,and generally applicable to ports,railway stations,freight yard,workshops,warehouses,oil fields and the airport and places,and forklifts could still enter the cabin and container handing operations within.In addition,forklifts are alseo widely used in military and special explosion—proof sector,some vehicles will be unmanned,that officers should hot work in places close to or for Flexible Manufacturing Systerm.In short, as the logistics and technological development and the enhancement of the level of industrialization,the use of fork lifts will be expanding ,and it will become a yield varieties with a lot of material handing machinery.

The forklift is based produces already on the market in Dalian 6113 BG-10-ton forklift design,the basit parameters was similar,for the largest load of 10 tons.The main degin of the design is the transmission, Other parts only briefly describes or do not given the design.Within this total,the transmission of three-axis,gearbex,sliding gear transmission,simple and compact structure,by the same agencies to achieve a variable speed transmission and reverse operation..

The major trend ofmodern technology developmentof the fork truck is to be fully in consideration of the friendly operation, the reliability, the safety, the goodmaintenance, the specialization, the series, and the diversificat, and to adopt new technology, to improve steering system, and to focuson energy saving and environmentprotection in order to promote the truck’s capacity and quality.

Based on the analysis of current status of international and domestic forklift truck form design, the key elements and design principles in forklift truck form design was researched using industriM design theory and methodology:It Was put forward that the form offorklift truck should be simple and lively tll smooth lines in order to convey the sense of strength and steadiness;the color strives simplicity to make people feel pleasant and light — mainly usingtones ofyeHow and orange;there shouldbe big ass atthefrontand back oftrucks;thein— struments should be easy to read.The research results provided practical reference for forklift truck design.

