设计简介

摘 要

本设计的题目是变速箱壳体专用镗床设计,主要目的是通过设计来运用所学的专业知识进行实践运用以提高自己独立分析和解决问题的能力。采用钻、扩、铰的传统工艺,不仅效率低,而且稳定性差,精度不容易保证,制约了生产的发展,于是决定自行设计一台高质量的专用机床。

在全面了解专用镗床的结构、工作原理的基础上,合理选用部件,设计出镗床的传动系统及执行机构。根据镗床的工作原理,确定了该镗床的结构与技术参数,给出了该镗床的结构设计方案。

根据设计方案,本文介绍了专用镗床的总体设计、结构设计和夹具的设计。夹具的设计是镗床设计中重要的一部分,因此夹具设计的好坏,将直接影响被加工零件的精度。本论文所设计的机床是用于镗孔,在加工生产线上同时加工3个孔,这样能大大提高生产效率,降低劳动强度,从而降低了零件的加工成本。

关键词 专用镗床;变速箱壳体;结构设计;夹具设计

Abstract

The topic of the paper is the structure design of special boring machine for shell of gearbox. The main purpose is to apply the professional knowledge to practice and improve the ability of analyzing and solving difficult problems. The traditional process which uses drill expands and articulation, not only gains the lower efficiency, moreover, its stability is bad and its precision is not easy to guarantee as well, so it restricted the production development. So we decide to design a high grade special purpose machine independently.

Based on the comprehensive understanding of the structure and working principle of the special boring machine, Reasonable selection of parts, Determine the boring machine's structure and technical parameters, given the structural design of the boring machine according to the working principle.

According to the design, this paper introduces a special boring machine's overall design, structural design, and fixture design. Fixture design is an important part of the boring machine design, Therefore the Fixture design is good or bad, Will directly affect the precision of machining parts. In the paper, the machine tool we designed is used for drilling hole, and it could process 3 holes in the production line simultaneously. So we enhance the production efficiency greatly, reduce the labor intensity, and reduce the components processing cost.

Key words The Special Boring Machine; Shell of Gearbox; Structure Design; Fixture Design

目 录

摘要 I本设计的题目是变速箱壳体专用镗床设计,主要目的是通过设计来运用所学的专业知识进行实践运用以提高自己独立分析和解决问题的能力。采用钻、扩、铰的传统工艺,不仅效率低,而且稳定性差,精度不容易保证,制约了生产的发展,于是决定自行设计一台高质量的专用机床。

在全面了解专用镗床的结构、工作原理的基础上,合理选用部件,设计出镗床的传动系统及执行机构。根据镗床的工作原理,确定了该镗床的结构与技术参数,给出了该镗床的结构设计方案。

根据设计方案,本文介绍了专用镗床的总体设计、结构设计和夹具的设计。夹具的设计是镗床设计中重要的一部分,因此夹具设计的好坏,将直接影响被加工零件的精度。本论文所设计的机床是用于镗孔,在加工生产线上同时加工3个孔,这样能大大提高生产效率,降低劳动强度,从而降低了零件的加工成本。

关键词 专用镗床;变速箱壳体;结构设计;夹具设计

Abstract

The topic of the paper is the structure design of special boring machine for shell of gearbox. The main purpose is to apply the professional knowledge to practice and improve the ability of analyzing and solving difficult problems. The traditional process which uses drill expands and articulation, not only gains the lower efficiency, moreover, its stability is bad and its precision is not easy to guarantee as well, so it restricted the production development. So we decide to design a high grade special purpose machine independently.

Based on the comprehensive understanding of the structure and working principle of the special boring machine, Reasonable selection of parts, Determine the boring machine's structure and technical parameters, given the structural design of the boring machine according to the working principle.

According to the design, this paper introduces a special boring machine's overall design, structural design, and fixture design. Fixture design is an important part of the boring machine design, Therefore the Fixture design is good or bad, Will directly affect the precision of machining parts. In the paper, the machine tool we designed is used for drilling hole, and it could process 3 holes in the production line simultaneously. So we enhance the production efficiency greatly, reduce the labor intensity, and reduce the components processing cost.

