设计简介

摘要

变速器是由传动机构和操纵机构两部分分组成的,它的功用是用来改变传动比,改变发动机传到驱动轮上的转矩和转速,以此来适应变化的行驶条件。变速器工作的目的是在原地起步,爬坡,转弯以及加速等各种不同行驶工况下,能够使汽车获得不同的牵引力以及速度,同时能够使发动机在最有利的工况范围内进行工作。除此之外,变速器设有空档和倒档。在发动机的曲轴转动方向不改变的前提下,使汽车能够倒退行驶,还可以利用空档来中断动力的传递,可以使发动机能够起动、怠速,并且便于变速器的换档或者进行动力输出。所以变速器的结构要求等对于汽车的动力性、传动平稳性、燃料经济性、换挡操纵的轻便性以及可靠性、舒适性和效率等都有着直接且重要的影响。

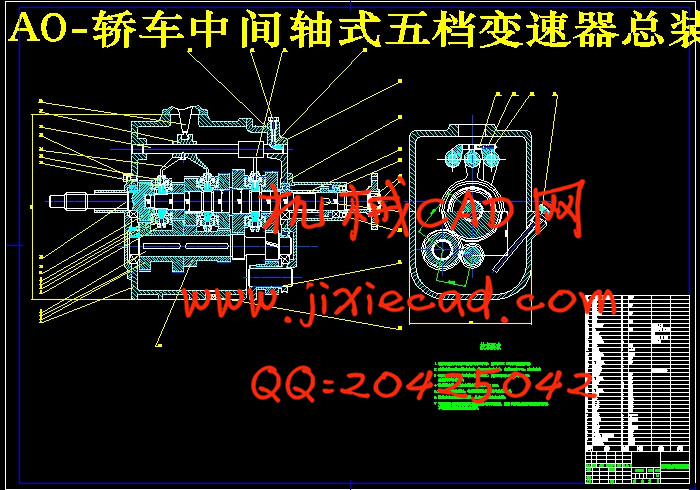

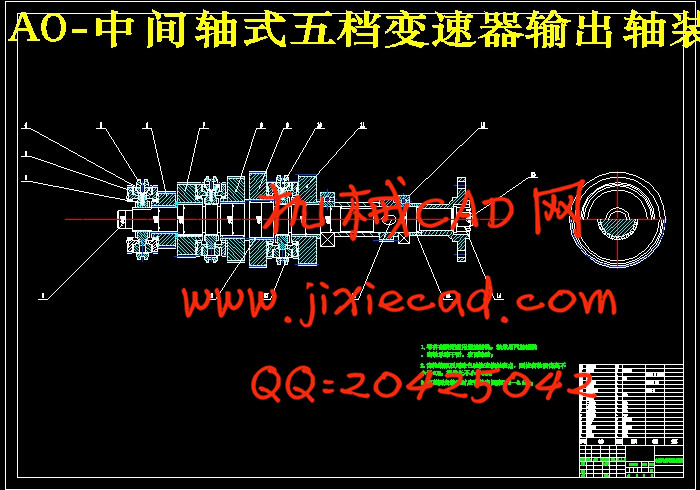

本设计研究了三轴五档手动变速器,其目的主要是在基于对机械原理、机械设计、等知识的熟练运用和掌握的同时,还要运用汽车构造、汽车理论、汽车设计、等专业学科知识,对三轴五档手动式变速器的整体以及各零部件进行设计,并且还要利用 AutoCAD、CAXA等二维软件绘制装配图和零件图,最后利用 PROE 以及 UG 等三维软件进行建模、装配等内容。首先,本文简要介绍了此次设计的研究目的和意义以及变速器的现状和发展的主要内容。其次,对三轴五档手动变速器的工作原理做了阐述,对不同的变速器的传动方案依次进行了比较,并且选择了合理的结构方案进行设计。最后,对三轴五档手动式变速器的各档齿轮、轴以及轴承做了较为详细的设计计算,并且对它们进行了受力分析、强度以及刚度的校核计算,同时还对同步器进行了选型。

关键词:变速器;档数;传动比;齿轮;轴;同步器;建模

变速器是由传动机构和操纵机构两部分分组成的,它的功用是用来改变传动比,改变发动机传到驱动轮上的转矩和转速,以此来适应变化的行驶条件。变速器工作的目的是在原地起步,爬坡,转弯以及加速等各种不同行驶工况下,能够使汽车获得不同的牵引力以及速度,同时能够使发动机在最有利的工况范围内进行工作。除此之外,变速器设有空档和倒档。在发动机的曲轴转动方向不改变的前提下,使汽车能够倒退行驶,还可以利用空档来中断动力的传递,可以使发动机能够起动、怠速,并且便于变速器的换档或者进行动力输出。所以变速器的结构要求等对于汽车的动力性、传动平稳性、燃料经济性、换挡操纵的轻便性以及可靠性、舒适性和效率等都有着直接且重要的影响。

本设计研究了三轴五档手动变速器,其目的主要是在基于对机械原理、机械设计、等知识的熟练运用和掌握的同时,还要运用汽车构造、汽车理论、汽车设计、等专业学科知识,对三轴五档手动式变速器的整体以及各零部件进行设计,并且还要利用 AutoCAD、CAXA等二维软件绘制装配图和零件图,最后利用 PROE 以及 UG 等三维软件进行建模、装配等内容。首先,本文简要介绍了此次设计的研究目的和意义以及变速器的现状和发展的主要内容。其次,对三轴五档手动变速器的工作原理做了阐述,对不同的变速器的传动方案依次进行了比较,并且选择了合理的结构方案进行设计。最后,对三轴五档手动式变速器的各档齿轮、轴以及轴承做了较为详细的设计计算,并且对它们进行了受力分析、强度以及刚度的校核计算,同时还对同步器进行了选型。