Keywords: fork truck; 3-axis; sliding gear transmission; compact

目 录

1 绪论

1.1 国内叉车外观造型设计的现状……………………………………1

1.2 国际叉车外观造型设计的现状……………………………………2

1.3 叉车造型设计几个方面……………………………………………2

1.4 叉车技术的发展趋势………………………………………………4

1.5 叉车在特殊条件下的应用……………………………………… 11

2 叉车设计总体方案

2.1 设计总体方案确定………………………………………………15

2.1.1 方案的制定原则……………………………………………15

2.1.2 设计方案的规划 …………………………………………………15

2.1.3 方案设计内容总结 ………………………………………………17

2.2 叉车发动机的选择………………………………………………17

2.2.1 发动机基本型式的选择…………………………………………17

2.2.2 发动机主要性能指标的选择……………………………………19

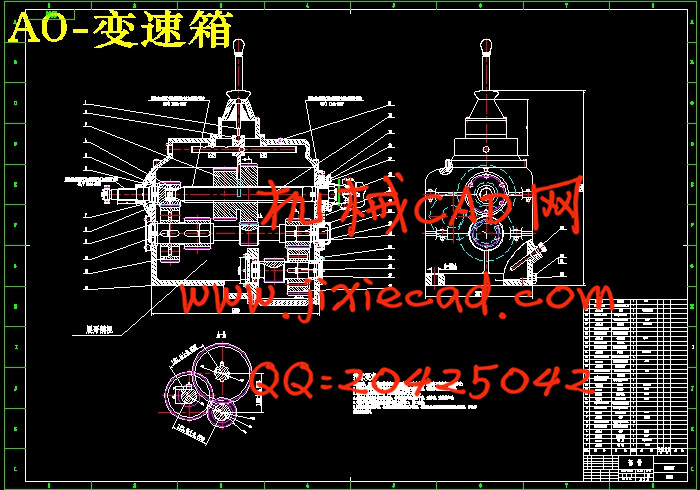

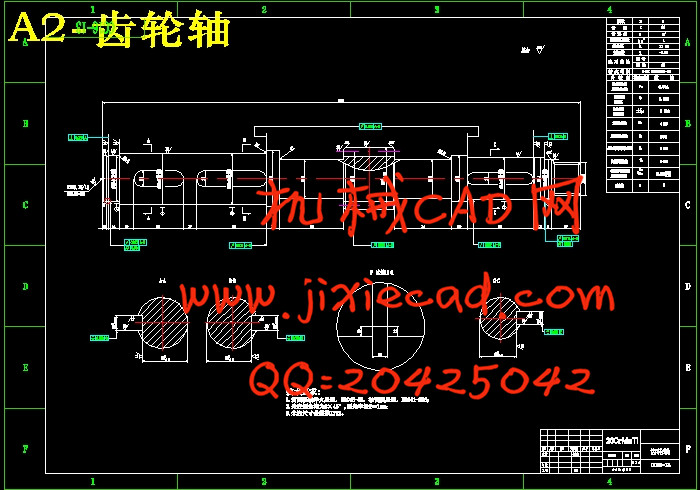

3 变速箱设计

3.1 变速箱的构造和原理……………………………………………23

3.2 变速箱的结构方案图……………………………………………26

3.3 变速箱主要参数的选择…………………………………………27

3.3.1 变速箱挂慢速档时参数选择……………………………………27

3.3.2 变速箱挂快速档时参数选择……………………………………30

3.3.3 变速箱挂倒档时参数选择……………………………………32

3.3.4 中心距确定………………………………………………………34

3.3.5 齿轮模数确定……………………………………………………34

3.3.6 齿数分配…………………………………………………………35

3.3.7 齿轮其他基本几何参数与结构图………………………………38

3.3.8 主要零件的计算…………………………………………………44

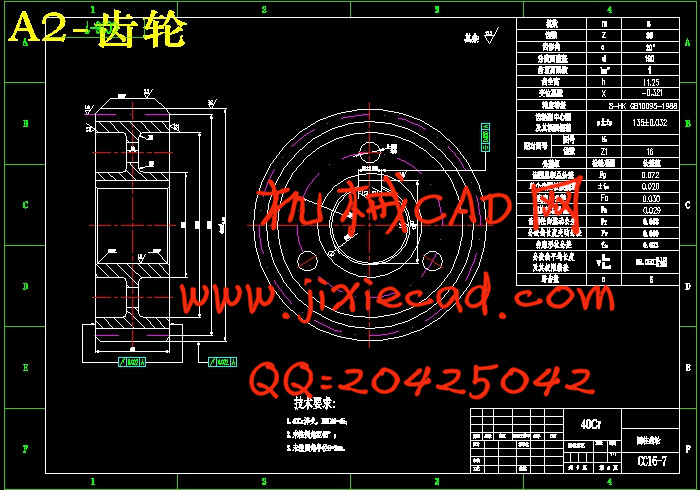

3.4 齿轮公差组的确定………………………………………………49

3.5 轴的结够设计及强度计算………………………………………50

3.5.1 第一轴的结够设计及强度计算…………………………………50

3.5.2 中间轴的结够设计及强度计算…………………………………63

3.6 轴承的选择与校核………………………………………………73

3.7 键的选择与校核…………………………………………………76

3.8 确定箱体的基本参数 ……………………………………………80

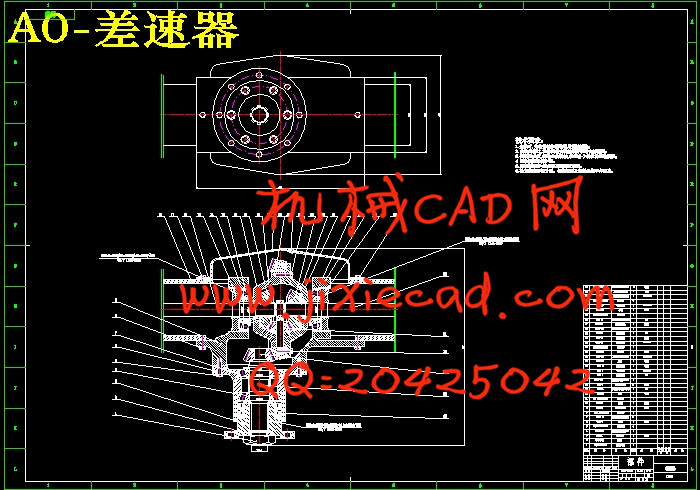

4 差速器设计

4.1 差速器的类型及选择 ………………………………………81

4.2 差速器齿轮设计…………………………………………………81

4.2.1 齿轮主要参数选择 ……………………………………………81

4.2.2 几何参数的计算……………………………………………………82

4.2.3 行星齿轮轴直径及支撑长度确定…………………………………84

4.3 齿轮强度计算 ……………………………………………84

4.4 主减速器齿轮几何尺寸计算……………………………………85

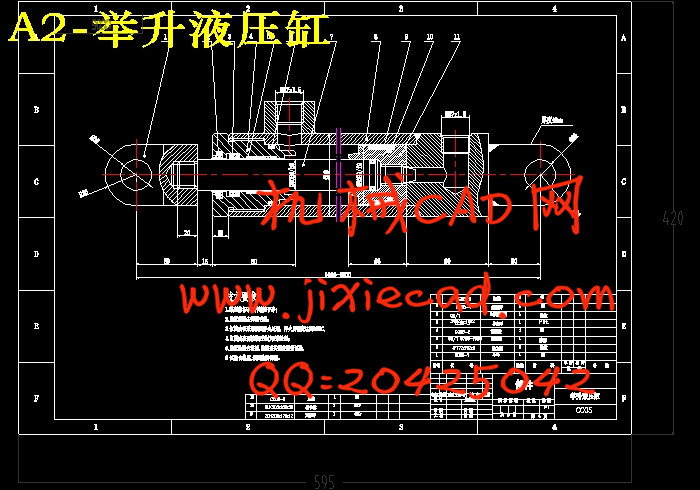

5 液压驱动与控制系统的设计

5.1 驱动马达的选择…………………………………………………86