Key words The Special Boring Machine; Shell of Gearbox; Structure Design; Fixture Design

目 录

Abstract II

第1章 绪 论 1

1.1 课题背景 1

1.2 研究目的及意义 1

1.3 国内外组合机床发展趋势 1

1.4 组合机床概述 4

1.5 设计的主要内容、方法和预期成果 6

第2章 壳体加工方案分析 7

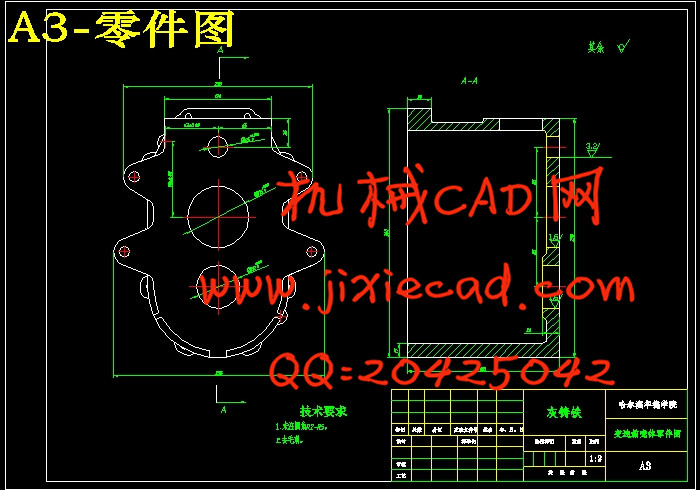

2.1 工件加工要求 7

2.2 工艺方案制定 7

2.3 确定切削用量及选择刀具 8

2.3.1 确定工序间余量 8

2.3.2 选择切削用量 8

2.3.3 选择刀具结构 9

2.4 确定切削力、切削扭矩、切削功率 9

2.5 通用部件的选用 11

2.6 本章小结 12

第3章 机床总体设计 13

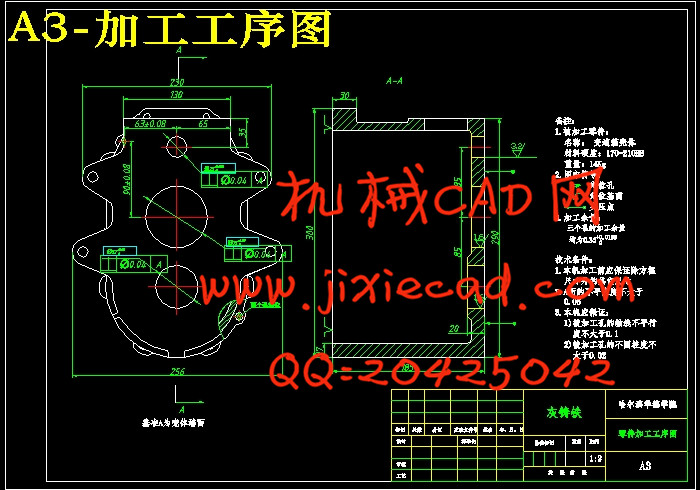

3.1 被加工零件工序图 13

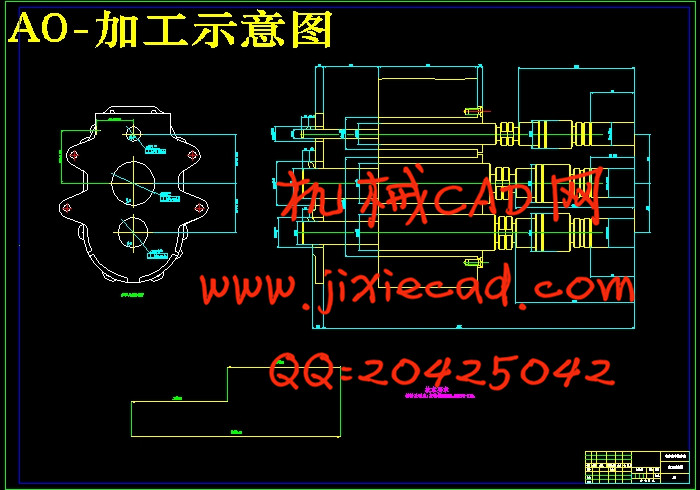

3.2 加工示意图 13

