设计简介

摘要:最近几年,建筑行业蓬勃发展。而在建筑机械里,混凝土搅拌机械是其中的基本设备之一。搅拌的混凝土关系到建筑的质量,而过去的机型如鼓筒型混凝土搅拌机存在许多问题如搅拌质量差、时间长、能耗高。自落式混凝土搅拌机尤其是其中之一的锥形反转出料搅拌机能更好的解决上述问题。

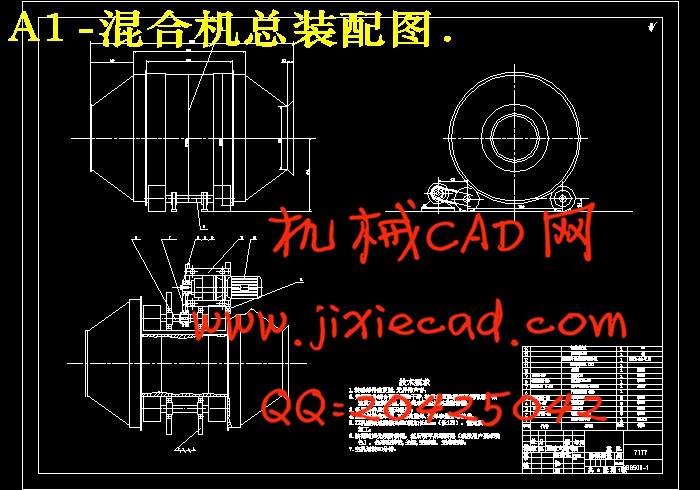

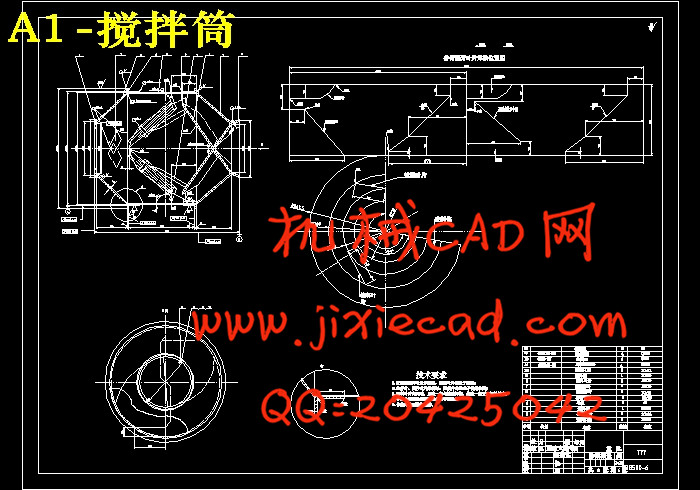

本文通过综合优化设计和类比的方法,结合以往的参数、数据和给出的原始资料、技术要求,对自落式混凝土搅拌机进行了设计。利用搅拌筒直径d=1560mm和其他条件,计算出搅拌筒的转速n=18r/min。根据原始数据——分批混合:1000kg/批、搅拌筒厚度h=4mm、装机容量:7.5千瓦、生产率:8-10吨/时等条件,计算出搅拌筒和混合料、支撑滚轮间相互作用的总力矩M,传动装置的总效率 =0.89,从而得出减速电机额定功率

