设计简介

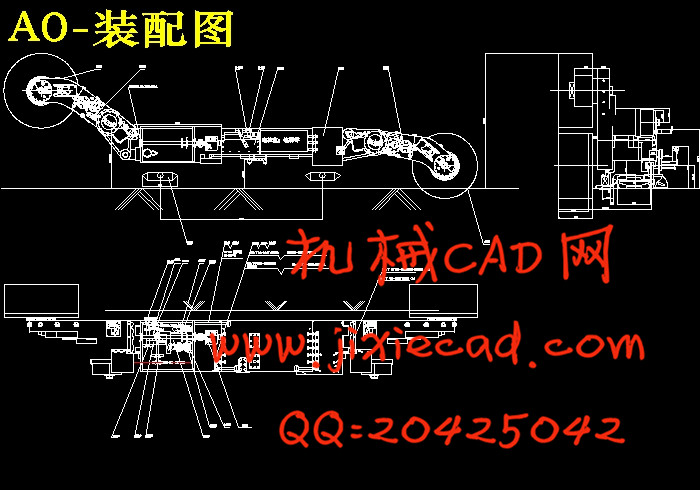

滚筒采煤机截割部分的设计

摘要 滚筒采煤机是煤炭采掘的重要设备。是实现煤矿生产机械化和现代化的重要设备之一。因此,它对提高煤的采掘效率有着重要的影响。目前,采煤机的设计技术已经发展的相当完善,但是在国内采煤机技术和国外相比依然还比较落后。

