设计简介

冲压式芡实剥壳机

摘要

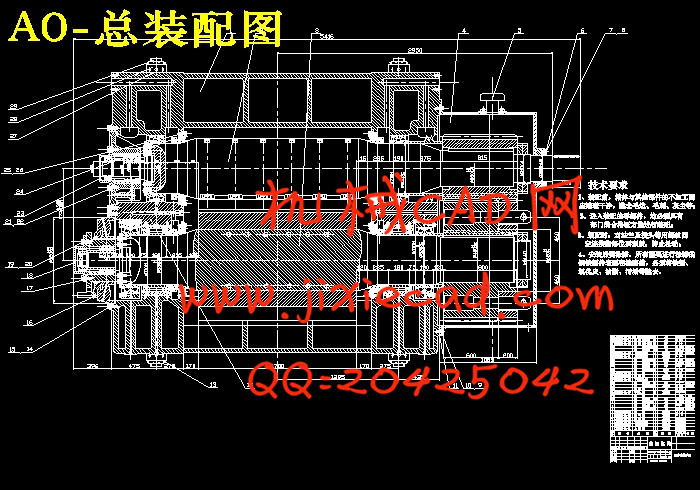

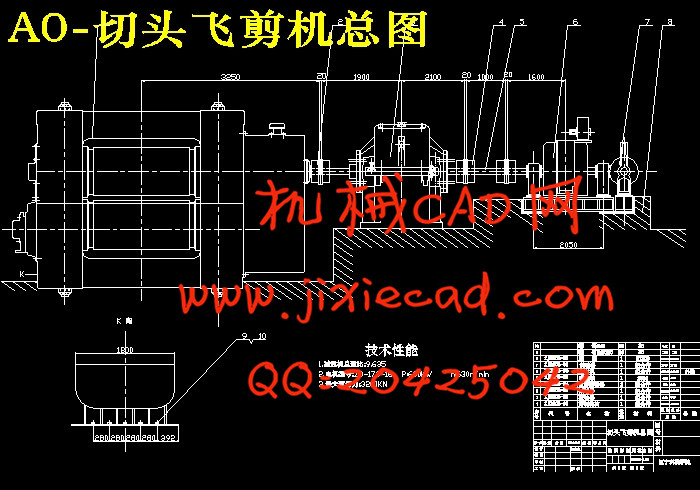

切头冲压式芡实剥壳机是1700热连轧机的单体设备,它的用途是切头、切尾,出现卡钢事故时,将轧件剪断,处理卡钢事故。有时也可剥壳定尺,检查轧件的质量。本溪钢铁公司1700热连轧厂的切头冲压式芡实剥壳机是为满足生产要求制造的,本设计就是改造切头、切尾冲压式芡实剥壳机及其主传动系统。重新选择主电机,新设计的减速机利用原剥壳机的底座,采用双电机,把剥壳机构的曲柄摇杆式改成转鼓式,减少了动力矩,提高了剥壳质量。

设计中,进行剥壳力的计算,选择主电机的容量,进行轴、齿轮的设计计算,进行剥壳机构的改进设计,取得较好的效果,有一定的经济效益。

该切头飞剪应用1700连轧厂,切头和切尾,以及事故处理也可作为1700横切机构设计参考。

关键词: 剥壳机,转股,切头,切尾

Abstract

The Head Metal Clipper Design

The head metal clipper is 1,700 hot companies rolling mills monomer equipment. Its use is cuts away the forehead, cuts away the tail, When it appear catches the steel and iron accident, It cuts by the rolling part, processing catches the steel and iron the matter. Sometimes also may cut the size which assigns, inspects is rolled over the part the quality.The Benxi iron and steel company 1,700 heat continuously roll over the manufacturing plant to cut away the forehead clipper are for satisfy the production request manufacture,This design is the transformation cuts away the forehead, cuts away the rear part clipper and its the main transmission system. Rechooses the main electrical machinery, the new design decelerates the machine use originally to cut the machine the foundation, uses the double electrical machinery, cuts the organization the crank rocker type to alter to the rotor drum type, reduced the kinetic moment, enhanced has cut the quality.

In the design, carries on the shearing force the computation, the choice main electrical machinery capacity, carries on the axis, the gear design calculation, carries on cuts the organization the improvement design, obtains a better effect, has the certain economic efficiency.

Should cut away the forehead to fly cuts should be used in 1700 continuously roll over the manufacturing plant, cuts away the forehead and cuts away the rear part, as well as the accident processes also may take 1,700 lateral shears organizations design reference.

