设计简介

摘 要

目前,随着我国工业的快速发展,各行各业对压力容器的使用越来越广泛,涉及的领域包括化工、橡胶、食品、医药、石油等方面,尤其是我国对橡胶产品的需求量越来越大,聚合反应釜是橡胶生产过程必不可少的反应容器,现在国内主要的反应釜的容积为30m³生产效率低,成本高,已经不能满足橡胶生产需求,更大容积的反应釜的设计刻不容缓。

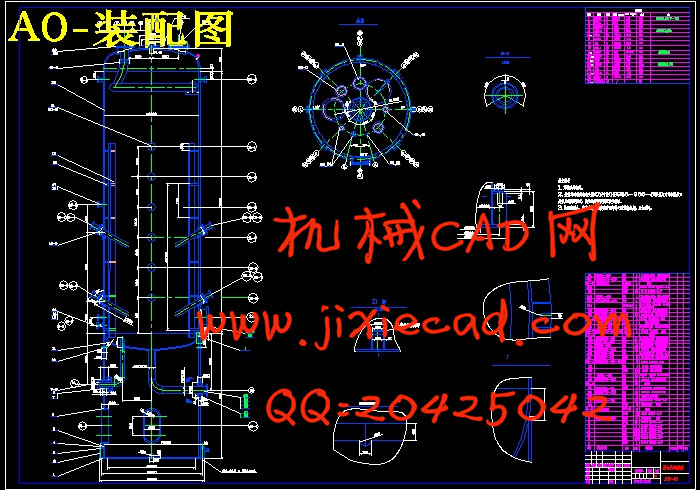

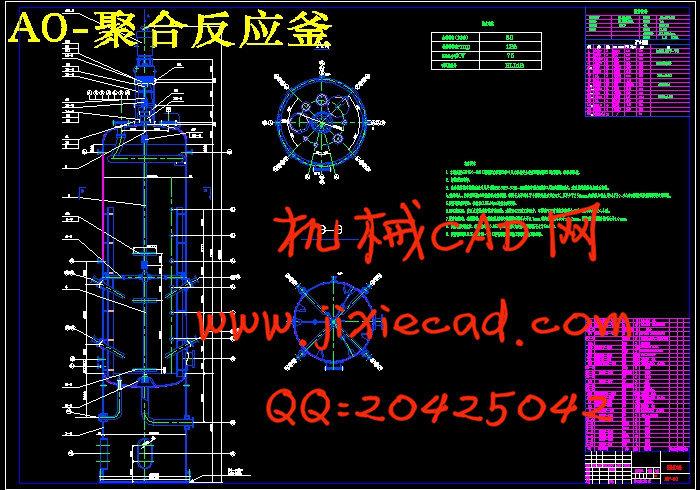

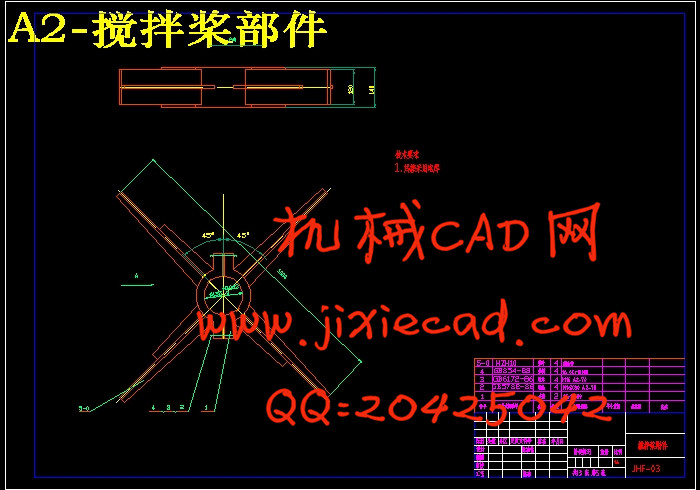

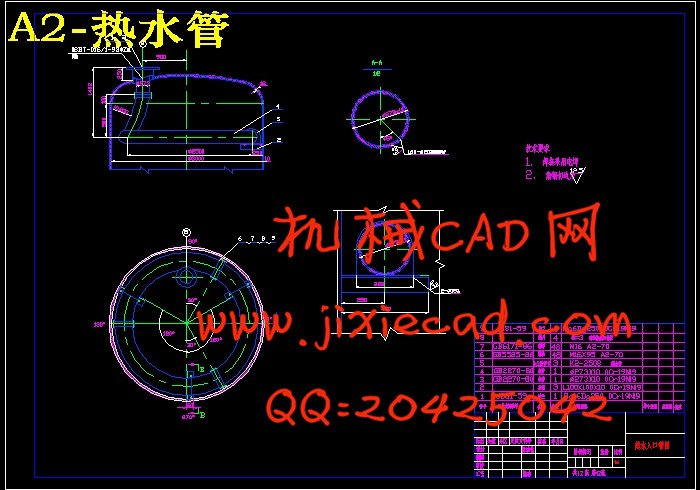

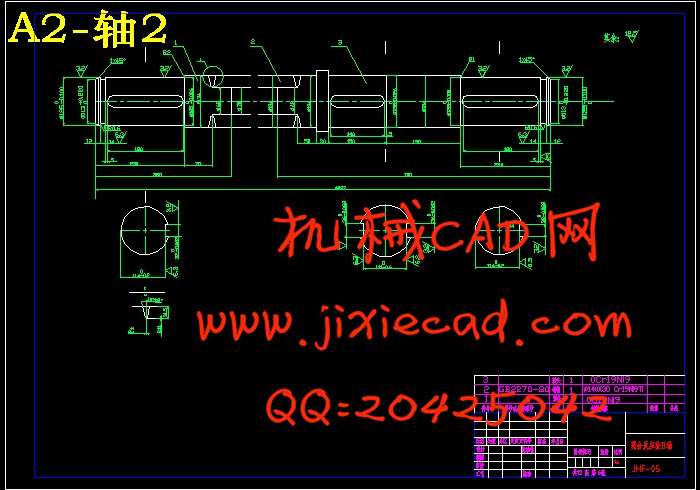

