设计简介

摘 要

随着工业生产规模的扩大,工人易发生安全事故,某公司方糖生产线上,方糖制作成功后需将方糖放到包装机中,因方糖数目多,工人搬运效率低,所需人员多,高温,噪声大,所以生产线的自动化水平须大力提高.本文设计了一个 2 自由度的真空吸头机械手,用做方糖的搬运,此机械手应用到生产线上可以缩短生产周期, 提高生产效率,避免工人了重复性劳动,并使生产更加可靠。

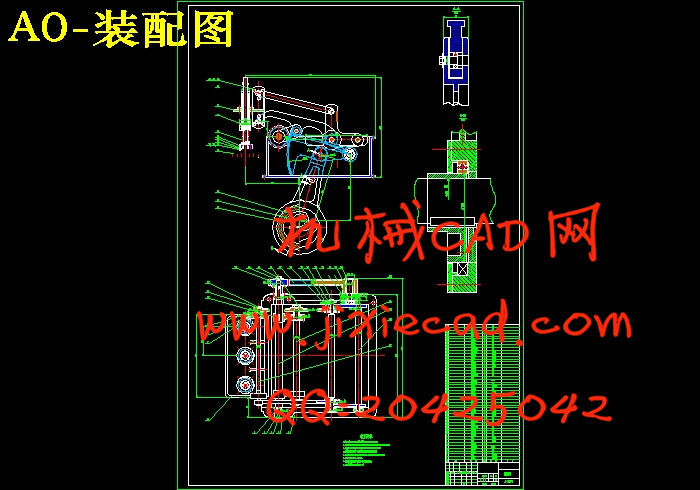

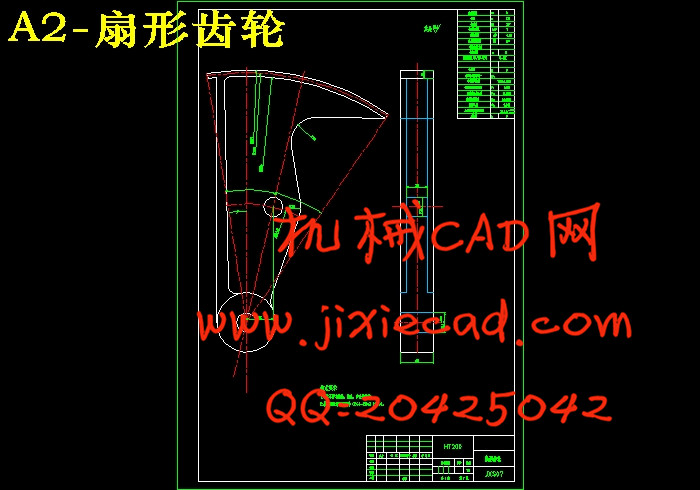

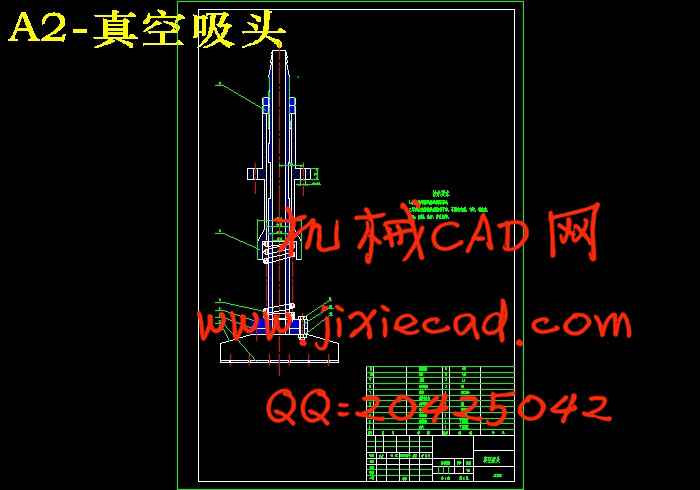

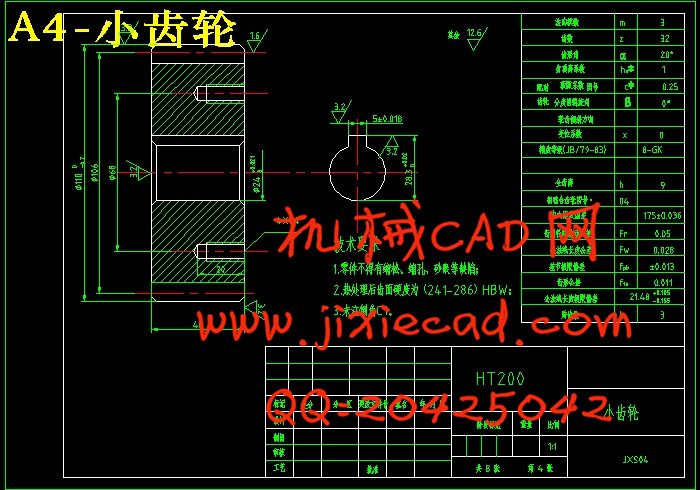

本文介绍了搬运类机械手的发展现况。展开了一个应用在方糖包装生产线的机械手的机构设计。本文运用机械原理知识解决了从电动机到真空吸头传动机构的方案设计。运用机械设计知识解决了机构的构件的尺寸,位置问题。再运用材料力学,理论力学知识完成了机构的强度校核。最后运用 CAD 软件完成了机构的装配图,零件图。

