设计简介

摘

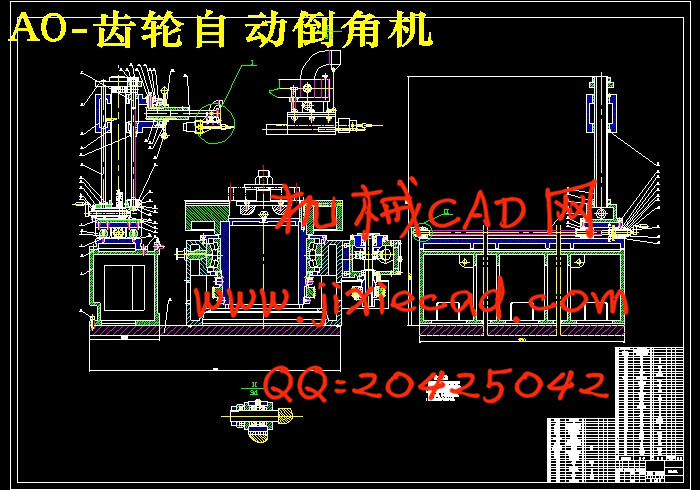

齿轮作为机械领域中重要的传动零件,它的加工制造一直受到人们的重视。其加工可分为粗加工和精加工。粗加工有滚齿、插齿等,精加工有剃齿、磨齿等。在经过粗加工后,齿的端部会产生飞边以及毛刺。由于锋利的棱角和毛刺的存在,影响其外观、传动精度、再加工和装配,并产生传动噪音,以至使齿轮的性能可靠性、寿命和润滑效果下降,更主要的是降低了齿轮的质量,而且还会导致整个机械系统不能正常工作,因此我们需要考虑给齿轮倒角去毛刺。现在齿轮加工后的去翻边毛刺已成为齿轮加工的必要工序。本设计中的倒角并不是指圆柱倒角,而是小倒角,也就是齿廓倒棱,所以我设计用磨头进行倒角,即磨棱倒角。由此我设计一个磨棱倒角机来实现对齿轮的自动倒角。本文对齿轮倒角技术进行了分析,并提出了齿轮自动倒角机的可行性方案。对机床进行了整体工作原理的设计和分析。对机床在工作情况下进行受力分析,设计出传动方案,并对其传动件进行设计、计算。得出了较合理的设计方案,解决了大型齿轮磨棱倒角效率低、工时长的问题,设计的齿轮磨棱倒角机有较为广阔的使用前景。

关键词:齿轮加工;机床结构设计;传动系统;磨削;磨棱倒角

Abstract

As an important mechanical part of the machinery field, the processing and manufacturing of the gear has always been taken seriously. Its processing can be divided into rough processing and finishing. It has a rolling teeth, inserted teeth, etc. When processed, the end of the tooth produces a flying edge, usually accompanied by a burr. Due to the presence of sharp edges and burrs, affect the appearance, the transmission accuracy and machining and assembly, and transmission noise, so the performance of the gear reliability, life and lubrication effect, more important is to reduce the quality of the gear, but also will cause the whole mechanical system can not work normally, so we need to consider for gear chamfering deburring. Along with the development of science and technology, the processing of the gear has become higher and higher, and the gear processing has become the necessary procedure of gear processing.This chamfering in the topic does not mean that the gear end chamfering, but a small chamfer, namely tooth profile chamfer, so I design using the chamfering grinding head, grinding chamfer edges. So I design a grinding machine to make the automatic chamfer of gear. In this paper, the technology of gear chamfering Angle is analyzed, and the feasible scheme of gear automatic chamfering machine is put forward. The design and analysis of the whole principle of machine tool. In the working condition of machine tool, the driving plan is designed and the transmission is designed and calculated. The more reasonable design scheme is obtained, solve the low efficiency of large gear grinding chamfer edges, long hours, design of gear grinding edges there are broad prospects for the use of the chamfering machine.

Key words: gear processing; grinding machine structure design;driving system; grinding; edge grinding and chamfering

