设计简介

摘要

冲压成形的冲压件具有重量轻、厚度薄、刚性好和质量稳定等一系列优点,冲压设备被广泛使用。但由于传统的冲床控制采用接触器、继电器控制,手工送料的方式,所以往往存在着效率低、速度慢、精度不能保证、安全存在隐患等方面的一系列问题,虽然购置新的数控设备可以解决这一问题,但往往资金投入较大,小型企业难以承受,若能在保留原有机床的基本功能基础上,对其进行适当的改造与改进,不失为一种好的方法。一方面可以节约资金,另一方面也不会使原来的机床闲置浪费,基于此种思想,我们对长治科达工贸公司生产餐盒的冲床进行了全面改造,本文对设计的详细过程进行了全方面的论述。

本论文在内容安排上首先介绍了题目的来源与意义及其相关的背景;系统方案的确定、总体的组成、设计思想与理论依据等;随后对系统进行了详细设计,包括:张力控制设计、电气控制主电路与辅助电路设计、PLC控制器的资源分配、电气连接、软件程序代码的编写、触摸屏部分的连接方式、控制界面的设计等;最后对通讯接口与上位机程序进行了详细设计,包括PLC-触摸屏-PC机的连接方式、通讯协议、以及详细的通讯代码等。

系统经调试自运行三个月以来,无论是在稳定性、可靠性方面,还是在系统的精度与效率方面都有了很大的提高,同时节约了成本,降低了操作人员的劳动强度与人身危险系数,使系统的自动化、现代化程度大大提高,本论文提出“PLC-触摸屏-代机”的控制方式在工业自动化控制中有一定的理论研究价值意义,控制过程的具体实施有较高的参考与使用价值,在同行业中有一定的推广与应用的实际意义。

关键词:PLc 控制触摸屏 自动送料机 冲床改造

Abstract

The stamping workpiece has a series of advages with light weight,thin thickness, good rigidity and stable quality and so on . The stamping equipment has been widely used. But traditional punch control often adopts the contactor and relay control and the method of sending material by hand , so problem exit in low efficiency ,slow speed ,precision not being guaranteed and potential safety . Although purchasing the new equipment of numerical control may solve these problems. But the fund to be invested is greater, small company is hard to bear. It will be a good method if we can carry out proper transformation and improvement for the original machine tool without changing its basic functions, which will not only economize fund but also make good use of original machine tool. Based on this thought, overall transformation of the punch producing the meal box in CHANG ZHI Ke Da trade company has been carried out. This paper will elaborate the process of design in detail.

This paper first introduces the background related to it and the meaning and source of this title, the definition of systematic scheme, overall composition and design thought and theoretical basis; then it carries out detailed design which includes tension control design, electrical control main circuit and supplementary circuit design , the resource allocation of PLC controller , electrical connection , software program code, the connected way of touch-screen, the design of control interface and etc; finally as for communication interface and last position machine it carries out detailed design that includes the connected way of “PLC-touch-screen-personal computer”, communication agreement as well as detailed communication code.

Running for three months, the debugged system has got great raising not only in stability and reliability but also in system’s precision and efficiency, at the same time it has economized cost, reduced the personal risk factor and efficiency, at the same time it has economized cost, reduced the personal risk factor and labour intensity and largely raised automatization and modernization of the system,.The control way “PLC- touch-screen-personal computer” put forward in this paper has the certain theoretical research value in industry and the control process has higher reference and use significance and has certain popularization and actual meaning of application in the field of industry.

