设计简介

摘要

预糊化营养米粉具有速溶即食的特点,是最易消化的大米制品。根据不同消费对象和不同配方又可分为:婴幼儿营养米粉、老年营养米粉和方便营养米粉。目前,这类食品具有广阔的市场前景.

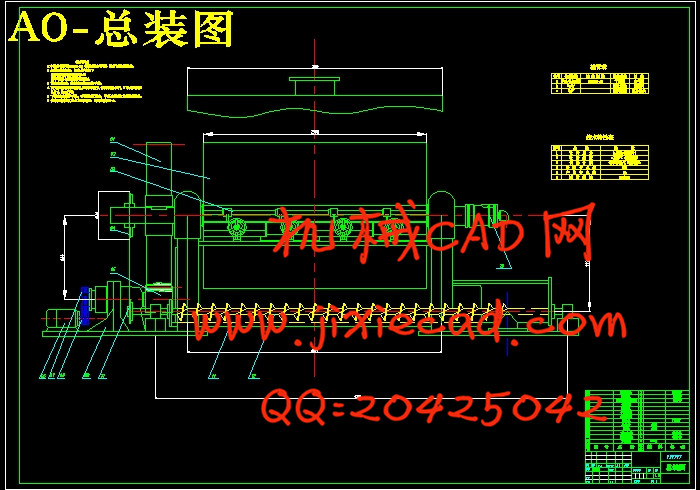

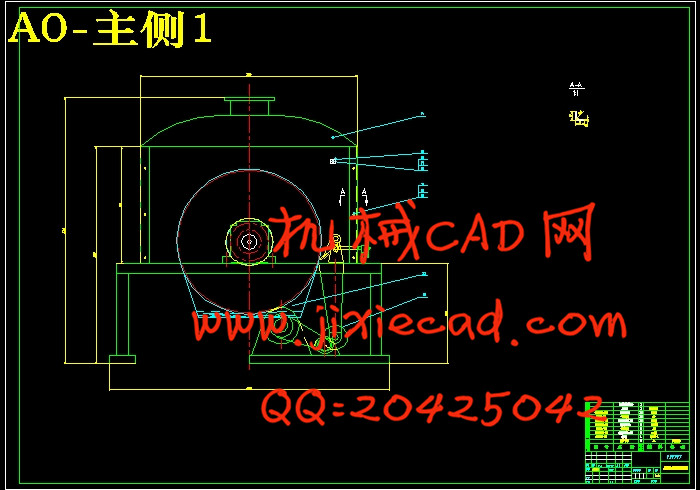

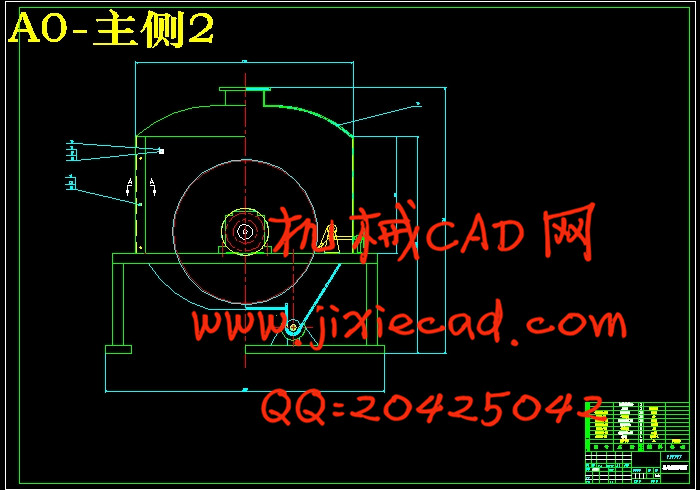

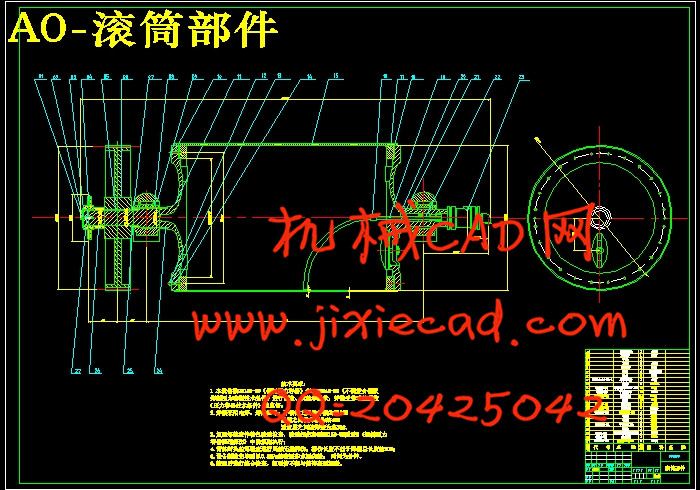

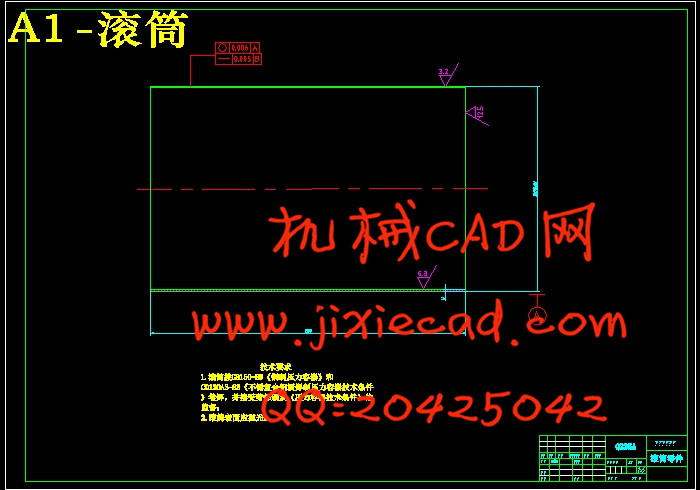

滚筒干燥器是通过转动的圆筒,以热传导的方式,将吸附在筒体外壁的液状物料或带状物料,进行干燥的一种连续操作设备。

其操作过程为:需干燥的处理的料液由高位槽流入滚筒干燥器的受料槽内。干燥滚筒在传动装置的驱动下,按规定的转速转动。物料由布膜装置,在滚筒壁面上形成料膜。筒内连续通入供热介质,加热筒体,由筒壁传热传热使料膜的湿分汽化,在通过刮刀将达到干燥要求的物料刮下,经过螺旋输送最后干燥器将成品输送到储槽内,然后进行包装。

关键词 :米粉;干燥;滚筒干燥器

Abstract

Pregelatinization nutrition with instant noodles, ready-to-eat characteristics is the most indigestible parts of rice products. According to different consumer targets and can be divided into different formula : Infant nutrition rice noodles, rice noodles and the elderly nutrition convenient nutrition rice noodles. At present, such food has broad market prospects.

Drum dryer through the rotating cylinder to heat conduction, will be adsorbed on the outer shell of liquid material or herpes materials, a dry continuous operation of equipment.

Its operating process : the need to dry the feed trough flows from the peak of the drum dryer subject within the trough. Drum drying in the driving gear, according to the rotational speed. Materials from cloth membrane device, the cylinder wall to form membrane materials. Tube leads to continuous heating medium, the heating cylinder, heat from Wall heat transfer membrane material made of moisture evaporation, through scraper will reach the requirements of the dry material scraped through the last screw conveyor dryer will be finished sending tanks, then packaged.

Key Words: rice noodles;dry ;drum dryer

目录

摘要...................................................................................................................................III

ABSTRACT......................................................................................................................IV

目录...................................................................................................................................V

1 绪论...............................................................................................................................1

1.1本课题研究的内容的意义 ...................................................................................1

