设计简介

摘要

科技的发展推动着生产力的提高,现如今的社会是一个迈向自动化的社会,用自动化的机械代替人工进行重复且繁重的生产作业是大势所趋。PLC以及伺服电机和气缸是现如今广泛应用于自动化产业的设备,这些设备的应用大大降低了自动化设备的生产成本,为自动化机械的普及提供了条件。

纤维手套是一种消耗量巨大的医用产品,在纤维手套的生产中卷边和翻面是最繁重的两个步骤,传统的生产技术是通过人工来完成这两个步骤,然而人工操作不仅效率低下,且由于手套的消耗量大故需要雇佣许多工人来进行生产,这使得手套的生产成本过高。

本次设计采用PLC控制技术,通过伺服电机以及气缸的运动,完成手套加工中最为繁重的卷边以及翻面过程,减轻工人的劳动强度,降低生产成本。

关键词 手套;自动;卷边;脱模

Abstract

The development of science and technology promotes the improvement of productivity. today's society is a society moving towards automation. it is the general trend to use automation machinery instead of manual to carry out repetitive and heavy production operations. Plc, servo motors and cylinders are widely used in automation industry at present. the application of these equipment greatly reduces the production cost of automation equipment and provides conditions for the popularization of automation machinery.

Fiber gloves is a kind of medical product with huge consumption. curling and turning over are the most complicated steps in the production of fiber gloves. traditional production technology is to finish these two steps manually. however, manual operation is not only inefficient, but also needs to employ many workers to produce gloves because of the high consumption of gloves, which makes the production cost of gloves too high.

Plc control technology is adopted in this design, and through the movement of servo motor and cylinder, the heaviest curling and turning process in glove processing is completed, thus reducing the labor intensity of workers and reducing the production cost.

Keywords Gloves Automatic edge curl Release

科技的发展推动着生产力的提高,现如今的社会是一个迈向自动化的社会,用自动化的机械代替人工进行重复且繁重的生产作业是大势所趋。PLC以及伺服电机和气缸是现如今广泛应用于自动化产业的设备,这些设备的应用大大降低了自动化设备的生产成本,为自动化机械的普及提供了条件。

纤维手套是一种消耗量巨大的医用产品,在纤维手套的生产中卷边和翻面是最繁重的两个步骤,传统的生产技术是通过人工来完成这两个步骤,然而人工操作不仅效率低下,且由于手套的消耗量大故需要雇佣许多工人来进行生产,这使得手套的生产成本过高。

本次设计采用PLC控制技术,通过伺服电机以及气缸的运动,完成手套加工中最为繁重的卷边以及翻面过程,减轻工人的劳动强度,降低生产成本。

关键词 手套;自动;卷边;脱模

Abstract

The development of science and technology promotes the improvement of productivity. today's society is a society moving towards automation. it is the general trend to use automation machinery instead of manual to carry out repetitive and heavy production operations. Plc, servo motors and cylinders are widely used in automation industry at present. the application of these equipment greatly reduces the production cost of automation equipment and provides conditions for the popularization of automation machinery.

Fiber gloves is a kind of medical product with huge consumption. curling and turning over are the most complicated steps in the production of fiber gloves. traditional production technology is to finish these two steps manually. however, manual operation is not only inefficient, but also needs to employ many workers to produce gloves because of the high consumption of gloves, which makes the production cost of gloves too high.

Plc control technology is adopted in this design, and through the movement of servo motor and cylinder, the heaviest curling and turning process in glove processing is completed, thus reducing the labor intensity of workers and reducing the production cost.

