设计简介

摘 要

众所周知,“实践是检验真理的唯一标准”。科学实验在人类认识和探索自

然规律的过程中起着至关重要的作用,可以说没有实验就没有现代科学。液压传

动技术是机械类专业的一门基础课程。液压教学实践表明,该课程只有通过理论

和实验相结合的方式教学才能取得良好的教学效果。为了满足现代化液压教学的

要求,本文提出了一种基于PLC控制的多功能液压实验台。根据该液压实验台

的用途,设计了液压系统的总体方案,并将液压仿真软件成功用于该实验台,最

后设计出实验台控制程序。该多功能液压教学实验台在液压教学方面有着广泛的

应用前景。

本论文对传统型与现代型液压综合实验台的研究现状做了全面的综述,对液压实验台的发展趋势做了详细的分析,并对液压教学中常用的液压元件和基本液压回路的组成和原理进行了详尽的理论分析、总结,为多功能液压实验台的液压回路设计奠定了可靠的理论基础,也为仿真软件的应用提供了依据。利用模块化的设计思想对多功能液压实验台的液压回路进行分块设计。将各模块优化组合,设计出多功能液压实验台的液压回路原理图,并对其功能进行了详尽的说明。

液压综合实验台包括电控、液控等,它的设计与制造将极大的缓解现有实验室实验设备短缺和落后的现状,同时电液控综合实验台在整个液压教学实验中将发挥很大的作用,是液压教学实验中不可缺少的重要组成部分。本论文重点叙述了液压综合实验台的系统组成和元件设置。从各方面分析与其它实验台的不同点,突出它的综合性,其最大的优点就是可以在一个实验平台上做多种实验,所做实验各元件和管路可由实验操作者自行设计、连接。设计主要围绕实验台的实验原理 以及整体结构而展开,然后辅以电气控制硬件部分的设计。

关键词 实验台 ;液压 ;电控 ;PLC

ABSTRACT

We all know, "practice is the sole criterion for testing truth." Scientific experiment in human self-awareness and exploration

the law plays a crucial role in the process, can be said that no experiment would be no modern science. Hydraulic transmission

Mechanical Engineering Technology is moving a basic course. Hydraulic practice shows that the program only through theoretical

experimental combination of teaching to achieve good teaching. In order to meet the teaching of modern hydraulic

Requirements, this paper, a PLC-based control of multi-function hydraulic test stand. According to the hydraulic test stand

Purposes, the overall design of the hydraulic system program and the success of hydraulic simulation software for the test bed, the most

After the test-bed design control procedures. The multi-function Hydraulic Experiment station in the hydraulic has a wide range of teaching

Application.

This thesis on traditional and modern hydraulic Comprehensive Experimental Research to do a comprehensive overview of the development of hydraulic test stand to do a detailed analysis of trends, and the teaching of commonly used hydraulic components and hydraulic components and the basic hydraulic circuit principle of a detailed theoretical analysis, summarized, multi-function hydraulic test stand hydraulic circuit design has laid a reliable theoretical foundation for the application of simulation software provided. Optimization of each module will be designed multi-function hydraulic test stand hydraulic circuit diagram, and the function carried out a detailed description.

Comprehensive test-bed including electric hydraulic control, hydraulic control, etc., and its design and manufacturing will greatly ease the current shortage of laboratory equipment, and the backward status, while integrated electro-hydraulic control of the entire bench will play a very Hydraulic Experiment larger role in the hydraulic experiment teaching an important and indispensable component. Focus of this paper describes the comprehensive test-bed system of hydraulic components and component settings. All aspects of analysis and other experimental platform differences, highlight its comprehensive, its biggest advantage is that you can do in a variety of experimental platform, experimental, experiments done by the various experimental components and pipeline operators to design, Primarily designed around the principle and the experimental test bed to start the whole structure, and then supplemented by the electrical control hardware design.

