设计简介

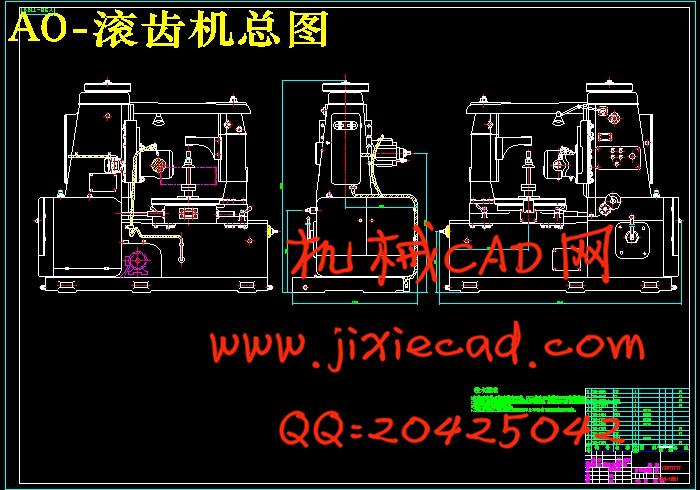

滚齿机差动机构、分度轴及走刀挂轮架设计

摘 要:随着工业技术的进步,滚齿机的发展也上升到了一个新的水平。滚齿机主要是用于加工圆柱齿轮和蜗轮的,在加工机床中占有很重要的地位。而现时我国的滚齿机发展还相对落后,极大限制了整个工业生产力水平的提高,所以我们必须对其进行设计改造。

