设计简介

摘 要

目前压缩机外壳切边和送料基本上是分开加工的,工人劳动强度高而且生产效率低下;随着全球气候不断变暖的趋向和人类社会物质生活水平的持续提高对空调系统进行降温的需求越来越高,然而空调的压缩机外壳的制造技术并没有显著的提高从而导致压缩机加工的生产效率十分低下。

论文研究的主要内容如下:

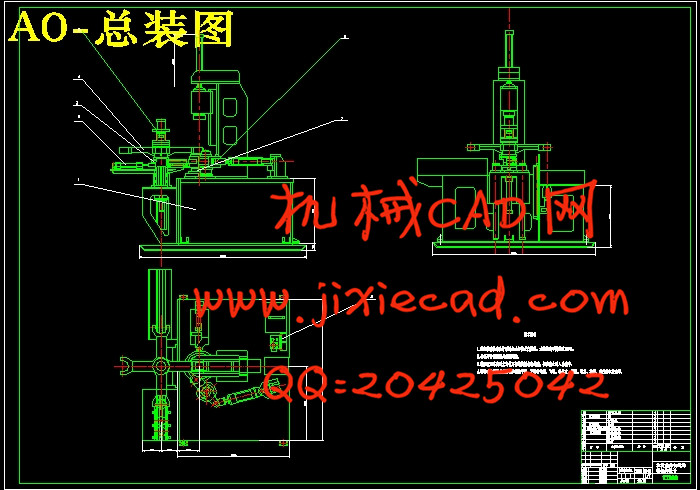

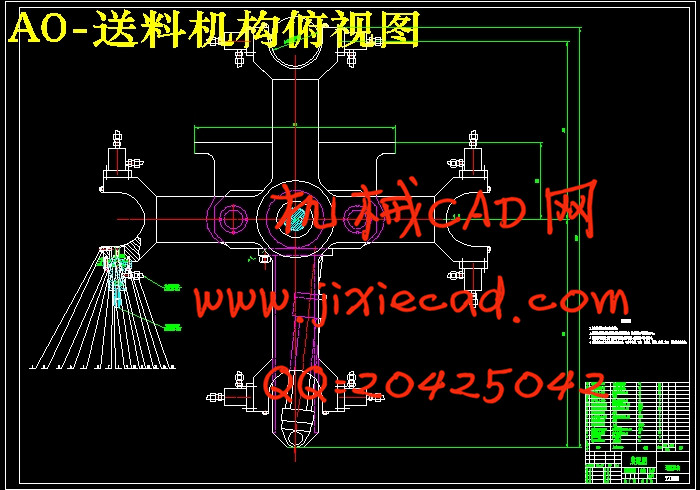

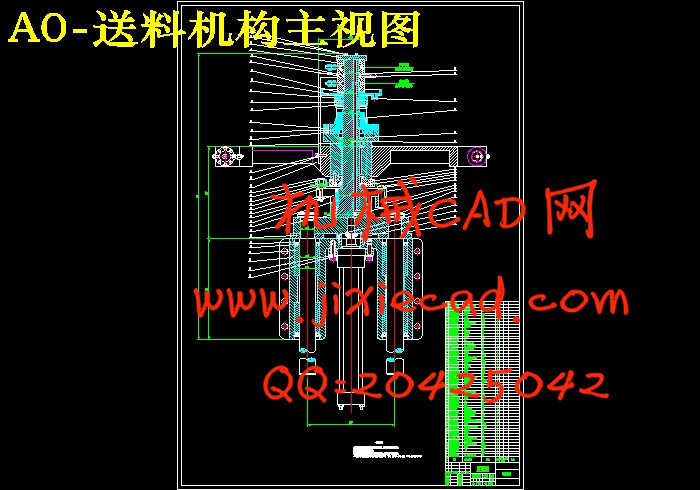

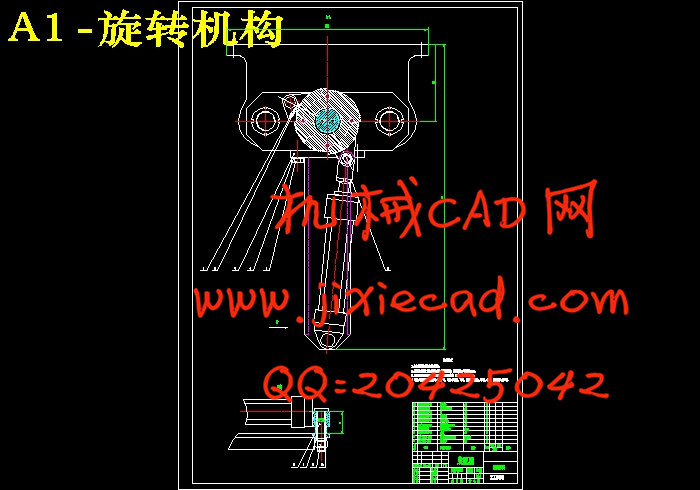

对切边送料机构的整体设计方案进行细致的研究,主要研究了在满足自动化要求前提下,机构运动原理及整体结构;通过基本的被输送零件壳体的外形分析,故本设计采用四转臂回转循环送料,四转臂采用可更换设计方便输送不同尺寸的零件,根据具体的被输送零件切换四转臂的尺寸大小,并对其运动状态进行分析。

运用 SolidWorks 软件对整体结构设计进行了三维仿真设计和模拟装配,并解决装配过程中可能遇到的问题并进行改进。

本设计方案对其他机械零件的切边送料机构的设计具有一定的参考应用价值。

关键词:送料;切边;机构设计;四转臂;液压缸

目前压缩机外壳切边和送料基本上是分开加工的,工人劳动强度高而且生产效率低下;随着全球气候不断变暖的趋向和人类社会物质生活水平的持续提高对空调系统进行降温的需求越来越高,然而空调的压缩机外壳的制造技术并没有显著的提高从而导致压缩机加工的生产效率十分低下。

论文研究的主要内容如下:

对切边送料机构的整体设计方案进行细致的研究,主要研究了在满足自动化要求前提下,机构运动原理及整体结构;通过基本的被输送零件壳体的外形分析,故本设计采用四转臂回转循环送料,四转臂采用可更换设计方便输送不同尺寸的零件,根据具体的被输送零件切换四转臂的尺寸大小,并对其运动状态进行分析。

运用 SolidWorks 软件对整体结构设计进行了三维仿真设计和模拟装配,并解决装配过程中可能遇到的问题并进行改进。

本设计方案对其他机械零件的切边送料机构的设计具有一定的参考应用价值。

关键词:送料;切边;机构设计;四转臂;液压缸

ABSTRACT

The compressor casing cutting and feeding basically is processed separately, high labor intensity and low production efficiency; with the continuous improvement of the global climate warming trend and the human society material life level of the air conditioning system to cool the increasingly high demand, but the manufacturing technology of air conditioning compressor shell was not significantly to improve the resulting compressor processing efficiency is very low.

The main contents of this paper are as follows:

A detailed research on the overall design scheme of the feeding mechanism of the cutting edge, is mainly discussed in this paper can meet the demand of automation under the premise of the mechanism movement principle and overall structure; through the basic shape of the shell is conveying parts analysis, so this design using four arm rotary feeding cycle, four rotating arms can be replaced by the design of convenient transportation different size of the parts according to the conveying parts switch four rotating arms the size of concrete, and the state of motion analysis.