Keywords: PLC;controls touch-screen;send material machine;punch transformation

目 录

中文摘要 I

英文摘要 iI

第1章 引言 1

1.1我国冲压设备与送料装置的现状及课题研究的实际意义 1

1.2课题研究的相关背景 3

1.3数控机床与自动送料技术的国内外发展概况及发展趋势 3

1.3.1数控机床的产生 3

1.3.2计算机数控的发展 3

1.3.3冲压设备及自动送料装置的发展方向 4

1.4课题研究的任务及达到的预期目标 5

第2章 系统的总体设计 6

2.1自动送料装置的平面图 6

2.2供料方案分析 6

2.3控制系统设计 7

2.3.1 控制系统的硬件设计 7

2.3.2控制系统的软件设计 8

第3章 冲床自动送料机构组件丝杠的设计 9

3.1计算选定编号 10

3.1.1导程 10

3.1.2平均转速 10

3.1.3平均载荷 10

3.1.4时间寿命与回转寿命 11

3.1.5额定动载荷 11

3.1.6预紧载荷 11

3.1.7丝杠螺纹长度 11

3.2丝杠公称直径 11

3.3滚珠丝杠传动系统刚度 12

3.3.1丝杠刚度 12

3.3.2螺母刚度 12

3.3.3支承刚度 13

3.3.4轴向总刚度 13

3.4总弹性变形量(单边) 13

3.5电机的选定 14

3.5.1驱动转矩 14

3.6检校 15

3.6.1丝杠理论容许轴向载荷 15

3.6.2丝杠工作容许轴向载荷 15

3.6.3临界转速 15

3.6.4允许工作转速 15

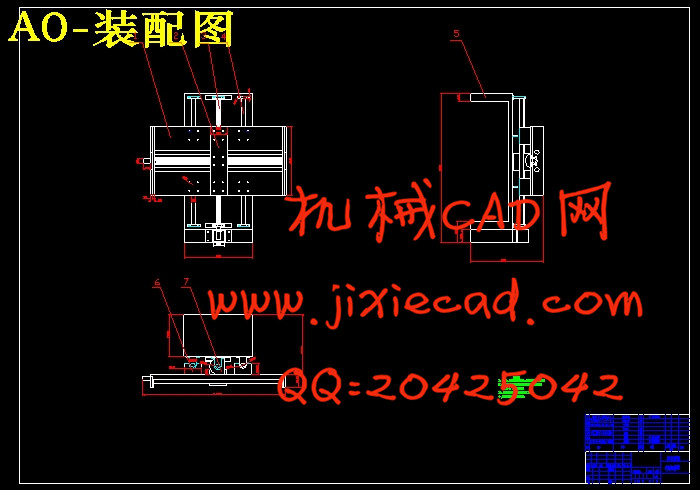

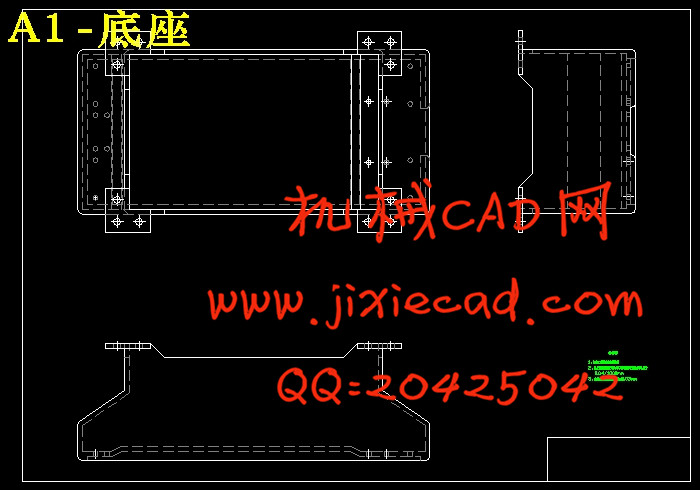

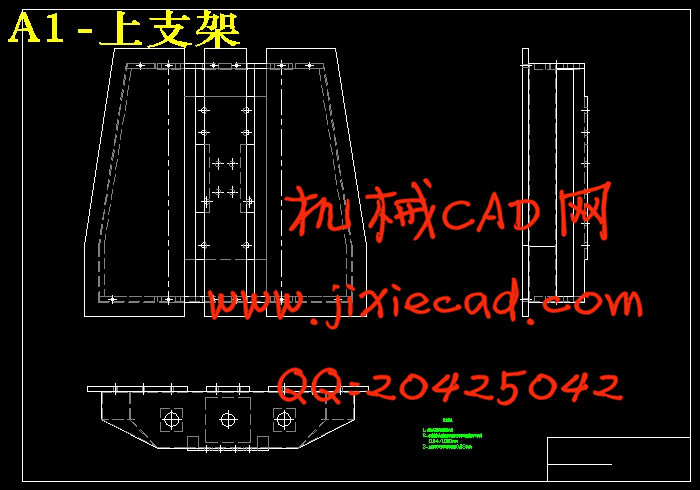

