设计简介

冲压成形目前在汽车、家电、电子等行业得到了广泛的应用,并且适用于大型零件或小批量生产。作为其组要成形机构,冲压机床在各个领域中起到越来越重要的作用。

本文主要介绍了冲压机床的基本概念,原理,以及在国内外的发展现状。然后具体阐述了曲柄压力机的组成和传动系统的构成。根据课题的要求,对冲压机床的传动系统进行了方案设计和选型。最后文章分别对曲柄连杆机构,齿轮部分,滑块部分及伺服电机的选用等进行了详细的计算与校核,并给出了传动系统各部分的三维造型的设计和总装配图。

关键词 冲压机床 冲床设计 传动系统 伺服电机

Abstract

Punch forming has been widely used in the automotive, appliance, electronics and other industries areas. It is very fit for large parts or small batch production. As the mainly part of the punch forming , Punch machine play an increasing important role in various fields.

This paper mainly introduces the basic concepts of punching machine, principle, as well as the development of the punching machine at home and abroad. And detail the composition of the crank presses and transmission components are described in detail.The design and selection of the transmission is proceeded in this paper in according to the requirement of the subject. The detailed calculation and checking about of the crank-connecting rod mechanism, respectively, gear parts, slider parts and the use of servo motors are described individually. At last, the 3D modeling of the transmission system and the generally assemble are given in this paper.

