设计简介

摘 要

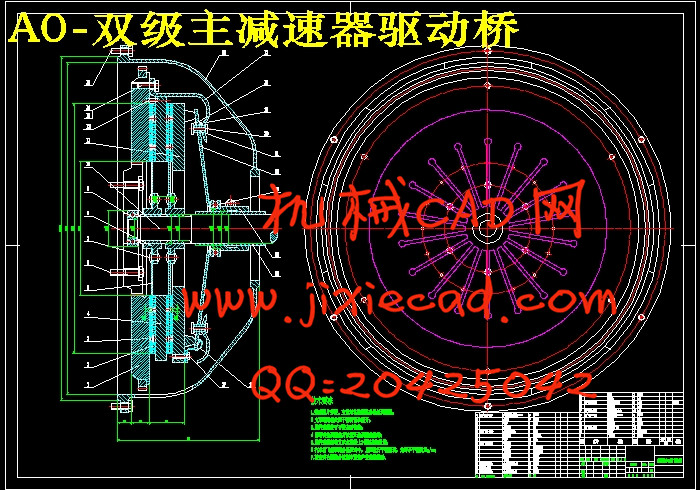

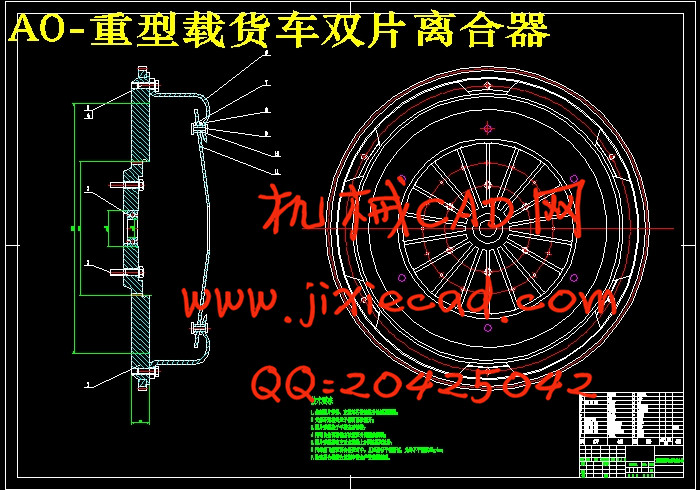

在整个汽车中,离合器的所占的空间虽然不大,但却在汽车传动系统中有不可取代的作用,离合器作为重要组成部件,离合器在性能和结构方面都得到很好的发展,在传递发动机动力的过程中,能够更好地实现动力的传输与切断,在传动系统承受较大转矩时不会使传动系发生过载情况。本次设计的题目是重型汽车双片离合器的设计与仿真,选择的是膜片弹簧,因为膜片弹簧在许多车型上面的广泛使用,膜片弹簧有着转矩容量大、操作简单、平衡性能好等优点,在设计完成一个产品后能够大量生产,提高生产效率,所以对膜片弹簧离合器的研究存在着非常重要的意义。这次毕业设计在说明书里面对重型汽车双片离合器的结构和参数的选择与计算都进行了详细的说明。

本文通过类比了其他车型离合器的参数选择,与不同类型的离合器比较,对离合器的各个组成部件进行比较,设计出各个部分的方案和其原理进行分析,再进行三维与运动仿真,对膜片弹簧进行有限元分析。根据重型汽车的使用条件和满载质量等参数的选择,按照汽车设计中离合器的设计步骤和要求,对离合器及组成部件进行设计与选择。

关键词:离合器;双片摩擦片;机械操纵;膜片弹簧;PORE;运动仿真

在整个汽车中,离合器的所占的空间虽然不大,但却在汽车传动系统中有不可取代的作用,离合器作为重要组成部件,离合器在性能和结构方面都得到很好的发展,在传递发动机动力的过程中,能够更好地实现动力的传输与切断,在传动系统承受较大转矩时不会使传动系发生过载情况。本次设计的题目是重型汽车双片离合器的设计与仿真,选择的是膜片弹簧,因为膜片弹簧在许多车型上面的广泛使用,膜片弹簧有着转矩容量大、操作简单、平衡性能好等优点,在设计完成一个产品后能够大量生产,提高生产效率,所以对膜片弹簧离合器的研究存在着非常重要的意义。这次毕业设计在说明书里面对重型汽车双片离合器的结构和参数的选择与计算都进行了详细的说明。