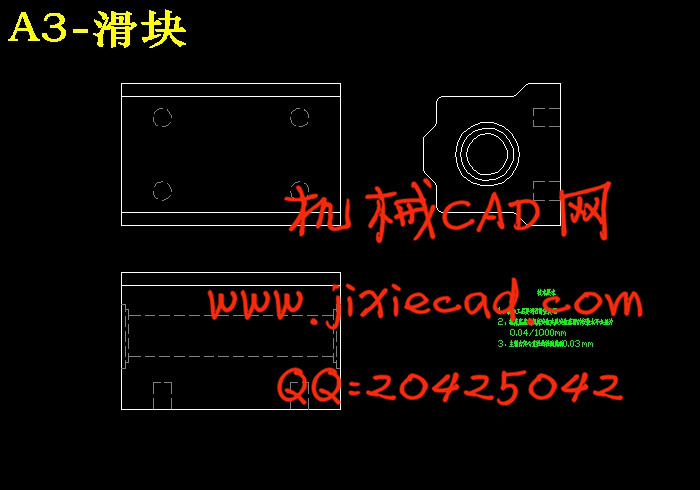

第4章 基于Pro/E的冲床自动送料机构装配图 16

4.1冲床自动送料机构重要组件零件图 16

4.1.1导向杆 16

4.1.2导向杆座 17

4.1.3丝杠 17

4.1.4丝杠螺母 17

4.1.5轴承支座 18

4.2冲床自动送料机构组件丝杠绘制过程 18

结论 21

结束语 23

参考文献 25

致谢 26

冲压成形的冲压件具有重量轻、厚度薄、刚性好和质量稳定等一系列优点,冲压设备被广泛使用。但由于传统的冲床控制采用接触器、继电器控制,手工送料的方式,所以往往存在着效率低、速度慢、精度不能保证、安全存在隐患等方面的一系列问题,虽然购置新的数控设备可以解决这一问题,但往往资金投入较大,小型企业难以承受,若能在保留原有机床的基本功能基础上,对其进行适当的改造与改进,不失为一种好的方法。一方面可以节约资金,另一方面也不会使原来的机床闲置浪费,基于此种思想,我们对长治科达工贸公司生产餐盒的冲床进行了全面改造,本文对设计的详细过程进行了全方面的论述。

本论文在内容安排上首先介绍了题目的来源与意义及其相关的背景;系统方案的确定、总体的组成、设计思想与理论依据等;随后对系统进行了详细设计,包括:张力控制设计、电气控制主电路与辅助电路设计、PLC控制器的资源分配、电气连接、软件程序代码的编写、触摸屏部分的连接方式、控制界面的设计等;最后对通讯接口与上位机程序进行了详细设计,包括PLC-触摸屏-PC机的连接方式、通讯协议、以及详细的通讯代码等。

系统经调试自运行三个月以来,无论是在稳定性、可靠性方面,还是在系统的精度与效率方面都有了很大的提高,同时节约了成本,降低了操作人员的劳动强度与人身危险系数,使系统的自动化、现代化程度大大提高,本论文提出“PLC-触摸屏-代机”的控制方式在工业自动化控制中有一定的理论研究价值意义,控制过程的具体实施有较高的参考与使用价值,在同行业中有一定的推广与应用的实际意义。