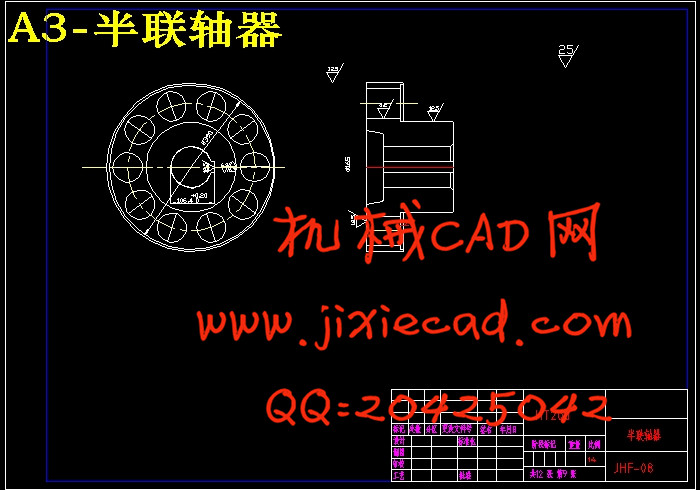

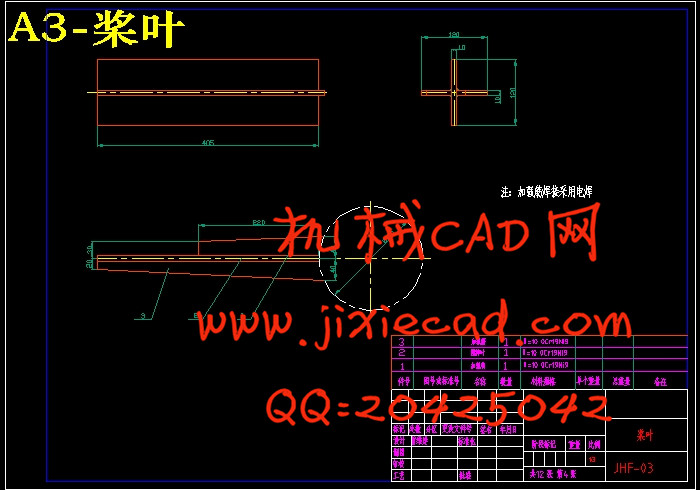

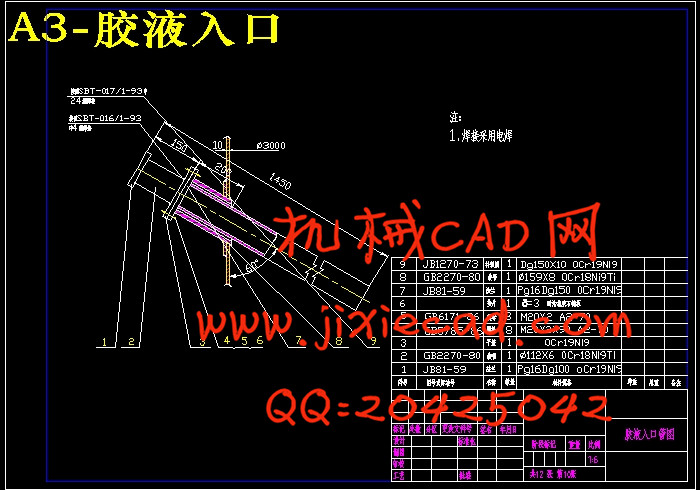

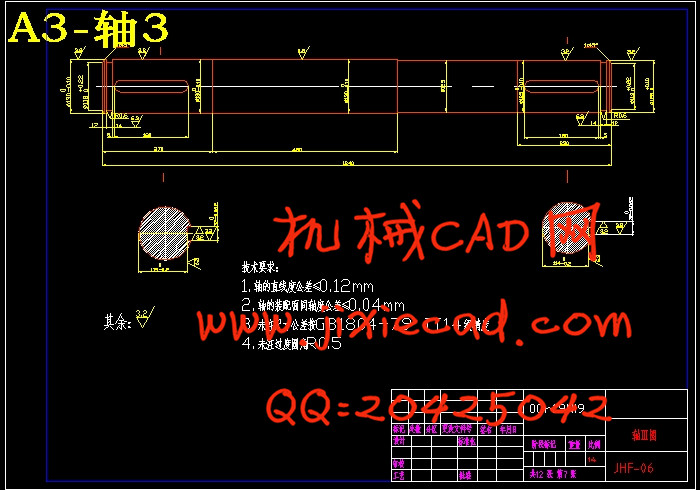

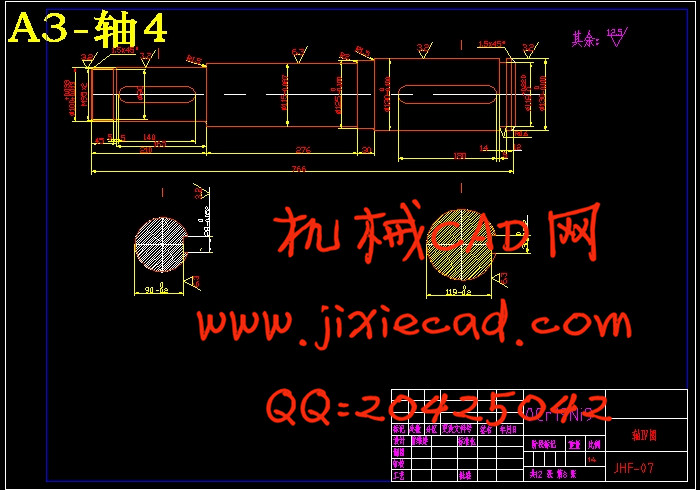

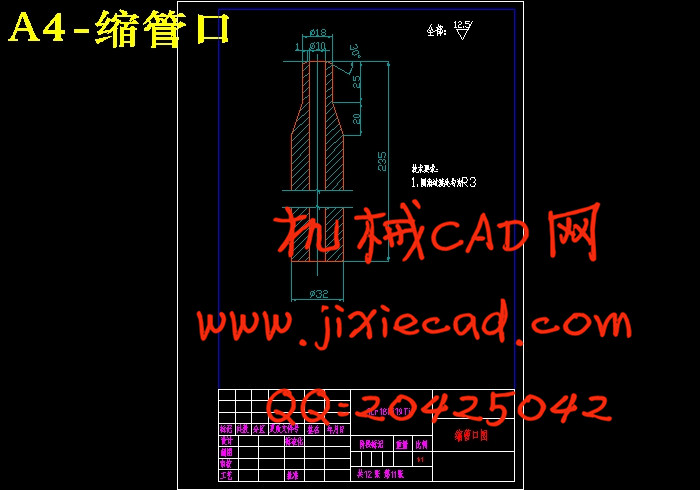

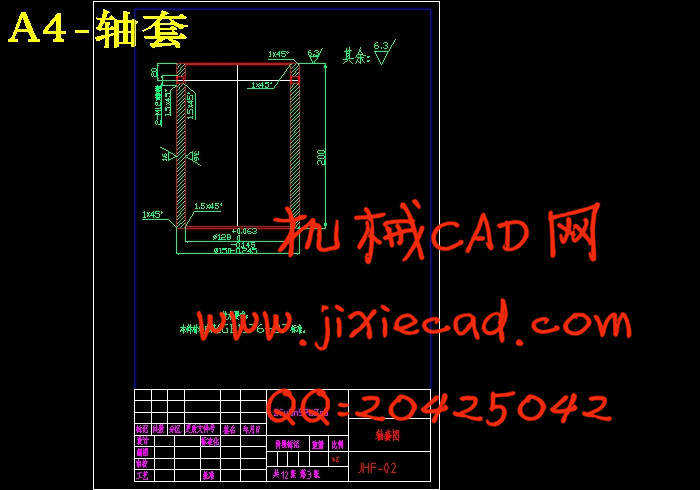

