设计简介

摘 要

机械手技术是综合了计算机、控制论、机构学、信息和传感技术、人工智能、仿生学等多学科而形成的高新技术,是当代研究十分活跃,应用日益广泛的一门学科。在现代制造领域和传动运输等应用中,机器手的作用越来越大。

该设计是为冲床的卸料系统而服务的。冲床的冲压频率快,而冲压模具为上出料模具,工人必须将冲压件取出后才能让送料系统继续工作,无形中降低了工作效率。由于机械手动作频率快,定位准确且无疲劳等因素,所以选用机械手可代替人工搬运,采用自动卸料装置能解决此问题。

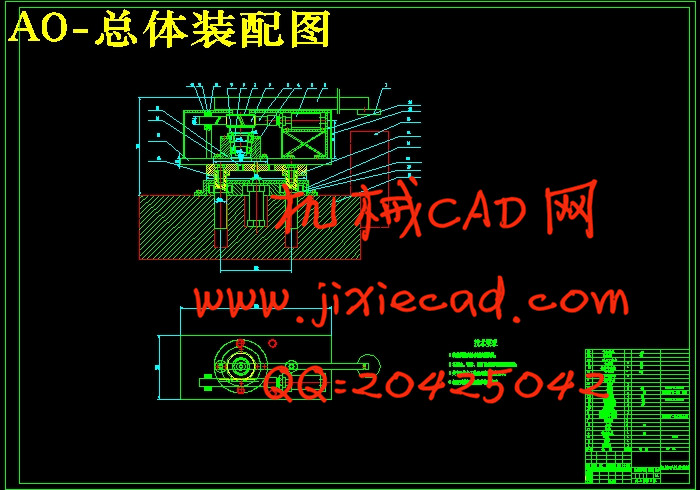

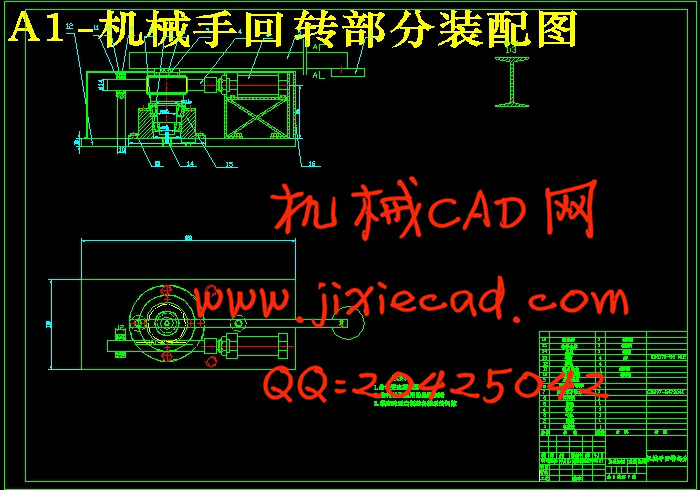

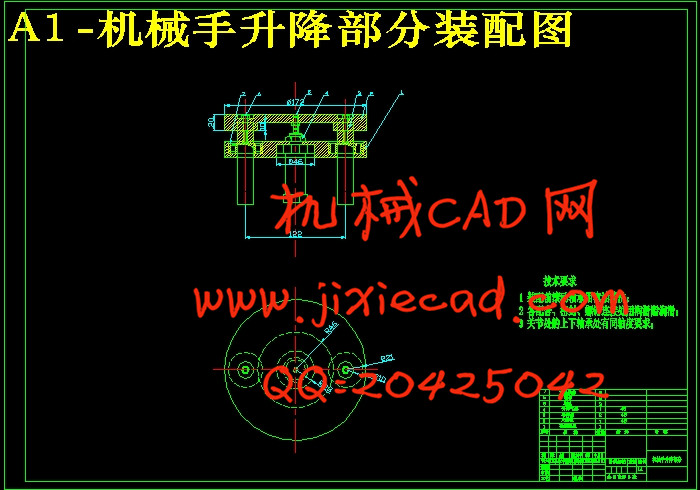

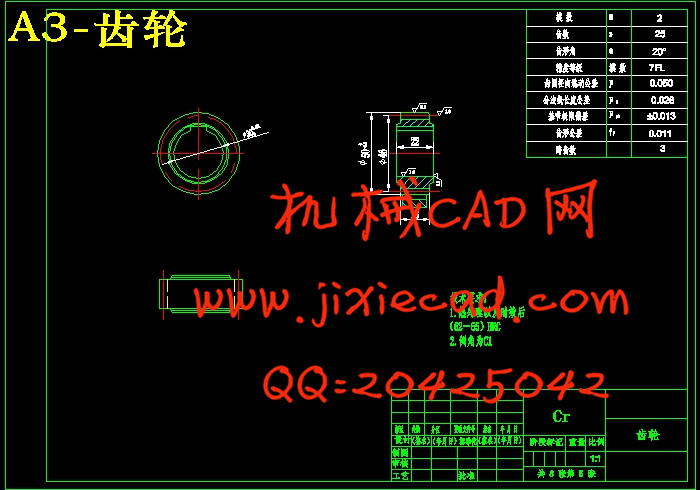

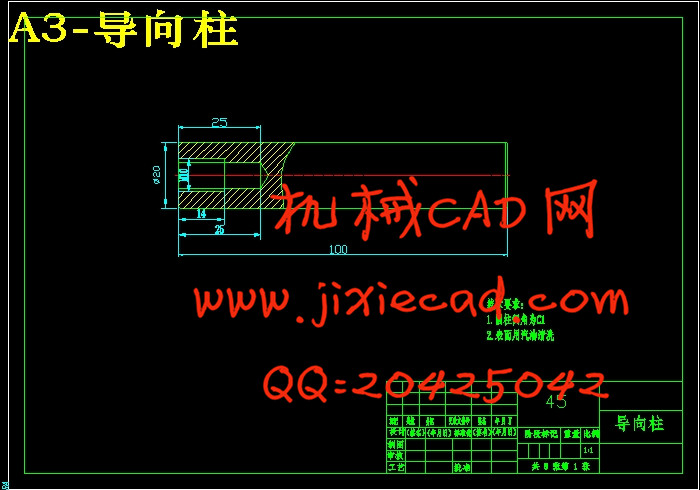

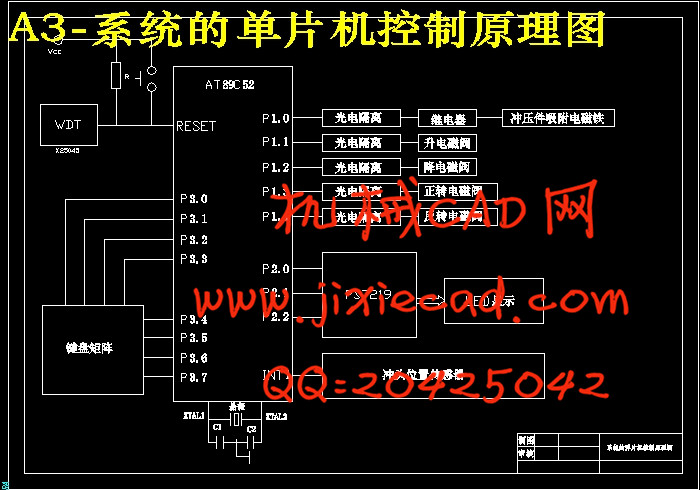

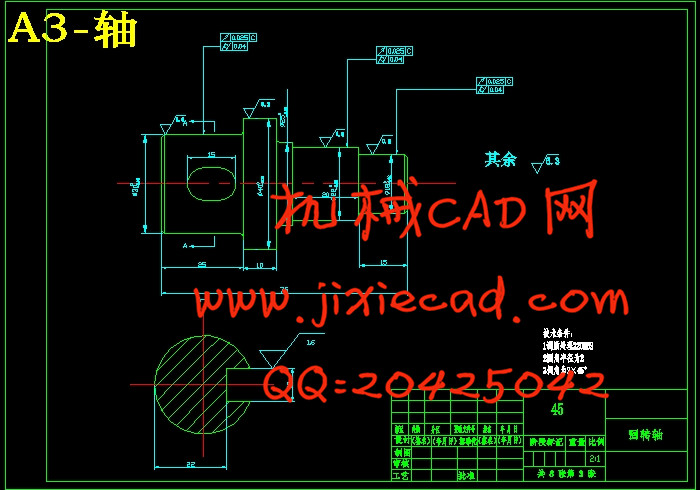

该设计完成了机械手的总体结构设计,其中包括升降部分及回转部分的设计,通过计算校核选取设计了气缸、轴、齿轮、端盖、摆杆、旋转支撑板等重要部件,此结构能较好的解决冲压件不易安全取出的问题。同时对系统构成和工作原理以及气动控制部分和单片机控制部分作了设计,升降和回转的动力由两个气缸提供,控制部分是由单片机控制电磁换向阀,从而控制气缸的运动。

该设计节省了卸料所花费的时间,提高了生产效率,并且提高产品质量,结构简单,具有一定的应用价值。

关键词:冲床;机械手;结构设计;控制系统

ABSTRACT

机械手技术是综合了计算机、控制论、机构学、信息和传感技术、人工智能、仿生学等多学科而形成的高新技术,是当代研究十分活跃,应用日益广泛的一门学科。在现代制造领域和传动运输等应用中,机器手的作用越来越大。

该设计是为冲床的卸料系统而服务的。冲床的冲压频率快,而冲压模具为上出料模具,工人必须将冲压件取出后才能让送料系统继续工作,无形中降低了工作效率。由于机械手动作频率快,定位准确且无疲劳等因素,所以选用机械手可代替人工搬运,采用自动卸料装置能解决此问题。

该设计完成了机械手的总体结构设计,其中包括升降部分及回转部分的设计,通过计算校核选取设计了气缸、轴、齿轮、端盖、摆杆、旋转支撑板等重要部件,此结构能较好的解决冲压件不易安全取出的问题。同时对系统构成和工作原理以及气动控制部分和单片机控制部分作了设计,升降和回转的动力由两个气缸提供,控制部分是由单片机控制电磁换向阀,从而控制气缸的运动。

