设计简介

摘要

随着我国经济的快速发展还有人们的生活水平的进步,更多的产业实现了用机械化作业代替了劳动力,如工业、农业、商业等,工业上最突出的是各种重工业大型器械的产生,农业上最突出的是各种小型农作物机器的产生,像插秧机、刨地机、耕耘机等,商业上最突出的就是各种智能化的机械的产生。如今我国国家主席习近平先生,提倡绿色环保是发展观的一场深刻革命,各级政府对节能减排目标的要求和节能环保型社会的建设,各国也在竞相发展环保型温室管理机。

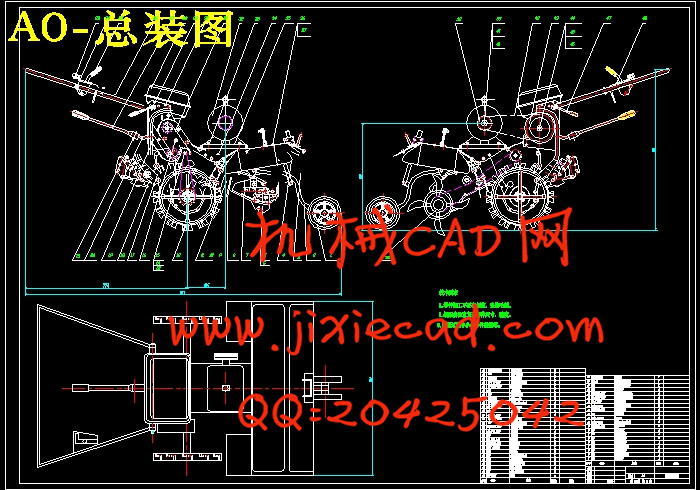

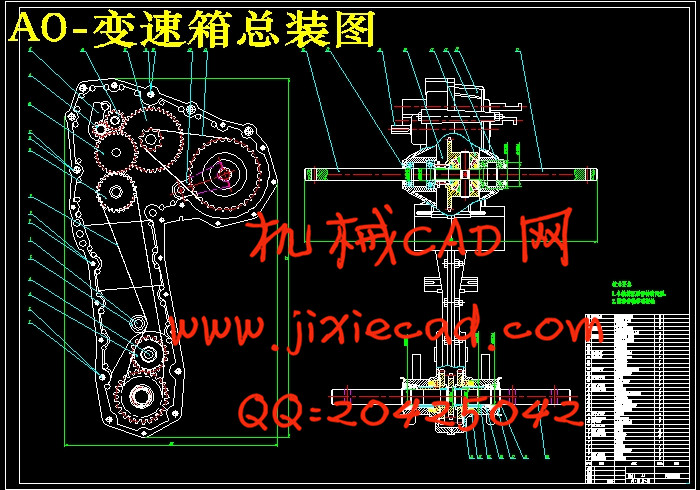

