设计简介

摘要

抛光机是机械制造业中的最重要的部分之一,也是精密加工技术必不可少的设备。这是因为精密加工和超精密加工技术不仅直接影响尖端技术和国防工业的发展,而且还影响机械产品的精度和表面质量,影响产品的国际竞争力。现在随着机械、电子、半导体、光学、传感器和测量技术以及材料科学的发展对精密加工和超精密加工技术有了更高的要求。尤其是随着集成电路(IC)工艺、技术的不断发展,硅单晶的直径尺寸越做越大,直径小于200mm的硅单晶已经进入商业生产应用的水平,大直径300mm的硅单晶抛光片也已在特征尺寸线宽小于0.13um的Ic器件工艺中得到了广泛应用,并已进入了研制、生产的阶段,直径大于400mm的硅单晶也进入了开发、研究的阶段,预计到2014年,将开始出现采用450mm硅片和36nm技术节点的半导体制造工厂。因此,对抛光的质量包括物理尺寸、平整度、表面粗糙度、纳米形貌、含氧量以及晶体完整性等指标的要求越来越高。传统的以研磨、化学腐蚀、为特征的加工工艺,已无法适应大尺寸工件高质量、离精度、高效率和低成本的加工要求。目前,化学机械抛光技术(CMP)被认为是能够实现晶圆表面局部平坦化和全局平坦化的最佳方法。硅晶圆抛光机床是化学机械抛光技术(CMP)的必要硬件支持。只有有效的设备支持才能开发出适合晶圆加工的相关工艺,确定合理的工艺参数。由于晶圆表面的加工质量要求很高,因此对CMP 机床的床身结构刚度要求很高尤其是主轴系统的要求更高。因此合理的进行主轴系统的完善设计非常关键。关键词:硅晶圆 抛光机 化学机械 主轴系统

Abstract

Polishing machine machinery manufacturing industry is one of the most important part of precision machining technology, is also the essential equipment. This is because the precision and ultra-precision machining technology not only directly affect the cutting-edge technology and the development of national defence industry, but also the influence of mechanical product precision and surface quality, influence the international competitiveness of products. Now with the machinery, electronics, semiconductor, optical, sensor and measurement technology and the development of material science in precision and ultra-precision machining technology have higher requirements. Especially with the integrated circuit ( IC ) technology, technology unceasing development, the diameter of silicon single crystal dimensions does bigger more, less than 200mm in diameter of single crystal silicon has entered commercial production application level, large diameter300mm silicon polished wafers have been in feature size width less than 0.13um Ic device technology has been widely applied in the, and has entered into the development, the production stage, more than 400mm in diameter of single crystal silicon also entered development, research stage, predict 2014, will begin using 450mm and36nmtechnology node silicon semiconductor manufacturing factory. Therefore, the polishing quality include physical size, roughness, surface roughness, nanoscale topography, oxygen content and crystal perfection index of the increasingly high demand. In the traditional grinding, chemical corrosion, for the characteristics of the processing technology, has been unable to adapt to the large size workpiece from high quality, precision, high efficiency and low cost processing requirements. At present, chemical mechanical polishing ( CMP ) is considered to be able to realize the surface of the wafer is partially planarized and global planarization optimal method. Silicon wafer polishing machine tool is a chemical mechanical polishing ( CMP ) of the necessary hardware support. Only effective equipment support can be developed for wafer processing technology, reasonable process parameters. Because the surface of the wafer processing quality requirement is very high, so the CMP machine tool bed structure stiffness requirements is very high especially the requirements of spindle system of higher. Therefore the reasonable design is the key to the improvement of spindle system.