5.2 举升液压缸的计算 ………………………………………………87

5.2.1 液压缸主要尺寸的确定 ………………………………………87

5.2.2 液压缸的结构设计 ……………………………………………90

5.3 货叉前端液压缸设计……………………………………………95

5.4 驱动方案的选择 …………………………………………………98

5.5 驱动方案的确定…………………………………………………100

6 液压系统的常见问题及解决措施 ……………………………………101

结论 ………………………………………………………………………107

参考文献 …………………………………………………………………108

最高车速为20km/h,最大爬坡角25°。

摘 要

叉车具有装卸和搬运功能,机动灵活,能适应多变的装卸搬运要求,普遍适用于港口、车站、货场、车间、仓库、油田及机场等处,还可以进入船舱和集装箱内进行装卸作业,除此之外,还广泛应用于军事部门和特殊防爆部门,有的车辆可无人驾驶,到人员不断接近的地方工作适用于柔性加工系统,总之,随着物流技术的不断发展和工业化水平的提高,叉车使用范围将日益扩大,成为一种产量与品种很多的装卸搬运机械。

本叉车是参照市场上已有产品大连6113BG型10吨叉车设计,基本参数与相近,最大载重量也为10吨,本设计主要设计了变速箱、起降油缸、差速器、货叉前端,其中货叉前端档块为创新点。

现代叉车技术发展的主要趋势是充分考虑舒适性、安全可靠性和可维护性 ,产品专业化、系列多样化,大量应用新技术,完善操控系统,重视节能和环保 ,全面提升产品的性能和品质。

通过对国际国内叉车造型设计的现状分析,运用工业设计的理论和方法,研究了叉车造型设计的要素及设计原则:造型要求简洁明快、线条流畅,以体现车身的力度感与坚实稳重的感;色彩.力求单纯,给人以轻松、愉悦的感觉,主色调以明度较高的黄 色、橙色为宜;车身前后左右要求有宽大的玻璃,仪表具有良好的可读性。研究结果对叉车设计具有重要的实际指导意义。

关键词:叉车; 三轴式; 滑移直齿轮变速; 紧凑

ABSTRACT

Forklifts can do handing works,and can flexibility to adapt to changing of handing requirements,and generally applicable to ports,railway stations,freight yard,workshops,warehouses,oil fields and the airport and places,and forklifts could still enter the cabin and container handing operations within.In addition,forklifts are alseo widely used in military and special explosion—proof sector,some vehicles will be unmanned,that officers should hot work in places close to or for Flexible Manufacturing Systerm.In short, as the logistics and technological development and the enhancement of the level of industrialization,the use of fork lifts will be expanding ,and it will become a yield varieties with a lot of material handing machinery.

