设计简介

摘要

随着我国汽车行业的不断发展壮大,对汽车空调的需求也随之增大,再加上目前全球气候的变暖,导致民用空调的需求也大大增加。然而,目前国内做空调设备的企业确非常少,而且多数采用进口设备进行加工,这样使空调制造企业的成本增加了许多。空调加工设备有弯管机、冲孔机、折弯机、管端成型机等。管端成型机作为空调加工设备的一种,在整个空调制造过程中起到了关键的作用。

本文研究设计管端成型机主要用于将铝管(还可用于铜管)的管端通过冲压的方式将其收口或扩口、加工成所需的管端形状。管端成型技术主要应用于空调机热交换器或汽车空调热交换器的管端连接。该设备适用于批量生产,可以完成直径为F8X1mm;F9.5X1.2mm;F12.7X1.2mm; F15.8X1.2mm;F19X1.5mm的铝管(或铜管)的管端成型加工。目前,国内专门制造用于管端成型的通用机床比较少,大多数都是专用机床,生产效率比较高,但是灵活性小,对于不同管件的加工具有一定的局限性。因此,有必要设计这样一种可以适应不同管件胀形加工的通用机床,并且在不需要进行大批量生产的情况下,代替了小批量单件生产时的手工胀管,而且可以节省时间和生产消耗,提高单件的生产效率,及时满足产品零部件的需要。因此本课题设计的这一产品具有较高的使用价值和普遍性。

关键词: 管端成型机;液压系统;主机;

Abstract

Unceasing grows strong along with our country automobile profession, also increases to automotive air conditioning's demand along with it, in addition the present global climate's warming, causes the civil air conditioning's demand also greatly to increase. However, domestic makes air-conditioning plant's enterprise to be firmly few at present, moreover uses most imports the equipment to carry on the processing, like this made the air conditioning Manufacturing firm's cost to increase many. The air conditioning processing equipment has the pipe bending machine, the punch press, the booklet bender, the jet shaper and so on. The jet shaper takes the air conditioning processing equipment's one kind, played the key role in the entire air conditioning process of manufacture.

This article studies the design jet shaper mainly to use in (may also use in the aluminum tube copper pipe) the jet through the ramming way it healing the jet shape which or the flaring, processes needs. The jet formation technology mainly applies in the air conditioner heat interchanger or the automotive air conditioning heat interchanger's jet connection. This equipment is suitable for the volume production, may complete the diameter is 8X1mm; 9.5X1.2mm; 12.7X1.2mm; 15.8X1.2mm; 19X1.5mm aluminum tube (or copper pipe) jet formation processing. At present, domestic makes specially uses in the jet formation the general engine bed being quite few, majority is the special purpose machine, the production efficiency is quite high, but the flexibility is small, has certain limitation regarding the different fitting's processing. Therefore, it is necessary to design such one kind to be possible to adapt the different fitting bulging processing general engine bed, and in does not need to carry on the production in enormous quantities in the situation, has replaced time the small batch piecework manual expanding tube, moreover may the saving of time and the productive consumption, enhances the single unit the production efficiency, satisfies the product spare part promptly the need. Therefore this topic design's this product has the high use value and the universality.

Key words: Jet shaper; Hydraulic system; Main engine;

