设计简介

摘 要

本文针对某类大型设备动力装置与减速装置的对接方案开展研究,旨在通过设计具有实时反馈功能的对接平台,在实现装配部件对接的的同时,达到提高对接精度与成功率、节省调整时间的目的。同时,使平台在实现对接功能时,有一定的适应性。可调整自己的位姿,应对不同条件下的对接要求。

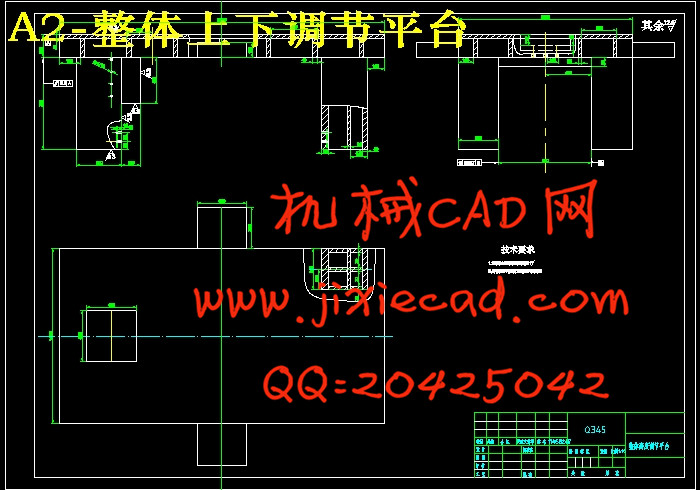

本文首先从平台的功能要求入手,分析平台机构自由度,完成动作分解与机构选型,确定平台机构总体设计方案,使其从原理上满足功能要求。

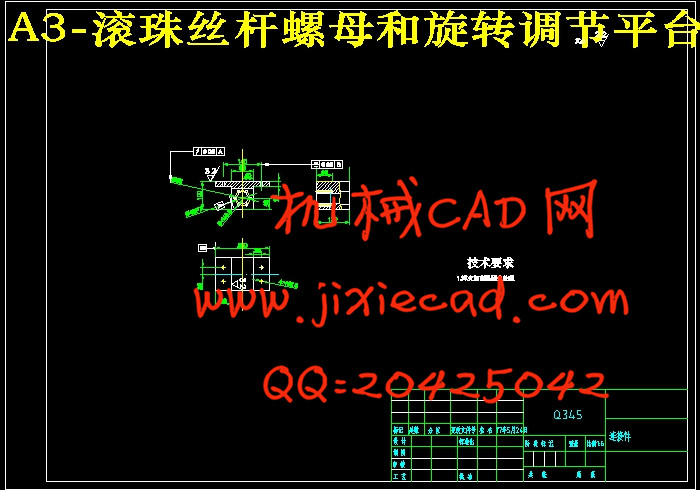

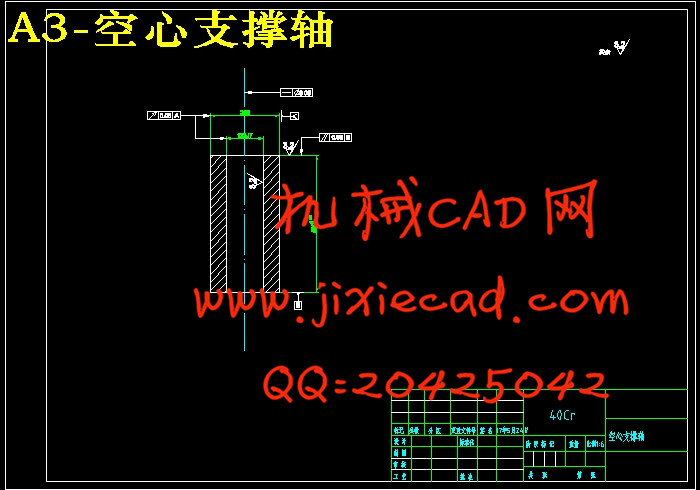

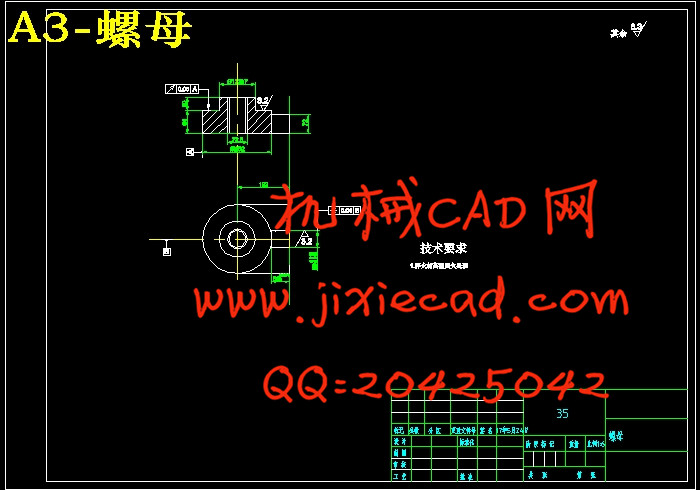

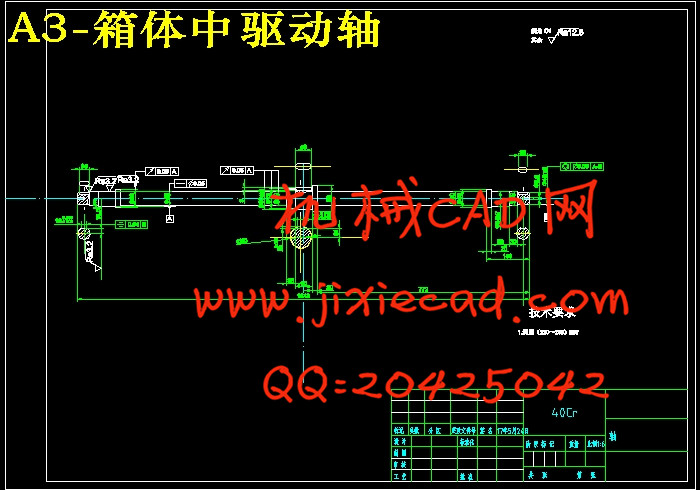

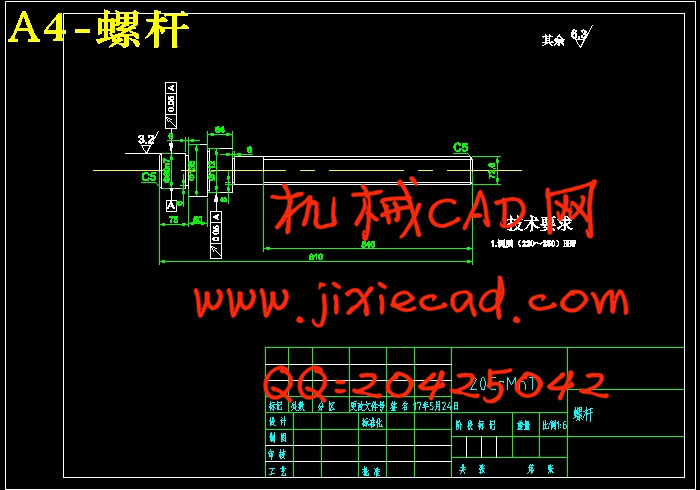

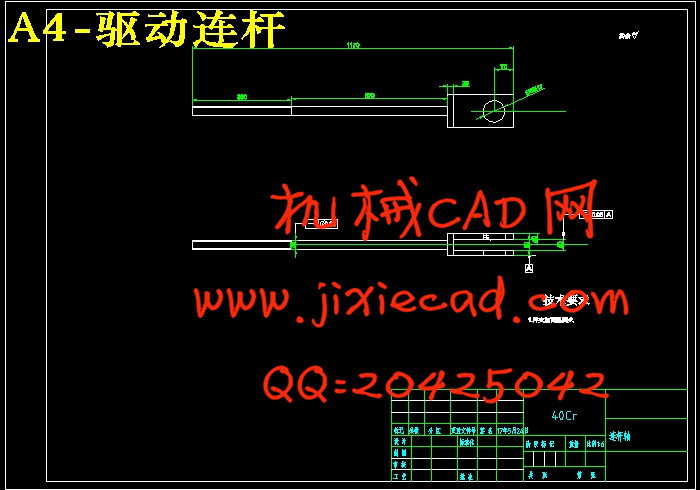

其次,对关键零部如齿轮副、传动丝杠、传动轴以及导轨等进行相关的设计计算,完成强度、刚度等性能的分析与校核,确保设计的结构能顺利完成设计任务。

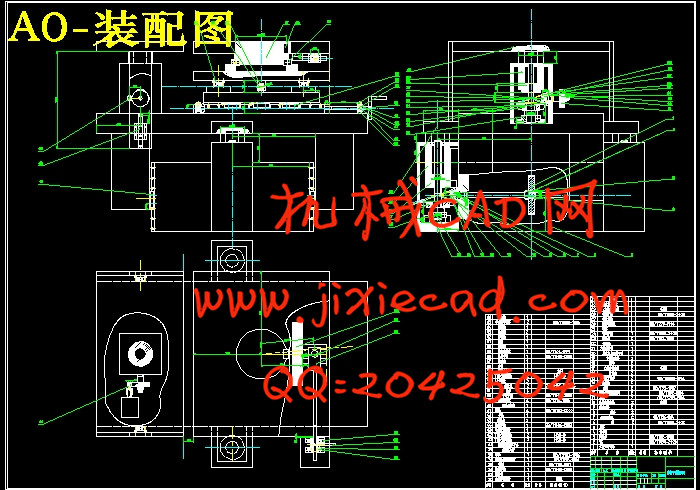

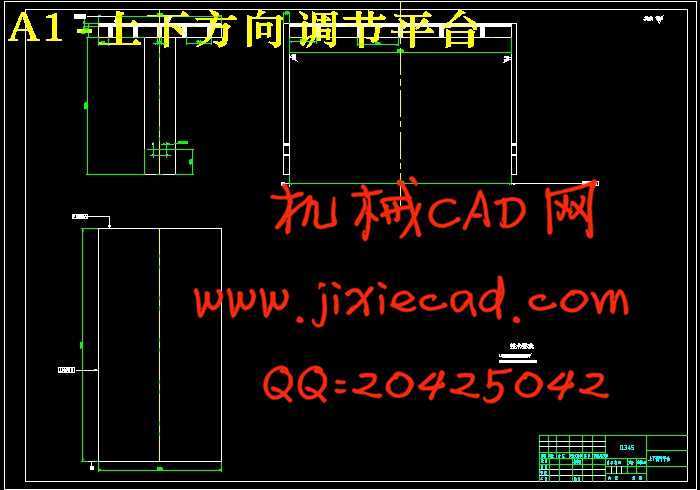

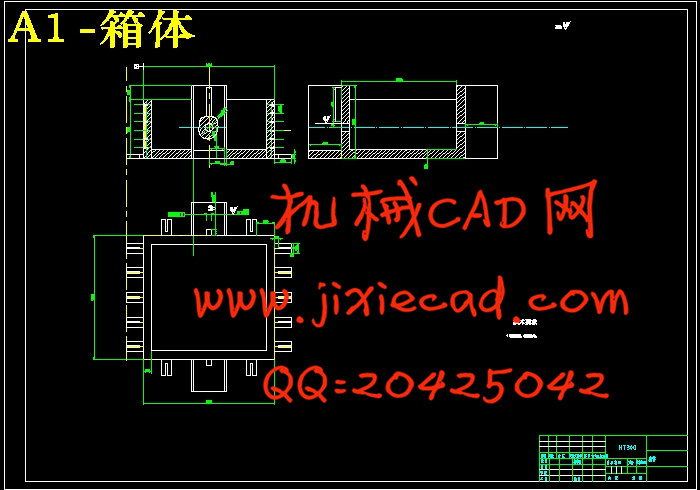

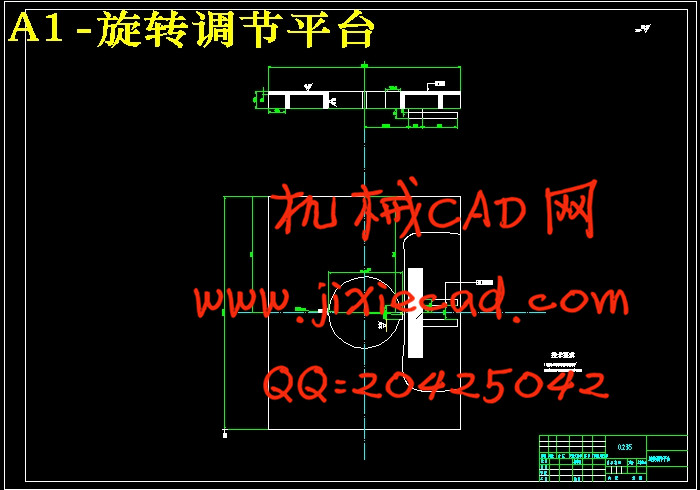

同时对平台具体结构进行尺寸综合,完成平台详细结构设计,确定关键部位配合精度,完成装配图与零件图,并采用 3D 软件建立了部分结构的三维模型。

最后,从保证调节精度的角度出发,对调节平台的控制方案以及部分控制元件进行选型与布置,并对调节精度进行分析。

关键词:对接平台,结构设计,丝杠,导轨,精度

本文针对某类大型设备动力装置与减速装置的对接方案开展研究,旨在通过设计具有实时反馈功能的对接平台,在实现装配部件对接的的同时,达到提高对接精度与成功率、节省调整时间的目的。同时,使平台在实现对接功能时,有一定的适应性。可调整自己的位姿,应对不同条件下的对接要求。

本文首先从平台的功能要求入手,分析平台机构自由度,完成动作分解与机构选型,确定平台机构总体设计方案,使其从原理上满足功能要求。

其次,对关键零部如齿轮副、传动丝杠、传动轴以及导轨等进行相关的设计计算,完成强度、刚度等性能的分析与校核,确保设计的结构能顺利完成设计任务。