本文通过类比了其他车型离合器的参数选择,与不同类型的离合器比较,对离合器的各个组成部件进行比较,设计出各个部分的方案和其原理进行分析,再进行三维与运动仿真,对膜片弹簧进行有限元分析。根据重型汽车的使用条件和满载质量等参数的选择,按照汽车设计中离合器的设计步骤和要求,对离合器及组成部件进行设计与选择。

关键词:离合器;双片摩擦片;机械操纵;膜片弹簧;PORE;运动仿真

Abstract

In the whole car, the clutch takes up a little space, but plays an irreplaceable role in automotive transmission system. As an important component, the clutch will get very good development on function and structure. It can better realize dynamic transmission and cutoff during transferring engine’s dynamic and won’t make drive system overload when drive system endures large torque. The topic of this design is the design and simulation of heavy-duty vehicle dual disc clutch, and it chooses diaphragm spring because it is widely used in many vehicle models and has the advantages of big torque capacity, simple operation and good balance performance. It can be produced in large amount and improve production efficiency after designing a product, so it is significant for the research on diaphragm spring clutch. This graduation design specifically describes the structure and parameter’s selection and calculation of heavy-type car dual disc clutch in introduction.

Through compared with the clutch parameter selection of other car models, various clutch, and various components of the clutch, this paper fist designs schemes of various section and analyses their principles, and then carries out three-dimension and motion simulation, and finally carries out finite element analysis. According to the the parameter selections such as the usage condition and full quality of the heavy-type car, as well as the clutch’s design procedures and requirements in car design, design and choose the clutch and component.

Key Words:clutch; dual disc friction; machinery control; diaphragm spring;

PORE;Motion simulation

摘 要 I

Abstract IIIn the whole car, the clutch takes up a little space, but plays an irreplaceable role in automotive transmission system. As an important component, the clutch will get very good development on function and structure. It can better realize dynamic transmission and cutoff during transferring engine’s dynamic and won’t make drive system overload when drive system endures large torque. The topic of this design is the design and simulation of heavy-duty vehicle dual disc clutch, and it chooses diaphragm spring because it is widely used in many vehicle models and has the advantages of big torque capacity, simple operation and good balance performance. It can be produced in large amount and improve production efficiency after designing a product, so it is significant for the research on diaphragm spring clutch. This graduation design specifically describes the structure and parameter’s selection and calculation of heavy-type car dual disc clutch in introduction.

Through compared with the clutch parameter selection of other car models, various clutch, and various components of the clutch, this paper fist designs schemes of various section and analyses their principles, and then carries out three-dimension and motion simulation, and finally carries out finite element analysis. According to the the parameter selections such as the usage condition and full quality of the heavy-type car, as well as the clutch’s design procedures and requirements in car design, design and choose the clutch and component.

Key Words:clutch; dual disc friction; machinery control; diaphragm spring;