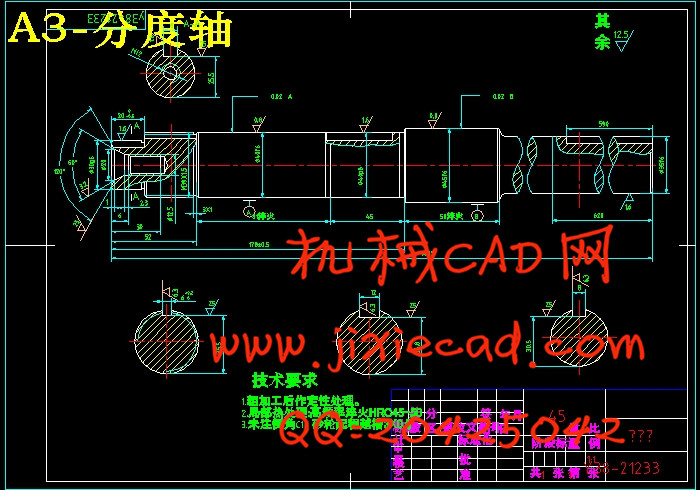

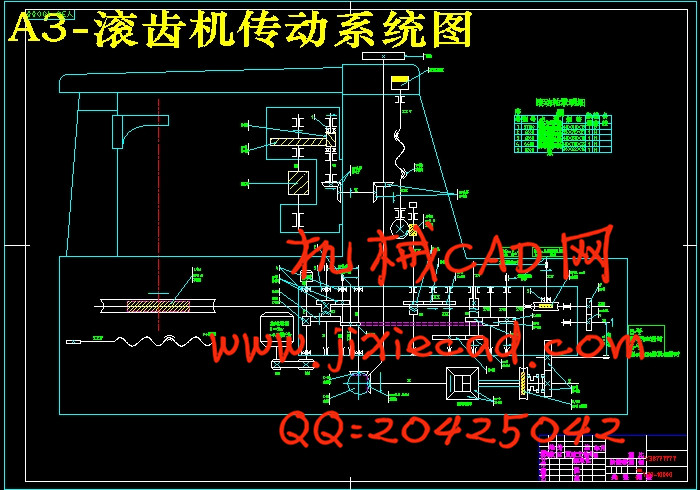

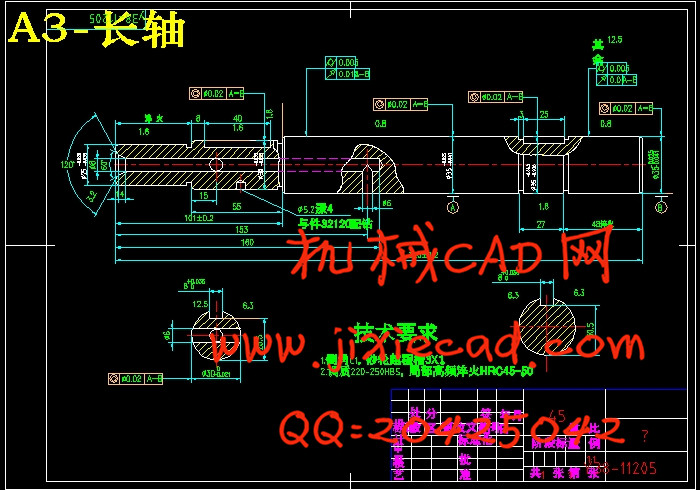

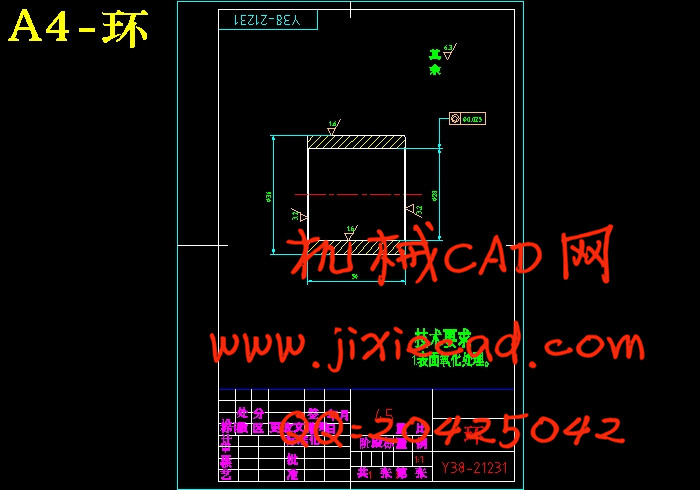

课题研究的主要内容是滚齿机的差动机构、分度轴及走刀挂轮架。滚斜齿时就要使用差动机构,差动机构位于齿轮箱的侧面,侧面最上方的方头上是机床工作台的光杠,方头下面第一个轴就是差动挂轮的主动轴。而传动箱内装有主传动进给差动机构构件和走刀挂轮架及分度轴部件,设计出的分度轴能满足加工要求,保证加工精度,且满足强度、刚度、寿命、工艺性与经济性等方面的要求。

关键词:滚齿机;分度轴;走刀挂轮架;差动机构

Design of Differential Motion Mechanism and the Dividing Spindle and the Gear Swing Frame for Feeding of the Gear-hobbing Machine

Abstract: Along with the industry technology progress, the gear-hobbing machine development also rose to a new level. The gear-hobbing machine mainly is uses in processing the cylindrical gears and the worm gear, in processes the machine hold the very important status. But at present our country's gear-hobbing machine development relatively is also backward, the entire industry productive forces level has been enormously limited, therefore we must carry on.

The main issue is the differential motion mechanism, the gear swing frame for feeding and the dividing spindle.Helical rolling will have the use of the differential motion mechanism,it is located in the side of the gearbox,the top side of the square head is a machine tool table light bars,square head is below the first axis of the active differential gear shaft.And there are the differential transmission, the dividing spindle, and the gear dividing swing frame in the gear box., The dividing spindle must satisfy some demands, such as intensity, rigidity, life, movement stability, structure rationality, convenience in loading and unloading, machining precision.

Key words: Gear-hobbing machine; the dividing spindle; the gear swing frame for feeding;Differential motion mechanism

