设计简介

摘 要

螺旋离心泵在国民的生产与生活中有着广泛的应用以及重要的意义,它涉及于国民经济的方方面面,如:渔业、排水、制糖、冶金等等。

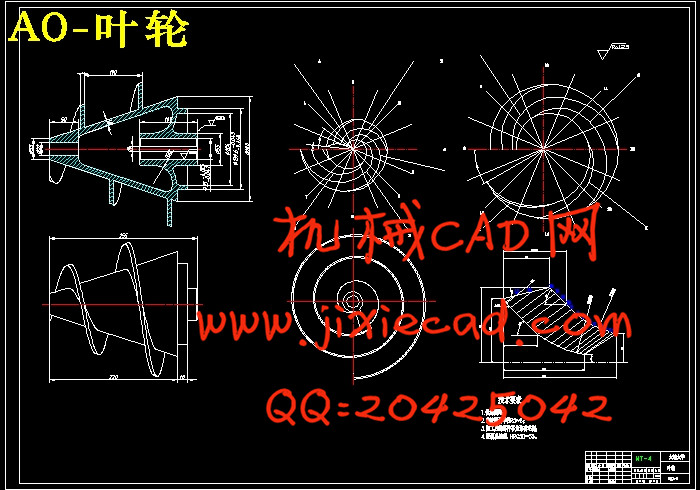

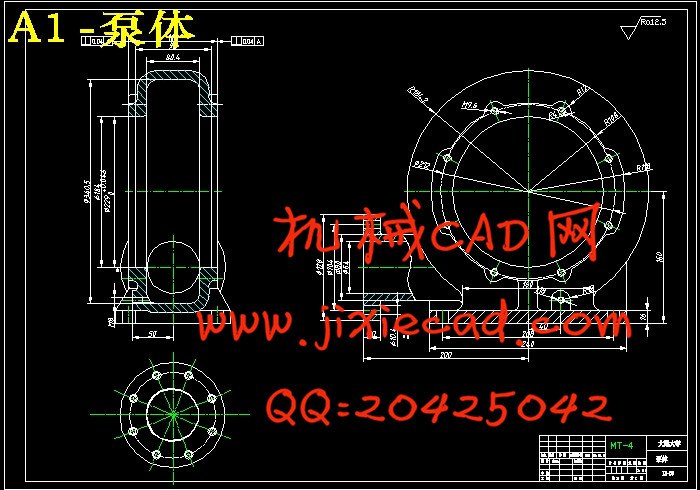

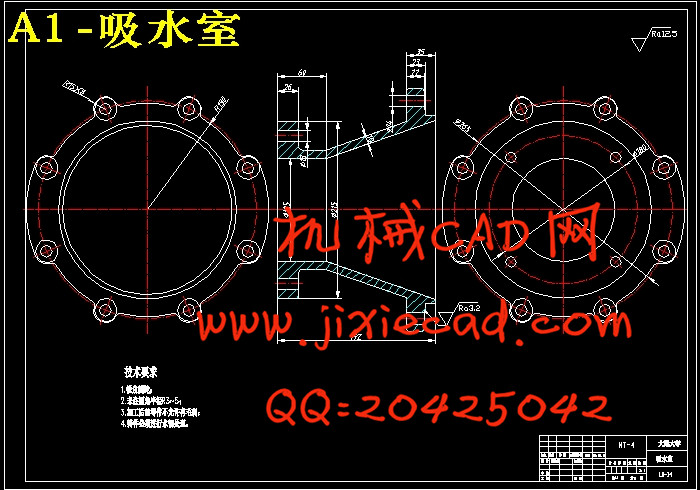

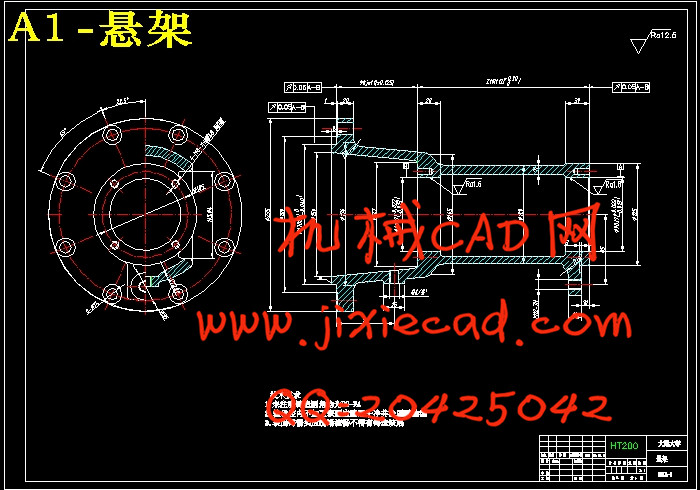

