设计简介

摘 要

发展节能车是未来汽车发展的趋势,而节能车车架轻量化则是影响节能车节能的关键因素之一。本论文即是以节能车车架的设计为研究基点,以降低油耗为出发点,分析车架结构对车辆油耗特性的影响规律,为节能车车架的设计做一些从理论到实战的基础研究工作。

国内汽车设计的主要手段是用传统的样车和旧车型作参考的模式,在对车架进行分析设计时经常会对车架进行大幅度的简化。随着计算机技术的高速发展,汽车车架的结构设计逐渐由传统的经验设计方法转向了现代设计方法。其中,有限元方法已经成为建立有限元模型、模拟车架的主要分析途径,并慢慢走向成熟。

本论文运用solidworks软件对车架进行建模,并进行利用有限元分析来分析车架的结构强度,然后再对车架进行优化,优化后再对车架进行验证,验证后对车架进行再优化,使车架结构达到最优的结果。本文不仅运用软件对车架进行设计分析,还对车架进行实物验证,力求设计出最合理的车架结构。

关键词:节能车;车架;轻量化;三维建模;静力分析;优化设计

ABSTRACT

The development of energy-saving vehicles is the trend of the future development of automobiles, and the lightweight of energy-saving vehicles is one of the key factors that affect the energy saving of energy saving vehicles. This thesis is that energy saving car chassis design as the research basis, in order to reduce the fuel consumption as a starting point, analysis the influence law of the frame structure of vehicle fuel consumption characteristics, for energy conservation design of the car frame to do some basic research from theory to practical work.

The main method of domestic automobile design is to use the traditional model and the old model as the reference model, and the vehicle frame can be greatly simplified in the analysis and design of the frame. With the rapid development of computer technology, the structure design of automobile frame is gradually changed from the traditional experience design method to the modern design method. Among them, the finite element method has become the main analytical way to establish the finite element model and the simulation frame, and gradually mature.

This paper use solidworks software modeling was carried out on the frame, and using finite element analysis to analyze the frame structure strength, and then optimize the frame, optimization of frame again after verification, validation of frame after optimization, the frame structure to achieve optimal results. This paper not only uses the software to design the frame, but also carries on the physical verification of the frame, and tries to design the most reasonable frame structure.

Key words: Fuel Efficient Veicle; Frame; Lightweight; Statical Analysis ; Optimizasion Design

发展节能车是未来汽车发展的趋势,而节能车车架轻量化则是影响节能车节能的关键因素之一。本论文即是以节能车车架的设计为研究基点,以降低油耗为出发点,分析车架结构对车辆油耗特性的影响规律,为节能车车架的设计做一些从理论到实战的基础研究工作。

国内汽车设计的主要手段是用传统的样车和旧车型作参考的模式,在对车架进行分析设计时经常会对车架进行大幅度的简化。随着计算机技术的高速发展,汽车车架的结构设计逐渐由传统的经验设计方法转向了现代设计方法。其中,有限元方法已经成为建立有限元模型、模拟车架的主要分析途径,并慢慢走向成熟。

本论文运用solidworks软件对车架进行建模,并进行利用有限元分析来分析车架的结构强度,然后再对车架进行优化,优化后再对车架进行验证,验证后对车架进行再优化,使车架结构达到最优的结果。本文不仅运用软件对车架进行设计分析,还对车架进行实物验证,力求设计出最合理的车架结构。

关键词:节能车;车架;轻量化;三维建模;静力分析;优化设计

ABSTRACT

The development of energy-saving vehicles is the trend of the future development of automobiles, and the lightweight of energy-saving vehicles is one of the key factors that affect the energy saving of energy saving vehicles. This thesis is that energy saving car chassis design as the research basis, in order to reduce the fuel consumption as a starting point, analysis the influence law of the frame structure of vehicle fuel consumption characteristics, for energy conservation design of the car frame to do some basic research from theory to practical work.

The main method of domestic automobile design is to use the traditional model and the old model as the reference model, and the vehicle frame can be greatly simplified in the analysis and design of the frame. With the rapid development of computer technology, the structure design of automobile frame is gradually changed from the traditional experience design method to the modern design method. Among them, the finite element method has become the main analytical way to establish the finite element model and the simulation frame, and gradually mature.

This paper use solidworks software modeling was carried out on the frame, and using finite element analysis to analyze the frame structure strength, and then optimize the frame, optimization of frame again after verification, validation of frame after optimization, the frame structure to achieve optimal results. This paper not only uses the software to design the frame, but also carries on the physical verification of the frame, and tries to design the most reasonable frame structure.