1.2国内外的发展概况 ...............................................................................................1

1.3本课题设计的目的.................................................................................................2

1.4本课题设计的要求和思想.....................................................................................2

1.5概述.........................................................................................................................2

1.6原材料供应情况及公用设施要求.........................................................................2

1.7工艺设计.................................................................................................................3

1.8主要设备(年产1000吨生产能力)...................................................................3

2 滚筒干燥器特性原理...................................................................................................6

2.1滚筒干燥器的特点.................................................................................................6

2.2滚筒干燥器的基本原理.........................................................................................6

2.3滚筒干燥器的分类.................................................................................................7

2.4被干燥物料及干燥介质的特性.............................................................................7

2.4.1被干燥物料的特性..........................................................................................7

2.4.2干燥介质的特性..............................................................................................8

2.5干燥过程的节能................................................................................................... 8

2.6改进干燥设备,强化干燥过程........................................................................... 8

3 滚筒干燥器的计算.....................................................................................................10

3.1滚筒干燥器的条件参数.......................................................................................10

3.2滚筒干燥器结构参数的计算...............................................................................10

3.2.1物料和热量衡算 干燥器的生产负荷...................................................... 10

3.2.2滚筒干燥器干燥面积,筒体直径,长度确定.......................................... 10

3.2.3滚筒干燥器的功率计算................................................................................11

