设计简介

摘要

汽车的转向系统在机械式转向系统的基础上随着技术的不断发展完善和人们的要求不断提高,动力式转向系系统因运而生并成为主流转向系统。动力转向系统是在驾驶员靠人力通过各连杆机构作用在转向轮的基础上辅助以发动机的动能通过转向加力装置转化为进行汽车转向的动能来实现转向快速,准确,轻便的一套系统。因此,对于动力转向系统,汽车转向所需的能量只有一小部分由驾驶员提供,而大部分能量由发动机通过转向加力装置提供。而且随着技术的完善,当动力转向系统的转向加力装置失效时,还可以靠转向系统的机械部分由驾驶员独立汽车转向所需的力,从而实现汽车转向。因此,动力式转向系统因其优良的稳定性。安全性和可操作性受到广泛推广[1]。

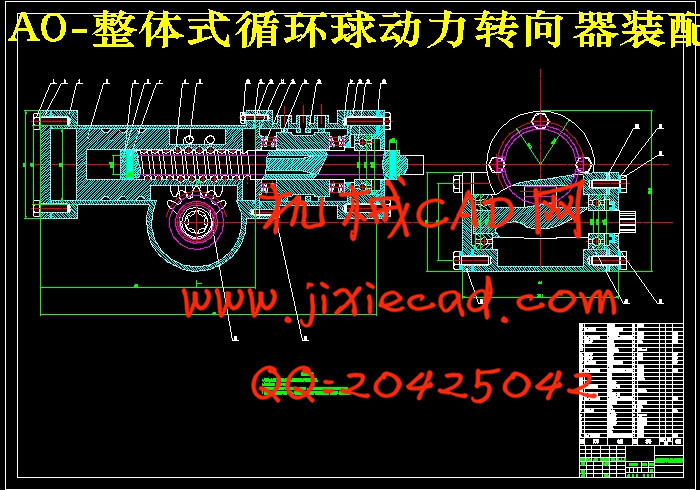

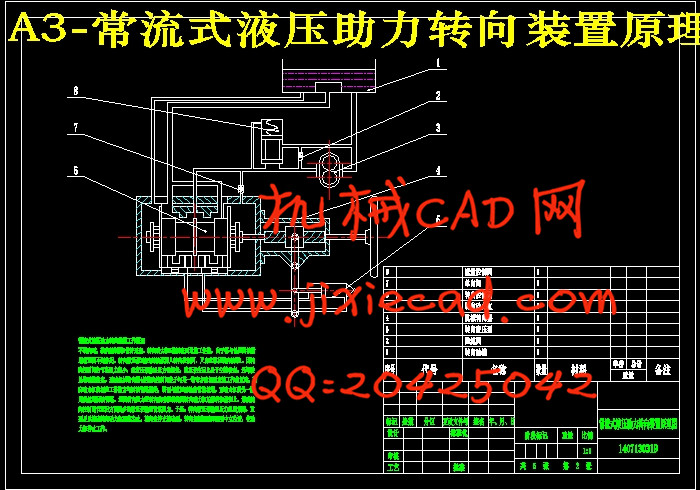

本文所设计的是中型汽车的转向系统,因此,本文根据中型汽车设计要求,选择整体式循环球式转向器,动力装置选用液压动力装置,并转向控制阀选用常流式滑阀转向阀等。通过查阅资料,参考文献等对动力转向系统的转向器各个零部件,液压动力缸参数及滑阀转向阀参数,转向系统的操纵机构和传动机构进行设计计算和强度校核。最后利用CAXA软件进行转向系统装配图及各零件图的绘制,利用UG三维建模软件对转向系统各个部分进行三维建模和仿真分析。

关键词:循环球式转向系统;液压助力;滑阀;二维装配;三维建模

汽车的转向系统在机械式转向系统的基础上随着技术的不断发展完善和人们的要求不断提高,动力式转向系系统因运而生并成为主流转向系统。动力转向系统是在驾驶员靠人力通过各连杆机构作用在转向轮的基础上辅助以发动机的动能通过转向加力装置转化为进行汽车转向的动能来实现转向快速,准确,轻便的一套系统。因此,对于动力转向系统,汽车转向所需的能量只有一小部分由驾驶员提供,而大部分能量由发动机通过转向加力装置提供。而且随着技术的完善,当动力转向系统的转向加力装置失效时,还可以靠转向系统的机械部分由驾驶员独立汽车转向所需的力,从而实现汽车转向。因此,动力式转向系统因其优良的稳定性。安全性和可操作性受到广泛推广[1]。