该设计节省了卸料所花费的时间,提高了生产效率,并且提高产品质量,结构简单,具有一定的应用价值。

关键词:冲床;机械手;结构设计;控制系统

ABSTRACT

The technology of robot is one new and high technology integrated with several disciplines, such as the computer, Kybernetika, agencies sciences, and information and sensor technology, artificial intelligence, bionics, and so on. It is one contemporary discipline with very active research and increasingly widespread application. In the modern manufacturing areas and transmission transportation applications, the role of the robot is more and more important.

This design is in the service of the unloading system of the punch. Because that the stamping frequency is fast and the stamping mold is for delivering, the feed system will go on after the stamping being taken out. Thus, the work efficiency is reduced. Due to the fast frequency, exact positioning and being without tiredness, it can be instead of the workers, and the above problem can be resolved by the automatic unload system.

In this design, the overall structure design of robot is finished, which consists of the lifting part and the slewing part. Through calculating and checking, some important parts, such as cylinders, axes, gears, covers, racker, rotating retaining plate, and so on, are chosen. Using this structure, the problem of the unsafety for taking out the stamping is well solved. At the same time, the system construction, the theory of operation, pneumatic control system and the SCM control system are designed. The power of lifting and slewing part is provide by two cylinders, and the electro-magnetic change-over valve is controlled by SCM to control the motion of the cylinders.

Using this design, the unloading time is shortened, the work efficiency is enhanced, and the quality of the productions is improved. Additionally, the structure of the design is simple and it has a high applied-value.

Key words: Punch; Robot; Structure design; Control system

目 录

摘要 Ⅰ

ABSTRACT Ⅱ

1 绪论 1

2 机械手方案设计 3

3 机械手结构设计 5

3.1 机械手总体设计 5

3.2 机械手零件选用及校核 8

3.3设计过程中的注意事项 16

4 机械手控制部分的设计 17

4.1 工业机器人控制系统的主要功能和控制方式 17

4.2 气动控制部分 18

4.3 单片机控制部分 20

5 机械手的保养 21

5.1 密封与润滑 21

5.2 机械手的维护与保养 22

6 总结 23

参考文献 24

致 谢 38