The forklift is based produces already on the market in Dalian 6113 BG-10-ton forklift design,the basit parameters was similar,for the largest load of 10 tons.The main degin of the design is the transmission, Other parts only briefly describes or do not given the design.Within this total,the transmission of three-axis,gearbex,sliding gear transmission,simple and compact structure,by the same agencies to achieve a variable speed transmission and reverse operation..

The major trend ofmodern technology developmentof the fork truck is to be fully in consideration of the friendly operation, the reliability, the safety, the goodmaintenance, the specialization, the series, and the diversificat, and to adopt new technology, to improve steering system, and to focuson energy saving and environmentprotection in order to promote the truck’s capacity and quality.

Based on the analysis of current status of international and domestic forklift truck form design, the key elements and design principles in forklift truck form design was researched using industriM design theory and methodology:It Was put forward that the form offorklift truck should be simple and lively tll smooth lines in order to convey the sense of strength and steadiness;the color strives simplicity to make people feel pleasant and light — mainly usingtones ofyeHow and orange;there shouldbe big ass atthefrontand back oftrucks;thein— struments should be easy to read.The research results provided practical reference for forklift truck design.

Keywords: fork truck; 3-axis; sliding gear transmission; compact

目 录

1 绪论

1.1 国内叉车外观造型设计的现状……………………………………1

1.2 国际叉车外观造型设计的现状……………………………………2

1.3 叉车造型设计几个方面……………………………………………2

1.4 叉车技术的发展趋势………………………………………………4

1.5 叉车在特殊条件下的应用……………………………………… 11

2 叉车设计总体方案

2.1 设计总体方案确定………………………………………………15

2.1.1 方案的制定原则……………………………………………15

2.1.2 设计方案的规划 …………………………………………………15

2.1.3 方案设计内容总结 ………………………………………………17

2.2 叉车发动机的选择………………………………………………17

2.2.1 发动机基本型式的选择…………………………………………17

2.2.2 发动机主要性能指标的选择……………………………………19

3 变速箱设计

3.1 变速箱的构造和原理……………………………………………23

3.2 变速箱的结构方案图……………………………………………26

3.3 变速箱主要参数的选择…………………………………………27

3.3.1 变速箱挂慢速档时参数选择……………………………………27

3.3.2 变速箱挂快速档时参数选择……………………………………30

3.3.3 变速箱挂倒档时参数选择……………………………………32

3.3.4 中心距确定………………………………………………………34

3.3.5 齿轮模数确定……………………………………………………34

3.3.6 齿数分配…………………………………………………………35

3.3.7 齿轮其他基本几何参数与结构图………………………………38

3.3.8 主要零件的计算…………………………………………………44

3.4 齿轮公差组的确定………………………………………………49

3.5 轴的结够设计及强度计算………………………………………50

3.5.1 第一轴的结够设计及强度计算…………………………………50

3.5.2 中间轴的结够设计及强度计算…………………………………63

3.6 轴承的选择与校核………………………………………………73

3.7 键的选择与校核…………………………………………………76

3.8 确定箱体的基本参数 ……………………………………………80

4 差速器设计

4.1 差速器的类型及选择 ………………………………………81

4.2 差速器齿轮设计…………………………………………………81

4.2.1 齿轮主要参数选择 ……………………………………………81

4.2.2 几何参数的计算……………………………………………………82

4.2.3 行星齿轮轴直径及支撑长度确定…………………………………84

4.3 齿轮强度计算 ……………………………………………84

4.4 主减速器齿轮几何尺寸计算……………………………………85

5 液压驱动与控制系统的设计

5.1 驱动马达的选择…………………………………………………86

5.2 举升液压缸的计算 ………………………………………………87

5.2.1 液压缸主要尺寸的确定 ………………………………………87

5.2.2 液压缸的结构设计 ……………………………………………90

5.3 货叉前端液压缸设计……………………………………………95

5.4 驱动方案的选择 …………………………………………………98

5.5 驱动方案的确定…………………………………………………100

6 液压系统的常见问题及解决措施 ……………………………………101

结论 ………………………………………………………………………107

参考文献 …………………………………………………………………108