目录

前言 1

1 管端成型机总体方案的选定 2

1.1无模成型 2

1.2 管端偏心回转成型 2

1.3 利用NC工作机的管端成型 3

1.4 机械成型 3

1.5 确定所选方案 3

1.6 管端成型处理机构的组成 3

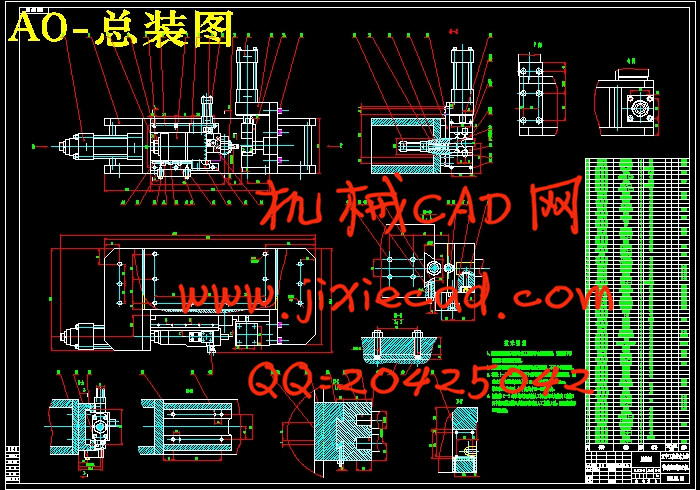

2 主机整体结构及各主要工作机构的设计与计算 5

2.1 主机整体结构的一般布置 5

2.2 管端成型机主机的工作原理 6

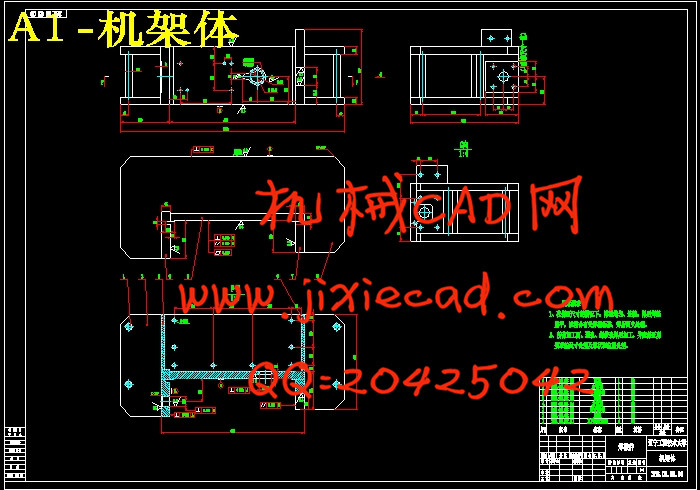

2.3 机架的结构设计 7

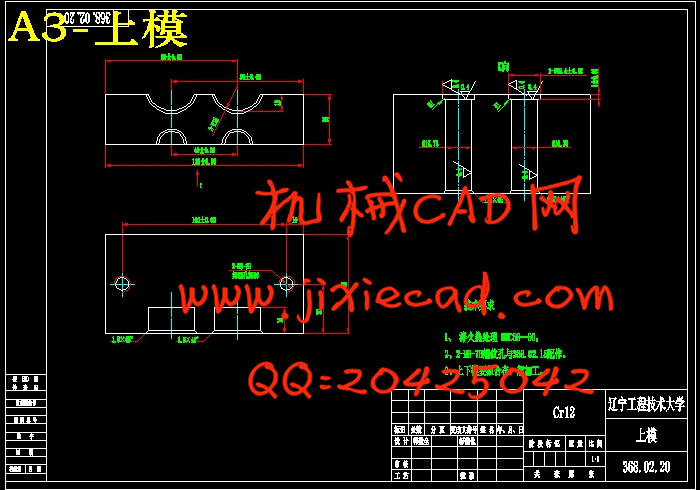

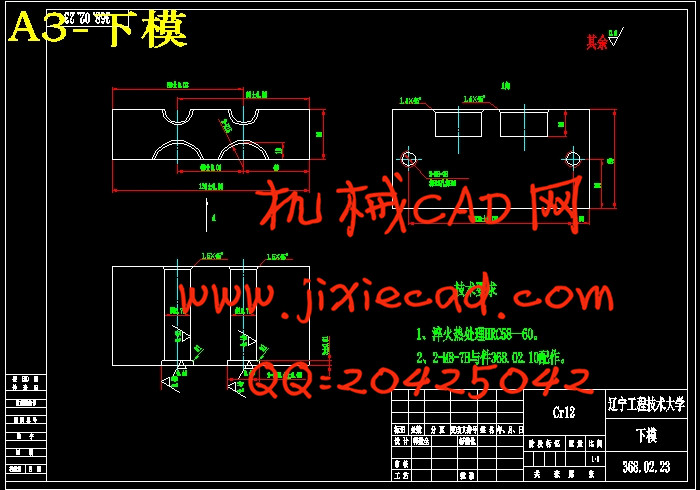

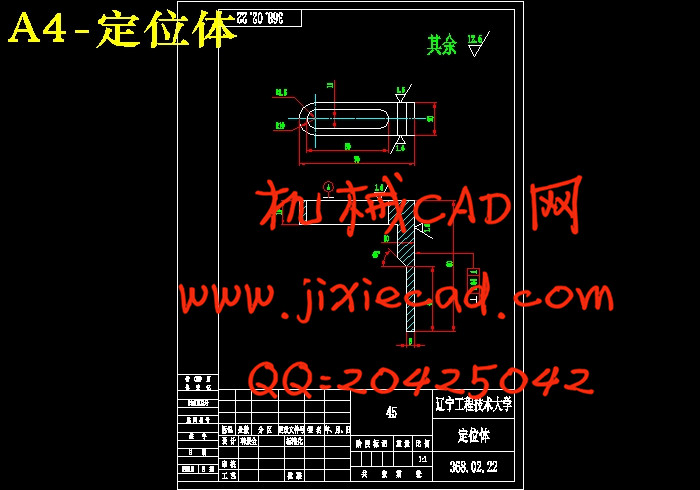

2.4 夹紧模具的设计 8

2.4.1 材料的选择 9

2.4.2 夹紧模具的强度计算 10

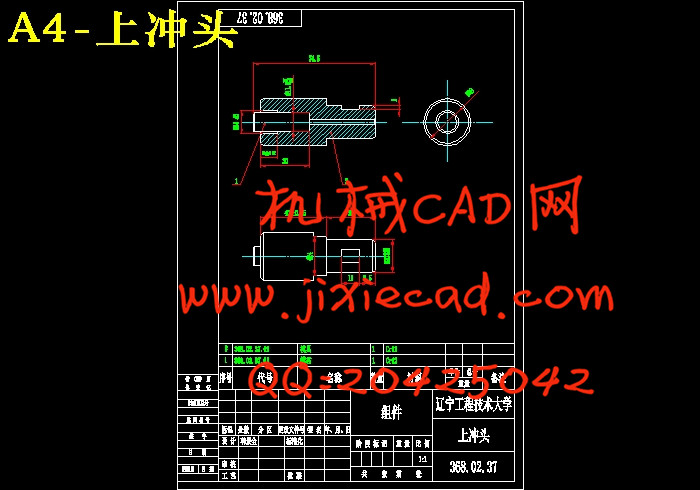

2.5 冲头的设计 10

2.5.1 材料的选择 12

2.5.2 冲头的强度计算 12

3 管端成型机的液压系统设计 13