Key words: test bed;hydraulic; electronic control; PLC

目 录

摘要..............................................................Ⅰ

第一章 前言 ...................................................1

1.1课题研究的背景 ........................................1

1.2课题研究的内容 ........................................1

1.3课题研究的目的与意义 ..................................2

1.3.1电液控综合实验台研究的目的与意义 .................2

1.3.2毕业设计的目的与意义 ............................2

第二章 液压系统实验原理 ....................................3

2.1 在实验台上可以完成的实验 ............................3

2.2液压系统原理............................................3

2.2.1 液压系统中工作压力形成原理实验 ....................3

2.2.2 液压泵性能实验 ........................................8

2.2.3 溢流阀性能实验 ......................................11

2.2.4 节流调速回路性能实验 ................................17

2.2.5 比例压力阀的性能实验..................................22

第三章 元件选择 ............................................27

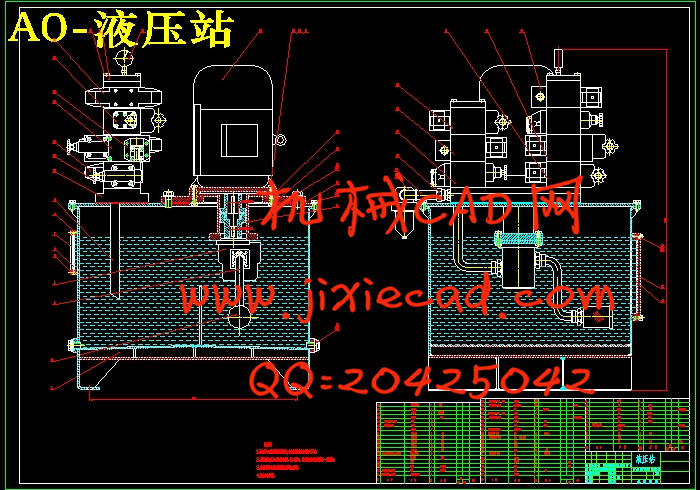

3.1 液压泵的选择..............................................27

3.1.1 定量泵的选择............................................27