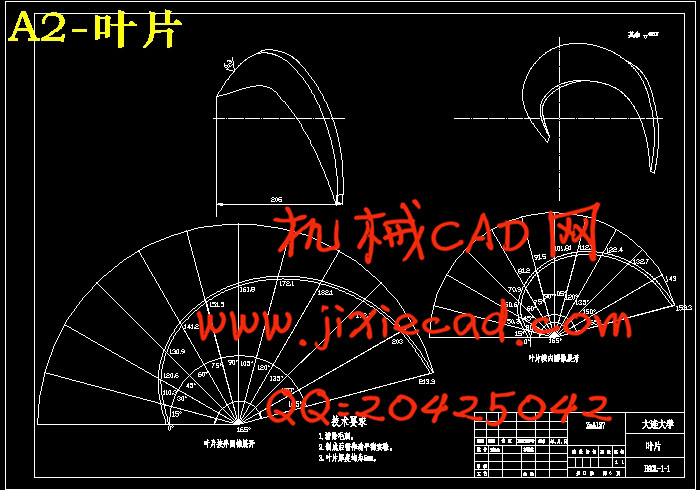

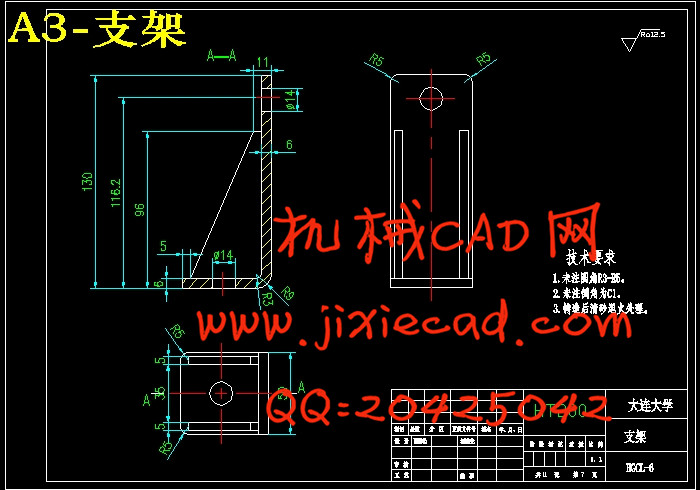

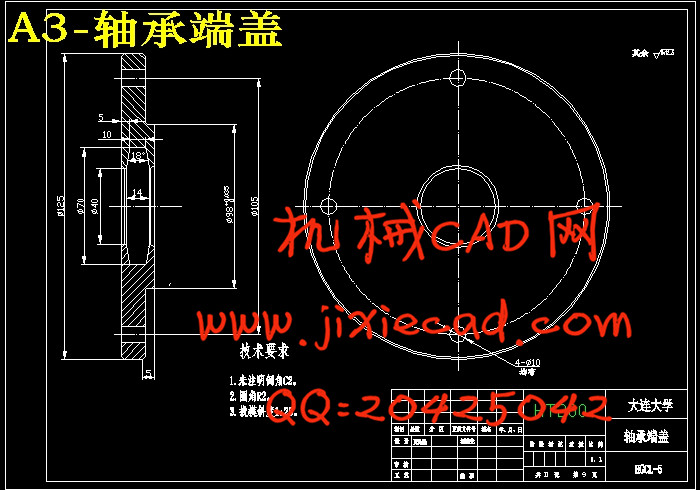

采取固液两种状态的流体的相关研究对叶轮等重要部分进行了水力设计。整篇文章始于结构的相关构造,分别进行了叶片、压水室、进水室的设计,重要零件的选择以及离心泵主要构件的强度计算。设计过程中充分考虑实际生产使用中所可能出现的问题,后根据问题对各零件的位置、形状及结构进行合理的设计。