3.1 设计规格、性能及对液压系统的要求 13

3.2 管端成型机的液压系统分析 14

3.2.1各液压缸的载荷分析 14

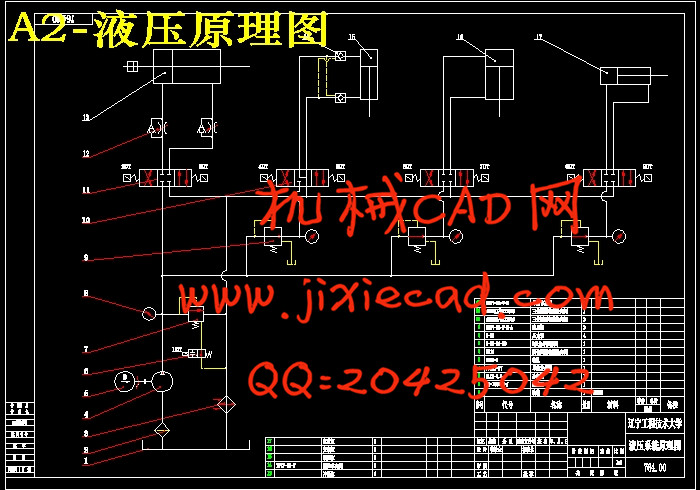

3.2.2 管端成型机的液压系统原理图 14

3.2.3 液压系统工作循环分析 15

3.3 液压元件的选用 17

3.3.1 液压阀的选用 17

3.3.2 辅助元件的选用 18

3.3.3 执行元件的确定 19

3.3.4 电动机的选择 19

4 管端成型机的液压缸设计计算和泵的参数计算 21

4.1 液压缸的设计计算 21

4.1.1 液压缸的选用 21

4.1.2 胀形力的计算 21

4.1.3 冲压缸载荷计算 21

4.1.4 冲压缸结构尺寸计算 24

4.1.5 计算液压缸的主要结构尺寸 24

4.1.6 油缸强度计算 27

4.1.7 夹紧油缸的设计计算 30

4.1.8 油缸强度计算 31

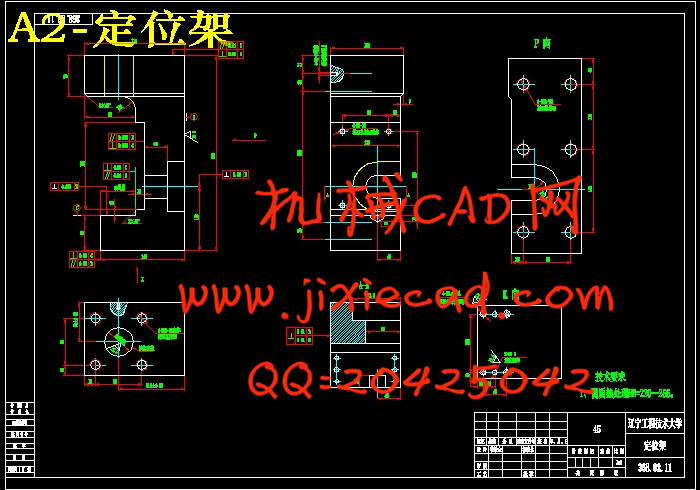

4.1.9 调整油缸和定位油缸的选择 33

4.2 泵的参数计算 34

4.2.1 泵的选用 34

4.2.2 泵的压力计算 34

4.2.3 计算所需要的泵的流量 34

5 液压系统性能验算 36