3.1.2变量泵的选择..........................................28

3.2 电动机的选择..............................................28

3.3 液压阀的选择..............................................28

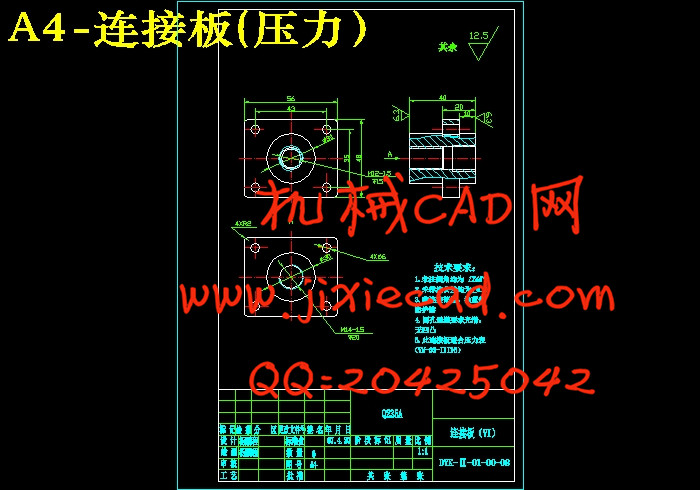

3.3.1溢流阀的选择.............................................29

3.3.2电磁换向阀的选择.........................................29

3.3.3调速阀的选择.............................................30

3.3.4节流阀的选择.............................................30

3.3.5单向阀的选择............................................30

3.3.6电液比例溢流阀的选择.....................................31

3.4 传感器的选择...............................................34

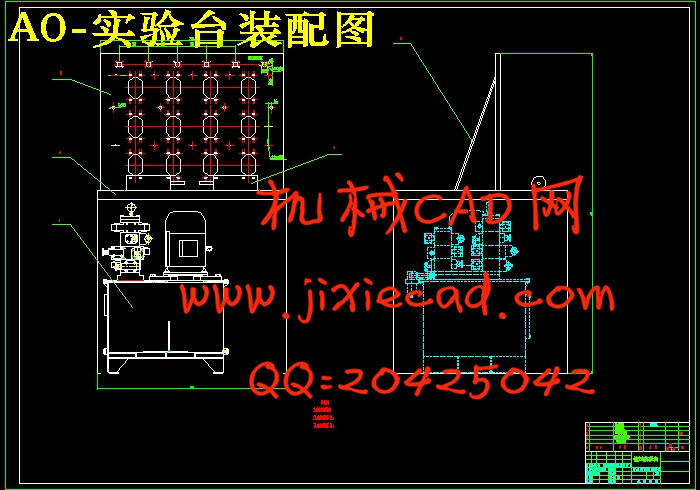

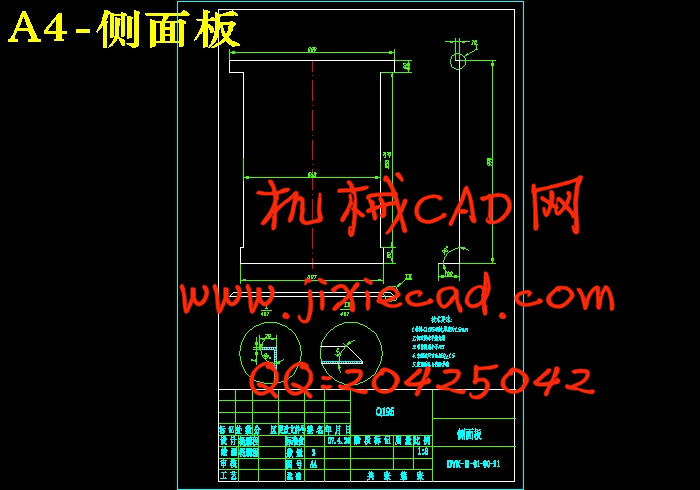

第四章 实验台台架设计 ......................................35

4.1实验台总体外形尺寸的确定................................35

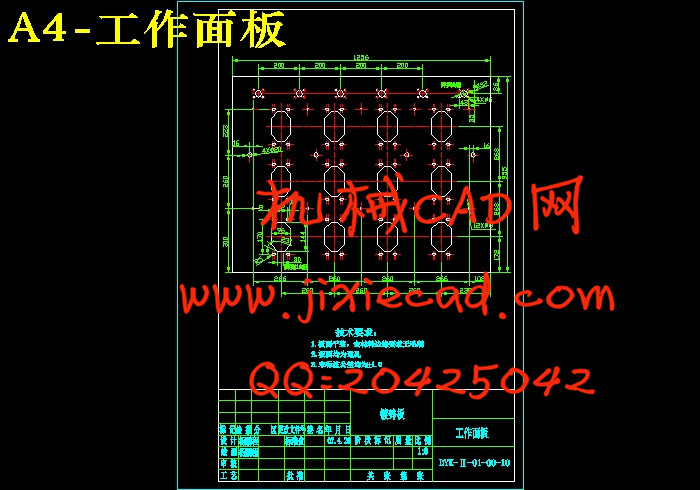

4.2实验台上部板面设计......................................36

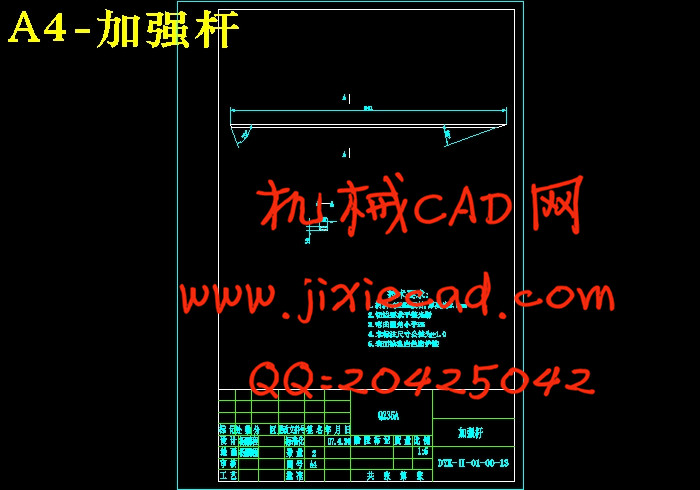

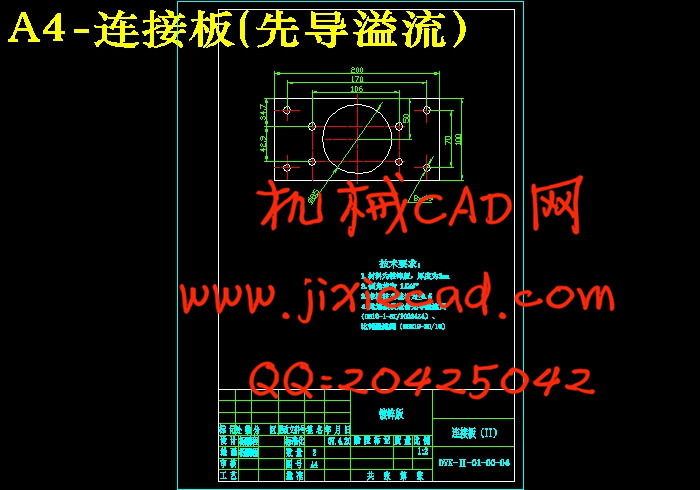

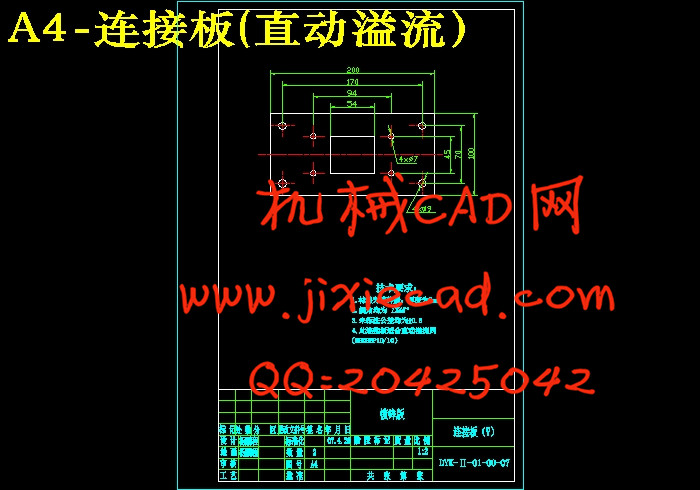

4.3实验台附件设计..........................................37