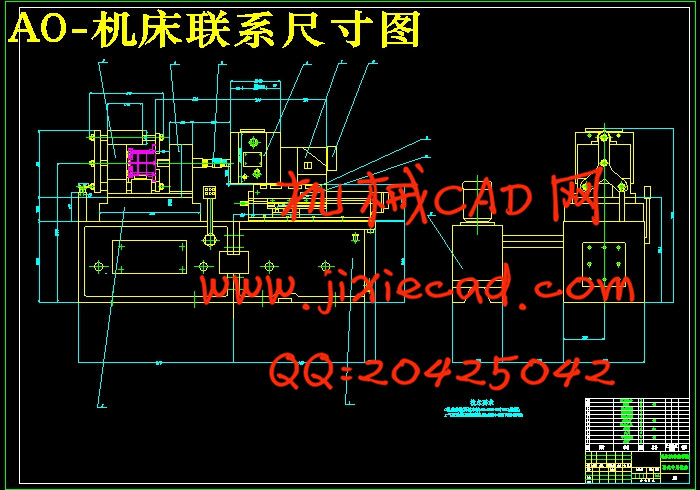

3.3 机床联系尺寸图 15

3.3.1 夹具轮廓尺寸的确定 16

3.3.2 机床装料高度H的确定 16

3.3.3 中间底座轮廓尺寸 17

3.3.4 主轴箱轮廓尺寸 17

3.4 机床生产率计算卡 18

第4章 多轴箱设计 21

4.1 多轴箱设计的原始依据图 21

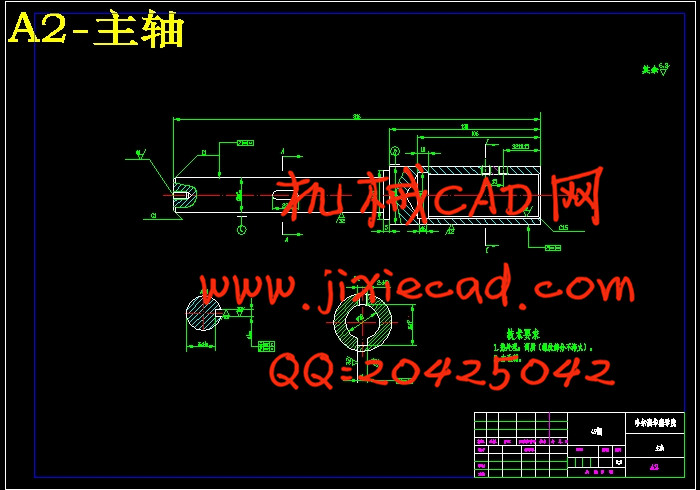

4.2 主轴的型式与直径的确定 21

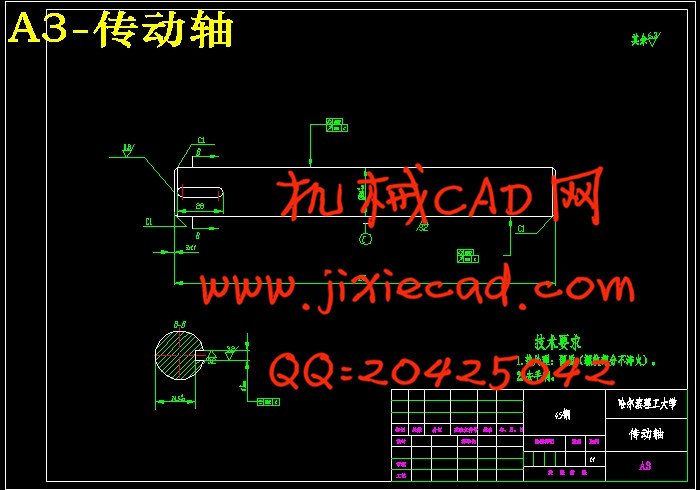

4.3 传动系统的设计 22

4.3.1 拟定传动路线 23

4.3.2 传动系统计算 23

4.4 三维模型 25

4.5 多轴箱的润滑 25

4.6 校核传动轴5轴 27

4.7 轴承寿命计算 30

4.8 绘制多轴箱总图及零件图 31

4.9 本章小结 31

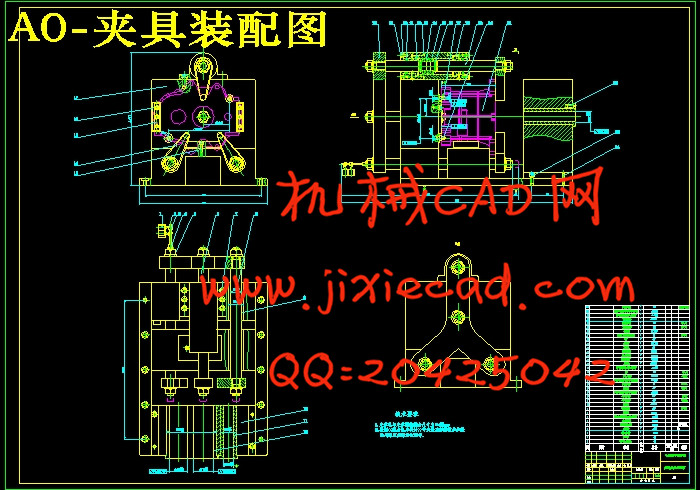

第5章 夹具设计 32

5.1 定位方案 32

5.2 导向装置 32

5.3 夹紧装置 33

5.4 本章小结 33

结论 34

致谢 35

参考文献 36