设计简介

摘 要

在汽车行驶过程中,我们常有这样的感受:汽车挂挡起步时,左脚逐渐抬起离合器踏板,右脚逐渐踏下加速踏板使发动机供油量增大,才能使汽车缓缓起步。换挡时,只有将离合器踏板踏下后,才能避免变速器齿轮打齿冲击;紧急制动时若来不及踩离合器踏板时,发动机和传动系统都受到很大冲击,但发动机和传动系的零部件却没有发生损坏故障。因此,离合器是直接连接到汽车动力总成发动机的组件。

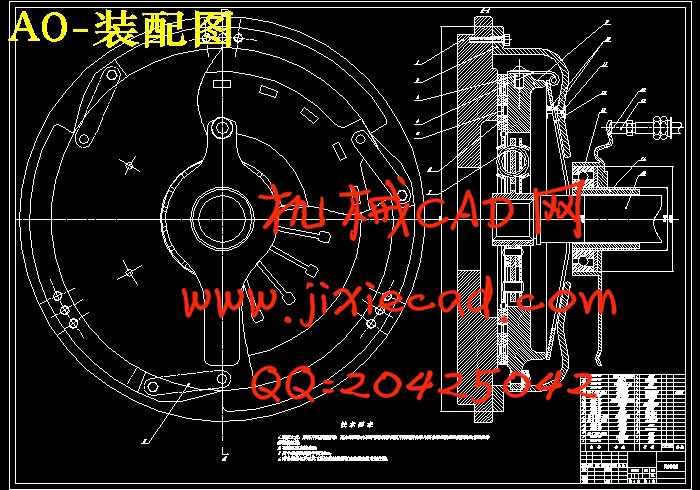

本文确定了离合器的基本参数及尺寸,及其约束条件。之后,依据推式膜片弹簧离合器的性能要求,对摩擦片,膜片弹簧,从动盘总成,离合器盖总成,分离轴承总成及操纵机构等进行设计计算和校核,设计出一种能满足汽车性能需求的离合器。然后依据所计算的数据画出装配图和零件图,且进行三维建模和仿真分析。

关键词:离合器;推式;膜片弹簧;设计;

在汽车行驶过程中,我们常有这样的感受:汽车挂挡起步时,左脚逐渐抬起离合器踏板,右脚逐渐踏下加速踏板使发动机供油量增大,才能使汽车缓缓起步。换挡时,只有将离合器踏板踏下后,才能避免变速器齿轮打齿冲击;紧急制动时若来不及踩离合器踏板时,发动机和传动系统都受到很大冲击,但发动机和传动系的零部件却没有发生损坏故障。因此,离合器是直接连接到汽车动力总成发动机的组件。

本文确定了离合器的基本参数及尺寸,及其约束条件。之后,依据推式膜片弹簧离合器的性能要求,对摩擦片,膜片弹簧,从动盘总成,离合器盖总成,分离轴承总成及操纵机构等进行设计计算和校核,设计出一种能满足汽车性能需求的离合器。然后依据所计算的数据画出装配图和零件图,且进行三维建模和仿真分析。

关键词:离合器;推式;膜片弹簧;设计;

Abstract

In the course of car driving, we often have this feeling: when the car starts to start, the left foot gradually raises the clutch pedal, and the right foot step down the accelerator pedal to increase the engine oil supply, in order to make the car start slowly. In shift, only when the clutch pedal is tread can avoid the gear gear impact. When the clutch pedal is too late to step on the clutch pedal, the engine and the transmission system are greatly impacted, but the parts of the engine and transmission system have no damage. Therefore, the clutch is a direct connection with the engine in the drive line of the automobile.