关键词:变速器;档数;传动比;齿轮;轴;同步器;建模

Abstract

The transmission is composed of two parts: the transmission mechanism and the control mechanism. Its function is to change the transmission ratio, the torque and the speed of the engine to the driving wheel, so as to adapt to the changing driving conditions. The purpose of transmission work is to make the vehicle obtain different traction and speed under different driving conditions such as starting in situ climbing slope turning and accelerating and at the same time making the engine work in the most favorable range. In addition, the transmission has a gap and reverse gear. Without changing the direction of crankshaft rotation of the engine, the car can go backwards and use the gap to interrupt the power. The transmission enables the engine to start, idle, and facilitate transmission shift or power output. Therefore, the structural requirements of transmission have a direct and important impact on the vehicle's power performance, transmission smoothness, fuel economy, shift handling portability, reliability, comfort and efficiency.

The purpose of this design is to apply and master the knowledge of mechanical principle, mechanical design, mechanical design and so on, but also to use automobile construction, automobile theory, automobile design, etc. The whole and parts of the three-axis and five-file manual transmission are designed, and the assembly drawing and part drawing are drawn by using the 2D software, such as AutoCAD, CAXA, etc. Finally, the 3D software, such as PROE and UG, is used to model the system. Assemble, etc. First of all, this paper briefly introduces the research purpose and significance of the design, as well as the current situation and the main development of the transmission. Want the content. Secondly, the working principle of three-axis and five-file manual transmission is expounded, the transmission schemes of different transmission are compared one by one, and a reasonable structure scheme is selected to design. Finally, the design and calculation of each gear, shaft and bearing of three-axis and five-speed manual transmission are carried out in detail, and the force analysis, strength and stiffness check and calculation are carried out, and the synchronizer is also selected.

Key words: transmission; number of gears; transmission ratio; gear; shaft; synchronizer; modeling

The transmission is composed of two parts: the transmission mechanism and the control mechanism. Its function is to change the transmission ratio, the torque and the speed of the engine to the driving wheel, so as to adapt to the changing driving conditions. The purpose of transmission work is to make the vehicle obtain different traction and speed under different driving conditions such as starting in situ climbing slope turning and accelerating and at the same time making the engine work in the most favorable range. In addition, the transmission has a gap and reverse gear. Without changing the direction of crankshaft rotation of the engine, the car can go backwards and use the gap to interrupt the power. The transmission enables the engine to start, idle, and facilitate transmission shift or power output. Therefore, the structural requirements of transmission have a direct and important impact on the vehicle's power performance, transmission smoothness, fuel economy, shift handling portability, reliability, comfort and efficiency.

The purpose of this design is to apply and master the knowledge of mechanical principle, mechanical design, mechanical design and so on, but also to use automobile construction, automobile theory, automobile design, etc. The whole and parts of the three-axis and five-file manual transmission are designed, and the assembly drawing and part drawing are drawn by using the 2D software, such as AutoCAD, CAXA, etc. Finally, the 3D software, such as PROE and UG, is used to model the system. Assemble, etc. First of all, this paper briefly introduces the research purpose and significance of the design, as well as the current situation and the main development of the transmission. Want the content. Secondly, the working principle of three-axis and five-file manual transmission is expounded, the transmission schemes of different transmission are compared one by one, and a reasonable structure scheme is selected to design. Finally, the design and calculation of each gear, shaft and bearing of three-axis and five-speed manual transmission are carried out in detail, and the force analysis, strength and stiffness check and calculation are carried out, and the synchronizer is also selected.

Key words: transmission; number of gears; transmission ratio; gear; shaft; synchronizer; modeling

目录

4.变速器齿轮的强度计算与材料的选择 19

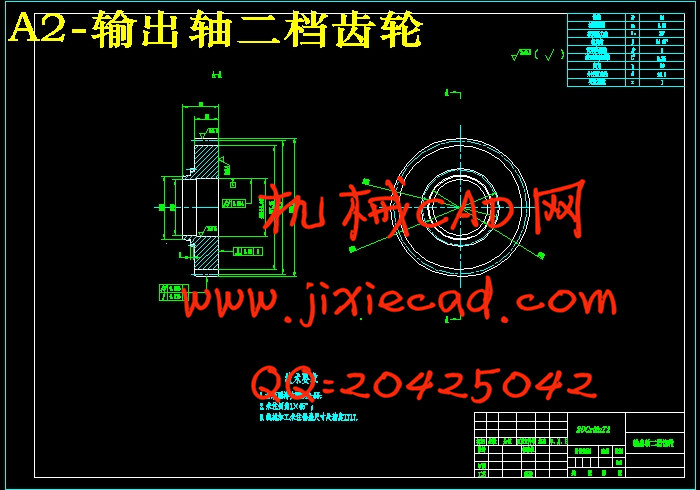

4.1 齿轮的强度计算与校核 24

4.1.1 齿轮弯曲强度计算 24

4.1.2 齿轮接触应力 27

5.变速器轴的强度计算与校核 30

5.1 确定轴的尺寸 30

5.2 轴的校核 31

6.变速器同步器的设计 38

7.变速器的装配及仿真分析 45

7.1 变速器的装配 45

7.2 变速器的仿真分析 47

7.3 变速器结构的有限元分析 38

8.结论 50

致谢 51

参考文献 52