Keywords Gloves Automatic edge curl Release

目 录

摘要 I

Abstract II

1 绪论 1

1.1 研究目的及意义 1

1.2 纤维手套生产现状 1

1.3 国内外手套卷边焊接和翻面机的发展 1

1.4 纤维手套卷边焊接和脱模装置综述 1

1.4.1卷边装置 1

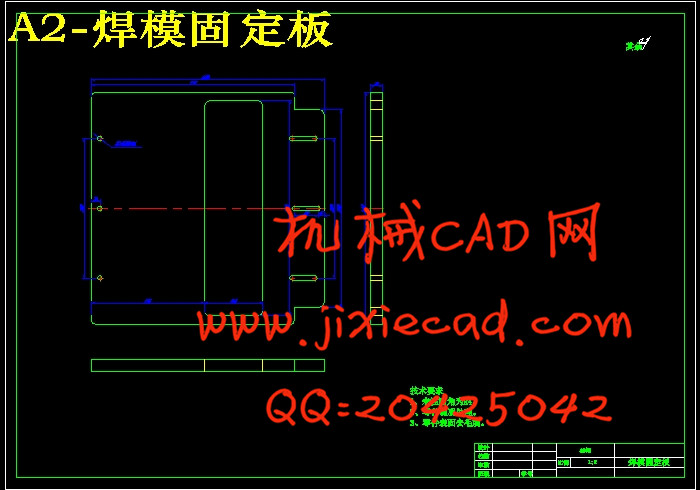

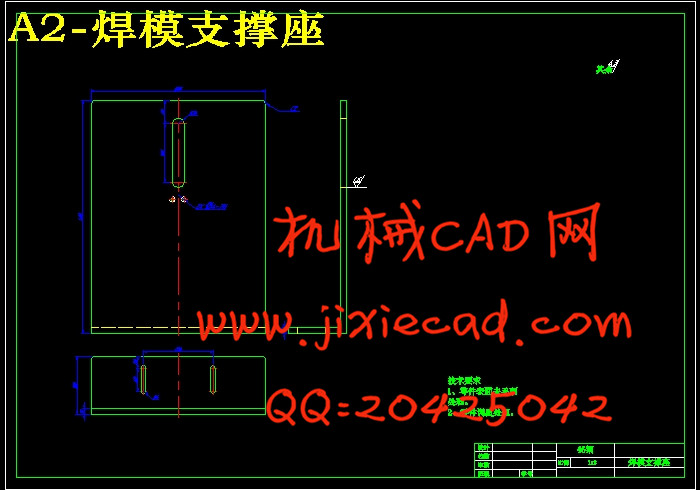

1.4.2 焊接装置 2

1.4.2 翻面装置 2

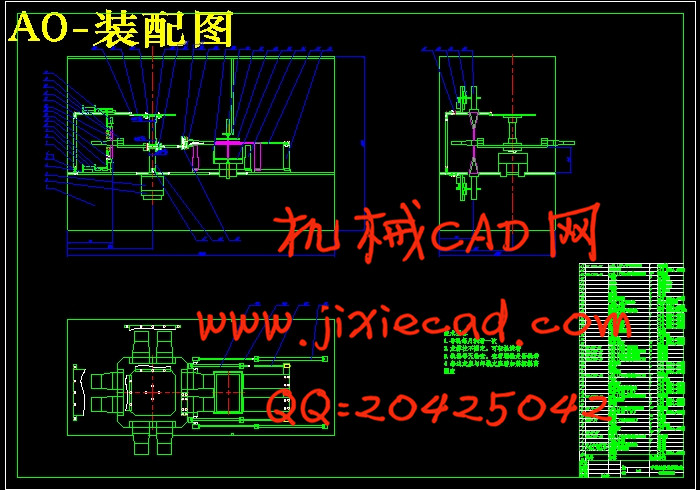

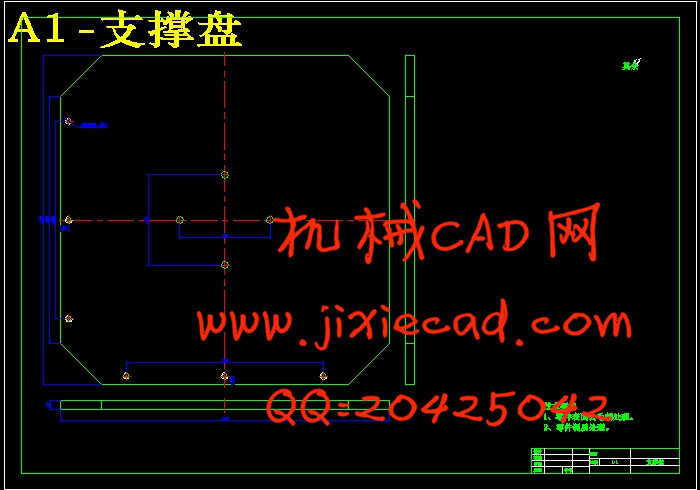

2 手套自动卷边焊接和脱模装置整体方案设计 3

2.1 纤维手套特性分析 3

2.2 设计参数及要求 3

2.3方案设计 3

3 驱动部分设计 4

3.1 电动机的选择计算 4

3.1.1 选择电动机的类型 4

3.1.2 确定电动机的运转模式 4

3.1.2 计算负载的转动惯量 4

3.1.2 确定电动机的转动惯量 5

3.1.2 确定电动机的转矩 5

3.2 气缸的选择计算 5

3.2.1 卷边推板气缸选择计算 5

3.2.2 卷边支座气缸选择计算 7

3.2.3 焊模气缸选择计算 8

3.2.4 脱模爪气缸选择计算 9

3.2.5 脱手套气缸选择计算 11

3.2.6 托手套气缸选择计算 11

3.2.7 脱模手模气缸选择计算 12

4 传动部分设计 14

4.1 减速器的选择计算 14

4.1.1 确定减速器的工作条件 14

4.1.2 初选减速器 14

4.2 直线导轨的选择 15

4.2.1 卷边推板导轨选择 15

4.2.2 卷边支座导轨选择 16

4.2.3 焊模导轨选择 16

5 PLC控制程序设计 18

5.1 可编程控制器 18

5.1.1 选择PLC型号 18

5.1.2 输入输出点的分配 18

5.1.3 程序运行框图 20

5.1.4 控制程序设计 20

结论 21

致谢 22

参考文献 23