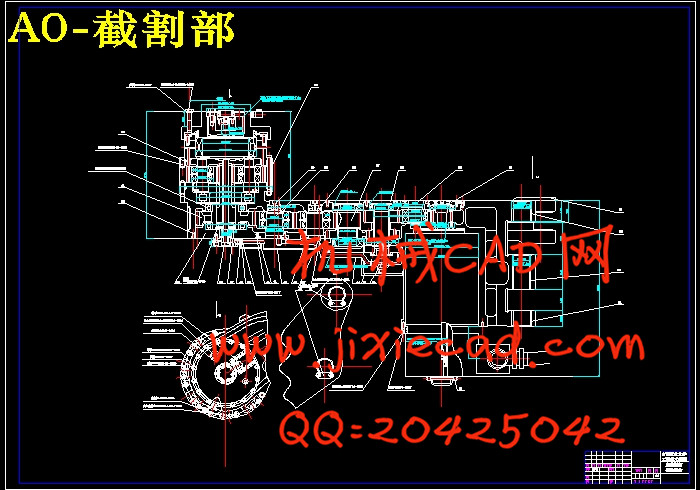

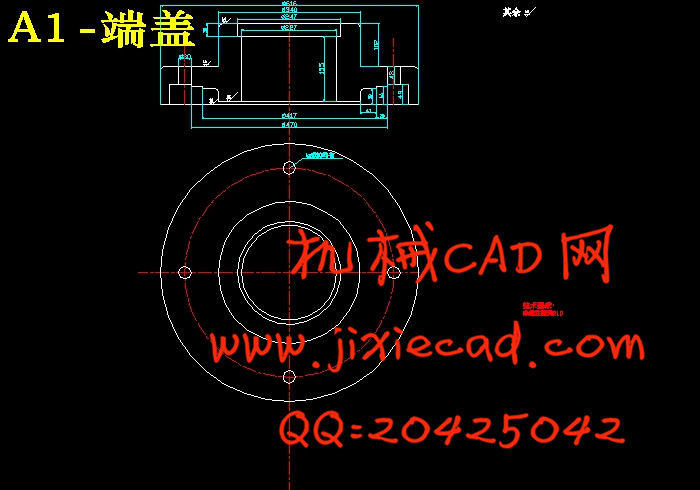

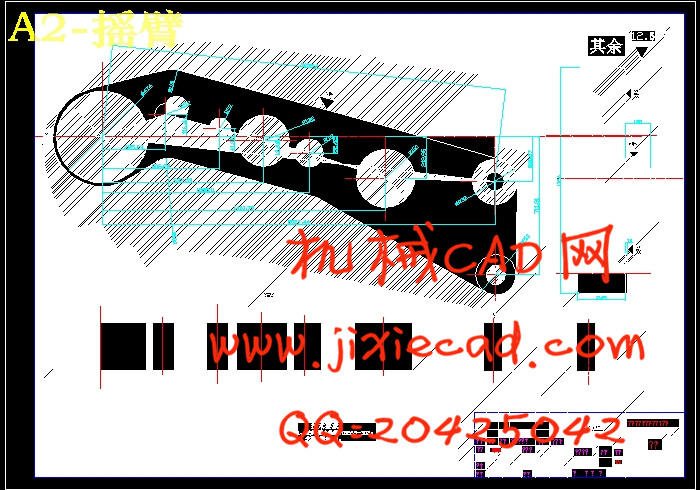

本次设计在吸取了前人经验的基础上设计了大功率,适合于中厚煤层的采煤机。对于采煤机的截割部进行了革新设计,采用强力耐磨型滚筒对称布置,提高了割煤效果和滚筒寿命,降低截齿消耗量和用户成本。机械传动系统采用直齿圆柱齿轮和行星轮传动动。故传动效率 高,容易安装和维护,分别用两台250KW的电动机驱动两截割部。截割部电机容量调整范围宽,其调整范围为150~300Kw,通过调整截割电机容量,可实现一机多型。截割部采用四行星单浮动结构,承载能力大,减小了结构尺寸。采用大角度弯摇臂设计,加大过煤空间,提高装煤效果,卧底量大。本次设计的采煤机采煤效率高,生产可随不同的煤质的变化生产不同的机型,市场适应性强。

关键词 采煤机 强力耐磨滚筒 截割部 弯摇臂 传动系统

The Design of Sheare Cutting Unit

Abstract

Sheare is an important equipment for excavation. It is one of the important facilities for the mechanization and modernization of coal-mining production. Hence it has important effects on the improvement of excavation efficiency. Presently the design technologies of sheares have developed relatively perfect. When comparing with abroad, however, the technology of this area is still behindhand.

Basing on assimilating the experience of people has worked in this area, this design, schemes out High-power sheare which is suitable for medium thickness seam. It does innovatory design on the cutting unit of shears by resorting to disposal symmetry of Mightiness Worn Roller, which improves the cutting effect and longevity. At the same time it reduces the wastage of truncation straight and customers’ cost. As to Machine driven system, its transmission resorts to spur gear and planetary wheel. Hence the transmission efficiency is improved and its installation and maintenance are easier. Two of the departments of crop are driven by two separate 250kw- electromotors. The modulation range of electromotors’ capacity in the departments of crop is large, which is ranging from 150kw to 300kw. Through the modulation of the electromotors’ capacity, the one machine-multi-type style can be carried out. The departments of crop resort to globe certificate floating structure, whose carrying capacity is large and reducing the structure measure. The applications of ply rockerarm increase the coal’s transit space and improve the coal’s load effect. The bottom taking

quantity is large. This design of sheare has the features as follows:

The excavation efficiency is high; the production of types can be different according to different coal quality. The adaptability in marketing is strong.

Key Words Sheare Mightiness Worn Roller cutting unit ply rockerarm transition system

