设计简介

摘 要

此次设计的矿用泥浆泵类型为5PS型矿用砂泵。伴随煤矿产业的不断展开与深化,对钻井设备和工具也不断有着新的要求和挑战。矿用泥浆泵是采矿工具的重要组成部分之一,逐步向高效率、高压力和高可靠性与安全性的方向发展,同时当代采矿业也对矿用泥浆泵的耐磨性性耐久性和使用寿命也有着越来越高的要求。本次设计的为离心式矿用泥浆泵,首先电动机与联轴器相接与泵轴相连,通电之后电动机带动泵轴与叶轮转动,这样就把电动机的动能通过叶轮转化为泵内液体的机械能与压力能。由于离心力的关系,泵液获得能量后经过压出室向排浆口流去,同时由于泵体内液体的流失造成叶轮进口的大气压降低所以又会源源不断的从进浆口不断吸入液体,这样就实现了矿液的循环。

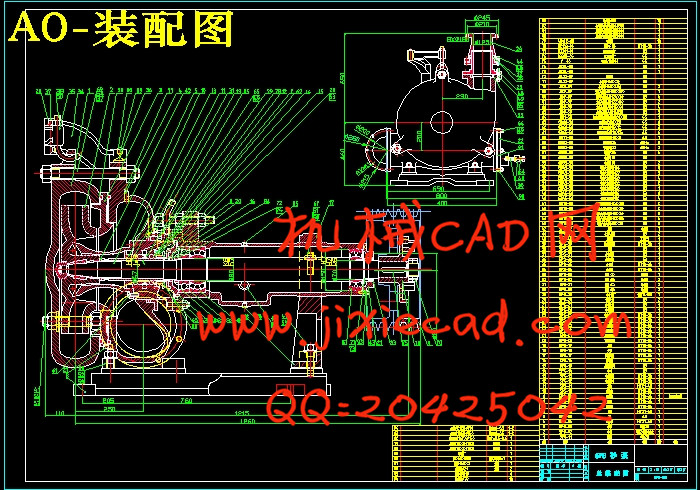

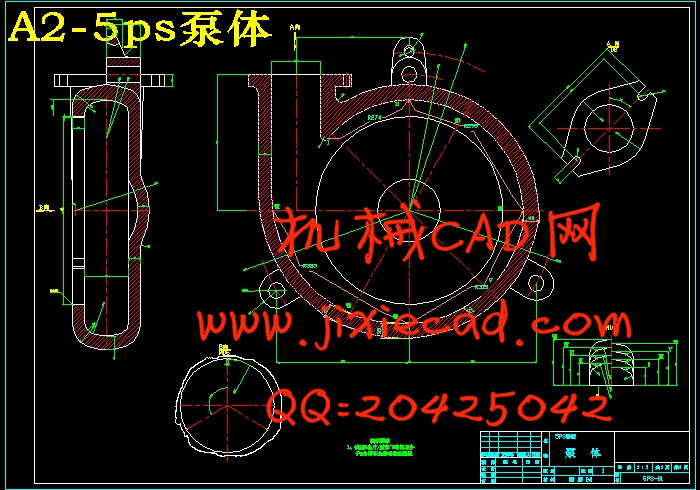

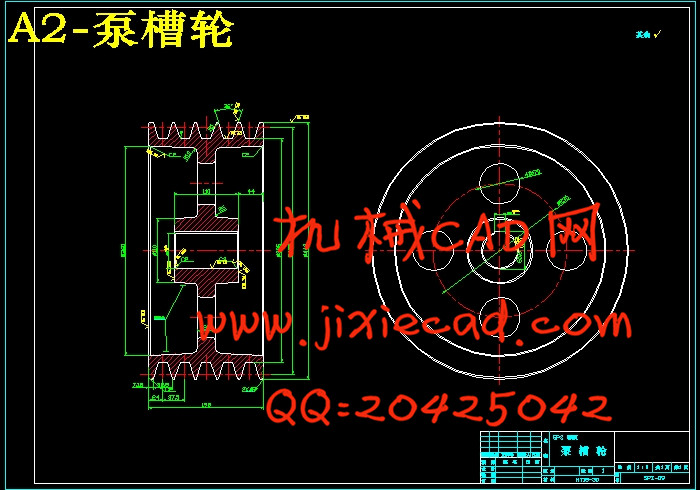

