设计简介

摘 要

压力机在汽车、电子、模具等方面有着很大的使用。在我国近 10 多年来,汽车一直作为国家的支柱产业,所以在汽车行业发展的同时,压力机械在这端时间内有着很大的进步。

关于可以调节速度的压力机需求越来越大,但在这方面,现在国内外更多的是用伺服电机实现的,但行星齿轮机构也是完全可以实现多个速度的调节,这种技术已经广泛应用于自动挡汽车的变速箱中,所以决定设计一个可以应用于压力机的行星齿轮机构。

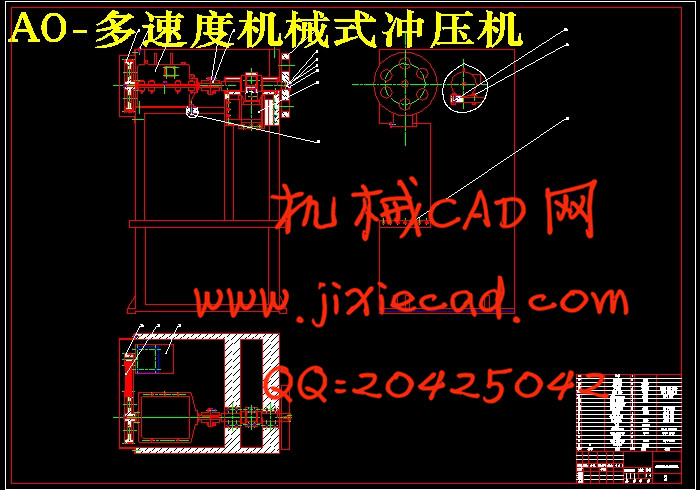

本毕业设计实在国内发展现状的基础上,添加了可以进行多速度控制的行星齿轮机构,它通过控制不同齿轮的固定与否,实现了压力机的多速度的调节,适应了压力机可以有多种速度的技术要求,可以根据不同的产品来调整不同的加工速度,适用不同的需要,从而提高生产效率。

本毕业设计的主要内容:

