设计简介

后制动板三大孔粗精镗机床总体设计及电气控制部分设计

摘要:本课题来源于江苏高精机电装备公司,课题基于PLC可编程逻辑控制技术,进行了后制动板粗精镗机床总体设计及电气控制部分设计,实现了对传统继电器-接触器控制技术改造。该机床是可用于孔粗、精镗加工的双面卧式双工位结构专用机床,能实现调整、循环两种工作方式。课题首先对现代可编程控制技术的应用、发展趋势作了简单的介绍,然后根据机床的基本技术要求对机床进行电气总体分布设计,接下来根据机床的操作需要对机床的操作面板进行按钮布置,并根据该机床的电气控制原理对该机床电气控制部分的主电路和控制电路进行设计。最后,详细介绍了PLC技术和三菱FX2N型PLC,同时根据需要使用了40个输入接点和30个输出接点,并使用三菱PLC编程软件对机床的夹具、滑台以及主轴的调整和循环动作进行PLC编程。将PLC技术应用于后制动板镗床组合机床,使该机床实现了除装卸工件以外的全部自动循环过程,避免了过去由于大量使用继电器带来的种种麻烦,改善并提高了控制性能,提高了生产效率,降低了生产成本。

关键词:后制动板;粗精镗;机床;电气控制;PLC

Three holes of the brake plate coarse boring machine part of the overall design and design of electrical control

字典

Abstract: This topic comes from high-precision mechanical and electrical equipment company in Jiangsu, which is subject-based PLC programmable logic control technology were boring after the braking plate coarse overall design of machine tools and electrical control design, implementation of the traditional relay - contactor control transformation . The machine can be used for hole coarse and fine processing of double-sided horizontal boring duplex structure special purpose machine, which can achieve the adjustment of the two work cycles. This topic first simply introduced the modern programmable control technology application and the development tendency,then designs the machine of electrical overall distribution by basic specification of the machine, thereupon arranges the operation kneading board buttons of the machine by operation need of the machine, and designs electrical control section main circuit and control circuit of the machine by electrical control principle of the machine. At last it in detail introduced the PLC technology and the PLC of FX2N of Mitsubishi, and distributed the 40 input contact points and 30 output contact points to compilation the PLC of Mitsubishi procedure of the movement of adjustment and entire machine circulation main axle, movement of platform and jig. The PLC technology will be applied to the rear brake plate boring machine tool, so that the machine achieved all the other parts except automatic loading and unloading cycle, avoiding the trouble of using a lot of relay in the past, improving and enhancing the control performance, enhancing the production efficiency and reducing the production cost.

Key words: Rear brake plate; Coarse and fine boring; Machine; Electrical control; PLC