Key words: Fuel Efficient Veicle; Frame; Lightweight; Statical Analysis ; Optimizasion Design

目 录

摘 要 I

ABSTRACT II

1 绪论 1

1.1节能车的概述 1

1.2节能车车架研究的目的和意义 1

1.3节能车的节能技术 1

1.4车架优化的技术手段 2

2 节能车车架的设计 3

2.1节能车车架研究的基本内容及设计路线 3

2.2车架结构选择 4

2.3车架材料的选择 5

2.4车架的结构设计 5

3 节能车车架模型的建立 8

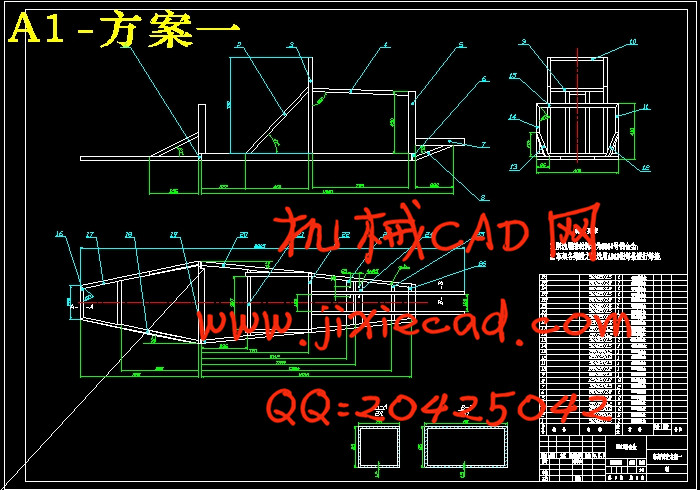

3.1车架方案一三维模型的建立 8

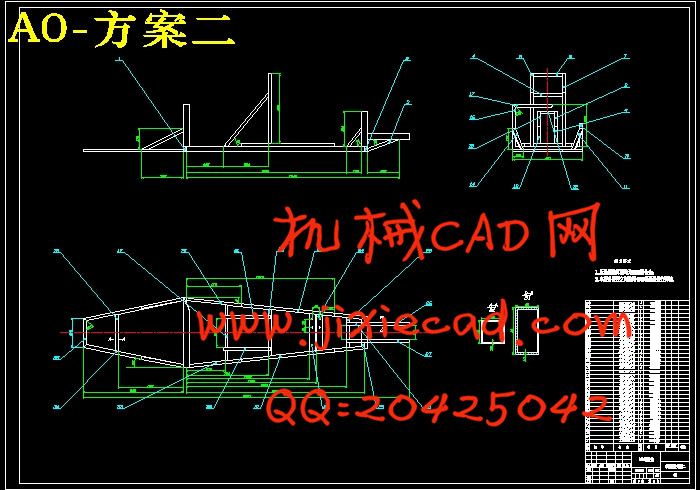

3.2节能车车架方案二三维模型的建立 9

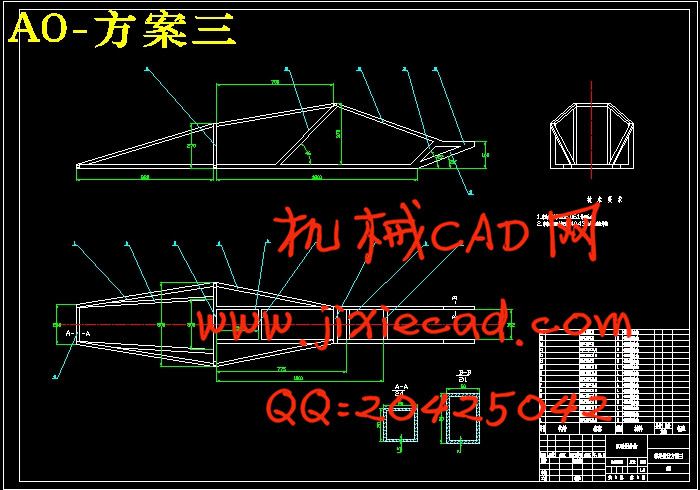

3.3车架方案三三维模型的建立 10

4 节能车车架有限元分析 13

4.1 Solidworks有限元分析应用简介 13

4.2节能车车架的结构静力分析 13

4.3车架方案三结构优化 22

5 节能车车架事物焊接及优化设计 25

5.1车架实物焊接 25

5.2节能车试跑结果分析 26

5.3验证后的优化设计 27

6 结论 30

参考文献 31

致 谢 43