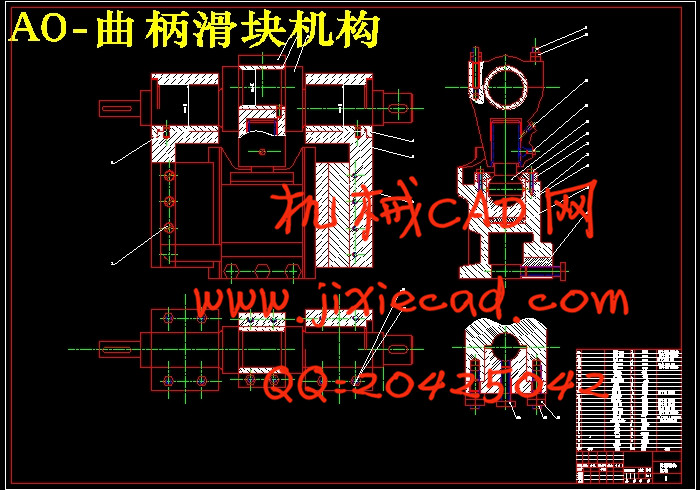

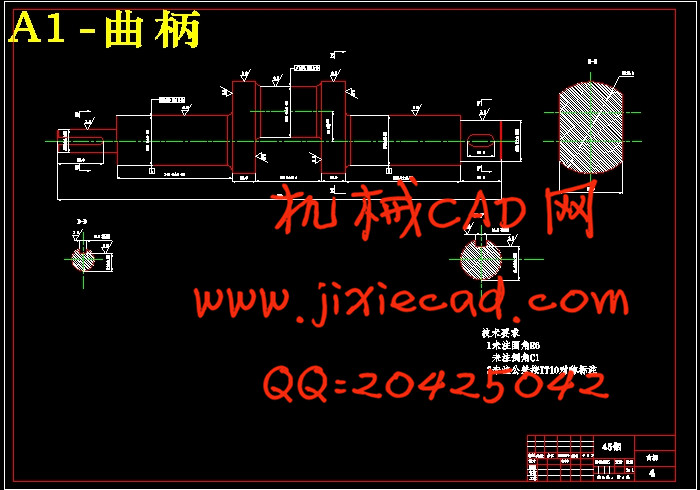

1.曲柄滑块机构的设计,包括曲轴的设计,可调连杆的设计,滑块的设计。

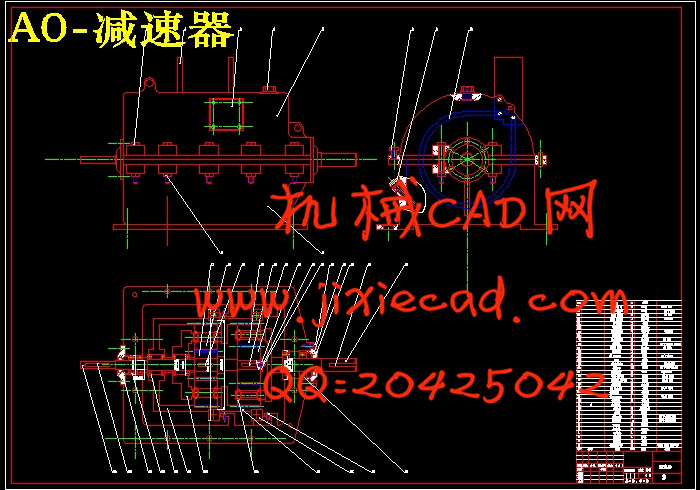

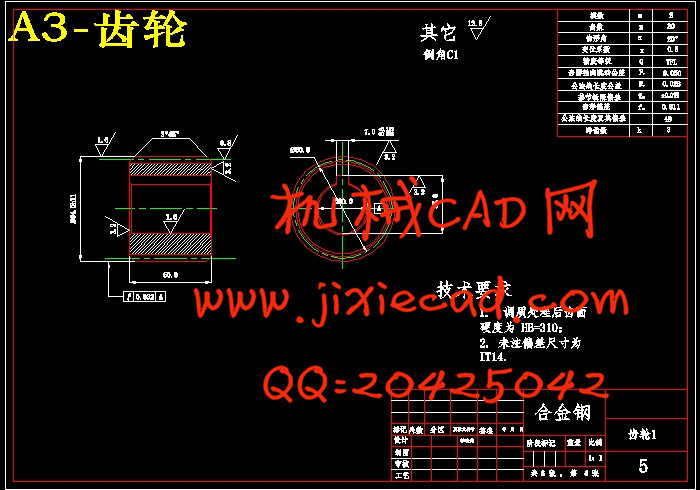

2.行星齿轮机构的设计,包括多速度轮系的方案设计,齿轮设计,定位方案设计。

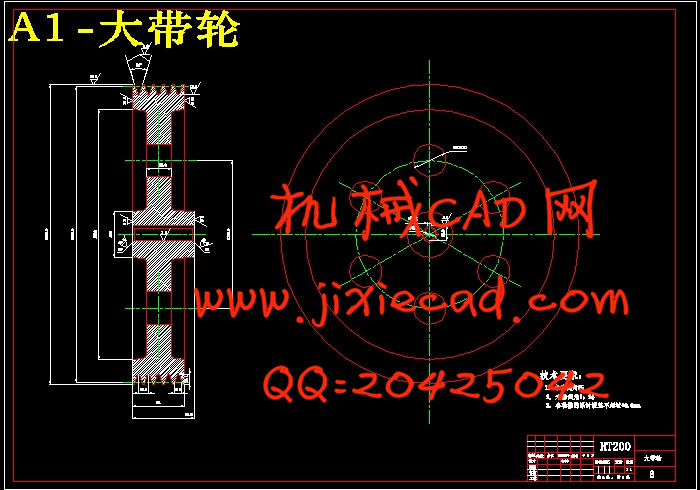

3.皮带轮的设计,包括皮带的设计,小带轮的设计和大带轮的设计。

通过这次设计,完成了以上的设计内容,而且将以上各个部件整合到了一起形成了一个完整的机器。使自己明白了一个真正机器的复杂程度,机械设计的基本设计过程,同时强化巩固加深了自己对轮系的认识,同时也为多速度压力机方面增多了一种新的多速度实现方式。