.Key words: silicon wafer; polishing machine; chemical machinery; spindle system

目录

摘要 I目录 1

1前言 3

1.1 概述 3

1.2抛光机的分类 4

1.3 常用抛光方法 5

1.4 抛光机现状及发展趋势 8

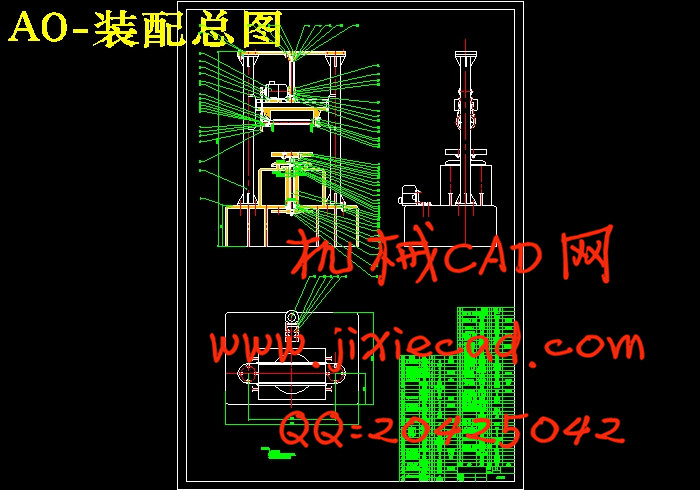

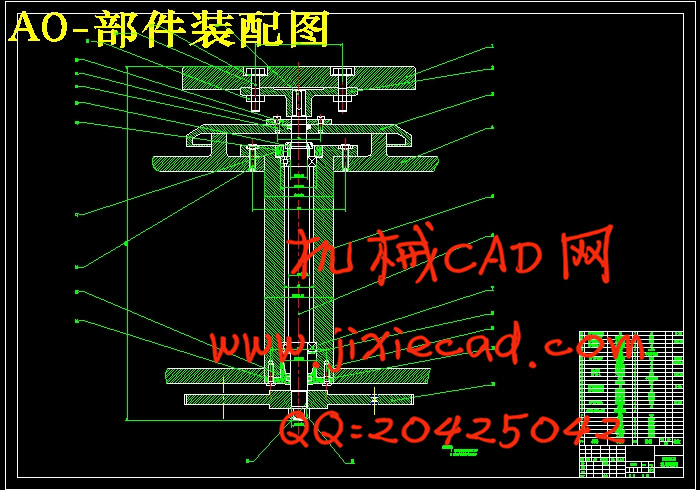

2 机械系统的设计 12

2.1抛光机的底座设计 12

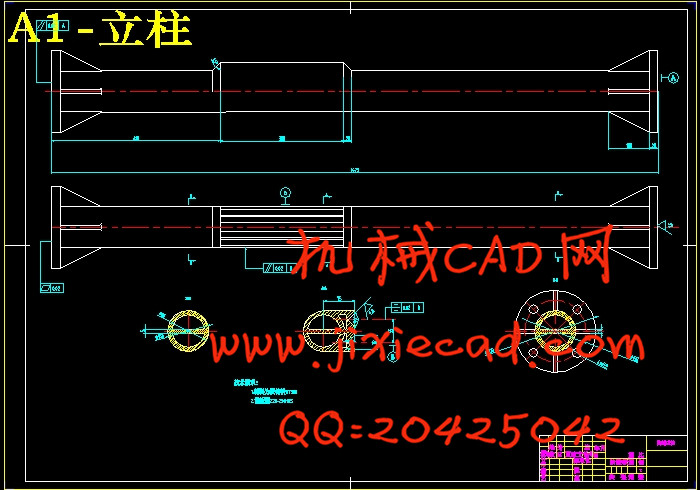

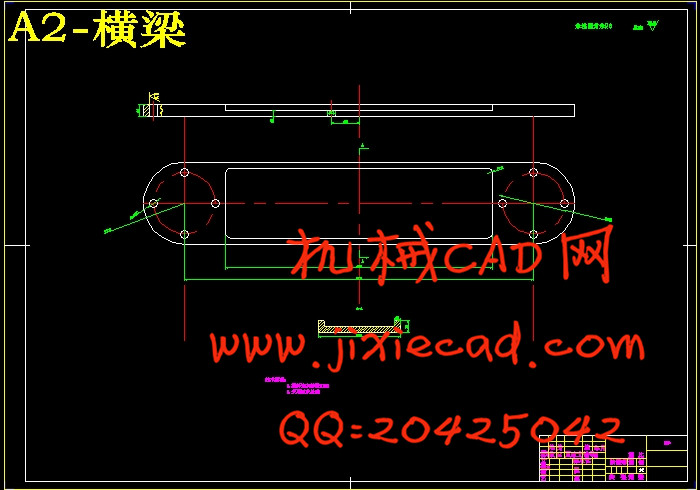

2.2立柱的设计 18

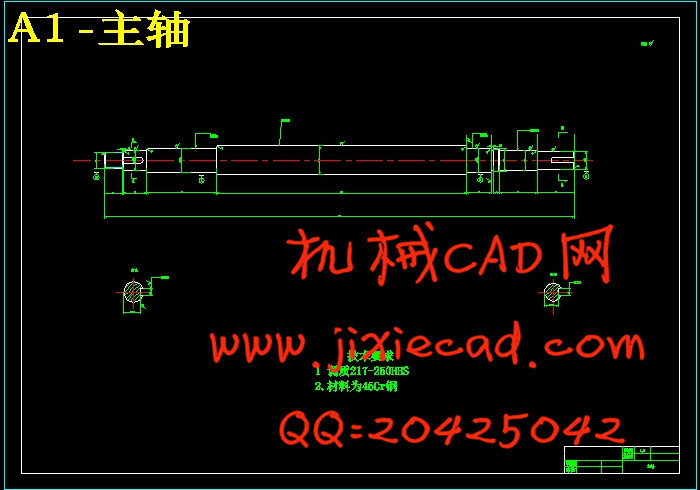

2.3 主轴系统的设计 20

3 传动部分的设计与计算 35

3.1 电机的选择 35

3.2 带传动的选型 36

3.3 同步带的介绍 38

3.3.1 同步带的特点 38

3.3.2 同步带分类 38

3.3.3 同步带传动的主要失效形式 39

3.4 同步带传动的设计计算 42

3.4.1 同步带传动的设计准则 42

3.4.2 同步带传动设计计算过程 43

4 液压系统的设计与计算 49

4.1 明确设计要求﹑进行工况分析 49

4.1.1工况分析 50

4.1.2执行元件的参数确定 54

4.2拟定液压系统原理图 60

4.2.1所用的液压执行元件的类型 60

4.2.2 液压回路的选择 61

4.3液压元件的计算和选择 62

4.3.1 液压泵的选择 62

4.3.2 阀类元件的选择 66

4.4绘制工作图和编制技术文件 68

结 论 71

致 谢 72

参考文献 73