设计简介

摘 要

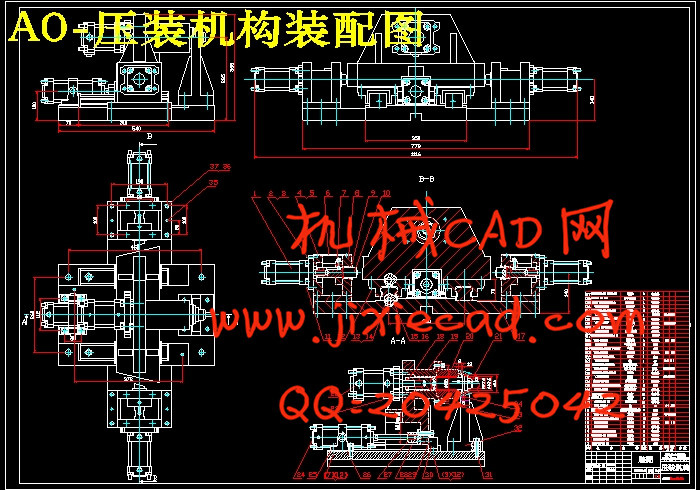

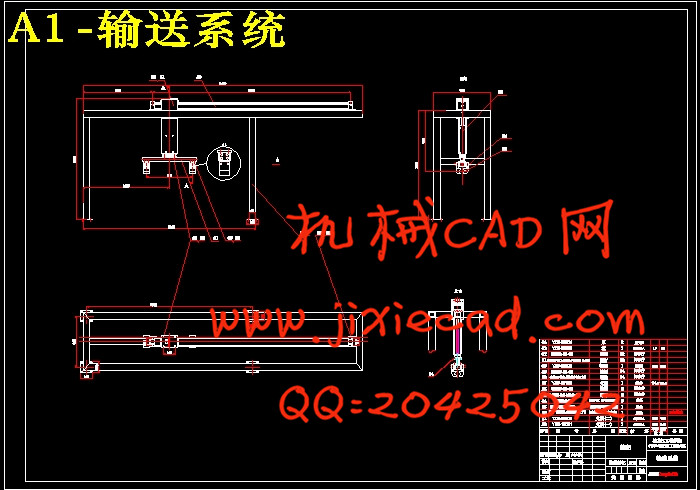

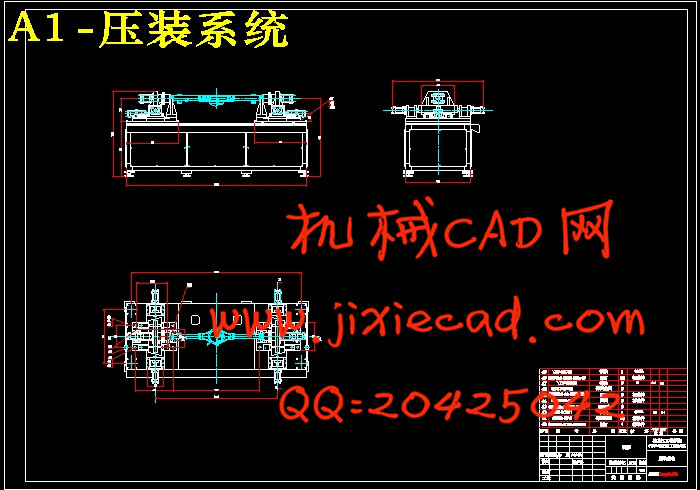

本文主要介绍轻型汽车后桥油封安装压入机的结构设计头。本机由床身、压装机构、输送机构、接件机构、气动系统、电气系统六大部分组成。该机为框架式结构,动力驱动方式为气动与液压传动,并靠电气系统进行控制。本实用新型的有益效果是:使用PLC控制,半自动化处理,劳动强度低,工作效率高,操作简易,普通操作人员简单培训及可上岗。人工操作失误具有自动声光报警提示。设备噪音低,安全可靠。一套动力设备可完成两个动作,具有联动功能,节约动力设备,节省成本。本设备主要用于汽车后桥两端部油封的自动压装及后桥的输送,采用本设备自动压装油封克服人力手工压装的不足,从而减轻了工人的劳动强度,提高产品压装油封的生产效率及质量。