目 录

1 前 言...............................................................1

2 总体设计.............................................................3

2.1 滚齿机工作原理.....................................................3

2.2 拟定选择传动方案...................................................3

2.3 主切削力的估算及电动机的选择.......................................7

3 差动机构设计........................................................9

3.1 总传动比的计算.....................................................9

3.2 传动比的分配.......................................................9

3.3 设计计算..........................................................10

3.3.1 螺旋伞齿轮的设计................................................10

3.3.2 运动合成机构设计................................................11

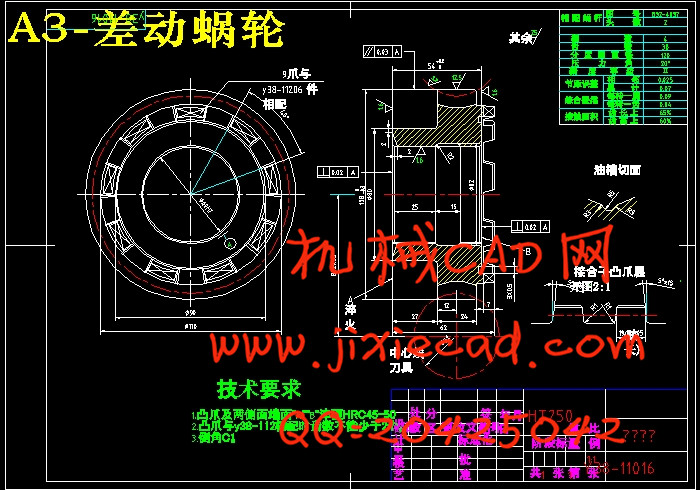

3.3.3 差动蜗轮设计....................................................12

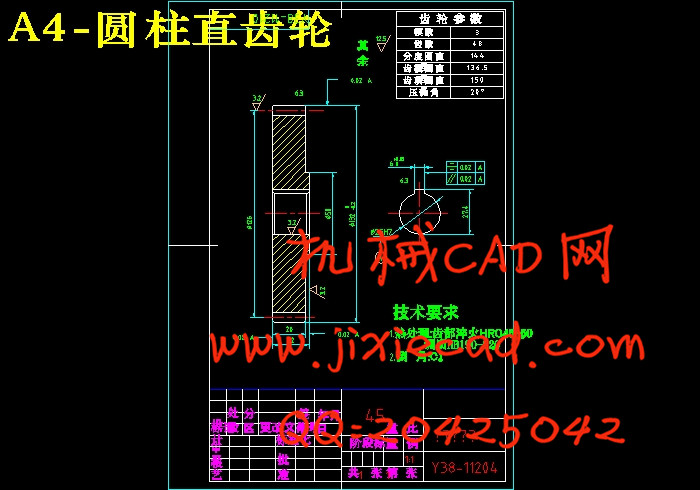

3.3.4 圆柱直齿轮的设计................................................16

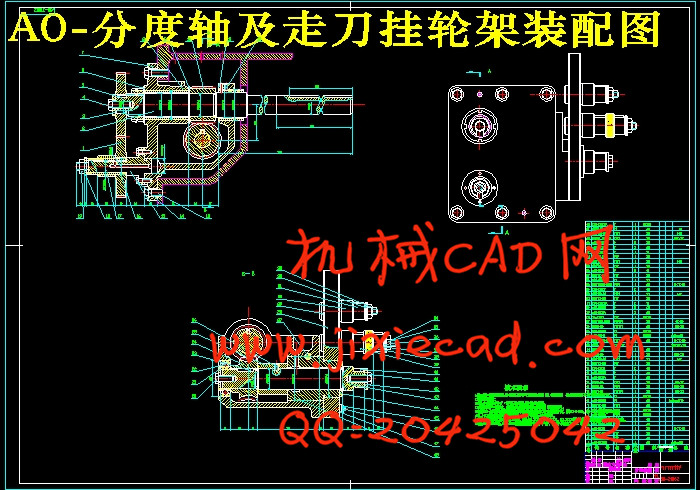

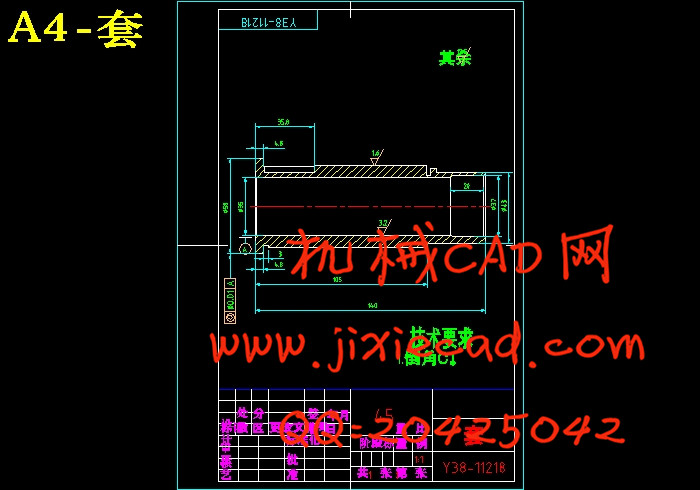

4 分度轴及走刀挂轮架的设计...........................................21

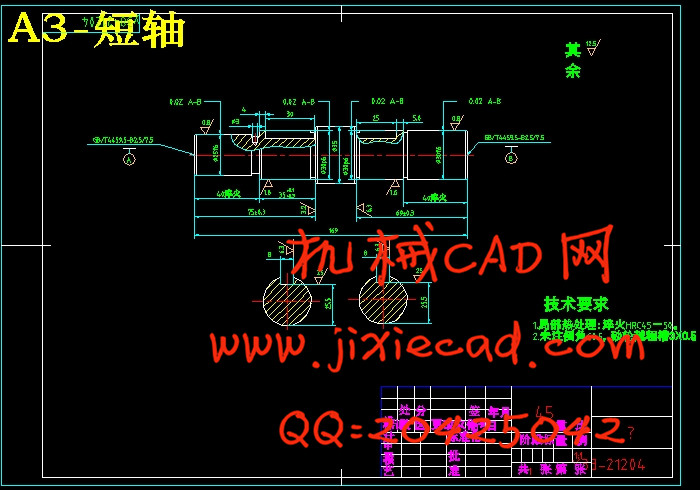

4.1 轴的设计..........................................................21

4.2 确定分度轴的材料及热处理方法......................................21

4.3 分度轴的结构设计..................................................21

4.4 分度轴强度的校核..................................................23

4.5 走刀挂轮架的设计..................................................24

5 结束语.............................................................26

参考文献..............................................................27

致 谢...............................................................28

摘 要:随着工业技术的进步,滚齿机的发展也上升到了一个新的水平。滚齿机主要是用于加工圆柱齿轮和蜗轮的,在加工机床中占有很重要的地位。而现时我国的滚齿机发展还相对落后,极大限制了整个工业生产力水平的提高,所以我们必须对其进行设计改造。

课题研究的主要内容是滚齿机的差动机构、分度轴及走刀挂轮架。滚斜齿时就要使用差动机构,差动机构位于齿轮箱的侧面,侧面最上方的方头上是机床工作台的光杠,方头下面第一个轴就是差动挂轮的主动轴。而传动箱内装有主传动进给差动机构构件和走刀挂轮架及分度轴部件,设计出的分度轴能满足加工要求,保证加工精度,且满足强度、刚度、寿命、工艺性与经济性等方面的要求。

关键词:滚齿机;分度轴;走刀挂轮架;差动机构

Design of Differential Motion Mechanism and the Dividing Spindle and the Gear Swing Frame for Feeding of the Gear-hobbing Machine

Abstract: Along with the industry technology progress, the gear-hobbing machine development also rose to a new level. The gear-hobbing machine mainly is uses in processing the cylindrical gears and the worm gear, in processes the machine hold the very important status. But at present our country's gear-hobbing machine development relatively is also backward, the entire industry productive forces level has been enormously limited, therefore we must carry on.