Keywords Punching Machine Punch design Transmission System Servo motor

目 录

1 引言 1

1.1 冲压机床 1

1.2 冲压机床主传动的分类 2

1.3 冲床设备安全防护 2

1.4 冲压机床在国内外的发展现状 3

1.5 论文主要研究内容及手段 4

2 曲柄压力机 5

2.1 曲柄压力机的结构 5

2.2 曲柄压力机传动系统结构形式 5

2.3 曲柄压力机传动系统的布置方式 6

2.4 曲柄压力机传动级数及速比的分配 6

2.5 本课题传动系统选型 7

3 传动系统设计 10

3.1 主要设计参数 10

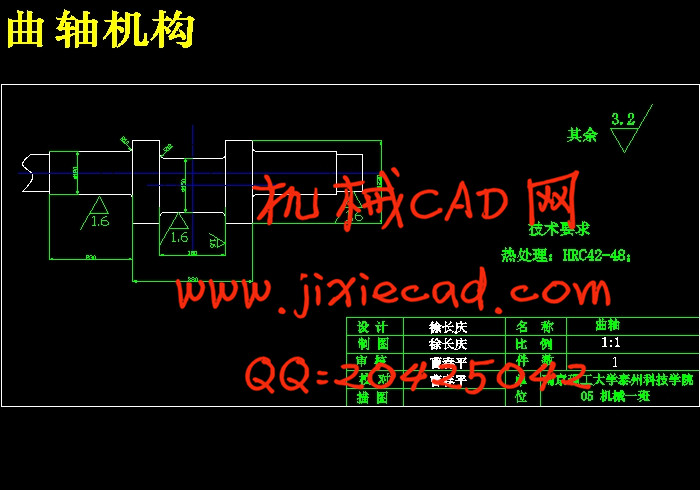

3.2 曲轴的确定 10

3.3 齿轮的计算 15

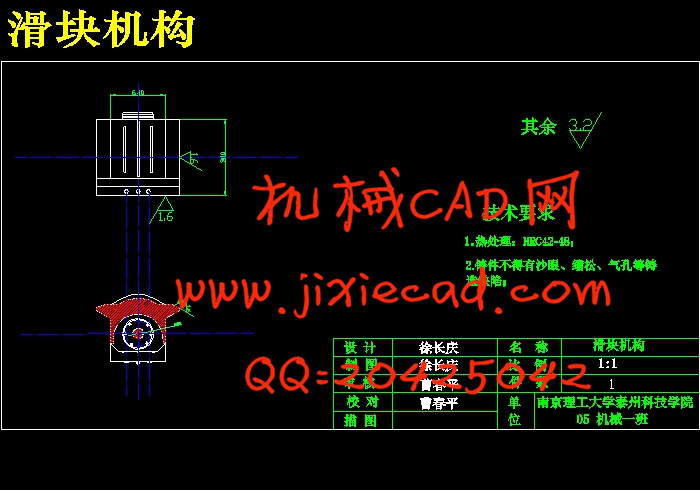

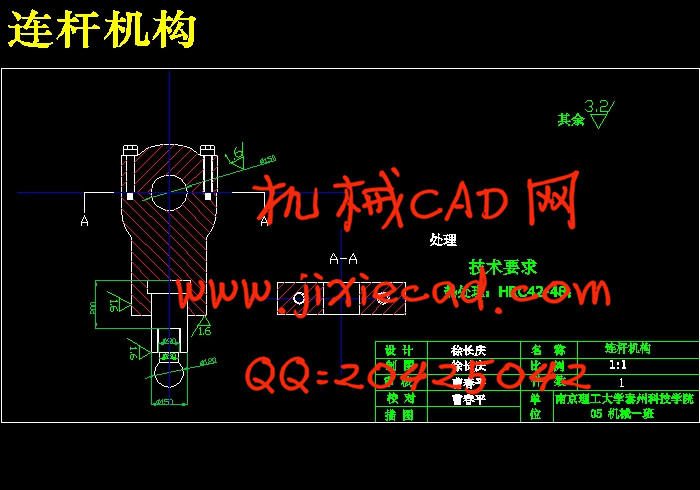

3.4 连杆及滑块的计算 17

4 伺服电机选型 22

4.1 伺服电机直接驱动可行性分析 22

4.2 电机选型分析 23

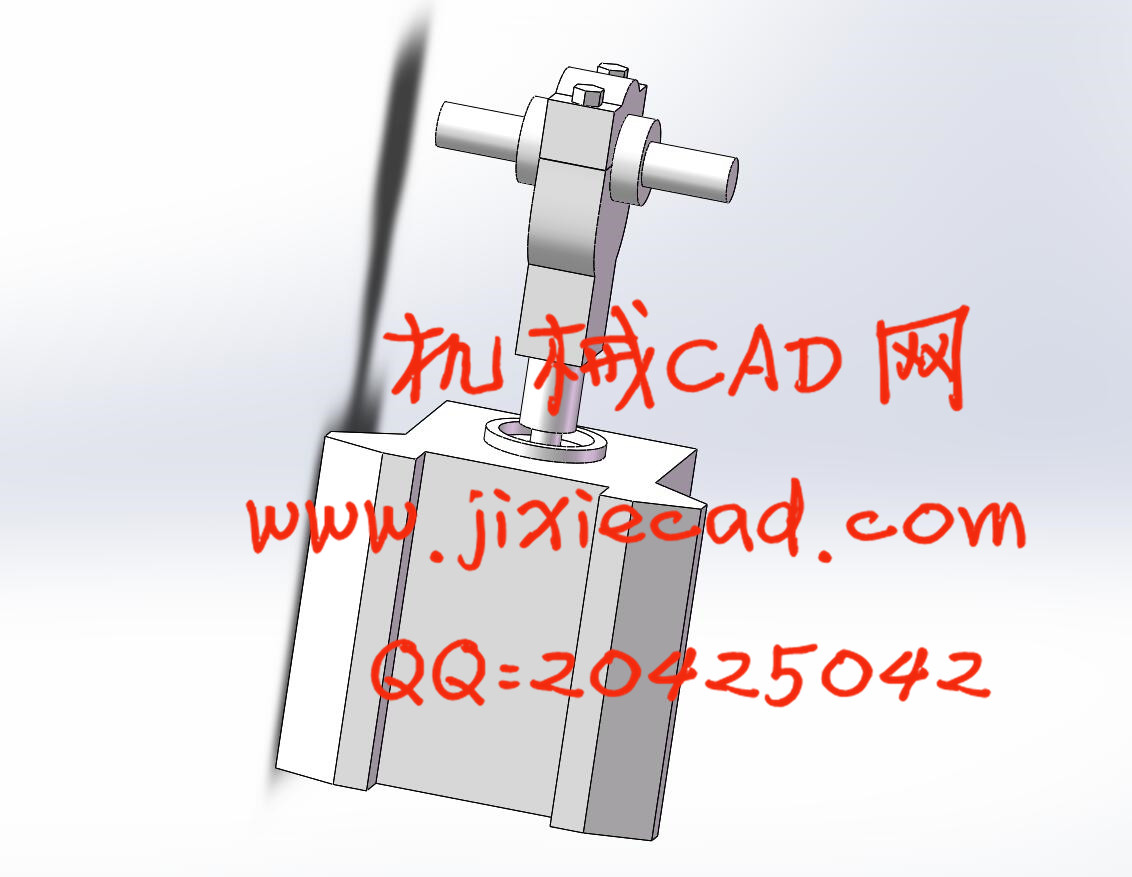

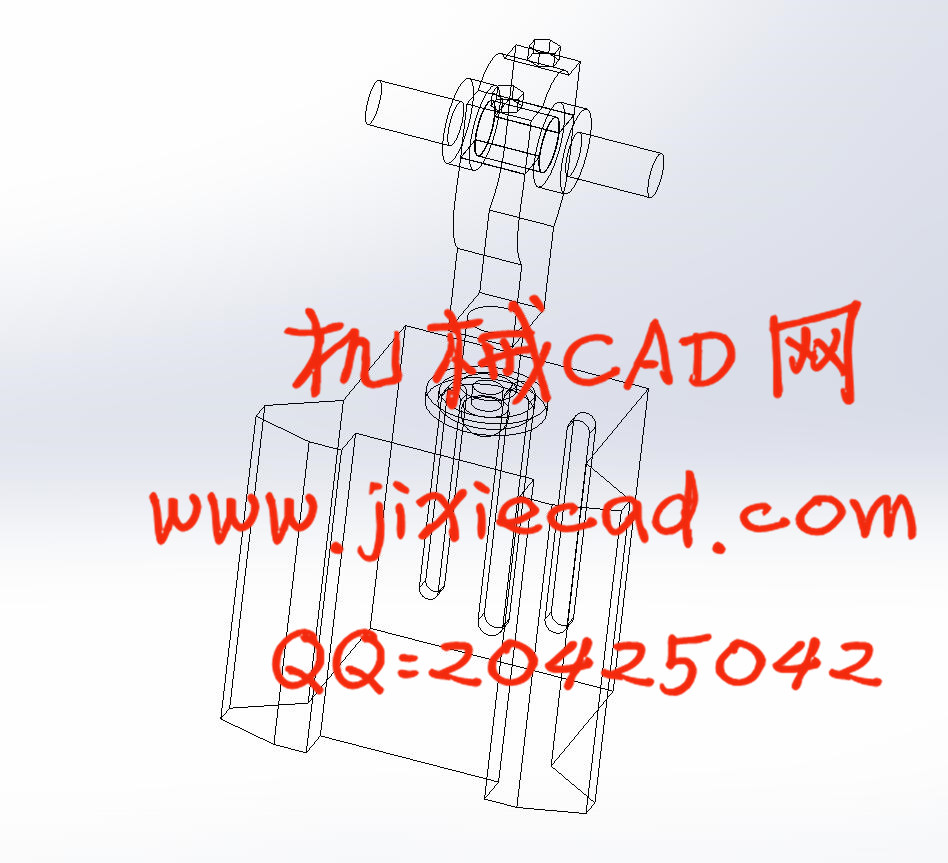

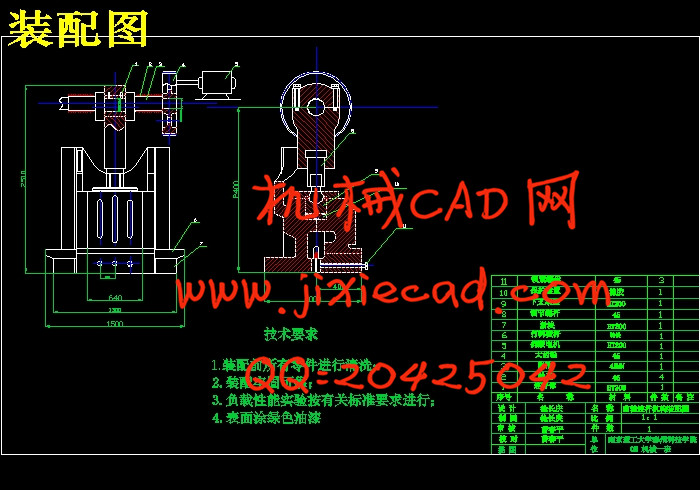

5 传动系统三维造型设计 29

5.1 三维造型软件的概述 29

5.2 各组成部分三维模型设计 29

5.3 装配图的设计 31

结束语 32

致谢 33

参考文献 34

本文主要介绍了冲压机床的基本概念,原理,以及在国内外的发展现状。然后具体阐述了曲柄压力机的组成和传动系统的构成。根据课题的要求,对冲压机床的传动系统进行了方案设计和选型。最后文章分别对曲柄连杆机构,齿轮部分,滑块部分及伺服电机的选用等进行了详细的计算与校核,并给出了传动系统各部分的三维造型的设计和总装配图。

关键词 冲压机床 冲床设计 传动系统 伺服电机

Abstract

Punch forming has been widely used in the automotive, appliance, electronics and other industries areas. It is very fit for large parts or small batch production. As the mainly part of the punch forming , Punch machine play an increasing important role in various fields.