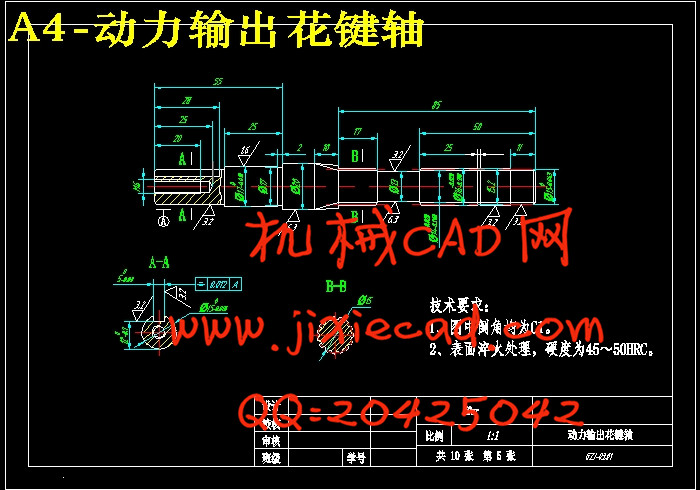

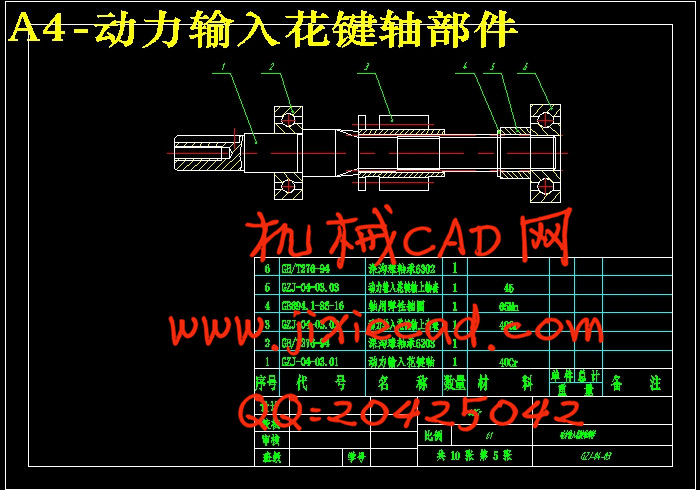

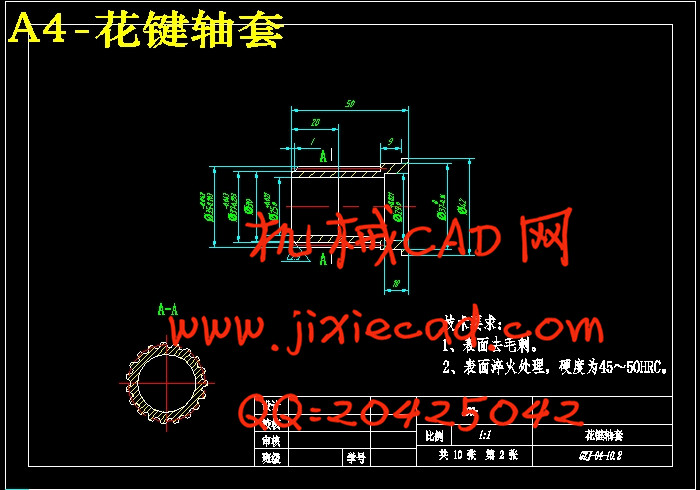

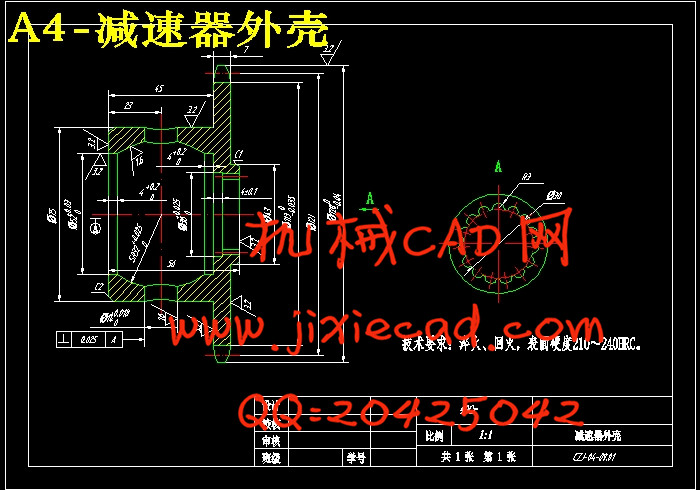

整机由动力源、控制部分、传动部分、执行部分、控制部分组成,控制部分又由右把手控制机构,显示器等、电源主要为蓄电池提供。蓄电池电压为 220v,传动部分由联轴器,减速器组成,通过转换控制器控制电动机输入电流大小控制机具前进速度和作业速度。

