设计简介

摘 要

本设计涉及一种切割装置,尤其涉及废纸回收设备中的一种切纸机。由于我国废纸回收质量远低与发达国家的水平,因此我国废纸回收率仅达到37.19% , 仍低于47.17%的世界平均水平和发达国家70% 左右的水平。废纸中的杂质特别是书刊装订处的胶粘物、金属物,不但对产品内在质量、外观质量有决定性影响,而且给生产过程造成无穷的后患。

为提高回收废纸的质量,对书刊装订处的胶粘物、金属物进行处理,本次论文主要针对书背处的书胶进行切割的设计。切纸机主要由支撑台架、传动机构、夹紧传动机构、切割系统组成。传动机构采取圆盘转动带动书本转动,夹紧机构用了六个夹紧模块进行夹紧,切割系统使用了锯齿进行切割,效率快。

通过此次设计,我们成功的设计出了书本切胶机,大大提高了废纸回收厂的工作效率,解放了更多的劳动力,对社会发展有重要意义。

关键词:切纸机;废纸回收;书胶;夹紧;切割;

ABSTRACT

The utility model relates to a cutting device, in particular to a paper cutter in waste paper recovery equipment. As the quality of waste paper recycling in our country is far lower than that of developed countries, the rate of waste paper recovery in China has reached only 37.19%, still lower than the world average level of 47.17% and about 70% in developed countries. Impurities in waste paper, especially the stickies and metals in the binding place of books and periodicals, not only have a decisive influence on the quality and appearance of the products, but also cause endless trouble for the production process.

In order to improve the quality of recycled paper, stickies, the metal of the bookbinding processing, this paper mainly in the back office, book glue cutting design. Paper cutting machine is mainly composed of support platform, transmission mechanism, clamping transmission mechanism, cutting system. The driving mechanism adopts the disk rotation to drive the books to rotate, and the clamping mechanism is clamped by a clamping module, and the cutting system adopts a saw tooth for cutting, and the efficiency is fast.

Through this design, we have successfully designed a book cutting machine, which greatly improves the efficiency of the waste paper recycling plant and liberates more labor force. It is of great significance to social development.

Key words: paper cutting machine; waste paper recycling; book glue; clamping; cutting;

目录

摘 要 I

ABSTRACT II

1 绪论 1

1.1本设计的研究意义 1

1.2目前国内外状况 1

1.3 本论文主要完成内容 2

2 总体方案的设计及选定 3

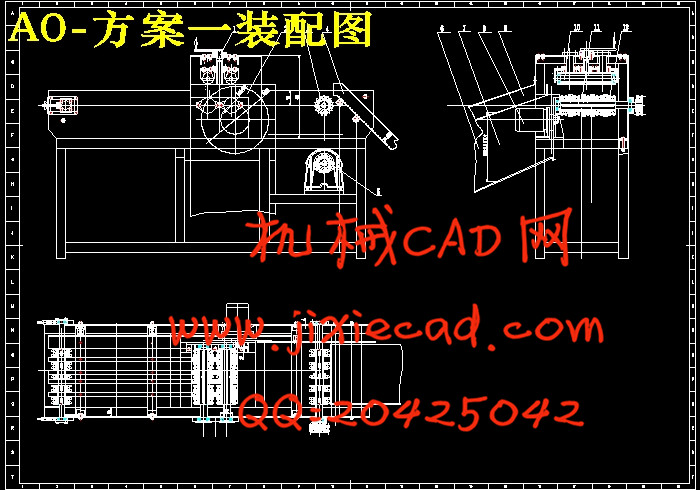

2.1方案一 3

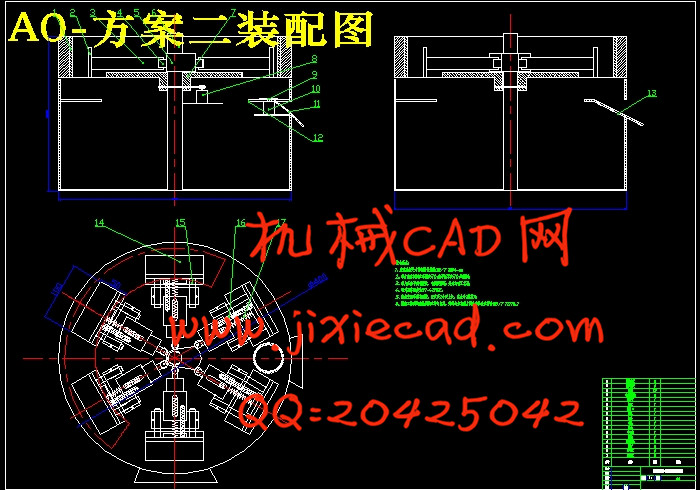

2.2方案二 6

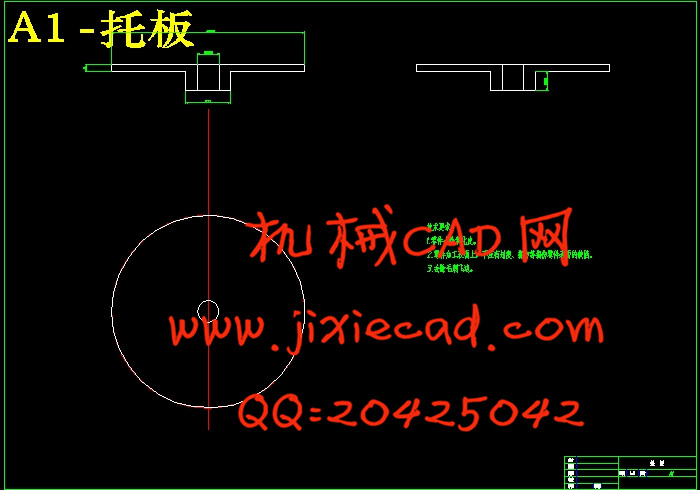

2.3最终方案的确定 8

3 机构主要部分的计算 9

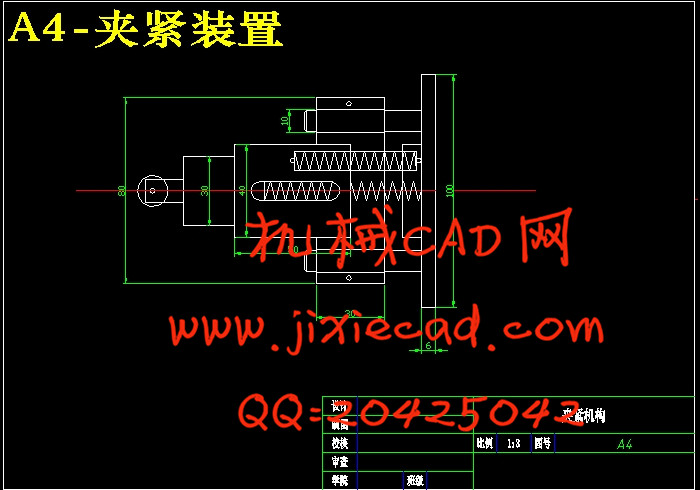

3.1夹紧力的计算 9

3.2电机、转盘转速、切割效率的计算 12

4 机构主要部分的设计原理 13

4.1夹紧设计的原理 13

4.2切胶装置的设计 14

4.3凸轮的设计 15

5 总结与展望 19

参考文献 20

致谢 21