关键词: 压入机;气动传动;液压传动;PLC控制

ABSTRACT

In this paper, light vehicle axle seals installed into the machine's structural design pressure head. The machine consists of bed, press-fit bodies, transport bodies, fittings, pneumatic system, electrical system, six major components. This machine frame structure, power-driven approach to pneumatic and hydraulic transmission, and control by electrical system. The beneficial effect of this utility model is: use PLC control, semi-automated processing, low labor strength, efficient, simple, common operator training and can be a simple induction. Manual errors with automatic sound and light alarm. Equipment, low noise, safe and reliable. A power plant to be completed by the two movements, with the linkage function, power saving devices and reducing costs. This equipment is mainly used for automobile rear axle oil seal both ends and fitted with Auto-delivery after the bridge, using the device automatically press-fit oil seal fitted to overcome the shortage of human hand pressure, thereby reducing labor intensity and improve the product pressure loaded oil seal production efficiency and quality

Key words: indentation machine; pneumatic transmission; hydraulic transmission; PLC control

目 录

本文主要介绍轻型汽车后桥油封安装压入机的结构设计头。本机由床身、压装机构、输送机构、接件机构、气动系统、电气系统六大部分组成。该机为框架式结构,动力驱动方式为气动与液压传动,并靠电气系统进行控制。本实用新型的有益效果是:使用PLC控制,半自动化处理,劳动强度低,工作效率高,操作简易,普通操作人员简单培训及可上岗。人工操作失误具有自动声光报警提示。设备噪音低,安全可靠。一套动力设备可完成两个动作,具有联动功能,节约动力设备,节省成本。本设备主要用于汽车后桥两端部油封的自动压装及后桥的输送,采用本设备自动压装油封克服人力手工压装的不足,从而减轻了工人的劳动强度,提高产品压装油封的生产效率及质量。

关键词: 压入机;气动传动;液压传动;PLC控制

ABSTRACT

In this paper, light vehicle axle seals installed into the machine's structural design pressure head. The machine consists of bed, press-fit bodies, transport bodies, fittings, pneumatic system, electrical system, six major components. This machine frame structure, power-driven approach to pneumatic and hydraulic transmission, and control by electrical system. The beneficial effect of this utility model is: use PLC control, semi-automated processing, low labor strength, efficient, simple, common operator training and can be a simple induction. Manual errors with automatic sound and light alarm. Equipment, low noise, safe and reliable. A power plant to be completed by the two movements, with the linkage function, power saving devices and reducing costs. This equipment is mainly used for automobile rear axle oil seal both ends and fitted with Auto-delivery after the bridge, using the device automatically press-fit oil seal fitted to overcome the shortage of human hand pressure, thereby reducing labor intensity and improve the product pressure loaded oil seal production efficiency and quality

Key words: indentation machine; pneumatic transmission; hydraulic transmission; PLC control