6 经济技术分析 38

结论 39

致 谢 40

参考文献 41

随着我国汽车行业的不断发展壮大,对汽车空调的需求也随之增大,再加上目前全球气候的变暖,导致民用空调的需求也大大增加。然而,目前国内做空调设备的企业确非常少,而且多数采用进口设备进行加工,这样使空调制造企业的成本增加了许多。空调加工设备有弯管机、冲孔机、折弯机、管端成型机等。管端成型机作为空调加工设备的一种,在整个空调制造过程中起到了关键的作用。

本文研究设计管端成型机主要用于将铝管(还可用于铜管)的管端通过冲压的方式将其收口或扩口、加工成所需的管端形状。管端成型技术主要应用于空调机热交换器或汽车空调热交换器的管端连接。该设备适用于批量生产,可以完成直径为F8X1mm;F9.5X1.2mm;F12.7X1.2mm; F15.8X1.2mm;F19X1.5mm的铝管(或铜管)的管端成型加工。目前,国内专门制造用于管端成型的通用机床比较少,大多数都是专用机床,生产效率比较高,但是灵活性小,对于不同管件的加工具有一定的局限性。因此,有必要设计这样一种可以适应不同管件胀形加工的通用机床,并且在不需要进行大批量生产的情况下,代替了小批量单件生产时的手工胀管,而且可以节省时间和生产消耗,提高单件的生产效率,及时满足产品零部件的需要。因此本课题设计的这一产品具有较高的使用价值和普遍性。