目录

1 引言 1

2 技术任务书 5

2.1滚筒的数量和位置 5

2.2 调高方式 5

2.3 摇臂 5

2.4 轴承 5

2.5 牵引方式 5

2.6 驱动方式 6

2.7 采煤机的附属设备 6

3 设计计算说明书 7

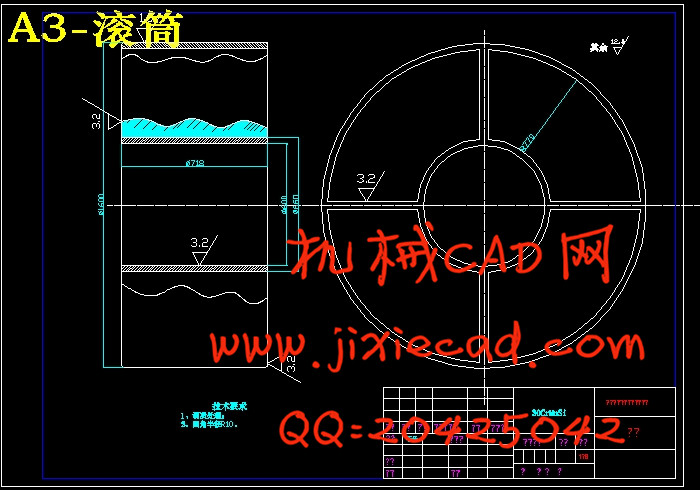

3.1 采煤机的滚筒 7

3.2 采高和截深 7

3.3 设计生产功率 7

3.4 装机功率 8

3.5 摇臂和电动机 9

3.6 滚筒采煤机截割部设计 10

3.6.1 螺旋滚筒设计 10

3.6.2 螺旋叶片的螺旋升角 10

3.6.3 切削厚度 10

3.6.4 螺旋滚筒的转向 11

3.6.5 滚筒的三个直径 11

3.6.6 滚筒升角 13

3.6.7 螺旋头数 13

3.6.8 截齿 14

3.6.9 截齿的材料以及截齿的固定 16

3.7 截割部减速器传动系统 16

3.7.1 截割部摇臂传动系统 16

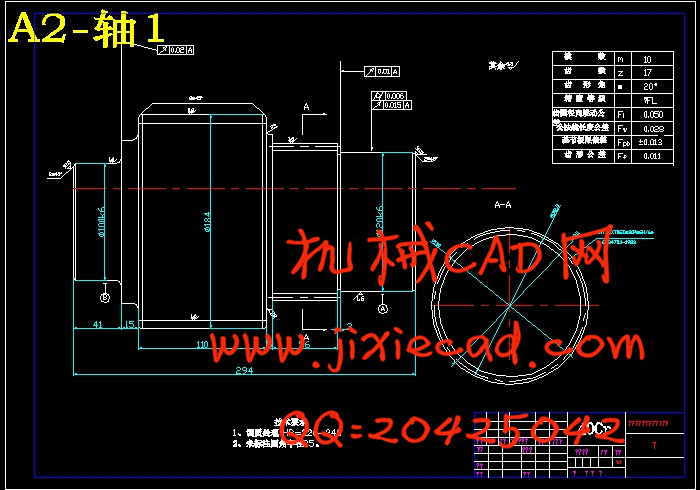

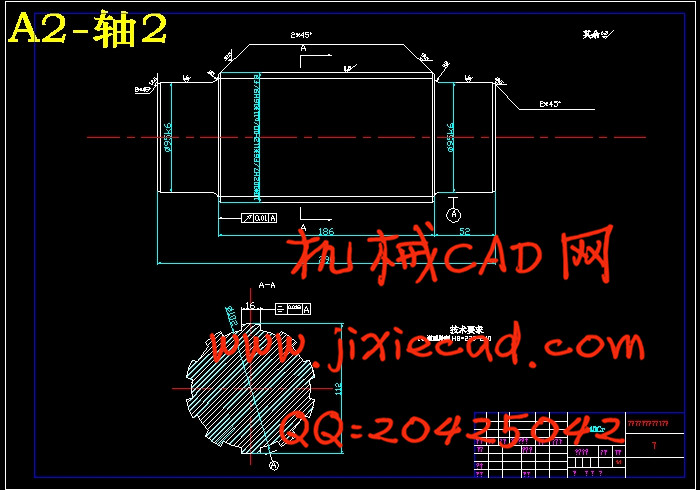

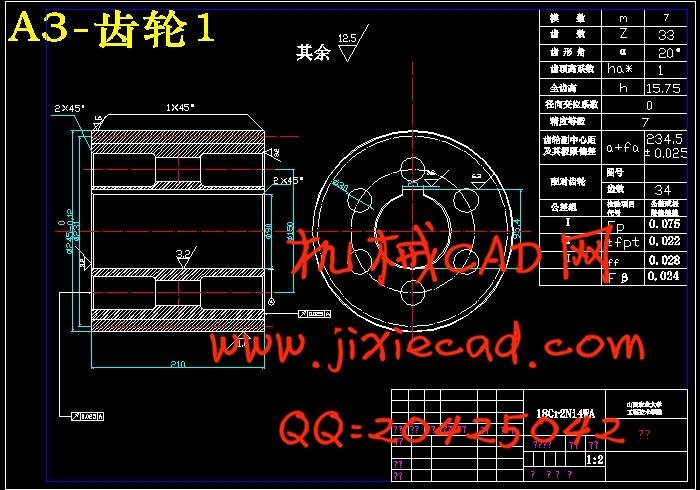

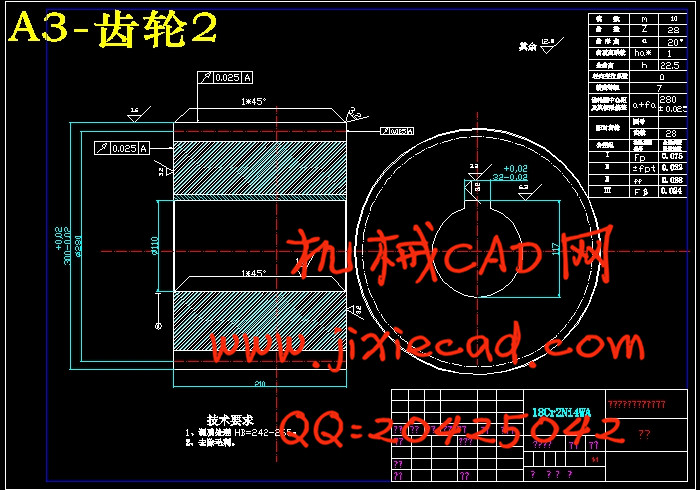

3.7.2 截割部摇臂传动系统齿轮 17

3.7.3各齿轮的基本尺寸及相关计算 17

3.7.4传动比以及输出转速 21

3.7.5 各轴承选用的规格和代号 22

3.7.6滚筒采煤机的摇臂 22

3.7.7 截割部减速器的润滑 23

4 使用说明书 24

4.1 产品名称 24

4.2 产品的用途和使用范围 24

4.3 主要结构 24

4.4 使用维护和注意事项 24

5 标准化审查报告 24

5.1产品图样的审查 24

5.2产品技术文件审查 25

6 技术和经济分析 25

7 总结 26

参考文献 28

致谢 30

摘要 滚筒采煤机是煤炭采掘的重要设备。是实现煤矿生产机械化和现代化的重要设备之一。因此,它对提高煤的采掘效率有着重要的影响。目前,采煤机的设计技术已经发展的相当完善,但是在国内采煤机技术和国外相比依然还比较落后。