故本次设计的反应釜容积为60m³,实现了大容积化设备,提高了其生产效率,釜内的反应温度为150℃,采用从底部进行通入蒸汽进行加热,采用蒸汽加热能使釜内受热均匀,使物料受热更均匀,反应更彻底,相比之前夹套加热传热效率更高。本次设计为反应釜釜体的设计,搅拌装置的选型与尺寸设计(其中搅拌叶选用的是平直桨叶,直叶桨搅拌速度相对于其他搅拌桨速度快,搅拌效率高),人孔的开孔及补强计算,传动装置,反应釜的轴封装置选用,支座的选型,选用焊接类型,同时绘制了零件图、反应釜釜体体图以及反应釜的装配图等。设计方法采用压力容器常规设计的方法,遵循《化工设备》要求,按照GB150-98《钢制压力容器》等技术法规执行。

目前,随着我国工业的快速发展,各行各业对压力容器的使用越来越广泛,涉及的领域包括化工、橡胶、食品、医药、石油等方面,尤其是我国对橡胶产品的需求量越来越大,聚合反应釜是橡胶生产过程必不可少的反应容器,现在国内主要的反应釜的容积为30m³生产效率低,成本高,已经不能满足橡胶生产需求,更大容积的反应釜的设计刻不容缓。

故本次设计的反应釜容积为60m³,实现了大容积化设备,提高了其生产效率,釜内的反应温度为150℃,采用从底部进行通入蒸汽进行加热,采用蒸汽加热能使釜内受热均匀,使物料受热更均匀,反应更彻底,相比之前夹套加热传热效率更高。本次设计为反应釜釜体的设计,搅拌装置的选型与尺寸设计(其中搅拌叶选用的是平直桨叶,直叶桨搅拌速度相对于其他搅拌桨速度快,搅拌效率高),人孔的开孔及补强计算,传动装置,反应釜的轴封装置选用,支座的选型,选用焊接类型,同时绘制了零件图、反应釜釜体体图以及反应釜的装配图等。设计方法采用压力容器常规设计的方法,遵循《化工设备》要求,按照GB150-98《钢制压力容器》等技术法规执行。