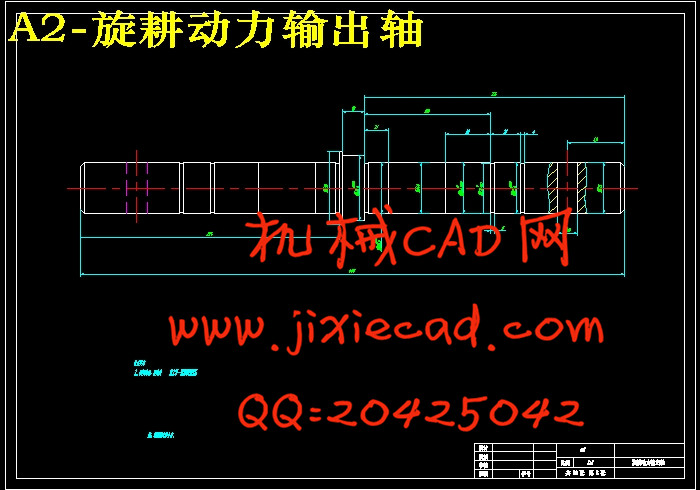

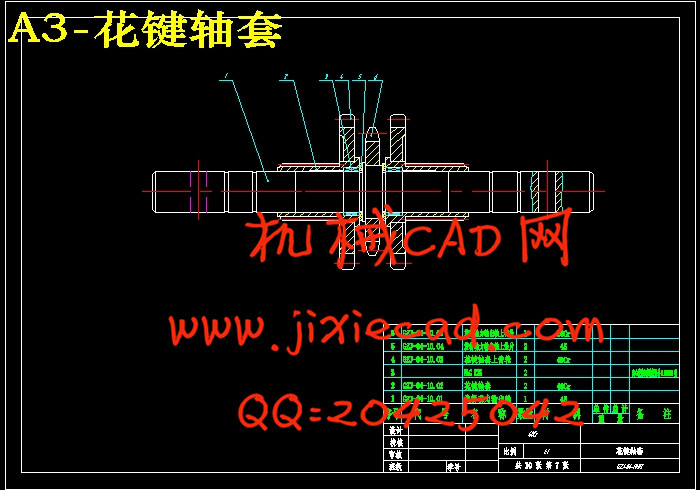

在对整机和关键部件的设计中,在老师指导下我做到了尽量减小机具的外形尺寸和重量,为使整个机具操作方便灵活;温室内的土质因为环境的原因,如过于湿润使土质韧性变差,导致在机器碎土时效率降低,通过相应的实验研究,旋耕机刀片的转速及其排列会与碎土的效率有一定的相关性,我们根据实验得出的结论对机器结构作出相应的改进以达到提高碎土效率的目的,因此,本课题的研究将把我省温室管理机提高到一个新水平上。

关键词 温室;电动;管理机;旋耕

随着我国经济的快速发展还有人们的生活水平的进步,更多的产业实现了用机械化作业代替了劳动力,如工业、农业、商业等,工业上最突出的是各种重工业大型器械的产生,农业上最突出的是各种小型农作物机器的产生,像插秧机、刨地机、耕耘机等,商业上最突出的就是各种智能化的机械的产生。如今我国国家主席习近平先生,提倡绿色环保是发展观的一场深刻革命,各级政府对节能减排目标的要求和节能环保型社会的建设,各国也在竞相发展环保型温室管理机。

整机由动力源、控制部分、传动部分、执行部分、控制部分组成,控制部分又由右把手控制机构,显示器等、电源主要为蓄电池提供。蓄电池电压为 220v,传动部分由联轴器,减速器组成,通过转换控制器控制电动机输入电流大小控制机具前进速度和作业速度。

在对整机和关键部件的设计中,在老师指导下我做到了尽量减小机具的外形尺寸和重量,为使整个机具操作方便灵活;温室内的土质因为环境的原因,如过于湿润使土质韧性变差,导致在机器碎土时效率降低,通过相应的实验研究,旋耕机刀片的转速及其排列会与碎土的效率有一定的相关性,我们根据实验得出的结论对机器结构作出相应的改进以达到提高碎土效率的目的,因此,本课题的研究将把我省温室管理机提高到一个新水平上。