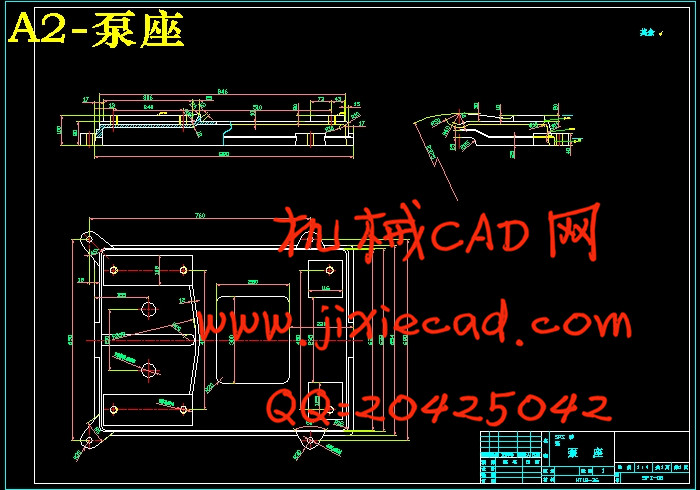

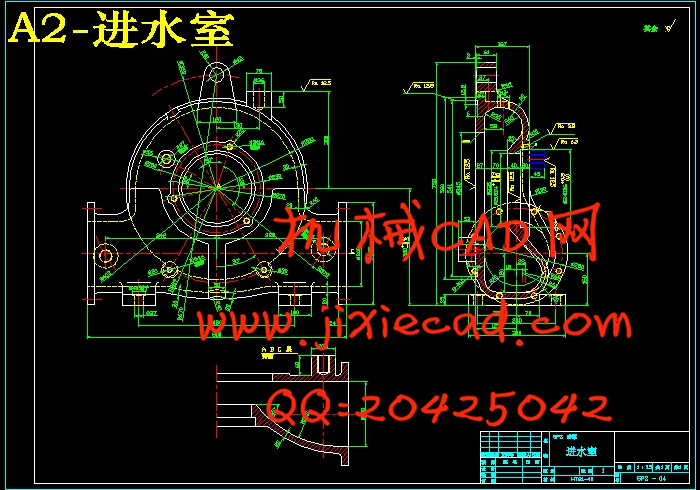

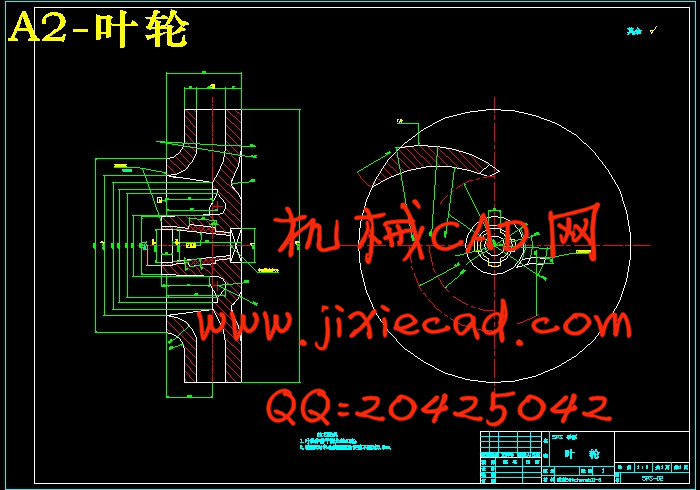

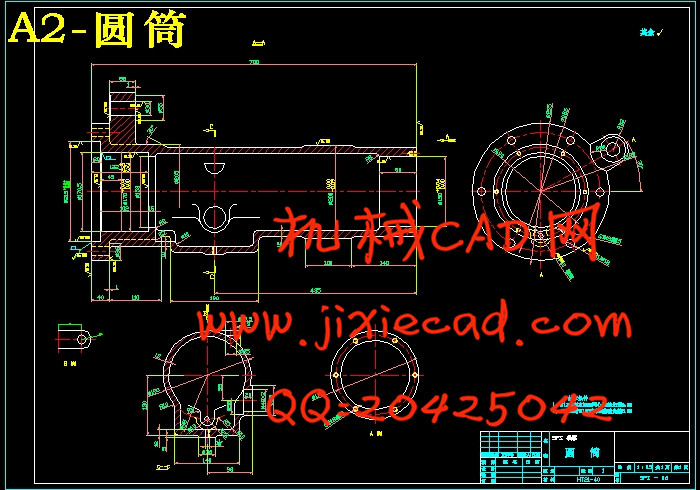

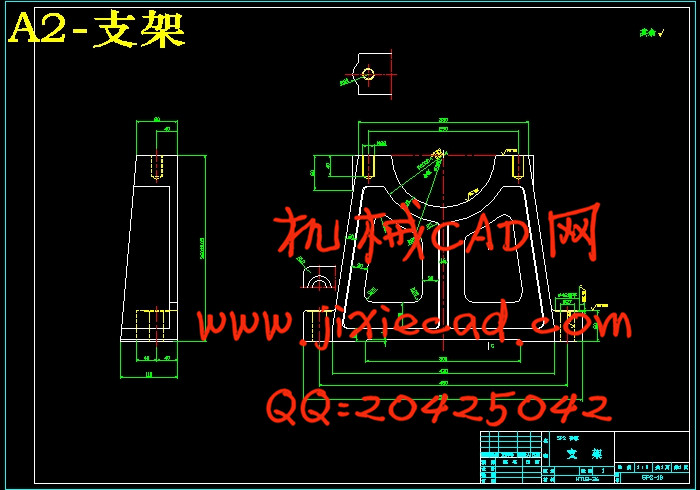

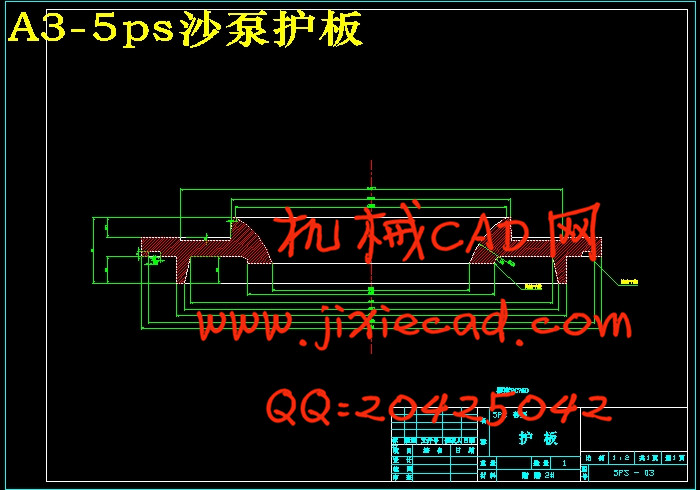

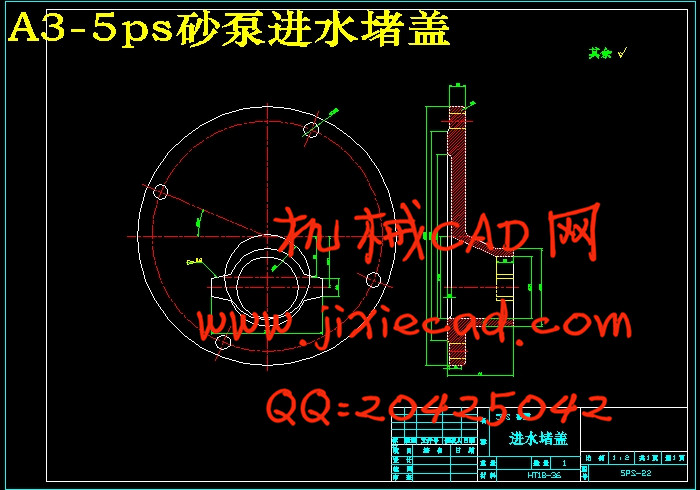

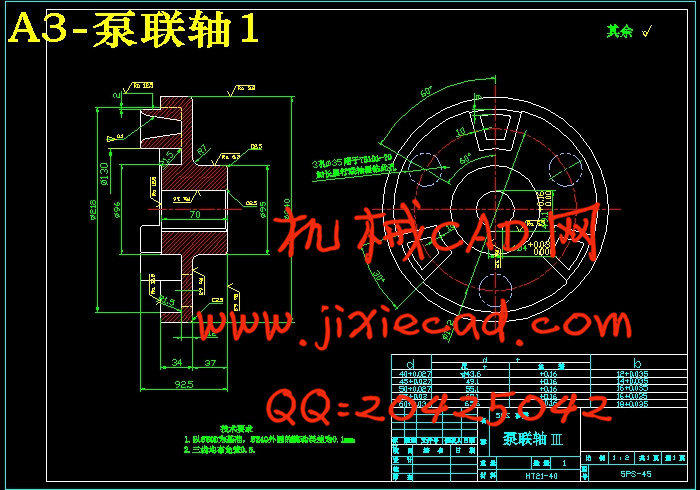

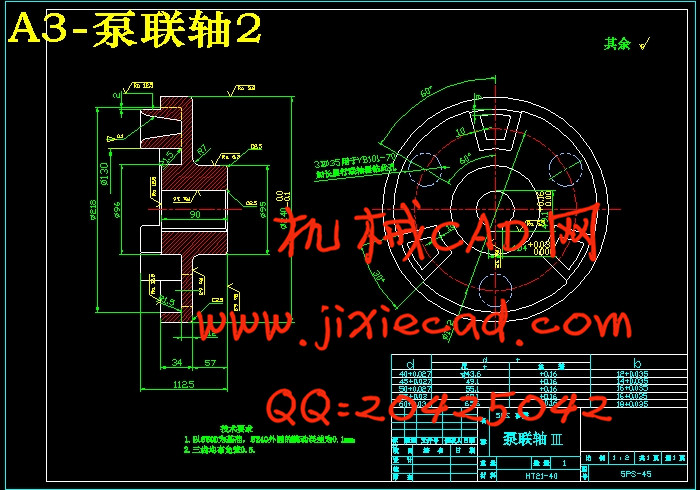

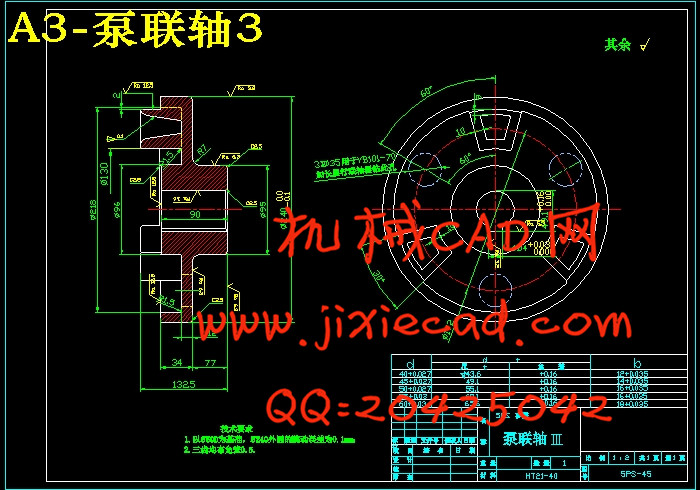