关键词:压力容器;搅拌器;聚合反应釜

ABSTRACT

At present, with the rapid development of China's industry, all walks of life on the use of pressure vessels more and more widely involved in areas such as chemical, rubber, food, medicine, oil, etc., especially China's demand for rubber products more and more The larger, the polymerization reactor is essential for the rubber production process reaction container, and now the main domestic reactor capacity of 30m³low production efficiency, high cost, has been unable to meet the needs of rubber production, the design of larger volume of the reactor without delay.

So the design of the reactor capacity of 60m³, to achieve a large volume of equipment to improve its production efficiency, the reactor temperature of 150℃, the use of steam from the bottom of the heating, the use of steam heating can make the kettle Heat evenly, so that the material is more uniform heat, the reaction more thoroughly, compared to the previous jacket heating heat transfer efficiency is higher. This design is designed for the reactor body design, mixing device selection and size design (which stir the leaves are selected straight blade, straight blade propeller stirring speed relative to other stirring blade speed, high stirring efficiency), people Hole of the hole and reinforcement calculation, transmission device, the reactor shaft seal device selection, bearing selection, selection of welding type, while drawing the parts, the reactor body and the reactor assembly diagram. Design methods using pressure vessel conventional design method, follow the《chemical equipment》requirements, in accordance with GB150-98《steel pressure vessel》and other technical regulations.

Key Words:Pressure vessel; agitator; polymerization reactor

目 录At present, with the rapid development of China's industry, all walks of life on the use of pressure vessels more and more widely involved in areas such as chemical, rubber, food, medicine, oil, etc., especially China's demand for rubber products more and more The larger, the polymerization reactor is essential for the rubber production process reaction container, and now the main domestic reactor capacity of 30m³low production efficiency, high cost, has been unable to meet the needs of rubber production, the design of larger volume of the reactor without delay.

So the design of the reactor capacity of 60m³, to achieve a large volume of equipment to improve its production efficiency, the reactor temperature of 150℃, the use of steam from the bottom of the heating, the use of steam heating can make the kettle Heat evenly, so that the material is more uniform heat, the reaction more thoroughly, compared to the previous jacket heating heat transfer efficiency is higher. This design is designed for the reactor body design, mixing device selection and size design (which stir the leaves are selected straight blade, straight blade propeller stirring speed relative to other stirring blade speed, high stirring efficiency), people Hole of the hole and reinforcement calculation, transmission device, the reactor shaft seal device selection, bearing selection, selection of welding type, while drawing the parts, the reactor body and the reactor assembly diagram. Design methods using pressure vessel conventional design method, follow the《chemical equipment》requirements, in accordance with GB150-98《steel pressure vessel》and other technical regulations.

Key Words:Pressure vessel; agitator; polymerization reactor

摘 要 II

ABSTRACT III

1 绪论 1

1.1 压力容器的概述 1

1.2 反应釜的发展方向 2

1.3 本文设计的研究内容 2

2 材料选择 3

3 反应釜结构设计 4

3.1 罐体的尺寸参数确定 4

3.2 传热部件 8

3.3 工艺开孔和接管 8

3.4 人孔的补强计算 9

4 搅拌器的选型 11

4.1 搅拌桨的选型 11

4.2 搅拌附件(挡板) 11

4.3 传动装置的选型 12

4.4 搅拌功率的计算 12

4.3 搅拌轴的计算 13

4.4 联轴器 14

4.5 安装支座 14

5 密封结构 15

6 安全检测 16

6.1 无损探伤 16

6.2 强度检验 16

6.3 致密性试验 18

7 结 论 19

参 考 文 献 20

致 谢 32