关键词:曲柄压力机;多速度压力机;行星齿轮机构

压力机在汽车、电子、模具等方面有着很大的使用。在我国近 10 多年来,汽车一直作为国家的支柱产业,所以在汽车行业发展的同时,压力机械在这端时间内有着很大的进步。

关于可以调节速度的压力机需求越来越大,但在这方面,现在国内外更多的是用伺服电机实现的,但行星齿轮机构也是完全可以实现多个速度的调节,这种技术已经广泛应用于自动挡汽车的变速箱中,所以决定设计一个可以应用于压力机的行星齿轮机构。

本毕业设计实在国内发展现状的基础上,添加了可以进行多速度控制的行星齿轮机构,它通过控制不同齿轮的固定与否,实现了压力机的多速度的调节,适应了压力机可以有多种速度的技术要求,可以根据不同的产品来调整不同的加工速度,适用不同的需要,从而提高生产效率。

本毕业设计的主要内容:

1.曲柄滑块机构的设计,包括曲轴的设计,可调连杆的设计,滑块的设计。

2.行星齿轮机构的设计,包括多速度轮系的方案设计,齿轮设计,定位方案设计。

3.皮带轮的设计,包括皮带的设计,小带轮的设计和大带轮的设计。

通过这次设计,完成了以上的设计内容,而且将以上各个部件整合到了一起形成了一个完整的机器。使自己明白了一个真正机器的复杂程度,机械设计的基本设计过程,同时强化巩固加深了自己对轮系的认识,同时也为多速度压力机方面增多了一种新的多速度实现方式。

关键词:曲柄压力机;多速度压力机;行星齿轮机构

ABSTRACT

Press machine is widely applied to industrial area, for example automobile, aviation, electricity, house appliances, and so on.As one of the symbol which measure a nation′s industrial level, is considered as the pillar industry of domestic economy by some major industrial developed countries and emerging industrial countries in today′s world. Its development mainly leads to the development of forging and stamping technology and equipment. The growth and progress of forging and stamping technology are centred around the development of automobile industry.

Based on the current situation of domestic development, this graduation project added the planetary gear mechanism which can carry on multi-speed control. By controlling whether the gears are fixed or not, it implemented press machine′s multi-speed adjustment, and adapted to the press machine′s developed direction. According to the different products, its different processing speeds satisfying different needs. Thus it improved productions′ efficiency.

The main contents:

1.The design of crank-slide mechanism. It including the designs of crank axle, adjusting connecting rod and slide block.

2.The design of planetary gear mechanism.It including the designs of multi-speed gear system, wheel gear, and localization scheme.

3.The design of belt pulley.It including the design of belt, the small pulley and the big pulley.

Through this graduation project, I finished the above contents, as well as, combined every single parts to form an integrated machine. I deeply understand the complexity of a true machine and the basic design process of a machine. At the same time, it reinforced my recognition for gear system and provided a new multi-speed pattern in press machine.

Key Words:crank press, planetary gear mechanism, multi-speed press.

Based on the current situation of domestic development, this graduation project added the planetary gear mechanism which can carry on multi-speed control. By controlling whether the gears are fixed or not, it implemented press machine′s multi-speed adjustment, and adapted to the press machine′s developed direction. According to the different products, its different processing speeds satisfying different needs. Thus it improved productions′ efficiency.

The main contents:

1.The design of crank-slide mechanism. It including the designs of crank axle, adjusting connecting rod and slide block.

2.The design of planetary gear mechanism.It including the designs of multi-speed gear system, wheel gear, and localization scheme.

3.The design of belt pulley.It including the design of belt, the small pulley and the big pulley.

Through this graduation project, I finished the above contents, as well as, combined every single parts to form an integrated machine. I deeply understand the complexity of a true machine and the basic design process of a machine. At the same time, it reinforced my recognition for gear system and provided a new multi-speed pattern in press machine.

Key Words:crank press, planetary gear mechanism, multi-speed press.

| 摘 | 要..................................................................................................................................... | I |

| ABSTRACT................................................................................................................................... | II |

| 3 | 冲压机驱动力的计算及及电机的选择............................................................................... | 3 |

| 4 | 曲柄滑块机构的设计........................................................................................................... | 4 |

| 5 | 传动系统的设计................................................................................................................... | 9 |

| 致 | 谢................................................................................................................................... | 33 |