本文完成了方糖包装生产线上机械手的结构设计,实现了预定功能需求,达到了高效、灵活的目的。

关键词:机械手;真空;结构设计

随着工业生产规模的扩大,工人易发生安全事故,某公司方糖生产线上,方糖制作成功后需将方糖放到包装机中,因方糖数目多,工人搬运效率低,所需人员多,高温,噪声大,所以生产线的自动化水平须大力提高.本文设计了一个 2 自由度的真空吸头机械手,用做方糖的搬运,此机械手应用到生产线上可以缩短生产周期, 提高生产效率,避免工人了重复性劳动,并使生产更加可靠。

本文介绍了搬运类机械手的发展现况。展开了一个应用在方糖包装生产线的机械手的机构设计。本文运用机械原理知识解决了从电动机到真空吸头传动机构的方案设计。运用机械设计知识解决了机构的构件的尺寸,位置问题。再运用材料力学,理论力学知识完成了机构的强度校核。最后运用 CAD 软件完成了机构的装配图,零件图。

本文完成了方糖包装生产线上机械手的结构设计,实现了预定功能需求,达到了高效、灵活的目的。

关键词:机械手;真空;结构设计

ABSTRACT

With the scale of industrial production becomes bigger, security accidents are more likely happened to workers. At a company of sugar production line, the sugar need to be put into the packaging machine after being made. Due to low efficiency, the required personnel, the high temperature, noise annulus large adsorption while the number of workers carrying sugar. This paper designs a 2 degree of freedom. the level of automation of production lines need to be improved urgently. Thist ype manipulator applied in the production line can shorten production cycle, improve production efficiency, avoid duplication of labor workers, and make the production more reliable.

This paper introduces the development of portable manipulator. The mechanism design of a manipulator used in packaging production line of sugar. In this paper, the mechanical principle is used to solve the design of the drive mechanism from the motor to the vacuum suction head. The mechanical design knowledge is used to solve the problem of the size and position of the components of the mechanism. Then the strength checking of the mechanism is completed by using the theory of material mechanics and theory mechanics. Finally, the assembly drawings and parts drawings of the mechanism are finished by using CAD software.

This paper completed the design of mechanical structure of sugar packaging production line in hand, to achieve the intended function requirements, to achieve the efficient and flexible objective.

Keywords: Manipulator; Vacuum; Configuration design

With the scale of industrial production becomes bigger, security accidents are more likely happened to workers. At a company of sugar production line, the sugar need to be put into the packaging machine after being made. Due to low efficiency, the required personnel, the high temperature, noise annulus large adsorption while the number of workers carrying sugar. This paper designs a 2 degree of freedom. the level of automation of production lines need to be improved urgently. Thist ype manipulator applied in the production line can shorten production cycle, improve production efficiency, avoid duplication of labor workers, and make the production more reliable.

This paper introduces the development of portable manipulator. The mechanism design of a manipulator used in packaging production line of sugar. In this paper, the mechanical principle is used to solve the design of the drive mechanism from the motor to the vacuum suction head. The mechanical design knowledge is used to solve the problem of the size and position of the components of the mechanism. Then the strength checking of the mechanism is completed by using the theory of material mechanics and theory mechanics. Finally, the assembly drawings and parts drawings of the mechanism are finished by using CAD software.

This paper completed the design of mechanical structure of sugar packaging production line in hand, to achieve the intended function requirements, to achieve the efficient and flexible objective.

Keywords: Manipulator; Vacuum; Configuration design

| 目 | 录 | ||||

| 摘 | 要....................................... | ............................................................................I | |||

| ABSTRACT | ............................................................................................................... | II | |||

| 1 | 绪论.................................................................................................................... | 1 | |||

| 1.1 | 选题背景.................................................................................................. | 1 | |||

| 1.2 | 国内外的发展现状.................................................................................. | 1 | |||

| 1.3 | 发展趋势.................................................................................................. | 2 | |||

| 2 | 真空吸头机械手方案的选择............................................................................ | 4 | |||

| 2.1 | 机械手设计方案分析.............................................................................. | 4 | |||

| 2.2 | 方案确定................................................................................................. | 7 | |||

| 3 | 机械手结构设计................................................................................................ | 8 | |||

| 3.1 | 电机的选择.............................................................................................. | 8 | |||

| 3.2 | 摇杆滑块结构设计.................................................................................. | 9 | |||

| 3.3 | 齿轮传动结构设计................................................................................ | 10 | |||

| 3.4 | 偏心轮的结构设计................................................................................ | 11 | |||

| 3.5 | 真空吸头的设计.................................................................................... | 13 | |||

| 4 | 机械手主要部件的强度校核.......................................................................... | 17 | |||

| 4.1 | 电机校核................................................................................................ | 17 | |||

| 4.2 | 偏心轮上传动键的校核........................................................................ | 18 | |||

| 4.3 | 偏心轮上的轴承校核............................................................................ | 18 | |||

| 4.4 | 齿轮的强度校核.................................................................................... | 19 | |||

| 4.5 | 传动轴的强度校核................................................................................ | 21 | |||

| 4.6 | 销的强度校核........................................................................................ | 22 | |||

| 4.7 | 整体结构的稳定性校核........................................................................ | 22 | |||

| 5 | 结论及展望...................................................................................................... | 23 | |||

| 参 考 文 献.......................................................................................................... | 24 | ||||

| 致 | 谢 | ................................................................................................................ | 39 | ||