4.4实验台材料的选择........................................38

4.5实验台强度设计..........................................39

4.6实验台强度校核..........................................40

4.7实验台外观设计..........................................43

结论 .......................................................45

致 谢 .......................................................46

众所周知,“实践是检验真理的唯一标准”。科学实验在人类认识和探索自

然规律的过程中起着至关重要的作用,可以说没有实验就没有现代科学。液压传

动技术是机械类专业的一门基础课程。液压教学实践表明,该课程只有通过理论

和实验相结合的方式教学才能取得良好的教学效果。为了满足现代化液压教学的

要求,本文提出了一种基于PLC控制的多功能液压实验台。根据该液压实验台

的用途,设计了液压系统的总体方案,并将液压仿真软件成功用于该实验台,最

后设计出实验台控制程序。该多功能液压教学实验台在液压教学方面有着广泛的

应用前景。

本论文对传统型与现代型液压综合实验台的研究现状做了全面的综述,对液压实验台的发展趋势做了详细的分析,并对液压教学中常用的液压元件和基本液压回路的组成和原理进行了详尽的理论分析、总结,为多功能液压实验台的液压回路设计奠定了可靠的理论基础,也为仿真软件的应用提供了依据。利用模块化的设计思想对多功能液压实验台的液压回路进行分块设计。将各模块优化组合,设计出多功能液压实验台的液压回路原理图,并对其功能进行了详尽的说明。

液压综合实验台包括电控、液控等,它的设计与制造将极大的缓解现有实验室实验设备短缺和落后的现状,同时电液控综合实验台在整个液压教学实验中将发挥很大的作用,是液压教学实验中不可缺少的重要组成部分。本论文重点叙述了液压综合实验台的系统组成和元件设置。从各方面分析与其它实验台的不同点,突出它的综合性,其最大的优点就是可以在一个实验平台上做多种实验,所做实验各元件和管路可由实验操作者自行设计、连接。设计主要围绕实验台的实验原理 以及整体结构而展开,然后辅以电气控制硬件部分的设计。

