设计简介

摘要

起重机械是一种循环、间歇运动的机械。常用于物品的装卸。经过这些年得发展,桥式起重机在现代生产活动中已一个不可取代的地位。随着时代的进步,起重机的自动化程度也逐步提高,从原始的用人和牲畜控制到了现代的机器控制。因此工厂对起重机的要求也是逐渐提高。起重机正面临着一场改革变化。

起重机一般指既有起升机构又有水平运动机构的起重设施,这些机构均是起重机基本的机械结构。我们一般根据其不同的水平运动形式,将起重机分为桥式起重机和臂架式旋转起重机。本次设计中我选用的是桥式起重机。

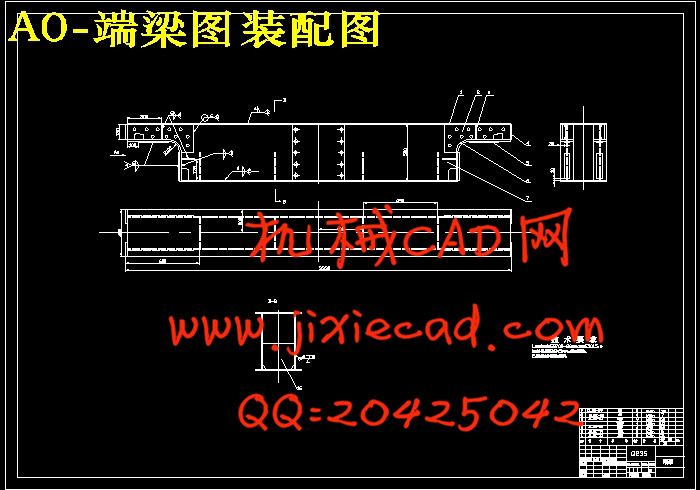

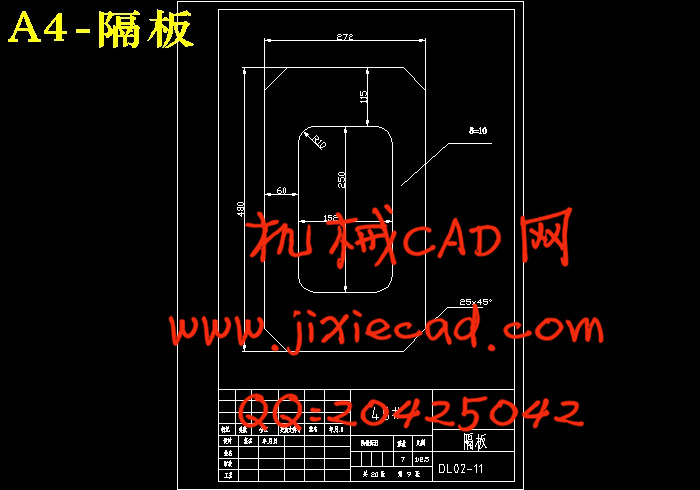

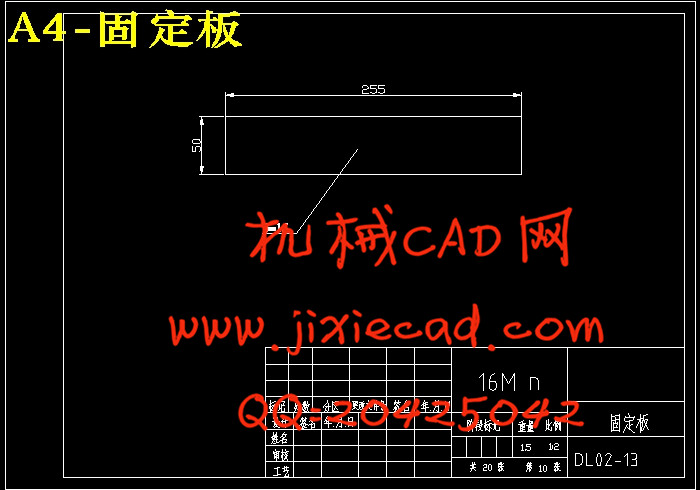

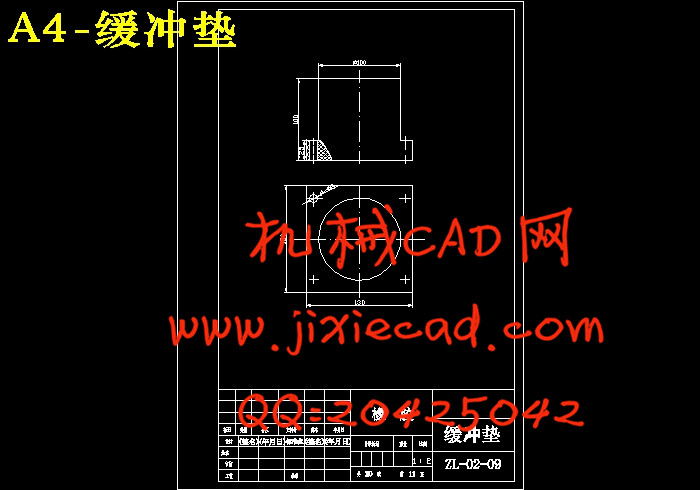

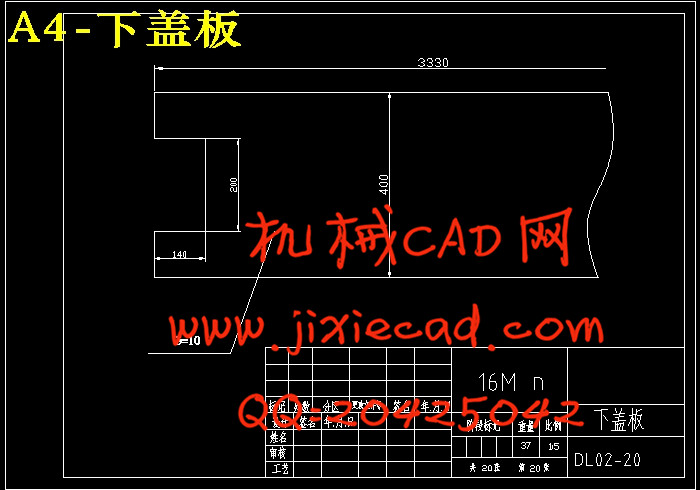

根据设计要求,本次设计主要是一个满足5T承载量的钢体结构,主要设计计算端梁、主梁的尺寸,并对其进行校核,端梁与主梁之间采用法兰式螺栓连接,并对缓冲器进行了选择和校核。文章后面还对焊接工艺进行了选择和分析。最终完善CAD工程图以及三维图,使其在实际生产操作中能够准确稳定的完成各项工作,提高生产效率,并成功投入到市场。

关键词:单梁桥式起重机;主梁;端梁;法兰连接;

起重机械是一种循环、间歇运动的机械。常用于物品的装卸。经过这些年得发展,桥式起重机在现代生产活动中已一个不可取代的地位。随着时代的进步,起重机的自动化程度也逐步提高,从原始的用人和牲畜控制到了现代的机器控制。因此工厂对起重机的要求也是逐渐提高。起重机正面临着一场改革变化。

起重机一般指既有起升机构又有水平运动机构的起重设施,这些机构均是起重机基本的机械结构。我们一般根据其不同的水平运动形式,将起重机分为桥式起重机和臂架式旋转起重机。本次设计中我选用的是桥式起重机。

根据设计要求,本次设计主要是一个满足5T承载量的钢体结构,主要设计计算端梁、主梁的尺寸,并对其进行校核,端梁与主梁之间采用法兰式螺栓连接,并对缓冲器进行了选择和校核。文章后面还对焊接工艺进行了选择和分析。最终完善CAD工程图以及三维图,使其在实际生产操作中能够准确稳定的完成各项工作,提高生产效率,并成功投入到市场。

关键词:单梁桥式起重机;主梁;端梁;法兰连接;

ABSTRACT

Lifting machinery is a circulating, intermittent movement of machinery. Commonly used in the loading and unloading of items. After these years of development, bridge cranes have an irreplaceable position in modern production activities. With the progress in these years, the degree of automation of the crane has been gradually improved, from the original employment and livestock control to the modern machine control. So the factory requirements for the crane is gradually increased. The crane is facing a reform and change.

Cranes generally refer to hoisting facilities with both lifting and horizontal movements, which are the basic mechanical structures of the crane. We generally divide cranes into bridge cranes and boom-type rotary cranes according to their different levels of movement.

According to the design requirement, This design mainly for a steel structure satisfy 5T load, and determine the size of crane girder and main beam. The size also need to be check and calculate. Bolt connection is used between girder and main beam. And I also choose the buffer, calculate and check whether it meet the design requirements. Finally, the welding process is designed and analyzed. CAD drawing and the graphic being finished, make it accurate and stable in actual production operations to complete the work, improve productivity, and finally being successfully brought on to the market.