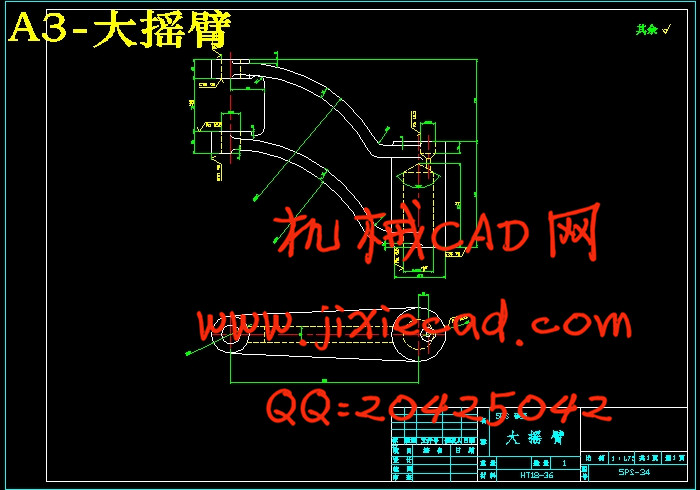

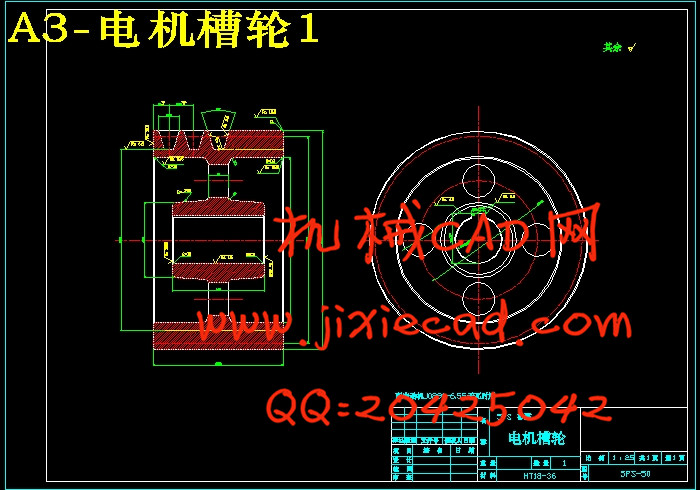

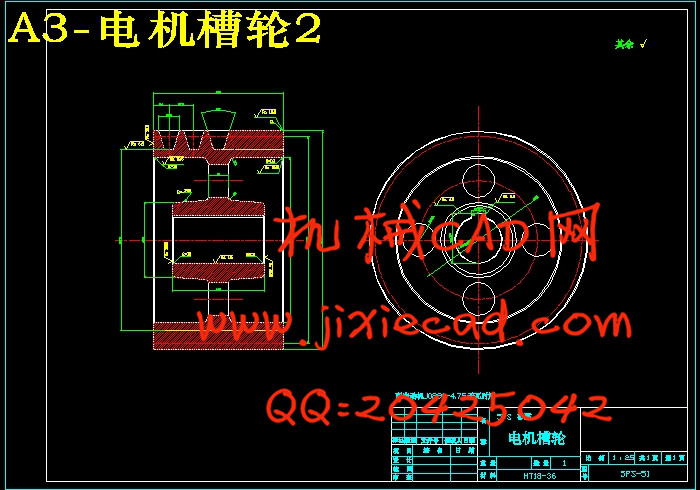

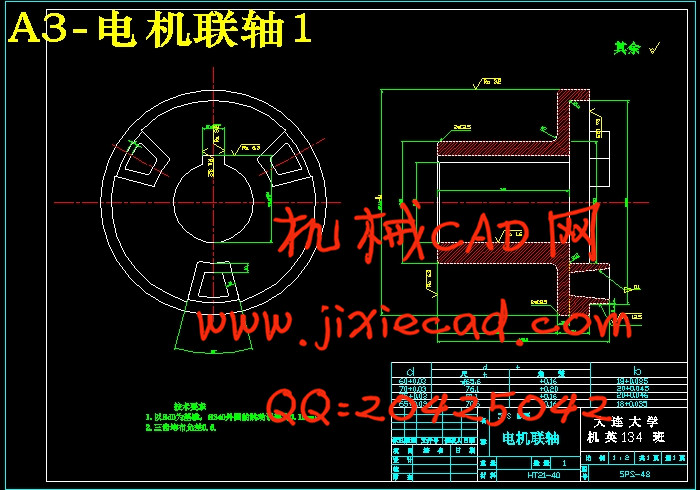

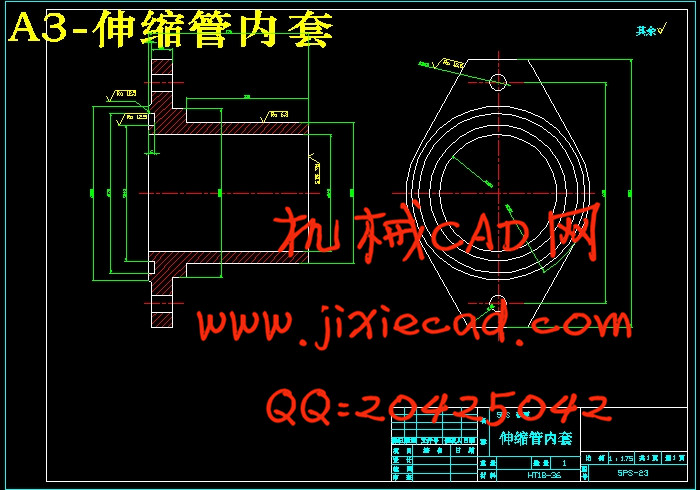

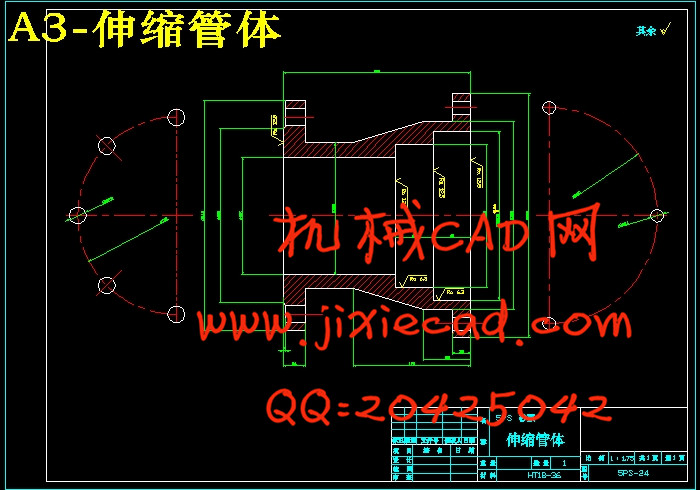

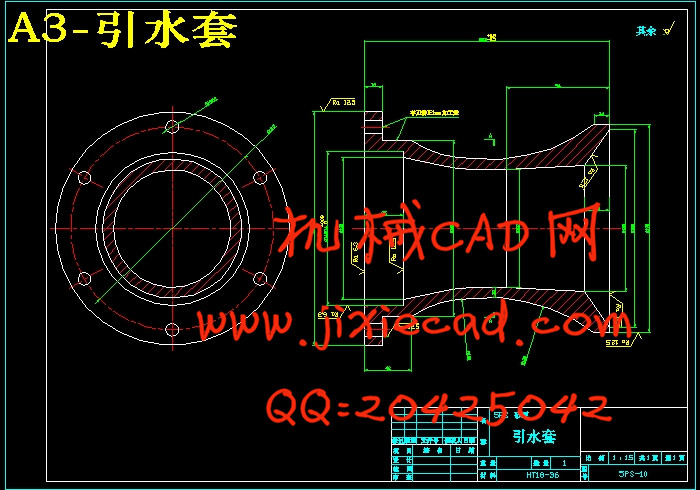

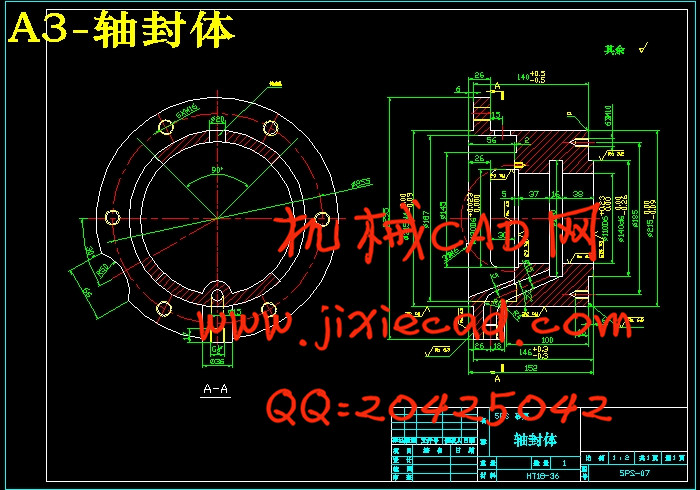

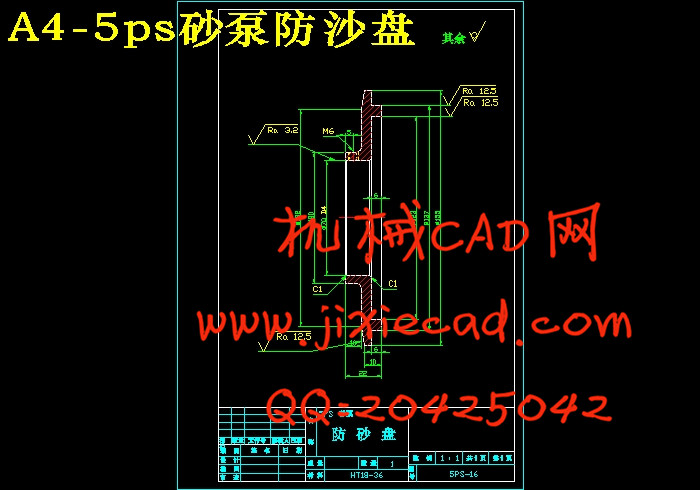

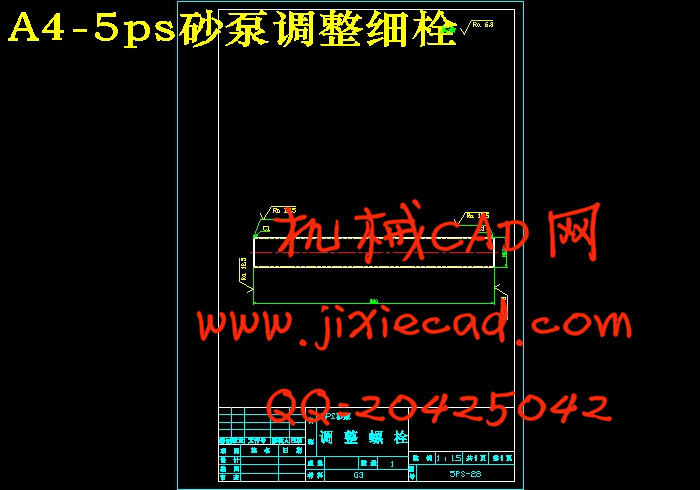