本文所设计的是中型汽车的转向系统,因此,本文根据中型汽车设计要求,选择整体式循环球式转向器,动力装置选用液压动力装置,并转向控制阀选用常流式滑阀转向阀等。通过查阅资料,参考文献等对动力转向系统的转向器各个零部件,液压动力缸参数及滑阀转向阀参数,转向系统的操纵机构和传动机构进行设计计算和强度校核。最后利用CAXA软件进行转向系统装配图及各零件图的绘制,利用UG三维建模软件对转向系统各个部分进行三维建模和仿真分析。

关键词:循环球式转向系统;液压助力;滑阀;二维装配;三维建模

Abstract

The steering system of automobile is based on the mechanical steering system. With the continuous development of technology and the improvement of peopleundefineds requirements, the power steering system has become the mainstream steering system because of its operation. The power steering system is to realize the rapid steering on the basis of the steering wheel acting by the driver by manpower through the connecting rod mechanism. The kinetic energy of the engine is converted into the kinetic energy of the automobile steering by the steering afterpower device. An accurate, portable system. Therefore, for power steering systems, only a small portion of the energy required for vehicle steering is provided by the driver, while most of the energy is provided by the engine through the steering afterburner. And with the improvement of technology, when the power steering systemundefineds steering afterforce device fails, the steering system can also rely on the mechanical part of the steering system by the driverundefineds independent vehicle steering force, so as to achieve vehicle steering. Therefore, the power steering system has excellent stability. Safety and operability are widely promoted.

In this article, the steering system of the medium vehicle is designed. Therefore, according to the design requirements of the medium vehicle, this paper selects the integral circulating ball steering gear, the hydraulic power device for the power plant, and the constant flow slide valve steering valve for the steering control valve, etc. Through consulting data, reference and so on, the design calculation and strength check of steering gear parts, hydraulic power cylinder parameters and slide valve steering valve parameters, steering mechanism and transmission mechanism of power steering system are carried out. Finally, CAXA software is used to draw the assembly drawing and every part drawing of steering system, and UG software is used to model and simulate each part of steering system.

Keywords: circulating ball steering system; hydraulic power; slide valve; 2D assembly; 3D modeling

The steering system of automobile is based on the mechanical steering system. With the continuous development of technology and the improvement of peopleundefineds requirements, the power steering system has become the mainstream steering system because of its operation. The power steering system is to realize the rapid steering on the basis of the steering wheel acting by the driver by manpower through the connecting rod mechanism. The kinetic energy of the engine is converted into the kinetic energy of the automobile steering by the steering afterpower device. An accurate, portable system. Therefore, for power steering systems, only a small portion of the energy required for vehicle steering is provided by the driver, while most of the energy is provided by the engine through the steering afterburner. And with the improvement of technology, when the power steering systemundefineds steering afterforce device fails, the steering system can also rely on the mechanical part of the steering system by the driverundefineds independent vehicle steering force, so as to achieve vehicle steering. Therefore, the power steering system has excellent stability. Safety and operability are widely promoted.

In this article, the steering system of the medium vehicle is designed. Therefore, according to the design requirements of the medium vehicle, this paper selects the integral circulating ball steering gear, the hydraulic power device for the power plant, and the constant flow slide valve steering valve for the steering control valve, etc. Through consulting data, reference and so on, the design calculation and strength check of steering gear parts, hydraulic power cylinder parameters and slide valve steering valve parameters, steering mechanism and transmission mechanism of power steering system are carried out. Finally, CAXA software is used to draw the assembly drawing and every part drawing of steering system, and UG software is used to model and simulate each part of steering system.