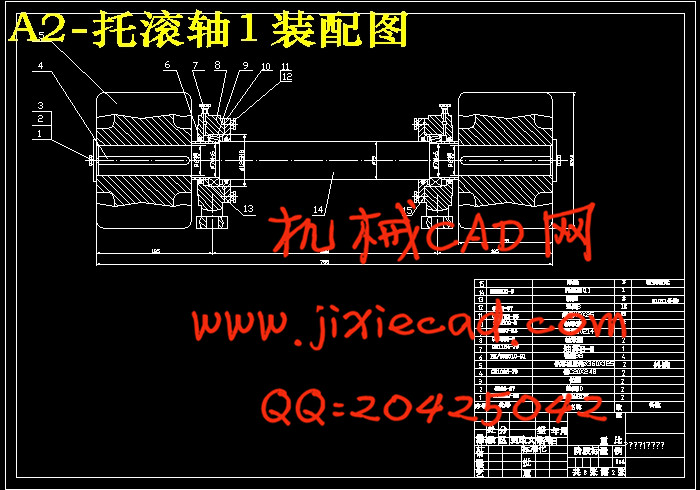

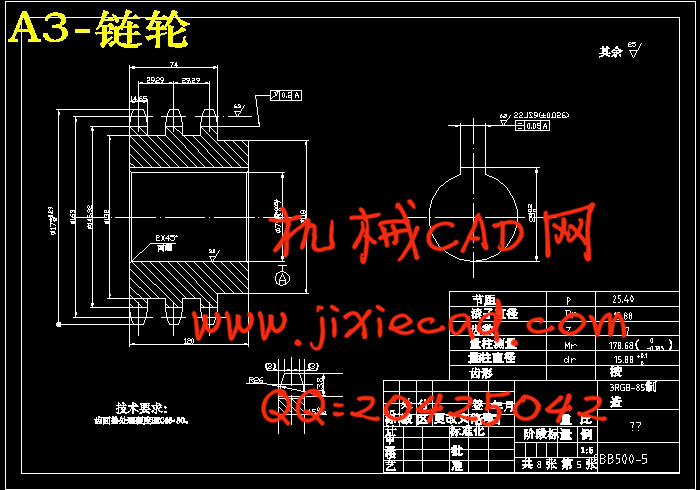

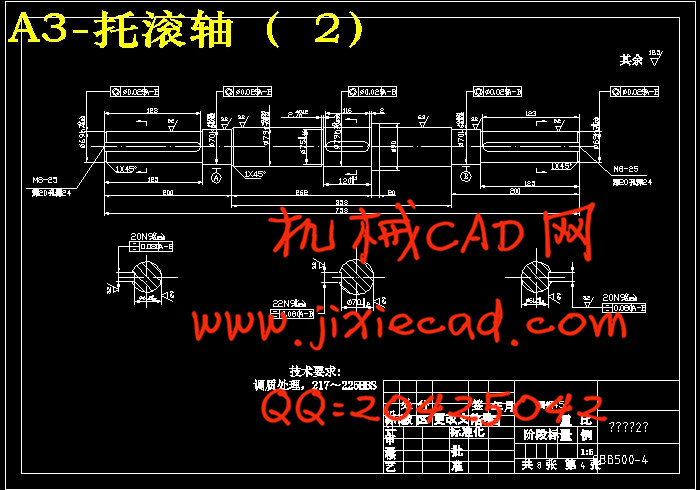

=0.89,从而得出减速电机额定功率 =7.5kw,减速比i=23,转速n=1500r/min。考虑搅拌机传动系统的要求,对托滚轴和减速电机之间采用链传动的连接方式,链传动比i=1.19,小链轮齿数Z=17,从动链轮齿数Z=20,链长L=2.5146mm,中心距a=1020.5mm。再确定要安装链轮和拖轮的托滚轴,材料为45#,调质处理,轴的最小处直径d=69mm。根据材料和载荷,设计出托滚轴的各段的长度和直径,最后进行校核验证。

=7.5kw,减速比i=23,转速n=1500r/min。考虑搅拌机传动系统的要求,对托滚轴和减速电机之间采用链传动的连接方式,链传动比i=1.19,小链轮齿数Z=17,从动链轮齿数Z=20,链长L=2.5146mm,中心距a=1020.5mm。再确定要安装链轮和拖轮的托滚轴,材料为45#,调质处理,轴的最小处直径d=69mm。根据材料和载荷,设计出托滚轴的各段的长度和直径,最后进行校核验证。

关键词:减速电机 混合单元摩擦传动 托滚轴设计 链传动

Abstract: In recent years, the construction industry develops rapidly. In the construction machinery, the concrete mixing machine is one of the basic equipment. The mixing concrete related to the quality of construction, but the past models such as the type of drums concrete mixer has many problem such as poor mixing quality, long duration and high energy consumption. The gravity type concrete mixing mixer especially one of these: cone reversal discharging mixer can solve the above problem for the better.