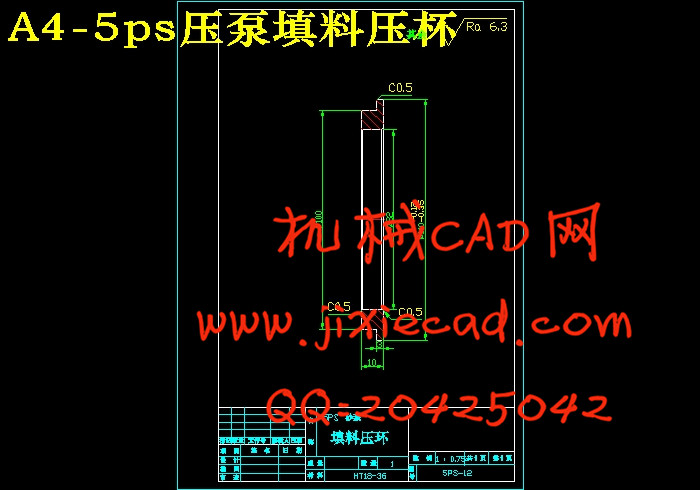

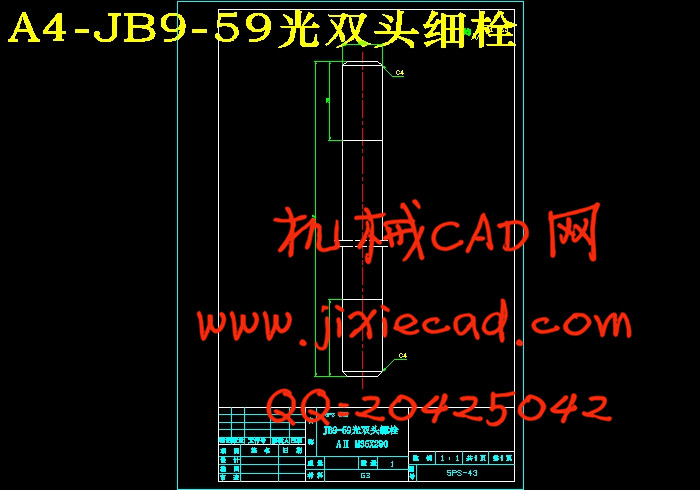

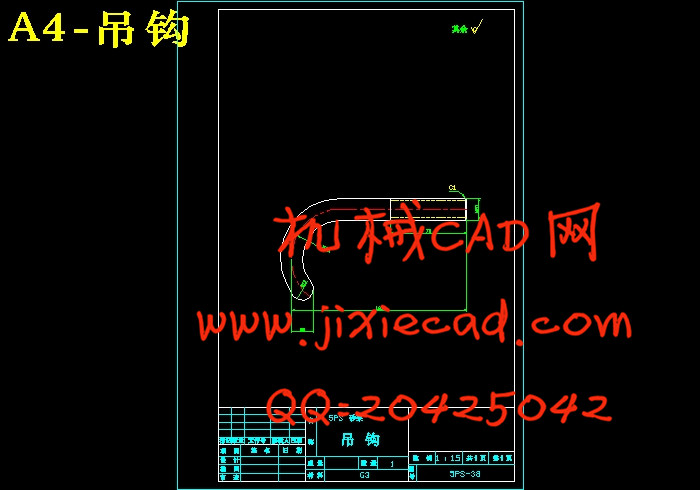

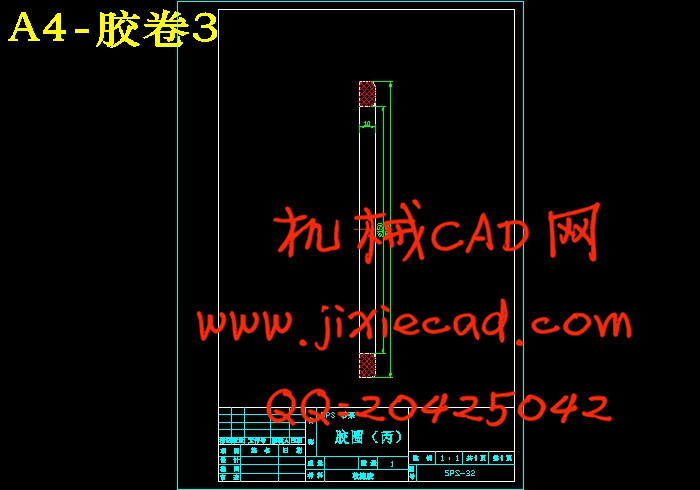

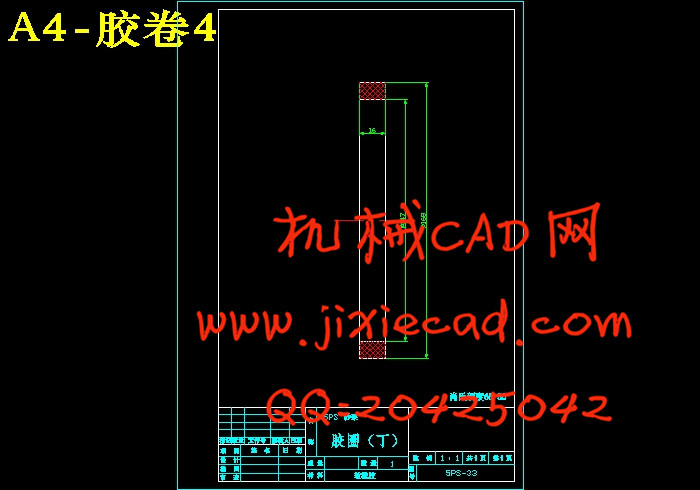

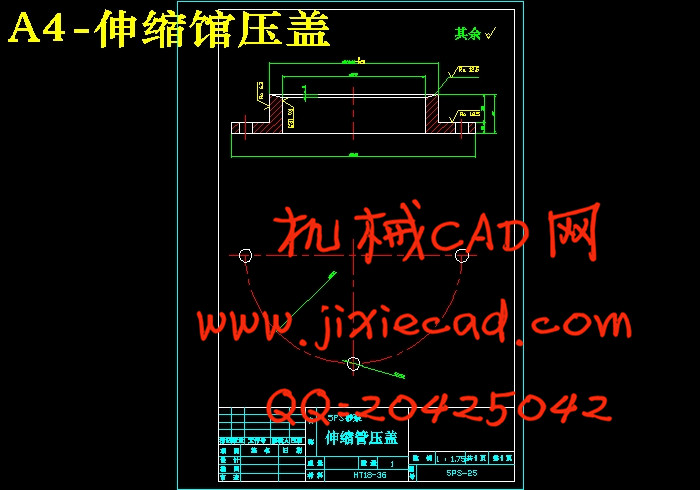

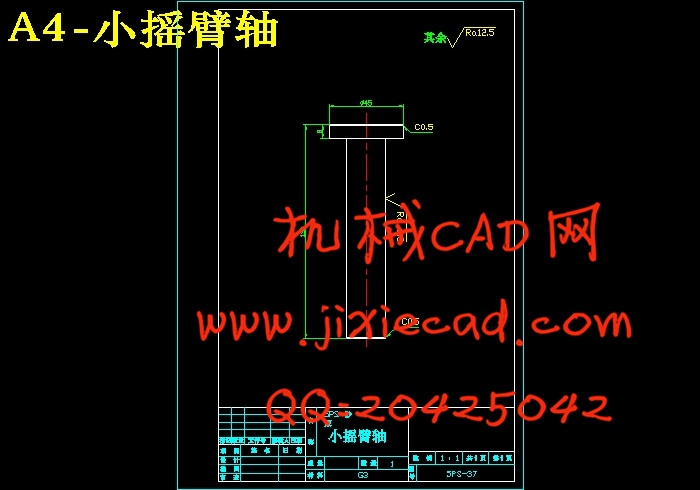

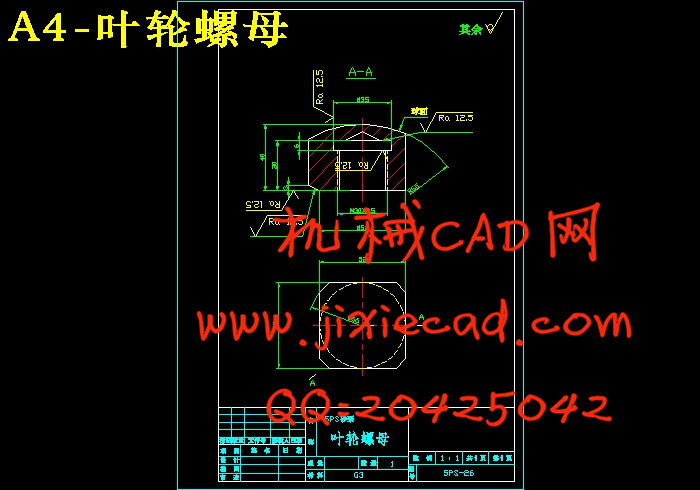

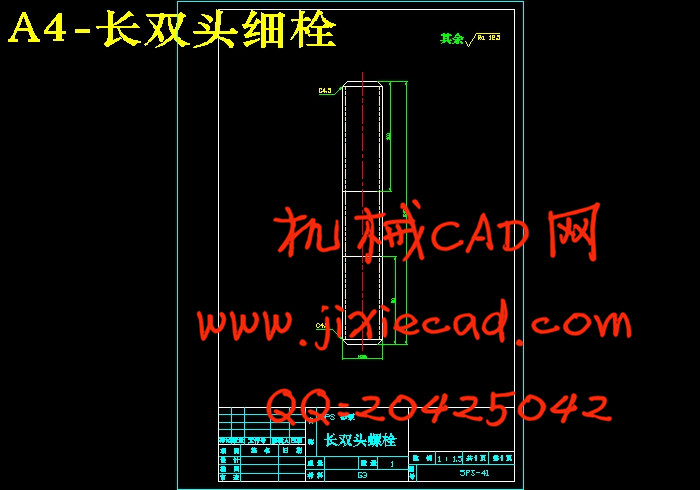