本次设计在吸取了前人经验的基础上设计了大功率,适合于中厚煤层的采煤机。对于采煤机的截割部进行了革新设计,采用强力耐磨型滚筒对称布置,提高了割煤效果和滚筒寿命,降低截齿消耗量和用户成本。机械传动系统采用直齿圆柱齿轮和行星轮传动动。故传动效率 高,容易安装和维护,分别用两台250KW的电动机驱动两截割部。截割部电机容量调整范围宽,其调整范围为150~300Kw,通过调整截割电机容量,可实现一机多型。截割部采用四行星单浮动结构,承载能力大,减小了结构尺寸。采用大角度弯摇臂设计,加大过煤空间,提高装煤效果,卧底量大。本次设计的采煤机采煤效率高,生产可随不同的煤质的变化生产不同的机型,市场适应性强。

关键词 采煤机 强力耐磨滚筒 截割部 弯摇臂 传动系统

The Design of Sheare Cutting Unit

Abstract

Sheare is an important equipment for excavation. It is one of the important facilities for the mechanization and modernization of coal-mining production. Hence it has important effects on the improvement of excavation efficiency. Presently the design technologies of sheares have developed relatively perfect. When comparing with abroad, however, the technology of this area is still behindhand.

Basing on assimilating the experience of people has worked in this area, this design, schemes out High-power sheare which is suitable for medium thickness seam. It does innovatory design on the cutting unit of shears by resorting to disposal symmetry of Mightiness Worn Roller, which improves the cutting effect and longevity. At the same time it reduces the wastage of truncation straight and customers’ cost. As to Machine driven system, its transmission resorts to spur gear and planetary wheel. Hence the transmission efficiency is improved and its installation and maintenance are easier. Two of the departments of crop are driven by two separate 250kw- electromotors. The modulation range of electromotors’ capacity in the departments of crop is large, which is ranging from 150kw to 300kw. Through the modulation of the electromotors’ capacity, the one machine-multi-type style can be carried out. The departments of crop resort to globe certificate floating structure, whose carrying capacity is large and reducing the structure measure. The applications of ply rockerarm increase the coal’s transit space and improve the coal’s load effect. The bottom taking

quantity is large. This design of sheare has the features as follows:

The excavation efficiency is high; the production of types can be different according to different coal quality. The adaptability in marketing is strong.

Key Words Sheare Mightiness Worn Roller cutting unit ply rockerarm transition system

目录

1 引言 1

2 技术任务书 5

2.1滚筒的数量和位置 5

2.2 调高方式 5

2.3 摇臂 5

2.4 轴承 5

2.5 牵引方式 5

2.6 驱动方式 6

2.7 采煤机的附属设备 6

3 设计计算说明书 7

3.1 采煤机的滚筒 7

3.2 采高和截深 7

3.3 设计生产功率 7

3.4 装机功率 8

3.5 摇臂和电动机 9

3.6 滚筒采煤机截割部设计 10

3.6.1 螺旋滚筒设计 10

3.6.2 螺旋叶片的螺旋升角 10

3.6.3 切削厚度 10

3.6.4 螺旋滚筒的转向 11

3.6.5 滚筒的三个直径 11

3.6.6 滚筒升角 13

3.6.7 螺旋头数 13

3.6.8 截齿 14

3.6.9 截齿的材料以及截齿的固定 16

3.7 截割部减速器传动系统 16

3.7.1 截割部摇臂传动系统 16

3.7.2 截割部摇臂传动系统齿轮 17

3.7.3各齿轮的基本尺寸及相关计算 17

3.7.4传动比以及输出转速 21

3.7.5 各轴承选用的规格和代号 22

3.7.6滚筒采煤机的摇臂 22

3.7.7 截割部减速器的润滑 23

4 使用说明书 24

4.1 产品名称 24

4.2 产品的用途和使用范围 24

4.3 主要结构 24

4.4 使用维护和注意事项 24

5 标准化审查报告 24

5.1产品图样的审查 24

5.2产品技术文件审查 25

6 技术和经济分析 25

7 总结 26

参考文献 28

致谢 30