Key words: the cutting machine, the rotor drum type, cuts away the forehead, cuts away the tail

目录

冲压式芡实剥壳机 3

摘要 3

Abstract 4

The Head Metal Clipper Design 4

1绪论 5

1.1课题选择的背景和目的 5

1.2 冲压式芡实剥壳机国内外发展现状 6

1.3 冲压式芡实剥壳机的现状 7

1.3.1冲压式芡实剥壳机在车间布置和作用 7

1.3.2冲压式芡实剥壳机的类型和特点 7

1.3.3 冲压式芡实剥壳机研究的内容和方法 8

2 方案的选择与评述 10

2.1方案选择 10

2.2方案评述 10

3 电机的选择 12

3.1剥壳力的计算 12

3.2剥壳机的扭矩计算 12

3.3剥壳时,转股稳定运转转速

3.4电机型式及电机容量的选择 13

4 主要零件的强度计算 16

4.1减速机的计算 16

4.1.1减速机的传动比分配 16

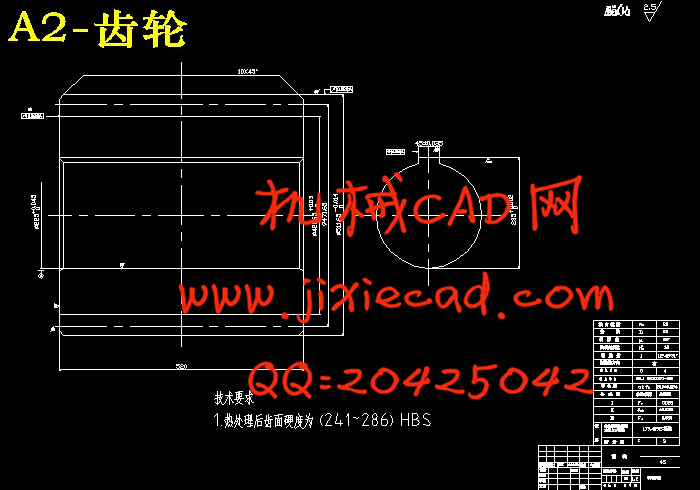

4.1.2减速机齿轮设计 16

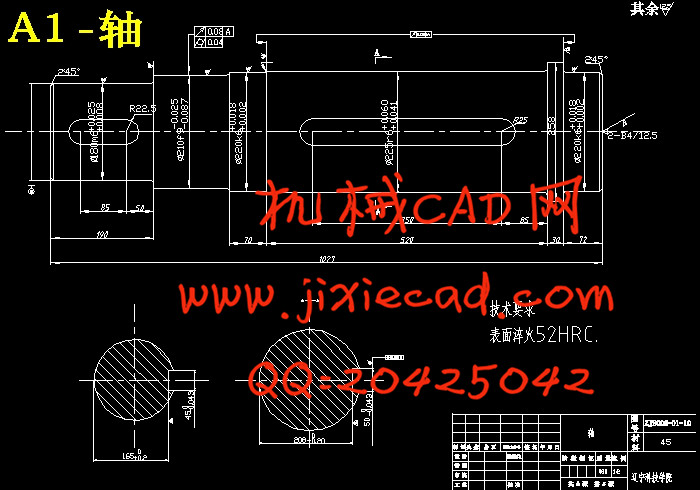

4.1.3 齿轮轴的设计计算 24

4.2剥壳的设计 29

4.2.1材料的选择 29

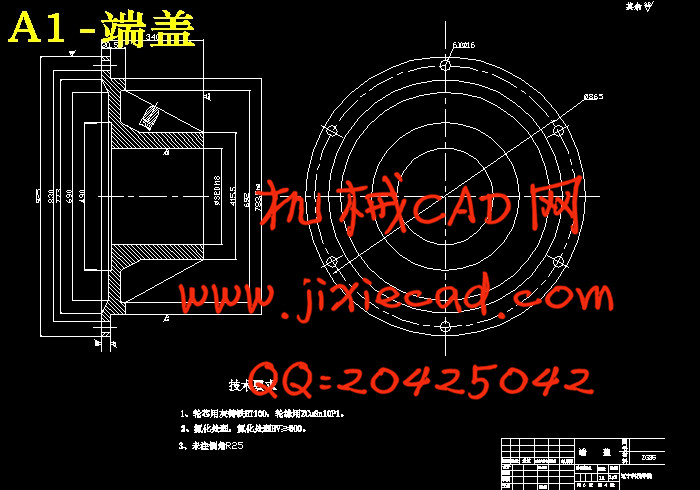

4.2.2剥壳的结构设计 29

4.3转股轴承的选择及校核 30

4.4侧隙调整机构的设计 31

4.5电动机的起动力矩的验算 32

4.5.1系统飞轮力矩的计算 32

4.5.2起动时间的计算 33

4.5.3起动转角的校核 33

5 润滑方法的选择 37

5.1减速机润滑方法及润滑油的选择 37

5.2冲压式芡实剥壳机的润滑 37

6试车方法和对控制的要求 38

6.1试车要求 38

6.2对控制系统的要求 38

7设备可靠性与经济评价 39

7.1机械设备的有效度 39

7.2投资回收期 39

专题-电动机选择与探讨 41

1.三相异步电动机的旋转原理 : 42

2.同步电动机在结构上大致有两种: 43

3.电机固有步距角: 44

4.步进电机的一些特点: 45

5.电动机的润滑 46

结论 47

致谢 48

参考文献 49