按照给定的初始设计参数,此次设计主要阐释了泥浆泵的工作原理以及完成了叶轮、泵轴、轴封机构、密封环及轴承等主体零部件的结构和参数设计和电动机型号的选择,并对泵轴和轴承进行了详细的强度和寿命校核,也进行了可行性分析,完成绘制了叶轮、泵体、压入室、泵轴等主要零的零件图以及泥浆泵的装配图。

关键词:矿用泥浆泵;叶轮;轴

Abstract

The design of the mine mud pump type for the 5PS mine sand pump. With the continuous development of the coal industry and in-depth, drilling equipment and tools also continue to have new requirements and challenges. Mine mud pump is one of the important components of mining drilling equipment, and gradually to the high efficiency, high pressure and high reliability and safety direction, while the contemporary mining industry is also mine wear resistance of mining mud And the service life also has a higher and higher requirements. This design is a centrifugal mine mud pump, the first motor and the coupling phase connected with the pump shaft connected to the motor after the drive pump shaft and impeller rotation, so put the motor kinetic energy through the impeller into the pump liquid mechanical With pressure energy. Due to the relationship between the centrifugal force, the pump after the energy obtained through the extrusion chamber to the slurry port flow, and because the loss of liquid in the pump caused by the impeller inlet atmospheric pressure drop will be a steady stream from the mouth into the liquid, To achieve the circulation of ore.

