设计简介

摘要

刹车系统伴随着汽车的发展,也在快速发展着,而制动器作为刹车系统的执行系统的一部分,其安全性也越来越受到现代人们的重视。货车的制动系统多为气压制动,由于货车质量很大,所以货车的制动器质量一般也很大,在考虑制动系统安全性的同时,如何做到制动器结构的轻量化和选材的绿色化也正在成为个汽车厂的研究方向。

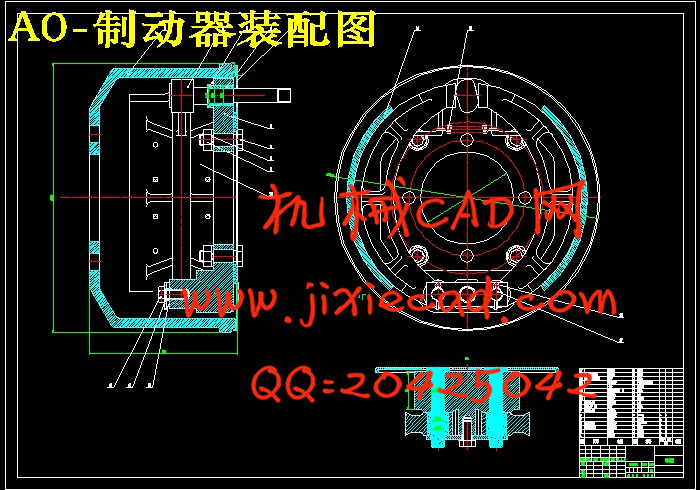

本次毕业设计,以重型货车为设计对象,对制动系的发展做了简单叙述,对货车制动器的结构件进行了设计,并通过三维软件进行了建模、运动仿真和有限元分析,检验了此次结构设计的合理性;然后使用CAXA电子图板绘制了二维零件图和装配图。

关键词:气压制动;制动器;结构设计;运动仿真;有限元分析

Abstract

Along with the development of automobile, brake system is also developing rapidly. As a part of brake system, the safety of brake system is paid more and more attention by modern people. The brake system of the freight car is mostly pneumatic brake. Because the quality of the truck is very large, the brake quality of the truck is generally very large, and the safety of the braking system is considered at the same time. How to achieve the light weight of brake structure and the greening of material selection is becoming the research direction of automobile factory.

In this graduation design, taking heavy truck as design object, the development of brake department is briefly described, the structure of truck brake is designed, the pneumatic drive mechanism is designed, and the motion simulation is carried out through three-dimensional software. The rationality of the structural design is tested, and then two dimensional part drawing and assembly drawing are drawn with CAXA electronic drawing board.

Key words: pneumatic brake; structure design; motion simulation;finite element analysis

目录

刹车系统伴随着汽车的发展,也在快速发展着,而制动器作为刹车系统的执行系统的一部分,其安全性也越来越受到现代人们的重视。货车的制动系统多为气压制动,由于货车质量很大,所以货车的制动器质量一般也很大,在考虑制动系统安全性的同时,如何做到制动器结构的轻量化和选材的绿色化也正在成为个汽车厂的研究方向。

本次毕业设计,以重型货车为设计对象,对制动系的发展做了简单叙述,对货车制动器的结构件进行了设计,并通过三维软件进行了建模、运动仿真和有限元分析,检验了此次结构设计的合理性;然后使用CAXA电子图板绘制了二维零件图和装配图。

关键词:气压制动;制动器;结构设计;运动仿真;有限元分析

Abstract

Along with the development of automobile, brake system is also developing rapidly. As a part of brake system, the safety of brake system is paid more and more attention by modern people. The brake system of the freight car is mostly pneumatic brake. Because the quality of the truck is very large, the brake quality of the truck is generally very large, and the safety of the braking system is considered at the same time. How to achieve the light weight of brake structure and the greening of material selection is becoming the research direction of automobile factory.

In this graduation design, taking heavy truck as design object, the development of brake department is briefly described, the structure of truck brake is designed, the pneumatic drive mechanism is designed, and the motion simulation is carried out through three-dimensional software. The rationality of the structural design is tested, and then two dimensional part drawing and assembly drawing are drawn with CAXA electronic drawing board.

Key words: pneumatic brake; structure design; motion simulation;finite element analysis