关键词 温室;电动;管理机;旋耕

Abstract

Along with our country's economic development but also the improvement of people's living standard, more and more industries realize the mechanical operation instead of the labor force, such as industrial agricultural business, industry the most prominent is the production of large equipment, all kinds of heavy industry is the most prominent agricultural production of all kinds of small agricultural machinery, such as rice transplanter cultivator digging machine, etc., the most prominent in business is all kinds of intelligent machines Now Mr President xi jinping in China insist on green development is the development of a profound revolution, governments at all levels of the requirements of energy conservation and emissions reduction targets and the construction of energy efficient and environmentally friendly society, so the development of energy efficient and environmentally friendly electric greenhouse management machine in the future market demand has a good development trend.

Travel mechanism combined with limited depth wheel rotary tillage resistance reducer fenders battery rack moving round rod tension wheel right hand lever motor control agencies voltage power display the machine USES 220 v motor as power source, through the coupling gear reducer pass power to rotary cultivator, by transforming the controller to control the motor input current size control machine speed and operating speed.

In the design of the whole machine and key parts, I have made it possible to minimize the shape and weight of the machine tool under the guidance of the teacher, so as to make the whole machine operation convenient and flexible. In the greenhouse soil moisture content is high, the machine broken soil properties, energy consumption increases, we on the structure of rotary tillage blade arrangement speed size was studied, using computer simulation technology, through the finite element analysis, optimized design of rotary tillage parts, improve the machine in the moisture content in the soil with high operation performance Therefore, this topic research will increase the greenhouse management machine in our province to a new level.

Keywords greenhouse electrical management machinery rotary

Along with our country's economic development but also the improvement of people's living standard, more and more industries realize the mechanical operation instead of the labor force, such as industrial agricultural business, industry the most prominent is the production of large equipment, all kinds of heavy industry is the most prominent agricultural production of all kinds of small agricultural machinery, such as rice transplanter cultivator digging machine, etc., the most prominent in business is all kinds of intelligent machines Now Mr President xi jinping in China insist on green development is the development of a profound revolution, governments at all levels of the requirements of energy conservation and emissions reduction targets and the construction of energy efficient and environmentally friendly society, so the development of energy efficient and environmentally friendly electric greenhouse management machine in the future market demand has a good development trend.

Travel mechanism combined with limited depth wheel rotary tillage resistance reducer fenders battery rack moving round rod tension wheel right hand lever motor control agencies voltage power display the machine USES 220 v motor as power source, through the coupling gear reducer pass power to rotary cultivator, by transforming the controller to control the motor input current size control machine speed and operating speed.

In the design of the whole machine and key parts, I have made it possible to minimize the shape and weight of the machine tool under the guidance of the teacher, so as to make the whole machine operation convenient and flexible. In the greenhouse soil moisture content is high, the machine broken soil properties, energy consumption increases, we on the structure of rotary tillage blade arrangement speed size was studied, using computer simulation technology, through the finite element analysis, optimized design of rotary tillage parts, improve the machine in the moisture content in the soil with high operation performance Therefore, this topic research will increase the greenhouse management machine in our province to a new level.

Keywords greenhouse electrical management machinery rotary

| 目 | 录 |

| 摘要 .................................................................................................................................................. | I |

| Abstract .......................................................................................................................................... | II |

| 1 绪论 ............................................................................................................................................. | 1 |

| 2 温室电动管理机的总体设计 ..................................................................................................... | 4 |

| 3 温室电动管理机零件及参数计算选择 ..................................................................................... | 7 |

| 4 温室电动管理机传动系统的设计 ........................................................................................... | 11 |

| 4.2.1 轴类的转动速度 .......................................................................................................... | 11 |

| 结论 ............................................................................................................................................... | 26 |

| 致谢 ............................................................................................................................................... | 27 |

| 参考文献 | ....................................................................................................................................... | 28 |