According to the given initial design parameters, this design mainly explains the working principle of the mud pump and completes the structure and parameter design of the main parts such as impeller, pump shaft, shaft seal mechanism, seal ring and bearing, and the choice of motor model, And the pump shaft and bearing a detailed strength and life check, but also carried out a feasibility analysis, completed the drawing of the impeller, pump, pressure chamber, pump shaft and other major zero parts and mud pump assembly diagram.

Keywords: mine mud pump; impeller; shaft.

此次设计的矿用泥浆泵类型为5PS型矿用砂泵。伴随煤矿产业的不断展开与深化,对钻井设备和工具也不断有着新的要求和挑战。矿用泥浆泵是采矿工具的重要组成部分之一,逐步向高效率、高压力和高可靠性与安全性的方向发展,同时当代采矿业也对矿用泥浆泵的耐磨性性耐久性和使用寿命也有着越来越高的要求。本次设计的为离心式矿用泥浆泵,首先电动机与联轴器相接与泵轴相连,通电之后电动机带动泵轴与叶轮转动,这样就把电动机的动能通过叶轮转化为泵内液体的机械能与压力能。由于离心力的关系,泵液获得能量后经过压出室向排浆口流去,同时由于泵体内液体的流失造成叶轮进口的大气压降低所以又会源源不断的从进浆口不断吸入液体,这样就实现了矿液的循环。

按照给定的初始设计参数,此次设计主要阐释了泥浆泵的工作原理以及完成了叶轮、泵轴、轴封机构、密封环及轴承等主体零部件的结构和参数设计和电动机型号的选择,并对泵轴和轴承进行了详细的强度和寿命校核,也进行了可行性分析,完成绘制了叶轮、泵体、压入室、泵轴等主要零的零件图以及泥浆泵的装配图。

关键词:矿用泥浆泵;叶轮;轴

Abstract

The design of the mine mud pump type for the 5PS mine sand pump. With the continuous development of the coal industry and in-depth, drilling equipment and tools also continue to have new requirements and challenges. Mine mud pump is one of the important components of mining drilling equipment, and gradually to the high efficiency, high pressure and high reliability and safety direction, while the contemporary mining industry is also mine wear resistance of mining mud And the service life also has a higher and higher requirements. This design is a centrifugal mine mud pump, the first motor and the coupling phase connected with the pump shaft connected to the motor after the drive pump shaft and impeller rotation, so put the motor kinetic energy through the impeller into the pump liquid mechanical With pressure energy. Due to the relationship between the centrifugal force, the pump after the energy obtained through the extrusion chamber to the slurry port flow, and because the loss of liquid in the pump caused by the impeller inlet atmospheric pressure drop will be a steady stream from the mouth into the liquid, To achieve the circulation of ore.

According to the given initial design parameters, this design mainly explains the working principle of the mud pump and completes the structure and parameter design of the main parts such as impeller, pump shaft, shaft seal mechanism, seal ring and bearing, and the choice of motor model, And the pump shaft and bearing a detailed strength and life check, but also carried out a feasibility analysis, completed the drawing of the impeller, pump, pressure chamber, pump shaft and other major zero parts and mud pump assembly diagram.

Keywords: mine mud pump; impeller; shaft.

目 录

摘 要 I

Abstract II

1.绪 论 1

1.1 泵的定义和用途 1

1.2 泵分类 1

1.3 矿用泥浆泵发展现状 1

1.4 矿用泥浆泵发展趋势 2

2.矿用泥浆泵的总体方案设计 3

2.1 矿用泥浆泵的工作原理 3

2.2泥浆泵基本参数 3

3.电动机的选择 5

3.1 电动机的介绍 5

3.2 电动机型号选择 5

4.联轴器的选择 6

4.1 联轴器的原理与分类 7

4.2 联轴器的选用及其特点 7

5 .泥浆泵主要零件的设计 8

5.1 泥浆泵主要参数的合理选择 8

5.1.1泥浆泵的额定流量Q 8

5.1.2泥浆泵的扬程H 8

5.1.3其他参数的选择 8

5.2 吸浆管与排浆管的设计 8

5.2.1吸浆管的直径计算: 8

5.2.2排浆管的直径计算 8

5.3叶轮的设计 8

5.3.1叶轮材料的选择 9

5.3.2 叶轮的结构设计 9

5.4泵轴的设计及校核 10

5.4.1轴径的初步计算 10

5.4.2轴的强度计算 12

5.5轴封机构的设计 16

5.5.1轴封机构的作用及方式 16

5.5.2轴封机构的结构形式设计 16

5.6密封环的设计 18

5.6.1密封环的用途 18

5.6.2密封环的材料 18

5.6.3密封环的结构 18

5.7轴承部件的设计 19

5.7.1轴承型号的选择 19

5.7.2轴承的润滑 19

5.7.3轴承的密封 19

5.7.4轴承的寿命校核 19

6. 泥浆泵的使用与维护 21

6.1 泥浆泵的安装 21

6.2 泥浆泵的维护 21

6.3 泥浆泵的正确使用 21

6.4 泥浆泵的润滑 22

6.5 其他注意事项 22

7. 矿用泥浆泵的可行性分析 23

结 论 24

参 考 文 献 25

致 谢 35