The basic parameters and dimensions of the clutch are determined and its constraint conditions are determined. Then, according to the performance requirements of the push diaphragm spring clutch, the design calculation and check of the friction plate, the diaphragm spring, the slave disk assembly, the clutch cover assembly, the separation bearing assembly and the control mechanism are carried out, and a clutch which can meet the performance requirements of the automobile is designed. Then the assembly drawing and part drawing are drawn based on the calculated data, and 3D modeling and simulation analysis are carried out.

Keywords:Clutch;Push type;diaphragm spring;design

In the course of car driving, we often have this feeling: when the car starts to start, the left foot gradually raises the clutch pedal, and the right foot step down the accelerator pedal to increase the engine oil supply, in order to make the car start slowly. In shift, only when the clutch pedal is tread can avoid the gear gear impact. When the clutch pedal is too late to step on the clutch pedal, the engine and the transmission system are greatly impacted, but the parts of the engine and transmission system have no damage. Therefore, the clutch is a direct connection with the engine in the drive line of the automobile.

The basic parameters and dimensions of the clutch are determined and its constraint conditions are determined. Then, according to the performance requirements of the push diaphragm spring clutch, the design calculation and check of the friction plate, the diaphragm spring, the slave disk assembly, the clutch cover assembly, the separation bearing assembly and the control mechanism are carried out, and a clutch which can meet the performance requirements of the automobile is designed. Then the assembly drawing and part drawing are drawn based on the calculated data, and 3D modeling and simulation analysis are carried out.