Keywords: circulating ball steering system; hydraulic power; slide valve; 2D assembly; 3D modeling

目录

前言 1

1汽车主要参数的确定 2

1.1汽车主要参数的选择 2

2转向系的主要参数 3

2.1转向器的效率 3

2.2转向系传动比的变化特性 4

2.2.1转向系传动比 4

2.2.2力传动比与转向系角传动比的关系 4

3循环球式转向器设计与计算 6

3.1 循环球式转向器主要参数的确定 6

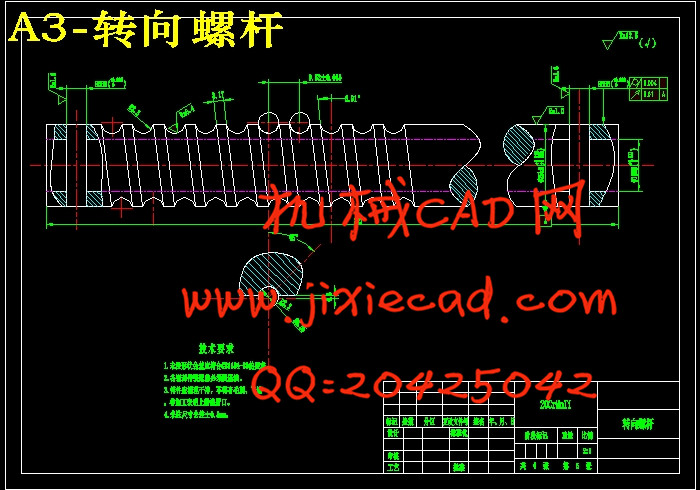

3.1.1螺杆、钢球、螺母传动副设计 6

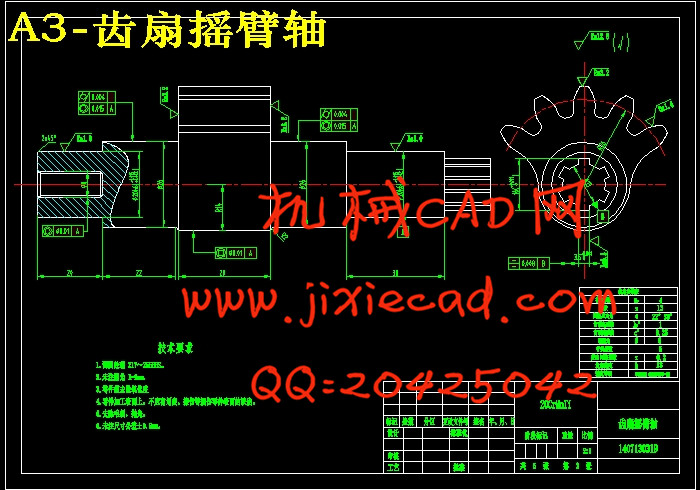

3.1.2齿条齿扇传动副的设计 8

3.2 循环球式转向器零件强度计算和校核 9

3.2.1转向系计算载荷的确定 9

3.2.2钢球与滚道间的接触应力

3.2.3齿的弯曲应力

3.2.4转向摇臂轴直径的确定 12

4液压动力转向系的设计计算 13

4.1液压动力转向机构布置方案的选择 13

4.2液压动力缸的设计计算 14

4.2.1动力缸内径

4.2.2活塞行程

4.2.3动力缸缸筒壁厚计算 15

4.3转向控制阀的设计计算 16

4.3.1预开隙

4.3.2滑阀总位移量

4.3.3滑阀直径

4.3.4滑阀中间位置时油液流速

4.3.5分配阀得泄漏量

4.3.6回位弹簧设计计算 17

4.4液压油罐容积和液压油泵排量的确定 18

5转向传动机构的设计 20

6循环球式转向器的三维建模与仿真分析 21

6.1转向螺杆的UG三维建模 21

6.2齿扇摇臂轴的UG三维建模 22

6.3转向螺母的UG三维建模 25

6.4转向扭杆的UG三维建模 27

6.5转向器壳体的UG三维建模 28

6.6循环球式转向器装配 30

6.7循环球式转向器的仿真运动分析 31

6.8循环球式转向器扭杆的有限元分析 33

7技术经济性分析 36

8结论 38

致谢 39

参考文献 40