设计简介

摘 要

打桩机作为机械设备广泛使用于建筑施工,码头,道路等桩基础施工的场景下。柴油打桩机凭借着其自身结构简单,成桩质量高,操作简单,工作效率高而被当今广泛使用。因此研究并设计柴油打桩机对社会基础设施建设有着积极的意义。

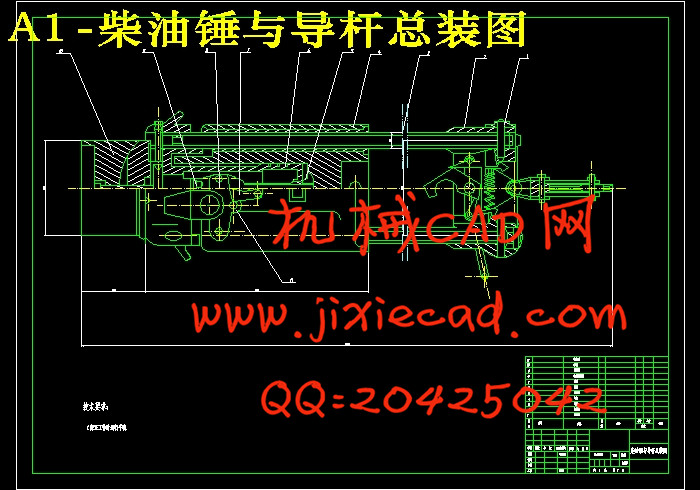

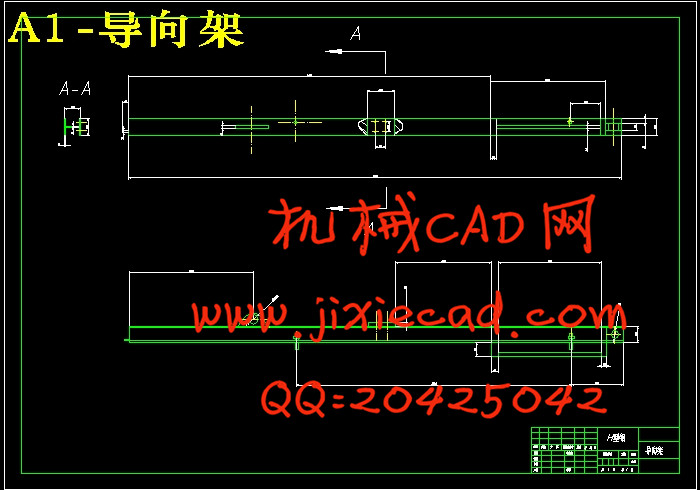

本题目以研究并设计工况为野外施工的柴油打桩机为主要任务。主要研究打桩机的总体设计与柴油锤和导向架设计以及主要零件的设计与计算。在此之间对导向架的材料选用,导向架具体结构布置,油管布置,液压马达,钢丝绳滚筒的安装形式进行了设计。根据在运输和作业时的两个极限位置确立了最终的导向架支撑液压缸的布置位置。最后根据柴油导杆式打桩机在实际施工中的的工作特性与特点设计了与其工作配套的液压系统与电气控制系统,并对系统使用的液压元器件进行了选择。

关键词:打桩机;柴油锤;液压控制系统

ABSTRACT

guide frame, the specific arrangement of the guide frame, the arrangement of the tubing, the installation of the hydraulic motor and the wire rope drum are carried out. The position of the final guide frame support hydraulic cylinder is established according to the two extreme positions during transport and operation. Finally, according to the working characteristics and characteristics of the diesel pole type piling machine in the actual construction, the hydraulic system and the electrical control system are designed, and the hydraulic components used in the system are selected.

Key words: pile driver; diesel hammer; hydraulic control system

目录

打桩机作为机械设备广泛使用于建筑施工,码头,道路等桩基础施工的场景下。柴油打桩机凭借着其自身结构简单,成桩质量高,操作简单,工作效率高而被当今广泛使用。因此研究并设计柴油打桩机对社会基础设施建设有着积极的意义。

本题目以研究并设计工况为野外施工的柴油打桩机为主要任务。主要研究打桩机的总体设计与柴油锤和导向架设计以及主要零件的设计与计算。在此之间对导向架的材料选用,导向架具体结构布置,油管布置,液压马达,钢丝绳滚筒的安装形式进行了设计。根据在运输和作业时的两个极限位置确立了最终的导向架支撑液压缸的布置位置。最后根据柴油导杆式打桩机在实际施工中的的工作特性与特点设计了与其工作配套的液压系统与电气控制系统,并对系统使用的液压元器件进行了选择。

关键词:打桩机;柴油锤;液压控制系统

ABSTRACT

| Piling machine as a mechanical equipment widely used in construction, | terminals, | roads | ||||

| and other pile foundation | construction under the scene. Diesel piling | machine | by virtue | of its | ||

| own simple structure, | pile | of high quality, simple operation, | high efficiency and is widely | |||

| used today. Therefore, | the study and design of diesel piling | machine | on the social | |||

| infrastructure construction | has a positive meaning. | |||||

| This topic to study and design conditions for the construction of diesel piling machine as | ||||||

| the main task. The main design of the pile driver and diesel hammer | and guide frame design | |||||

| and design and calculation of the main parts. In this way, the design | of the material of the | |||||

guide frame, the specific arrangement of the guide frame, the arrangement of the tubing, the installation of the hydraulic motor and the wire rope drum are carried out. The position of the final guide frame support hydraulic cylinder is established according to the two extreme positions during transport and operation. Finally, according to the working characteristics and characteristics of the diesel pole type piling machine in the actual construction, the hydraulic system and the electrical control system are designed, and the hydraulic components used in the system are selected.