同时对平台具体结构进行尺寸综合,完成平台详细结构设计,确定关键部位配合精度,完成装配图与零件图,并采用 3D 软件建立了部分结构的三维模型。

最后,从保证调节精度的角度出发,对调节平台的控制方案以及部分控制元件进行选型与布置,并对调节精度进行分析。

关键词:对接平台,结构设计,丝杠,导轨,精度

ABSTRACT

In this paper, for the docking program of some large-scale equipment power plant and the gear reduction device’ research, it aims to design a docking platform with real-time feedback function, which can achieve the improvement of docking precision and success rate and reduce the adjustment time while realizing the docking of assembly parts. At the same time, the platform in the realization of docking function, there is a certain degree of adaptability. It can adjust their position, to deal with different conditions of the docking requirements.

The paper begins with the functional requirements of the platform, analysis platform mechanism freedom, complete action decomposition and institutional selection, and determine the overall design of the platform to make it meet the functional requirements from the principle.

Second, for the key parts such as gears, drive screw, drive shaft and rail, doing the relevant design calculation and completing the strength, stiffness and other performance analysis and verification to ensure that the design of the structure can successfully complete the design task.

At the same time, integrated specific structure size of platform, complete the detailed structure of the platform design, determine cooperate precision of the key parts, complete the assembly diagram and parts diagram, and use 3D software to establish the three-dimensional model of the partial structure.

Finally, from the point of view of the accuracy of regulation, the control scheme of the adjustment platform and some control elements should be selected and arranged, and the adjustment precision should be analyzed.

Keywords: docking platform, structural design, screw, rail, precision

In this paper, for the docking program of some large-scale equipment power plant and the gear reduction device’ research, it aims to design a docking platform with real-time feedback function, which can achieve the improvement of docking precision and success rate and reduce the adjustment time while realizing the docking of assembly parts. At the same time, the platform in the realization of docking function, there is a certain degree of adaptability. It can adjust their position, to deal with different conditions of the docking requirements.

The paper begins with the functional requirements of the platform, analysis platform mechanism freedom, complete action decomposition and institutional selection, and determine the overall design of the platform to make it meet the functional requirements from the principle.

Second, for the key parts such as gears, drive screw, drive shaft and rail, doing the relevant design calculation and completing the strength, stiffness and other performance analysis and verification to ensure that the design of the structure can successfully complete the design task.

At the same time, integrated specific structure size of platform, complete the detailed structure of the platform design, determine cooperate precision of the key parts, complete the assembly diagram and parts diagram, and use 3D software to establish the three-dimensional model of the partial structure.

Finally, from the point of view of the accuracy of regulation, the control scheme of the adjustment platform and some control elements should be selected and arranged, and the adjustment precision should be analyzed.

Keywords: docking platform, structural design, screw, rail, precision