本文设计的螺旋离心泵可以实现固液两种状态的流体的运输。与其他类型的泵相比,

其功率曲线平坦;良好的调节性能;泵的吸入性能好;具有优良的抗汽蚀性能;还可输送油水混合物而不致乳化等优点,可以广泛运用到现代化生产中去。首先,通过对螺旋离心泵的现况及类型原理进行了分析并拟定设计方案;接着,对主要零件包括,叶轮、泵壳、泵轴和通用件等进行了设计与选择计算;然后,对主要零部件的强度进行了校核;最后,

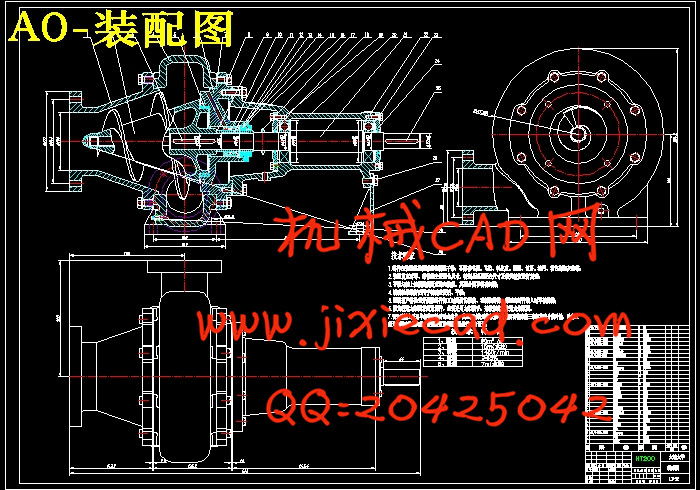

绘制系统 2D 装配图和主要零件图并进行 3D 造型设计。

关键词 固液两相流体;螺旋离心泵;结构设计;叶轮

ABSTRACT

Screw centrifugal pump in the national production and life has been widely used and important sense, it involves all aspects of our national economy, such as: fishing, drainage, sugar, metallurgy and so on.

Take the solid-liquid two states of fluid related research on the important parts such as impeller hydraulic design.Entire article begins with the structure of the related structure, separately carried on the blade, the pressurized water chamber, the design of the inlet chamber, the choice of important parts and the strength calculation of centrifugal pump main components.Design process fully consider the possible problems in the use of actual production, according to the problems on the parts after the location, shape and structure of reasonable design.

In this paper, design of screw centrifugal pump can realize solid-liquid two status of transportation of the fluid.Compared with other types of pump, the power curve flat;Good regulation performance;Pump inhalation can be good;It has excellent resistance to cavitation performance;Can also transport oil-water mixture without emulsification etc, and can be widely used in the modern production. First of all, through the analysis of the current situation and type of the screw centrifugal pump, the design scheme is proposed. Then, the main parts include the design and selection of the main parts, such as impeller, pump casing, pump shaft and general parts, and then check the strength of the main parts. Finally, the 2D assembly drawings and the main parts of the system are designed.