PORE;Motion simulation

摘 要 I

1绪论 1

1.1 离合器概述 1

1.2 汽车离合器的现状及发展 1

1.2.1 汽车离合器的现状 1

1.3 离合器设计要求 1

2 方案分析与选定 2

2.1 从动盘数的选择 2

2.2 压紧弹簧和布置形式的选择 3

2.3 膜片弹簧支承形式的选择 5

2.4 压盘的驱动方式 6

3 摩擦片参数设计 6

3.1 摩擦片参数设计基本原理 6

3.2 摩擦片参数设计计算 7

3.2.1 摩擦片摩擦因数f、摩擦面数面数Z和离合器间隙△t 7

3.2.2摩擦片外径D、内径d和厚度b的确定 8

3.2.3离合器后备系数β的确定 8

3.2.4离合器传递的最大静摩擦力矩TC 9

3.2.5 单位压力

3.3 离合器摩擦片基本参数的校核 9

3.3.1 最大圆周速度 9

3.3.2 单位摩擦面积传递转矩 10

3.3.3 单位压力

3.3.4 单位摩擦面积滑磨功 10

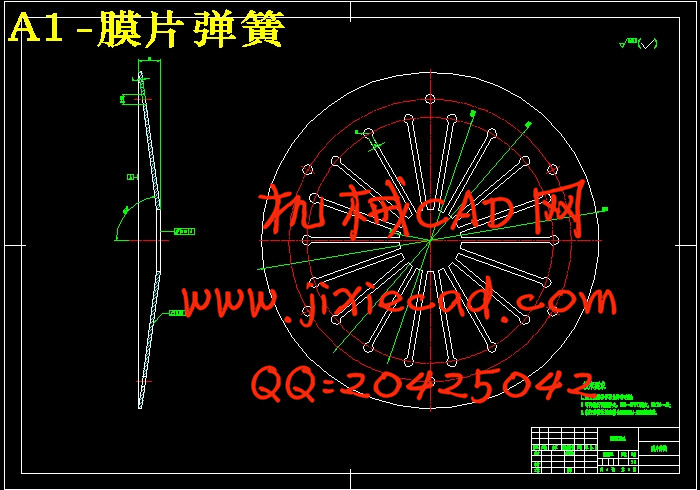

4 膜片弹簧设计 11

4.1 膜片弹簧主要参数的选择 11

4.1.1 H/h比值的选择 11

4.1.2 R及R/r的确定 12

4.1.3 膜片弹簧起始圆锥底角α 12

4.1.4 分离指数目n和切槽宽δ1、δ2以及半径re 12

4.1.5 支承圈平均半径r1和膜片弹簧与压盘的接触半径R1 12

4.2 绘制膜片弹簧的特性曲线 12

4.3 确定膜片弹簧的工作点位置 13

4.4 求离合器彻底分离时分离轴承作用的载荷F2 14

4.5 求分离轴承的行程λ2 14

4.6 膜片弹簧强度校核 15

4.7 膜片弹簧的材料及其制造工艺 15

5 其他主要部件的设计 16

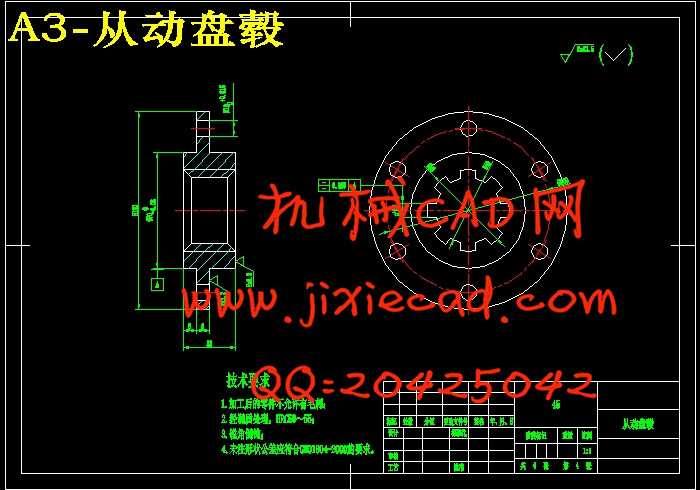

5.1 从动盘总成设计计算 16

5.1.1 从动片 16

5.2 压盘和离合器盖的设计 18

5.2.1 压盘几何尺寸的确定 18

5.2.2 离合器盖的设计 18

5.2.3 支承环 19

5.3 操纵系统的设计 19

5.3.1 对操纵机构的基本要求 19

5.3.2 踏板位置 19

5.3.3 踏板行程 19

6 三维建模 20

6.1 膜片弹簧的三维建模 20

6.2 从动盘的三维建模 22

6.3 从动盘毂三维建模 24

6.4 摩擦盘的三维建模 25

6.5 离合器壳的三维建模 27

6.6飞轮壳体的三维建模 29

6.7 分离套筒的三维建模 30

6.7飞轮的三维建模 31

6.8 离合器的装配建模 33

7 离合器的三维运动仿真 38

8 膜片弹簧有限元分析 39

9 技术经济性分析 43

结论 44

致 谢 45

参考文献 46