目录

前言 1

1 制动系的总体设计 2

1.1制动系统设计要求 2

1.2制动系参数的选择 3

1.3汽车总质量 3

1.4制动力与制动力分配系数 3

1.5制动强度与利用附着系数 7

1.6 制动器最大制动力矩 8

2 制动器的设计与计算 10

2.1鼓式制动器的主要参数 10

2.1.1制动鼓内径D 10

2.1.2摩擦衬片宽度b及包角

2.1.3摩擦衬片起始角

2.1.4制动蹄支撑点位置坐标a和c 12

2.1.5制动器中心到张开力作用线的距离e 12

2.1.6摩擦衬片摩擦系数

2.2制动器主要零部件的结构设计 13

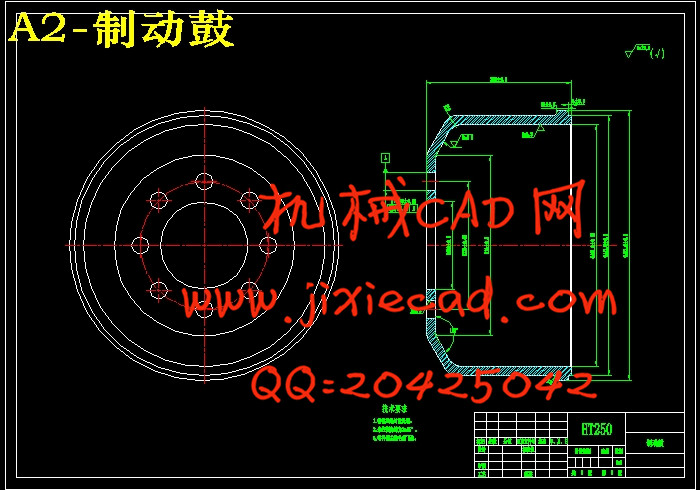

2.2.1制动鼓 13

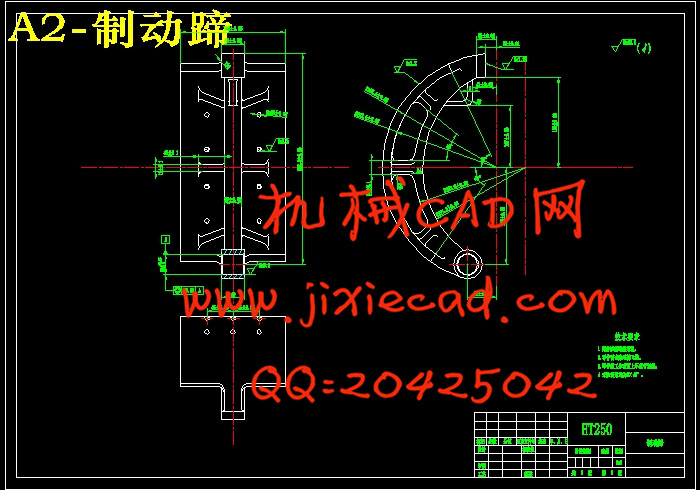

2.2.2制动蹄 13

2.2.3摩擦衬片 13

2.2.4支承 14

2.2.5张开机构 14

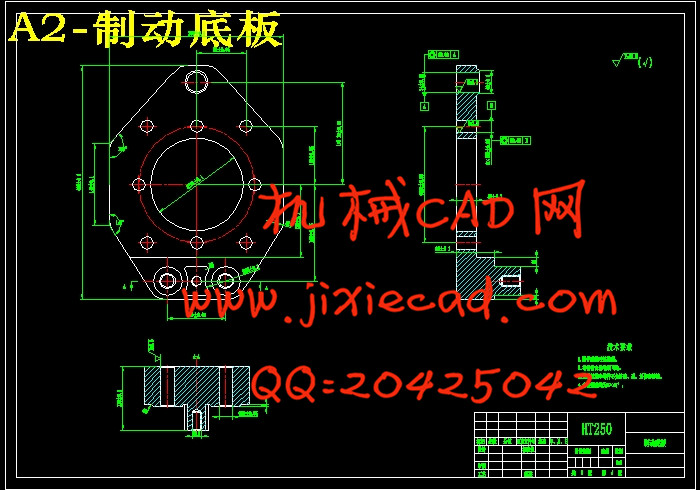

2.2.6制动底板 14

2.2.7制动间隙调整方法及相应机构 14

2.3鼓式制动器的计算 15

2.3.1计算蹄片上的制动力矩 15

2.3.2检查制动蹄有无自锁 17

2.4衬片磨损特性的计算 18

2.5驻车制动计算 19

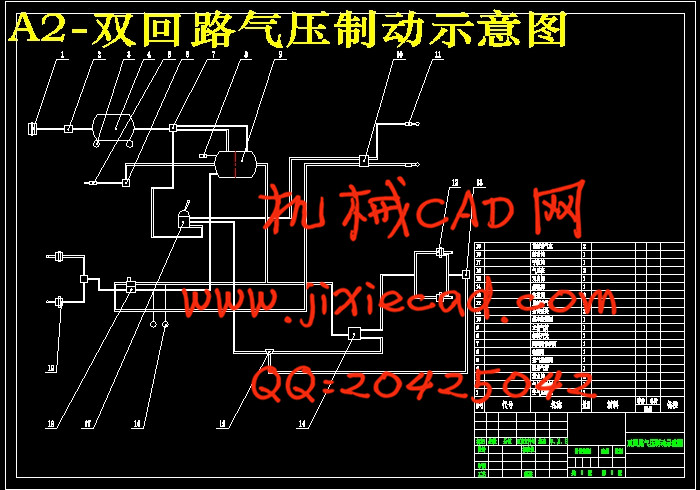

3气压制动驱动机构的设计计算 21

3.1气压制动驱动机构的基本组成 21

3.1.1供能装置 21

3.1.2控制装置 21

3.1.3制动气室 21

3.2气压驱动机构的基本原理 21

3.3制动气室的设计计算 22

3.4气管直径的选择 24

4制动器的建模与运动仿真 25

4.1零件的建模 25

4.1.1制动蹄的建模 25

4.1.2制动底板的建模 26

4.1.3制动鼓的建模 27

4.1.4凸轮轴的建模 28

4.1.5挡尘板的建模 29

4.1.6摩擦衬片的建模 30

4.2零件的装配 30

4.3制作爆炸视图 32

4.4运动仿真分析 33

5对制动鼓的温度场的有限元分析 35

5.1操作流程 35

5.2结果分析 36

6技术经济性分析 39

7结论 40

致谢 41

参考文献 42