3.2.4传动装置设计................................................................................................12

3.2.5滚筒组件的强度和刚度计算........................................................................16

3.2.6密封罩和排气管的设计................................................................................24

4 设备的安装和调试.....................................................................................................26

4.1设备的安装...........................................................................................................26

4.2可能的故障现象和解决方案...............................................................................26

5 设备的维护和保养.....................................................................................................27

6 设计小结.....................................................................................................................28

致谢.................................................................................................................................29

参考文献............................................................................................................................30

预糊化营养米粉具有速溶即食的特点,是最易消化的大米制品。根据不同消费对象和不同配方又可分为:婴幼儿营养米粉、老年营养米粉和方便营养米粉。目前,这类食品具有广阔的市场前景.

滚筒干燥器是通过转动的圆筒,以热传导的方式,将吸附在筒体外壁的液状物料或带状物料,进行干燥的一种连续操作设备。

其操作过程为:需干燥的处理的料液由高位槽流入滚筒干燥器的受料槽内。干燥滚筒在传动装置的驱动下,按规定的转速转动。物料由布膜装置,在滚筒壁面上形成料膜。筒内连续通入供热介质,加热筒体,由筒壁传热传热使料膜的湿分汽化,在通过刮刀将达到干燥要求的物料刮下,经过螺旋输送最后干燥器将成品输送到储槽内,然后进行包装。

关键词 :米粉;干燥;滚筒干燥器

Abstract

Pregelatinization nutrition with instant noodles, ready-to-eat characteristics is the most indigestible parts of rice products. According to different consumer targets and can be divided into different formula : Infant nutrition rice noodles, rice noodles and the elderly nutrition convenient nutrition rice noodles. At present, such food has broad market prospects.

Drum dryer through the rotating cylinder to heat conduction, will be adsorbed on the outer shell of liquid material or herpes materials, a dry continuous operation of equipment.

Its operating process : the need to dry the feed trough flows from the peak of the drum dryer subject within the trough. Drum drying in the driving gear, according to the rotational speed. Materials from cloth membrane device, the cylinder wall to form membrane materials. Tube leads to continuous heating medium, the heating cylinder, heat from Wall heat transfer membrane material made of moisture evaporation, through scraper will reach the requirements of the dry material scraped through the last screw conveyor dryer will be finished sending tanks, then packaged.

Key Words: rice noodles;dry ;drum dryer

目录

摘要...................................................................................................................................III

ABSTRACT......................................................................................................................IV

目录...................................................................................................................................V

1 绪论...............................................................................................................................1

1.1本课题研究的内容的意义 ...................................................................................1

1.2国内外的发展概况 ...............................................................................................1

1.3本课题设计的目的.................................................................................................2

1.4本课题设计的要求和思想.....................................................................................2

1.5概述.........................................................................................................................2

1.6原材料供应情况及公用设施要求.........................................................................2

1.7工艺设计.................................................................................................................3

1.8主要设备(年产1000吨生产能力)...................................................................3

2 滚筒干燥器特性原理...................................................................................................6

2.1滚筒干燥器的特点.................................................................................................6

2.2滚筒干燥器的基本原理.........................................................................................6

2.3滚筒干燥器的分类.................................................................................................7

2.4被干燥物料及干燥介质的特性.............................................................................7

2.4.1被干燥物料的特性..........................................................................................7

2.4.2干燥介质的特性..............................................................................................8

2.5干燥过程的节能................................................................................................... 8

2.6改进干燥设备,强化干燥过程........................................................................... 8

3 滚筒干燥器的计算.....................................................................................................10

3.1滚筒干燥器的条件参数.......................................................................................10

3.2滚筒干燥器结构参数的计算...............................................................................10

3.2.1物料和热量衡算 干燥器的生产负荷...................................................... 10

3.2.2滚筒干燥器干燥面积,筒体直径,长度确定.......................................... 10

3.2.3滚筒干燥器的功率计算................................................................................11

3.2.4传动装置设计................................................................................................12

3.2.5滚筒组件的强度和刚度计算........................................................................16

3.2.6密封罩和排气管的设计................................................................................24

4 设备的安装和调试.....................................................................................................26

4.1设备的安装...........................................................................................................26

4.2可能的故障现象和解决方案...............................................................................26

5 设备的维护和保养.....................................................................................................27

6 设计小结.....................................................................................................................28

致谢.................................................................................................................................29

参考文献............................................................................................................................30