关键词: 管端成型机;液压系统;主机;

Abstract

Unceasing grows strong along with our country automobile profession, also increases to automotive air conditioning's demand along with it, in addition the present global climate's warming, causes the civil air conditioning's demand also greatly to increase. However, domestic makes air-conditioning plant's enterprise to be firmly few at present, moreover uses most imports the equipment to carry on the processing, like this made the air conditioning Manufacturing firm's cost to increase many. The air conditioning processing equipment has the pipe bending machine, the punch press, the booklet bender, the jet shaper and so on. The jet shaper takes the air conditioning processing equipment's one kind, played the key role in the entire air conditioning process of manufacture.

This article studies the design jet shaper mainly to use in (may also use in the aluminum tube copper pipe) the jet through the ramming way it healing the jet shape which or the flaring, processes needs. The jet formation technology mainly applies in the air conditioner heat interchanger or the automotive air conditioning heat interchanger's jet connection. This equipment is suitable for the volume production, may complete the diameter is 8X1mm; 9.5X1.2mm; 12.7X1.2mm; 15.8X1.2mm; 19X1.5mm aluminum tube (or copper pipe) jet formation processing. At present, domestic makes specially uses in the jet formation the general engine bed being quite few, majority is the special purpose machine, the production efficiency is quite high, but the flexibility is small, has certain limitation regarding the different fitting's processing. Therefore, it is necessary to design such one kind to be possible to adapt the different fitting bulging processing general engine bed, and in does not need to carry on the production in enormous quantities in the situation, has replaced time the small batch piecework manual expanding tube, moreover may the saving of time and the productive consumption, enhances the single unit the production efficiency, satisfies the product spare part promptly the need. Therefore this topic design's this product has the high use value and the universality.

Key words: Jet shaper; Hydraulic system; Main engine;

目录

前言 1

1 管端成型机总体方案的选定 2

1.1无模成型 2

1.2 管端偏心回转成型 2

1.3 利用NC工作机的管端成型 3

1.4 机械成型 3

1.5 确定所选方案 3

1.6 管端成型处理机构的组成 3

2 主机整体结构及各主要工作机构的设计与计算 5

2.1 主机整体结构的一般布置 5

2.2 管端成型机主机的工作原理 6

2.3 机架的结构设计 7

2.4 夹紧模具的设计 8

2.4.1 材料的选择 9

2.4.2 夹紧模具的强度计算 10

2.5 冲头的设计 10

2.5.1 材料的选择 12

2.5.2 冲头的强度计算 12

3 管端成型机的液压系统设计 13

3.1 设计规格、性能及对液压系统的要求 13

3.2 管端成型机的液压系统分析 14

3.2.1各液压缸的载荷分析 14

3.2.2 管端成型机的液压系统原理图 14

3.2.3 液压系统工作循环分析 15

3.3 液压元件的选用 17

3.3.1 液压阀的选用 17

3.3.2 辅助元件的选用 18

3.3.3 执行元件的确定 19

3.3.4 电动机的选择 19

4 管端成型机的液压缸设计计算和泵的参数计算 21

4.1 液压缸的设计计算 21

4.1.1 液压缸的选用 21

4.1.2 胀形力的计算 21

4.1.3 冲压缸载荷计算 21

4.1.4 冲压缸结构尺寸计算 24

4.1.5 计算液压缸的主要结构尺寸 24

4.1.6 油缸强度计算 27

4.1.7 夹紧油缸的设计计算 30

4.1.8 油缸强度计算 31

4.1.9 调整油缸和定位油缸的选择 33

4.2 泵的参数计算 34

4.2.1 泵的选用 34

4.2.2 泵的压力计算 34

4.2.3 计算所需要的泵的流量 34

5 液压系统性能验算 36

6 经济技术分析 38

结论 39

致 谢 40

参考文献 41