Considering the previous parameters,data and original data,technical requirements which has given,this papers design the gravity type concrete mixing mixer taking the methods of integrated optimal design and analog. Using the mixing tube diameter d = 1560mm and other conditions to calculate the speed of mixing tube n = 18r/min. According to the original data - batch mixed: 1000kg / batches, the mixing tube thickness h = 4mm, capacity: 7.5 kW, 8-productivity of 10 tons / h and other conditions, to calculate the total moment M between mixing tube and mixture as well as interaction support rollers, the overall efficiency of gear =0.89, so as to receive the gear motor rated power

=0.89, so as to receive the gear motor rated power =7.5kw, reduction ratio i = 23, rotational speed n = 1500r/min. Considering the request of the mixer drive system, the placement between the care roller and the gear motor is connected by chain drive ,chain drive ratio i = 1.19, the small sprocket number of teeth Z = 17, and the driven sprocket number of teeth Z = 20, chain length L = 2.5146mm, center distance a = 1020.5mm. Next,confirming the care roller which demand installing the chain wheel and tug ,to determine its material is 45#、quenching and tempering, the minimum diameter of shaft is d = 69mm. According to the material and the loading, we design the roller care of all of the length and diameter , and check verification finally.

=7.5kw, reduction ratio i = 23, rotational speed n = 1500r/min. Considering the request of the mixer drive system, the placement between the care roller and the gear motor is connected by chain drive ,chain drive ratio i = 1.19, the small sprocket number of teeth Z = 17, and the driven sprocket number of teeth Z = 20, chain length L = 2.5146mm, center distance a = 1020.5mm. Next,confirming the care roller which demand installing the chain wheel and tug ,to determine its material is 45#、quenching and tempering, the minimum diameter of shaft is d = 69mm. According to the material and the loading, we design the roller care of all of the length and diameter , and check verification finally.

Key words: Geared Motor Mixed friction drive unit Care roller design Chain drive

本文通过综合优化设计和类比的方法,结合以往的参数、数据和给出的原始资料、技术要求,对自落式混凝土搅拌机进行了设计。利用搅拌筒直径d=1560mm和其他条件,计算出搅拌筒的转速n=18r/min。根据原始数据——分批混合:1000kg/批、搅拌筒厚度h=4mm、装机容量:7.5千瓦、生产率:8-10吨/时等条件,计算出搅拌筒和混合料、支撑滚轮间相互作用的总力矩M,传动装置的总效率

关键词:减速电机 混合单元摩擦传动 托滚轴设计 链传动

Abstract: In recent years, the construction industry develops rapidly. In the construction machinery, the concrete mixing machine is one of the basic equipment. The mixing concrete related to the quality of construction, but the past models such as the type of drums concrete mixer has many problem such as poor mixing quality, long duration and high energy consumption. The gravity type concrete mixing mixer especially one of these: cone reversal discharging mixer can solve the above problem for the better.

Considering the previous parameters,data and original data,technical requirements which has given,this papers design the gravity type concrete mixing mixer taking the methods of integrated optimal design and analog. Using the mixing tube diameter d = 1560mm and other conditions to calculate the speed of mixing tube n = 18r/min. According to the original data - batch mixed: 1000kg / batches, the mixing tube thickness h = 4mm, capacity: 7.5 kW, 8-productivity of 10 tons / h and other conditions, to calculate the total moment M between mixing tube and mixture as well as interaction support rollers, the overall efficiency of gear

Key words: Geared Motor Mixed friction drive unit Care roller design Chain drive