Key words: pile driver; diesel hammer; hydraulic control system

目录

摘 要 I

ABSTRACT II

1.绪论 1

1.1 工作的理论意义和应用价值 1

1.2 打桩机的种类与特点 1

1.3 导杆式柴油打桩机的沉桩规格与其他设计要求 2

1.4 总体设计思路 2

2.总体方案设计 3

2.1 执行元件总体设计 3

2.2 车体布局 3

2.3 车身货箱长度的确定以及车辆型号的选用 4

3.柴油锤设计 4

3.1 柴油打桩锤锤体重量设计 4

3.2 桩帽设计 5

3.3 柴油锤其他尺寸设计 6

4.导向架设计 6

4.1 导向架材料选取 6

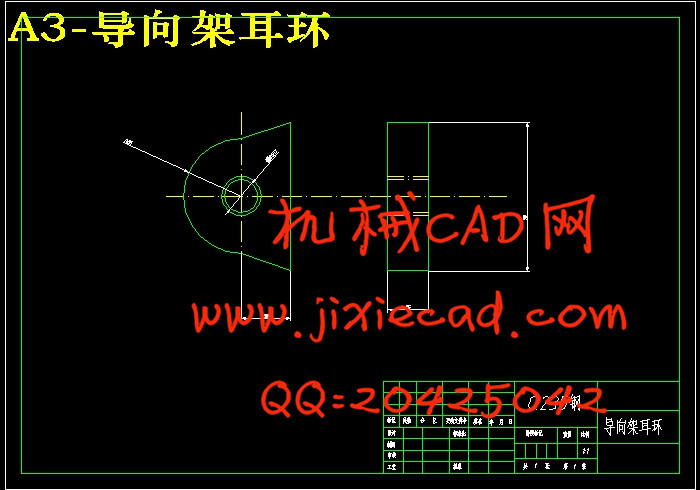

4.2 其余部件设计 7

5.液压缸位置及行程设计 8

5.1 导向架支撑液压缸设计 8

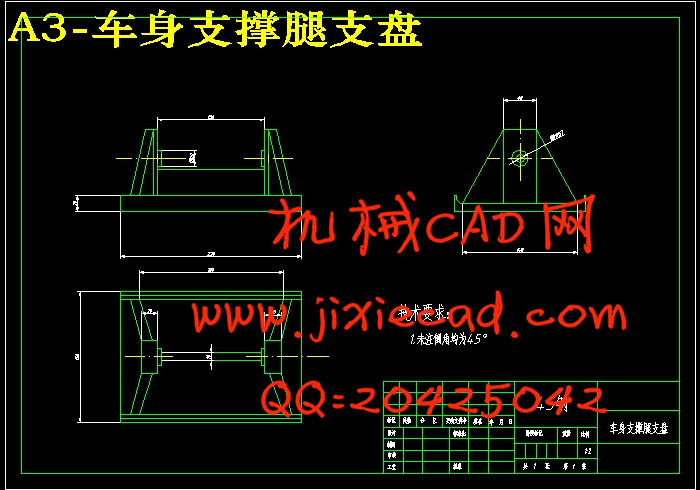

5.2 车身支撑液压缸,扶桩机构液压缸与液压马达的设计 10

5.3 缸体材料选用及技术要求 10

5.4 缸体端部连接方式与活塞杆端部结构 10

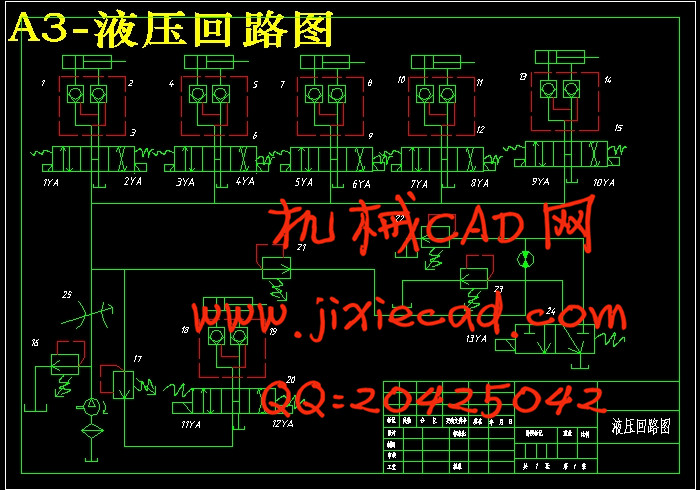

6.液压系统设计 11

6.1 初选系统工作压力 11

6.2 液压缸主要结构尺寸 11

6.3 液压缸动作顺序 13

6.4 液压系统回路设计 13

6.5 液压元件的选用 14

7.电气系统设计 17

7.1 控制系统的选用 17

7.2 PLC 程序设计 18

8.导向架弯曲强度校核 21

结论 23

参考文献 24

致谢 25