Keywords:Clutch;Push type;diaphragm spring;design

目录

前言 1

1离合器的介绍 2

1.1 离合器概述 2

1.2 离合器的组成及功用 2

1.3膜片弹簧离合器的原理 3

1.4膜片弹簧离合器的优点 3

2离合器结构方案选取 5

2.1 本课题参数及要求 5

2.2 离合器设计基本要求 5

2.3 离合器结构设计 6

2.3.1 从动盘数的选择 6

2.3.2 压紧弹簧和布置形式的选择 6

2.3.3压盘的驱动方式 6

2.3.4分离轴承的选择 7

2.3.5 离合器的通风散热 7

2.3.6从动盘总成的选择 7

3离合器主要参数的选择 9

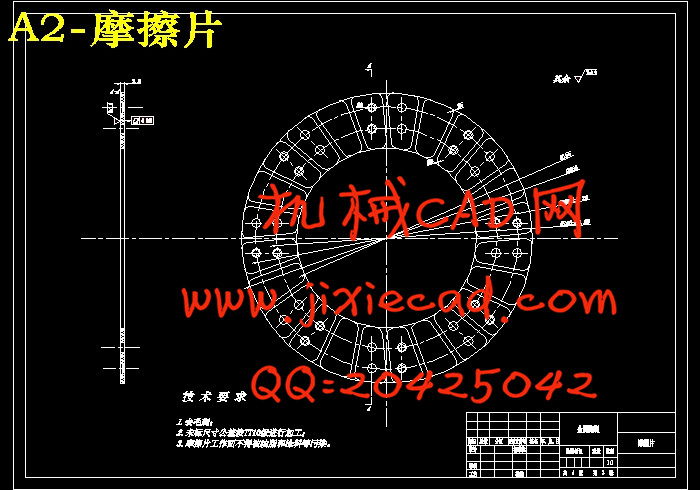

3.1 摩擦片主要尺寸的确定 9

3.2 后备系数β的确定 10

3.3 单位压力P0的确定 11

3.4摩擦因数f的选择 11

3.5 摩擦片的优化 11

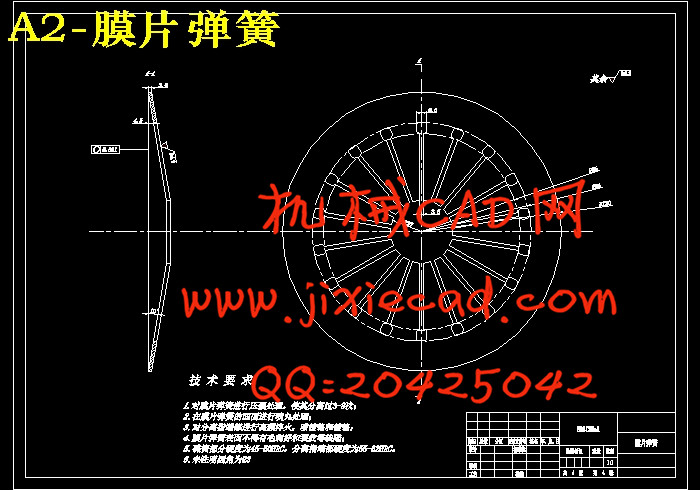

4膜片弹簧的设计 12

4.1 膜片弹簧基本参数的选择 12

4.1.1 H/h 比值的选择 12

4.1.2 碟簧部分大端半径R、内半径r及R/r 的比值确定 13

4.1.3 弹簧起始圆锥底角

4.1.4 膜片弹簧小端半径r0 及分离轴承作用半径

4.1.5 分离指数目n 切槽宽度

4.1.6压盘加载点R1 和支撑环加载点半径r1尺寸选择 13

4.2 膜片弹簧的设计 14

4.2.1绘制

4.3 膜片弹簧工作点位置的选择 16

4.4 离合器彻底分离时分离轴承作用的载荷 17

4.5 分离轴承的行程

4.6 膜片弹簧的强度校核 18

4.7 膜片弹簧的优化 19

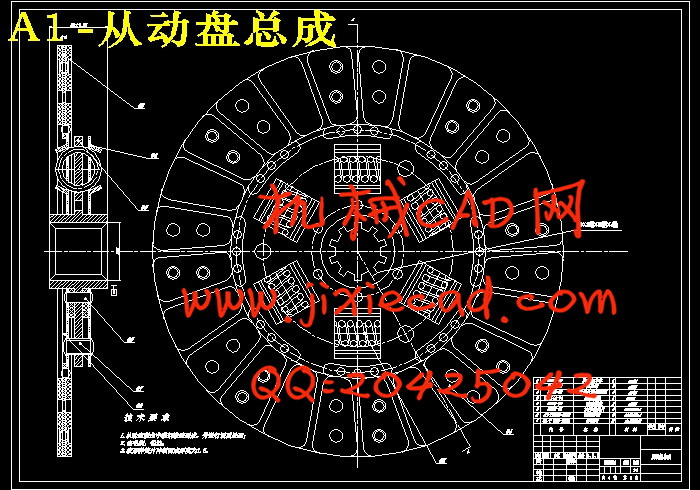

5从动盘总成设计 21

5.1 从动盘的组成形式及要求 21

5.2 从动片设计 21

5.3 从动盘毂设计 21

5.4 花键强度校核 22

5.5 扭转减振器的设计 23

5.5.1 扭转减振器的功能 23

5.5.2 扭转减振器主要参数的选择 23

5.5.3 减振弹簧的计算 25

6压盘和离合器盖的设计 27

6.1压盘传动方案的选择 27

6.2压盘的材料选择 27

6.3 压盘几何尺寸的确定 27

6.4离合器盖的设计 28

7离合器操纵机构的设计 29

7.1操纵机构的设计 29

7.1.1 操纵机构的组成及优点 29

7.1.2 踏板行程S的计算 29

7.2 踏板力

7.3 助力器缸直径计算 30

7.4分离轴承的选择 31

8离合器的建模及仿真分析 32

8.1摩擦片和膜片弹簧的三维建模 32

8.2从动盘总成的三维建模 33

8.3离合器盖总成和操纵机构的三维建模及其离合器总成 35

8.4离合器模型三维仿真分析 37

8.4.1离合器正常状态仿真 37

8.4.2离合器工作状态仿真 38

8.5压盘的有限元分析 40

9轿车膜片弹簧离合器系统技术经济性分析 43

10结论 44

致谢 45

参考文献 46