关键词:PLc 控制触摸屏 自动送料机 冲床改造

Abstract

The stamping workpiece has a series of advages with light weight,thin thickness, good rigidity and stable quality and so on . The stamping equipment has been widely used. But traditional punch control often adopts the contactor and relay control and the method of sending material by hand , so problem exit in low efficiency ,slow speed ,precision not being guaranteed and potential safety . Although purchasing the new equipment of numerical control may solve these problems. But the fund to be invested is greater, small company is hard to bear. It will be a good method if we can carry out proper transformation and improvement for the original machine tool without changing its basic functions, which will not only economize fund but also make good use of original machine tool. Based on this thought, overall transformation of the punch producing the meal box in CHANG ZHI Ke Da trade company has been carried out. This paper will elaborate the process of design in detail.

This paper first introduces the background related to it and the meaning and source of this title, the definition of systematic scheme, overall composition and design thought and theoretical basis; then it carries out detailed design which includes tension control design, electrical control main circuit and supplementary circuit design , the resource allocation of PLC controller , electrical connection , software program code, the connected way of touch-screen, the design of control interface and etc; finally as for communication interface and last position machine it carries out detailed design that includes the connected way of “PLC-touch-screen-personal computer”, communication agreement as well as detailed communication code.

Running for three months, the debugged system has got great raising not only in stability and reliability but also in system’s precision and efficiency, at the same time it has economized cost, reduced the personal risk factor and efficiency, at the same time it has economized cost, reduced the personal risk factor and labour intensity and largely raised automatization and modernization of the system,.The control way “PLC- touch-screen-personal computer” put forward in this paper has the certain theoretical research value in industry and the control process has higher reference and use significance and has certain popularization and actual meaning of application in the field of industry.

Keywords: PLC;controls touch-screen;send material machine;punch transformation

目 录

中文摘要 I

英文摘要 iI

第1章 引言 1

1.1我国冲压设备与送料装置的现状及课题研究的实际意义 1

1.2课题研究的相关背景 3

1.3数控机床与自动送料技术的国内外发展概况及发展趋势 3

1.3.1数控机床的产生 3

1.3.2计算机数控的发展 3

1.3.3冲压设备及自动送料装置的发展方向 4

1.4课题研究的任务及达到的预期目标 5

第2章 系统的总体设计 6

2.1自动送料装置的平面图 6

2.2供料方案分析 6

2.3控制系统设计 7

2.3.1 控制系统的硬件设计 7

2.3.2控制系统的软件设计 8

第3章 冲床自动送料机构组件丝杠的设计 9

3.1计算选定编号 10

3.1.1导程 10

3.1.2平均转速 10

3.1.3平均载荷 10

3.1.4时间寿命与回转寿命 11

3.1.5额定动载荷 11

3.1.6预紧载荷 11

3.1.7丝杠螺纹长度 11

3.2丝杠公称直径 11

3.3滚珠丝杠传动系统刚度 12

3.3.1丝杠刚度 12

3.3.2螺母刚度 12

3.3.3支承刚度 13

3.3.4轴向总刚度 13

3.4总弹性变形量(单边) 13

3.5电机的选定 14

3.5.1驱动转矩 14

3.6检校 15

3.6.1丝杠理论容许轴向载荷 15

3.6.2丝杠工作容许轴向载荷 15

3.6.3临界转速 15

3.6.4允许工作转速 15

第4章 基于Pro/E的冲床自动送料机构装配图 16

4.1冲床自动送料机构重要组件零件图 16

4.1.1导向杆 16

4.1.2导向杆座 17

4.1.3丝杠 17

4.1.4丝杠螺母 17

4.1.5轴承支座 18

4.2冲床自动送料机构组件丝杠绘制过程 18

结论 21

结束语 23

参考文献 25

致谢 26