SolidWorks software is used to carry out the 3D simulation design and simulation assembly of the whole structure design, and to solve the problems that may be encountered during the assembly process and to improve them.

This design has certain reference value for the design of the cutting edge feeding mechanism of other mechanical parts.

Key Words:Feeding; cutting edge; mechanism design; four arm; Hydraulic cylinder

The compressor casing cutting and feeding basically is processed separately, high labor intensity and low production efficiency; with the continuous improvement of the global climate warming trend and the human society material life level of the air conditioning system to cool the increasingly high demand, but the manufacturing technology of air conditioning compressor shell was not significantly to improve the resulting compressor processing efficiency is very low.

The main contents of this paper are as follows:

A detailed research on the overall design scheme of the feeding mechanism of the cutting edge, is mainly discussed in this paper can meet the demand of automation under the premise of the mechanism movement principle and overall structure; through the basic shape of the shell is conveying parts analysis, so this design using four arm rotary feeding cycle, four rotating arms can be replaced by the design of convenient transportation different size of the parts according to the conveying parts switch four rotating arms the size of concrete, and the state of motion analysis.

SolidWorks software is used to carry out the 3D simulation design and simulation assembly of the whole structure design, and to solve the problems that may be encountered during the assembly process and to improve them.

This design has certain reference value for the design of the cutting edge feeding mechanism of other mechanical parts.

Key Words:Feeding; cutting edge; mechanism design; four arm; Hydraulic cylinder