The main issue is the differential motion mechanism, the gear swing frame for feeding and the dividing spindle.Helical rolling will have the use of the differential motion mechanism,it is located in the side of the gearbox,the top side of the square head is a machine tool table light bars,square head is below the first axis of the active differential gear shaft.And there are the differential transmission, the dividing spindle, and the gear dividing swing frame in the gear box., The dividing spindle must satisfy some demands, such as intensity, rigidity, life, movement stability, structure rationality, convenience in loading and unloading, machining precision.

Key words: Gear-hobbing machine; the dividing spindle; the gear swing frame for feeding;Differential motion mechanism

目 录

1 前 言...............................................................1

2 总体设计.............................................................3

2.1 滚齿机工作原理.....................................................3

2.2 拟定选择传动方案...................................................3

2.3 主切削力的估算及电动机的选择.......................................7

3 差动机构设计........................................................9

3.1 总传动比的计算.....................................................9

3.2 传动比的分配.......................................................9

3.3 设计计算..........................................................10

3.3.1 螺旋伞齿轮的设计................................................10

3.3.2 运动合成机构设计................................................11

3.3.3 差动蜗轮设计....................................................12

3.3.4 圆柱直齿轮的设计................................................16

4 分度轴及走刀挂轮架的设计...........................................21

4.1 轴的设计..........................................................21

4.2 确定分度轴的材料及热处理方法......................................21

4.3 分度轴的结构设计..................................................21

4.4 分度轴强度的校核..................................................23

4.5 走刀挂轮架的设计..................................................24

5 结束语.............................................................26

参考文献..............................................................27

致 谢...............................................................28