目 录

摘要 I

Abstract II

第1章 绪论 1

1.1 选题的目的和意义 2

1.2 国内外的研究现状 2

1.3 设计研究的主要内容 1

第2章 后桥油封压入机的总体方案设计 4

2.1 设备用途 4

2.2 适用条件 4

2.3规格及性能 4

2.4 结构形式 4

2.5 工作原理 5

2.6后桥油封轴向压入力的计算 6

2.6.1轴向压入力的分析 7

2.6.2轴向压入力的计算 7

2.7 本章小结 7

第3章 用Auto CAD和CATIA设计机械装配图 8

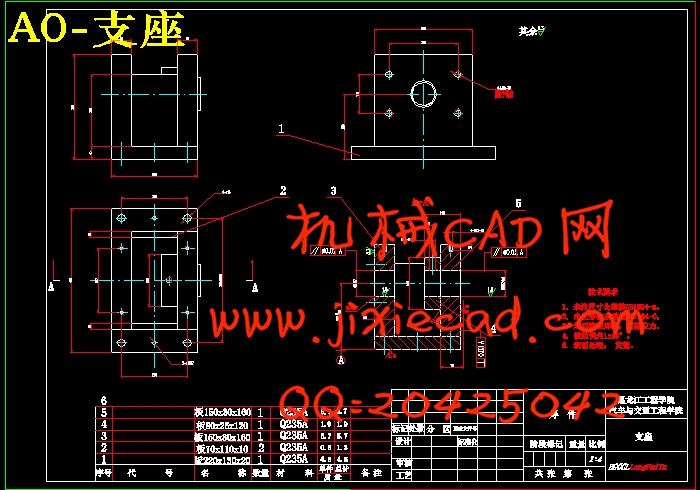

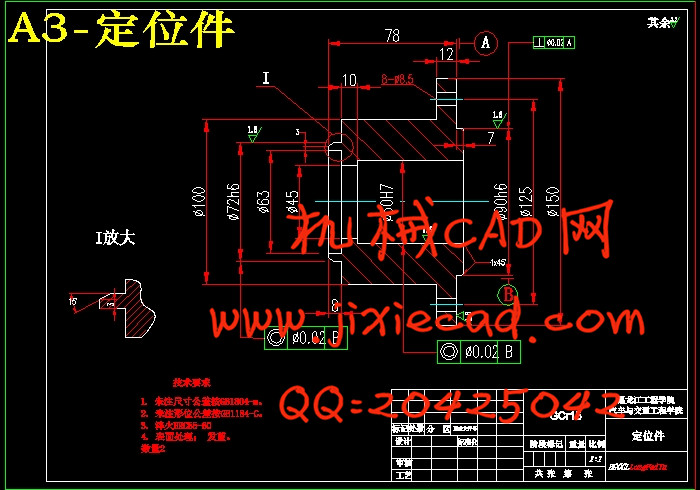

3.1主要零件的Auto CAD图 9

3.1.1支座 9

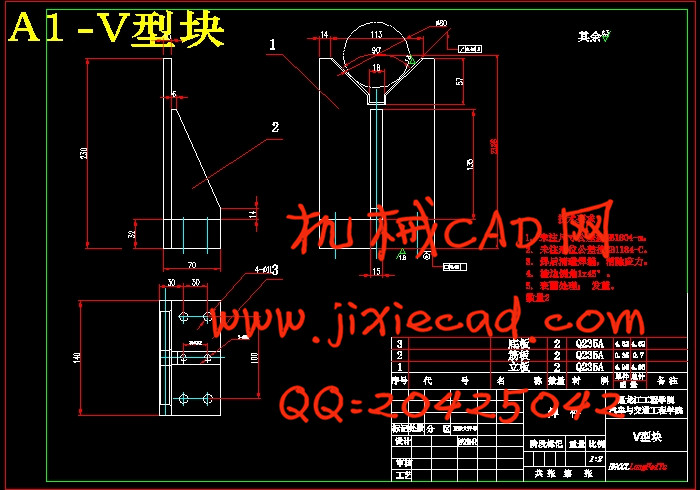

3.1.2挡块 9

3.1.3挡块 9

3.2主要零件的CATIA图 10

3.2.1油封压入装置 11

3.2.2工作台 12

3.2.3后桥V型支座 13

3.3本章小结 13

第4章 电机驱动与控制部分的设计 14

4.1控制对象状态确定 14

4.2控制方案的设计与选择 14

4.3硬件电路的设计 14

4.3.1进步电机驱动电路设计 14

4.3.2 计数方式的选择 16

4.3.3 显示电路设计 16

4.3.4 单片机电源电路的设计 16

4.4 PC、PLC、PT的通讯 17

4.5电气原理图 19

4.6本章小结 19

第5章 设备的安装调整及保养与检测 21

5.1安装 21

5.2调整 21

5.2.1压装机构调整 21

5.2.2夹紧松开缸调整 22

5.3试车运行与操作 23

5.3.1试车运行 23

5.3.2操作 23

5.3.3运行 24

5.4操作事项 25

5.5保养与维修 26

5.6故障与排除 27

5.7触摸屏(PT)工艺流程图 28

5.8本章小结 28

结论 29

参考文献 30

致谢 31