关键词 实验台 ;液压 ;电控 ;PLC

ABSTRACT

We all know, "practice is the sole criterion for testing truth." Scientific experiment in human self-awareness and exploration

the law plays a crucial role in the process, can be said that no experiment would be no modern science. Hydraulic transmission

Mechanical Engineering Technology is moving a basic course. Hydraulic practice shows that the program only through theoretical

experimental combination of teaching to achieve good teaching. In order to meet the teaching of modern hydraulic

Requirements, this paper, a PLC-based control of multi-function hydraulic test stand. According to the hydraulic test stand

Purposes, the overall design of the hydraulic system program and the success of hydraulic simulation software for the test bed, the most

After the test-bed design control procedures. The multi-function Hydraulic Experiment station in the hydraulic has a wide range of teaching

Application.

This thesis on traditional and modern hydraulic Comprehensive Experimental Research to do a comprehensive overview of the development of hydraulic test stand to do a detailed analysis of trends, and the teaching of commonly used hydraulic components and hydraulic components and the basic hydraulic circuit principle of a detailed theoretical analysis, summarized, multi-function hydraulic test stand hydraulic circuit design has laid a reliable theoretical foundation for the application of simulation software provided. Optimization of each module will be designed multi-function hydraulic test stand hydraulic circuit diagram, and the function carried out a detailed description.

Comprehensive test-bed including electric hydraulic control, hydraulic control, etc., and its design and manufacturing will greatly ease the current shortage of laboratory equipment, and the backward status, while integrated electro-hydraulic control of the entire bench will play a very Hydraulic Experiment larger role in the hydraulic experiment teaching an important and indispensable component. Focus of this paper describes the comprehensive test-bed system of hydraulic components and component settings. All aspects of analysis and other experimental platform differences, highlight its comprehensive, its biggest advantage is that you can do in a variety of experimental platform, experimental, experiments done by the various experimental components and pipeline operators to design, Primarily designed around the principle and the experimental test bed to start the whole structure, and then supplemented by the electrical control hardware design.

Key words: test bed;hydraulic; electronic control; PLC

目 录

摘要..............................................................Ⅰ

第一章 前言 ...................................................1

1.1课题研究的背景 ........................................1

1.2课题研究的内容 ........................................1

1.3课题研究的目的与意义 ..................................2

1.3.1电液控综合实验台研究的目的与意义 .................2

1.3.2毕业设计的目的与意义 ............................2

第二章 液压系统实验原理 ....................................3

2.1 在实验台上可以完成的实验 ............................3

2.2液压系统原理............................................3

2.2.1 液压系统中工作压力形成原理实验 ....................3

2.2.2 液压泵性能实验 ........................................8

2.2.3 溢流阀性能实验 ......................................11

2.2.4 节流调速回路性能实验 ................................17

2.2.5 比例压力阀的性能实验..................................22

第三章 元件选择 ............................................27

3.1 液压泵的选择..............................................27

3.1.1 定量泵的选择............................................27

3.1.2变量泵的选择..........................................28

3.2 电动机的选择..............................................28

3.3 液压阀的选择..............................................28

3.3.1溢流阀的选择.............................................29

3.3.2电磁换向阀的选择.........................................29

3.3.3调速阀的选择.............................................30

3.3.4节流阀的选择.............................................30

3.3.5单向阀的选择............................................30

3.3.6电液比例溢流阀的选择.....................................31

3.4 传感器的选择...............................................34

第四章 实验台台架设计 ......................................35

4.1实验台总体外形尺寸的确定................................35

4.2实验台上部板面设计......................................36

4.3实验台附件设计..........................................37

4.4实验台材料的选择........................................38

4.5实验台强度设计..........................................39

4.6实验台强度校核..........................................40

4.7实验台外观设计..........................................43

结论 .......................................................45

致 谢 .......................................................46