This paper mainly introduces the basic concepts of punching machine, principle, as well as the development of the punching machine at home and abroad. And detail the composition of the crank presses and transmission components are described in detail.The design and selection of the transmission is proceeded in this paper in according to the requirement of the subject. The detailed calculation and checking about of the crank-connecting rod mechanism, respectively, gear parts, slider parts and the use of servo motors are described individually. At last, the 3D modeling of the transmission system and the generally assemble are given in this paper.

Keywords Punching Machine Punch design Transmission System Servo motor

目 录

1 引言 1

1.1 冲压机床 1

1.2 冲压机床主传动的分类 2

1.3 冲床设备安全防护 2

1.4 冲压机床在国内外的发展现状 3

1.5 论文主要研究内容及手段 4

2 曲柄压力机 5

2.1 曲柄压力机的结构 5

2.2 曲柄压力机传动系统结构形式 5

2.3 曲柄压力机传动系统的布置方式 6

2.4 曲柄压力机传动级数及速比的分配 6

2.5 本课题传动系统选型 7

3 传动系统设计 10

3.1 主要设计参数 10

3.2 曲轴的确定 10

3.3 齿轮的计算 15

3.4 连杆及滑块的计算 17

4 伺服电机选型 22

4.1 伺服电机直接驱动可行性分析 22

4.2 电机选型分析 23

5 传动系统三维造型设计 29

5.1 三维造型软件的概述 29

5.2 各组成部分三维模型设计 29

5.3 装配图的设计 31

结束语 32

致谢 33

参考文献 34