Keywords: Single bridge crane;main beam; end beam; flanged coupling

Lifting machinery is a circulating, intermittent movement of machinery. Commonly used in the loading and unloading of items. After these years of development, bridge cranes have an irreplaceable position in modern production activities. With the progress in these years, the degree of automation of the crane has been gradually improved, from the original employment and livestock control to the modern machine control. So the factory requirements for the crane is gradually increased. The crane is facing a reform and change.

Cranes generally refer to hoisting facilities with both lifting and horizontal movements, which are the basic mechanical structures of the crane. We generally divide cranes into bridge cranes and boom-type rotary cranes according to their different levels of movement.

According to the design requirement, This design mainly for a steel structure satisfy 5T load, and determine the size of crane girder and main beam. The size also need to be check and calculate. Bolt connection is used between girder and main beam. And I also choose the buffer, calculate and check whether it meet the design requirements. Finally, the welding process is designed and analyzed. CAD drawing and the graphic being finished, make it accurate and stable in actual production operations to complete the work, improve productivity, and finally being successfully brought on to the market.

Keywords: Single bridge crane;main beam; end beam; flanged coupling

目 录

摘 要 I

ABSTRACT II

1 绪论 1

2 箱形结构主梁和端梁的设计 3

2.1 箱形梁式桥架的主要尺寸确定 3

2.2 主梁主要尺寸的确定 5

2.3 端梁截面尺寸的确定 6

3 主梁和端梁的校核 7

3.1 主梁强度计算 7

3.2 主梁强度的校验 10

3.3 刚度计算 12

3.4 主梁的稳定性计算 12

3.5 端梁强度计算 13

3.6 端梁强度校核 14

4 主要焊缝的计算 17

4.1 主梁翼缘焊缝计算 17

4.2 主梁上盖板焊缝 17

4.3 端梁的焊缝计算 17

4.3 主梁、端梁连接焊缝计算 18

4.4 角焊缝强度计算 18

5 主梁与端梁连接计算 19

5.1 法兰板连接焊缝计算 20

5.2 法兰连接螺栓的计算 21

6 起重机的机构工作级别和钢丝绳选择 23

6.1 机构利用等级、 23

6.2 机构载荷状态 23

6.3 机构工作级别 23

6.4 钢丝绳的选用 23

6.5 钢丝绳直径的计算 23

7 起重机小车的设计 25

7.1 起重小车轨道的选择 25

7.2 起重机小车轨道的尺寸校核 25

8 焊接工艺设计 28

8.1 焊接 28

9 缓冲器 32

结 论 35

参考文献 36