目 录

1 前言 1

1.1 课题的来源 1

1.2 国内外现状及发展趋势 2

1.3 设计的思路及解决的主要问题 3

2 机床总体设计......................................................... 4

2.1 工艺方案的拟订 4

2.2 确定切削用量 5

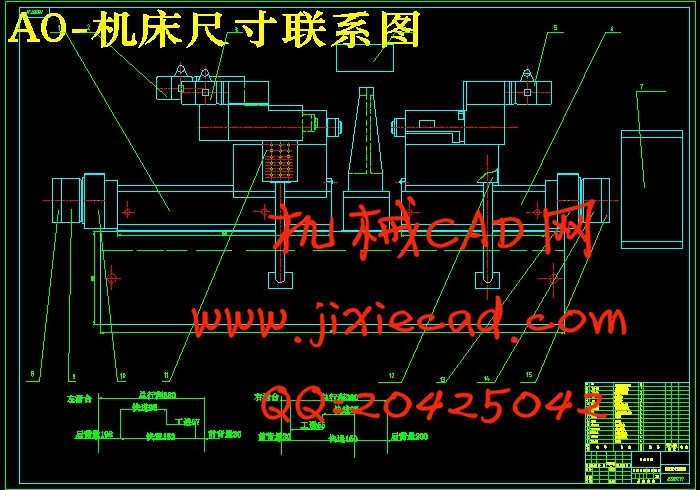

2.3 机床尺寸联系总图的确定 7

3 机床的电气控制部分设计 10

3.1 机床的控制要求 10

3.2 机床控制方案的确定 11

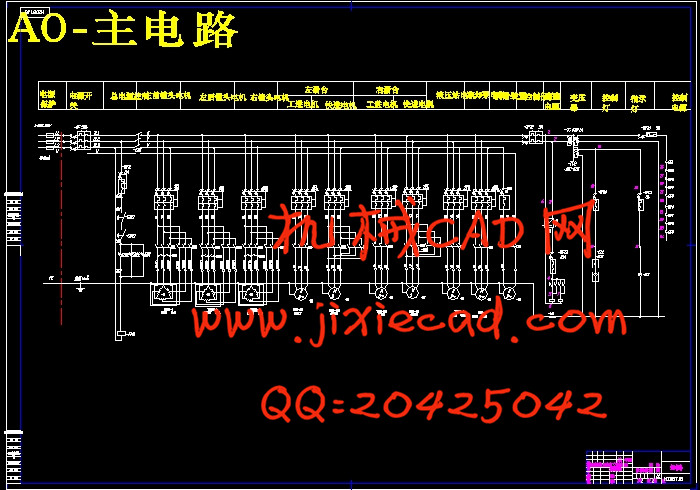

3.3 机床主电路的设计 12

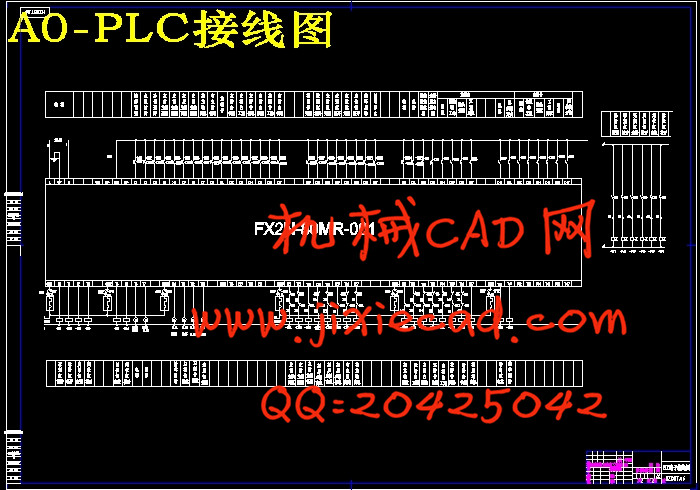

3.4 PLC控制部分硬件的设计 13

3.5 PLC控制部分软件的设计 18

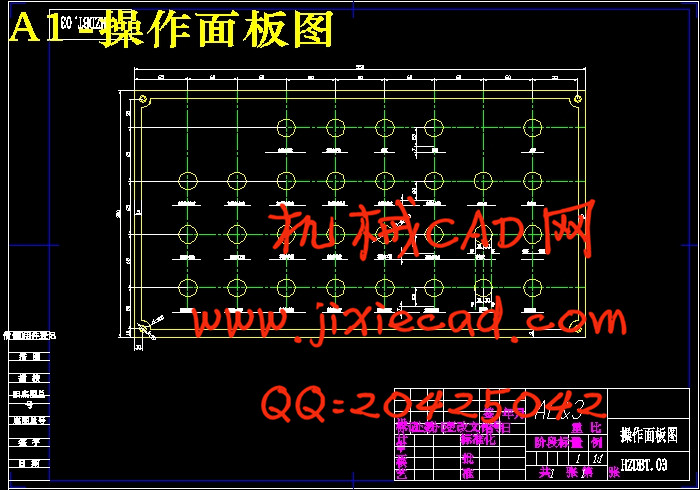

3.6 操作面板的设计 20

4 结论 21

参考文献 22

致谢 23

附录 24

摘要:本课题来源于江苏高精机电装备公司,课题基于PLC可编程逻辑控制技术,进行了后制动板粗精镗机床总体设计及电气控制部分设计,实现了对传统继电器-接触器控制技术改造。该机床是可用于孔粗、精镗加工的双面卧式双工位结构专用机床,能实现调整、循环两种工作方式。课题首先对现代可编程控制技术的应用、发展趋势作了简单的介绍,然后根据机床的基本技术要求对机床进行电气总体分布设计,接下来根据机床的操作需要对机床的操作面板进行按钮布置,并根据该机床的电气控制原理对该机床电气控制部分的主电路和控制电路进行设计。最后,详细介绍了PLC技术和三菱FX2N型PLC,同时根据需要使用了40个输入接点和30个输出接点,并使用三菱PLC编程软件对机床的夹具、滑台以及主轴的调整和循环动作进行PLC编程。将PLC技术应用于后制动板镗床组合机床,使该机床实现了除装卸工件以外的全部自动循环过程,避免了过去由于大量使用继电器带来的种种麻烦,改善并提高了控制性能,提高了生产效率,降低了生产成本。

关键词:后制动板;粗精镗;机床;电气控制;PLC

Three holes of the brake plate coarse boring machine part of the overall design and design of electrical control

字典

Abstract: This topic comes from high-precision mechanical and electrical equipment company in Jiangsu, which is subject-based PLC programmable logic control technology were boring after the braking plate coarse overall design of machine tools and electrical control design, implementation of the traditional relay - contactor control transformation . The machine can be used for hole coarse and fine processing of double-sided horizontal boring duplex structure special purpose machine, which can achieve the adjustment of the two work cycles. This topic first simply introduced the modern programmable control technology application and the development tendency,then designs the machine of electrical overall distribution by basic specification of the machine, thereupon arranges the operation kneading board buttons of the machine by operation need of the machine, and designs electrical control section main circuit and control circuit of the machine by electrical control principle of the machine. At last it in detail introduced the PLC technology and the PLC of FX2N of Mitsubishi, and distributed the 40 input contact points and 30 output contact points to compilation the PLC of Mitsubishi procedure of the movement of adjustment and entire machine circulation main axle, movement of platform and jig. The PLC technology will be applied to the rear brake plate boring machine tool, so that the machine achieved all the other parts except automatic loading and unloading cycle, avoiding the trouble of using a lot of relay in the past, improving and enhancing the control performance, enhancing the production efficiency and reducing the production cost.

Key words: Rear brake plate; Coarse and fine boring; Machine; Electrical control; PLC

目 录

1 前言 1

1.1 课题的来源 1

1.2 国内外现状及发展趋势 2

1.3 设计的思路及解决的主要问题 3

2 机床总体设计......................................................... 4

2.1 工艺方案的拟订 4

2.2 确定切削用量 5

2.3 机床尺寸联系总图的确定 7

3 机床的电气控制部分设计 10

3.1 机床的控制要求 10

3.2 机床控制方案的确定 11

3.3 机床主电路的设计 12

3.4 PLC控制部分硬件的设计 13

3.5 PLC控制部分软件的设计 18

3.6 操作面板的设计 20

4 结论 21

参考文献 22

致谢 23

附录 24