Key words: Solid - liquid two - phase fluid; spiral centrifugal pump;

structural design; impelle

目 录

螺旋离心泵在国民的生产与生活中有着广泛的应用以及重要的意义,它涉及于国民经济的方方面面,如:渔业、排水、制糖、冶金等等。

采取固液两种状态的流体的相关研究对叶轮等重要部分进行了水力设计。整篇文章始于结构的相关构造,分别进行了叶片、压水室、进水室的设计,重要零件的选择以及离心泵主要构件的强度计算。设计过程中充分考虑实际生产使用中所可能出现的问题,后根据问题对各零件的位置、形状及结构进行合理的设计。

本文设计的螺旋离心泵可以实现固液两种状态的流体的运输。与其他类型的泵相比,

其功率曲线平坦;良好的调节性能;泵的吸入性能好;具有优良的抗汽蚀性能;还可输送油水混合物而不致乳化等优点,可以广泛运用到现代化生产中去。首先,通过对螺旋离心泵的现况及类型原理进行了分析并拟定设计方案;接着,对主要零件包括,叶轮、泵壳、泵轴和通用件等进行了设计与选择计算;然后,对主要零部件的强度进行了校核;最后,

绘制系统 2D 装配图和主要零件图并进行 3D 造型设计。

关键词 固液两相流体;螺旋离心泵;结构设计;叶轮

ABSTRACT

Screw centrifugal pump in the national production and life has been widely used and important sense, it involves all aspects of our national economy, such as: fishing, drainage, sugar, metallurgy and so on.

Take the solid-liquid two states of fluid related research on the important parts such as impeller hydraulic design.Entire article begins with the structure of the related structure, separately carried on the blade, the pressurized water chamber, the design of the inlet chamber, the choice of important parts and the strength calculation of centrifugal pump main components.Design process fully consider the possible problems in the use of actual production, according to the problems on the parts after the location, shape and structure of reasonable design.

In this paper, design of screw centrifugal pump can realize solid-liquid two status of transportation of the fluid.Compared with other types of pump, the power curve flat;Good regulation performance;Pump inhalation can be good;It has excellent resistance to cavitation performance;Can also transport oil-water mixture without emulsification etc, and can be widely used in the modern production. First of all, through the analysis of the current situation and type of the screw centrifugal pump, the design scheme is proposed. Then, the main parts include the design and selection of the main parts, such as impeller, pump casing, pump shaft and general parts, and then check the strength of the main parts. Finally, the 2D assembly drawings and the main parts of the system are designed.

Key words: Solid - liquid two - phase fluid; spiral centrifugal pump;

structural design; impelle

目 录

| 摘 | 要........................................................ | Ⅰ | |

| ABSTRACT........................................................ | Ⅱ | ||

| 1 | 绪论 | .......................................................... | 1 |

| 1.1 | 研究背景及意义........................................................................................ | 1 | |

| 1.2 | 螺旋离心泵概述....................................................................................... | 1 | |

| 1.3 | 螺旋离心泵的国内外研究形状................................................................ | 3 | |

| 2 | 总体设计...................................................... | 5 | |

| 2.1 | 设计要求.................................................................................................... | 5 | |

| 2.2 | 方案的确定............................................................................................... | 5 | |

| 2.3 | 原动机的选择............................................................................................ | 6 | |

| 2.4 | 水力设计.................................................................................................... | 7 | |

| 3 | 主要零件的设计与选择计算...................................... | 8 | |

| 3.1 | 叶轮设计.................................................................................................... | 8 | |

| 3.2 | 泵轴的设计.............................................................................................. | 16 | |

| 3.2 | 压水室的设计.......................................................................................... | 17 | |

| 3.4 | 主要通用零部件的选择.......................................................................... | 19 | |

| 4 | 主要零件的强度计算........................................... | 21 | |

| 4.1 | 泵体的强度计算...................................................................................... | 21 | |

| 4.2 | 叶轮强度计算.......................................................................................... | 21 | |

| 4.3 | 泵轴的强度校核...................................................................................... | 22 | |

| 4.4 | 键的校核.................................................................................................. | 23 | |

| 4.5 | 轴承的校核.............................................................................................. | 24 | |

| 5 | 三维建模..................................................... | 25 | |

| 6 | 环保分析..................................................... | 28 | |

| 总结............................................................ | 29 | ||

| 参 考 文 献..................................................... | 30 | ||

| 致谢............................................................ | 40 | ||