目 录

摘 要 I

Abstract II

1 绪论 1

1.1 课题背景 1

1.2齿轮磨棱机研究目的和意义 1

1.3齿轮磨棱机国内外发展状况 2

1.4课题概述 3

1.4.1 齿轮磨棱的实质和种类 3

1.4.2 磨棱的作用 3

1.4.3 齿轮磨棱机的分类及工作 4

1.5 本课题主要研究内容 4

第2章 齿轮磨棱倒角运动分析 5

2.1 随动系统 5

2.2 磨头的选择 5

2.3 磨头的磨削力分析 8

2.4 磨头位置及角度分析 9

2.4.1 磨头位置 9

2.4.2 磨棱角度分析 10

2.5 磨削过程中力平衡分析及调节 11

2.6本章小结 11

第3章 齿轮磨棱机结构设计 13

3.1 机床总体结构分析及设计思路 13

3.1.1 待磨削齿轮的规格 13

3.1.2 预确定齿轮磨棱机床的技术参数 13

3.1.3 机床总体机构分析及设计思路 13

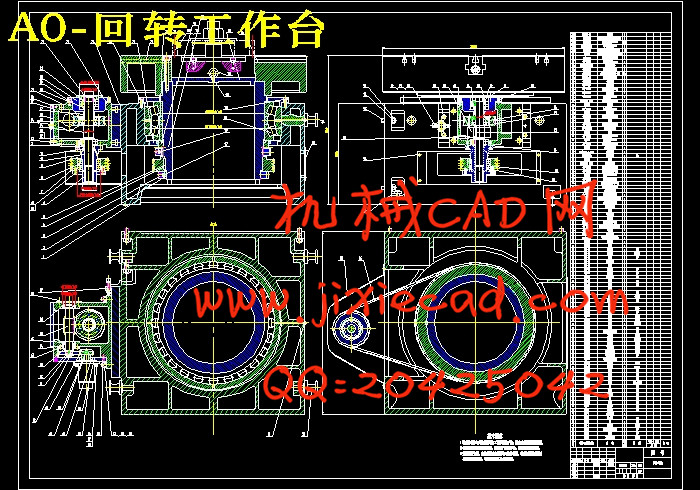

3.2 回转工作台的设计 15

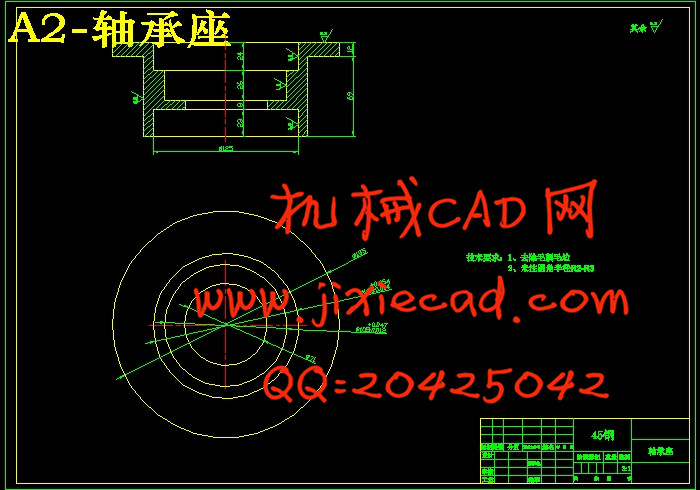

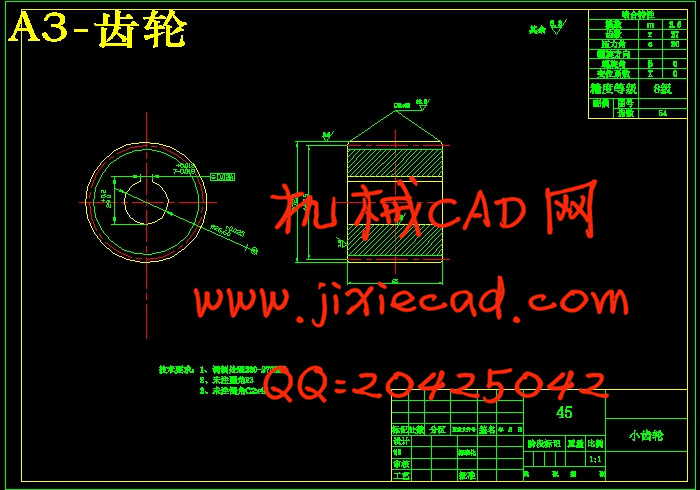

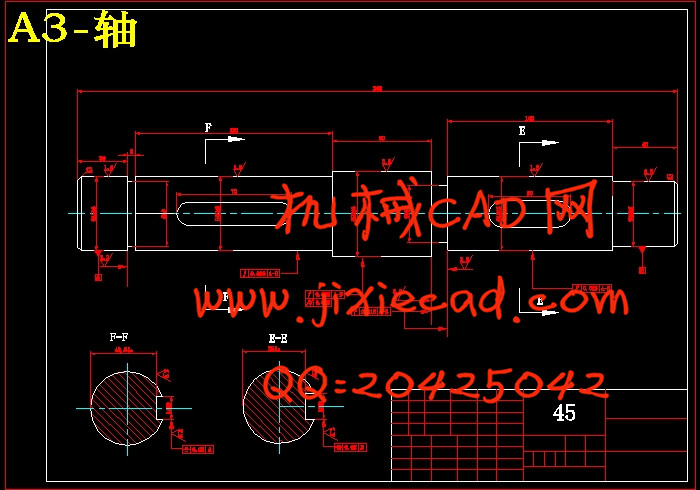

3.2.1 传动系统的设计 15

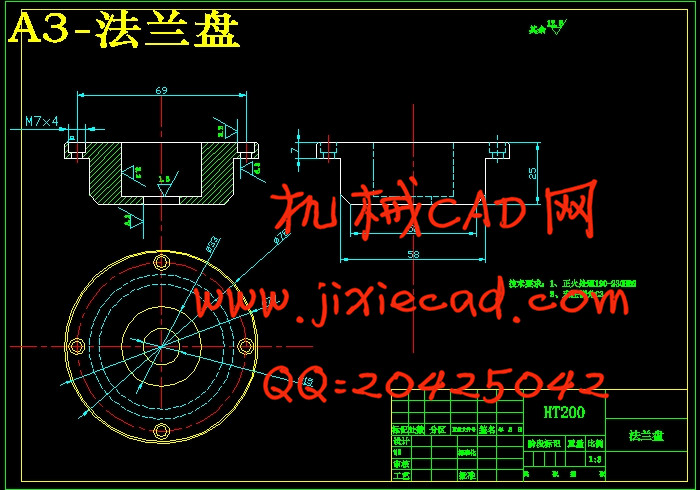

3.2.2 检测台的设计及其它部件的介绍 35

3.3 本章小结 37

结 论 38

参考文献 39

致 谢 53