设计简介

摘 要

齿轮作为机械领域重要的传动零件,应用于各个领域,其加工制造一直受到人们的重视。随着科学技术的发展,人们对齿轮的加工要求越来越高,齿轮加工后的去翻边毛刺已成为齿轮加工的必要工序。齿轮翻边毛刺的去除对其外观、传动精度、再加工和装配等都有很大的提高。并且能够降低机械传动产生的噪音,提高齿轮配合精度,从而提高齿轮的可靠性、寿命和润滑效果。

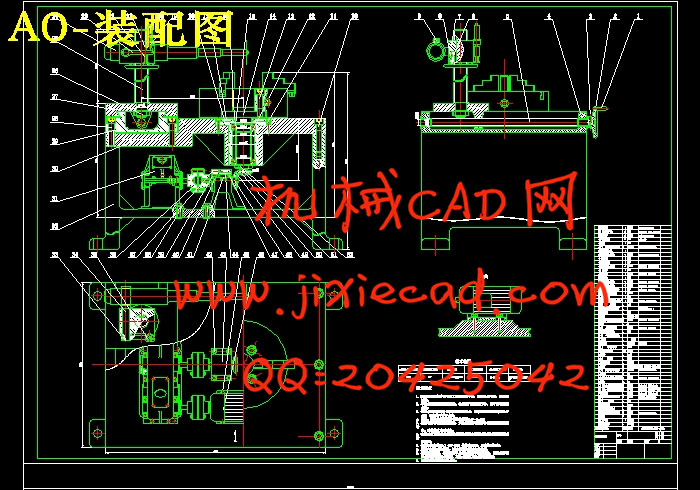

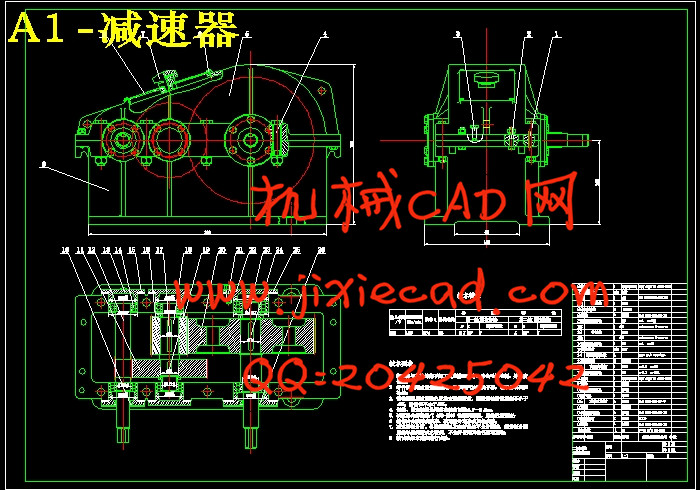

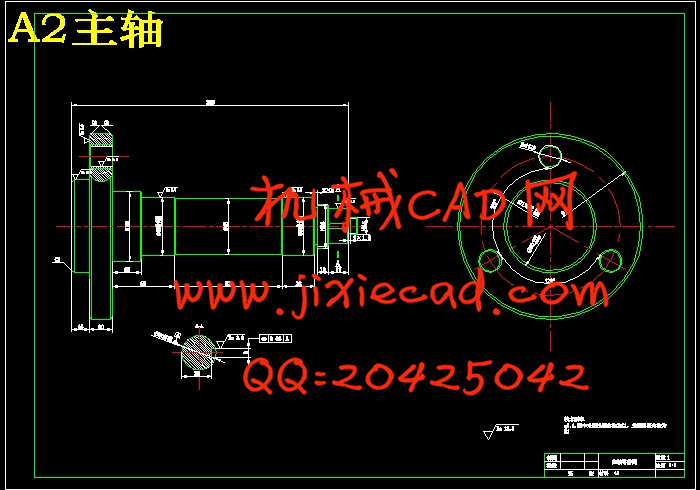

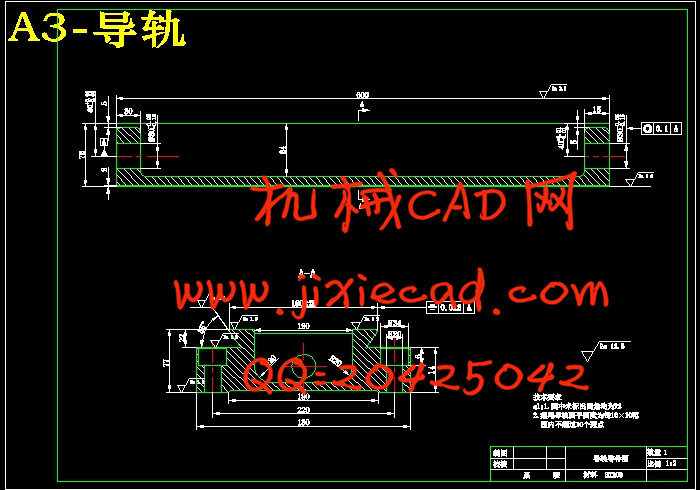

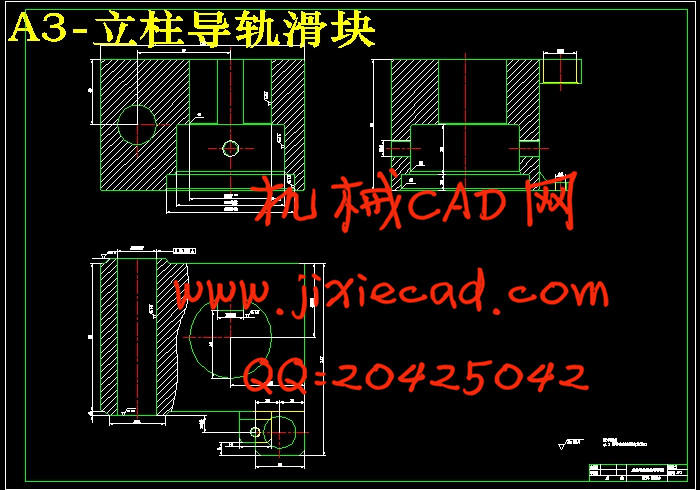

本文对齿轮磨棱倒角技术进行了分析,并提出了齿轮倒角机的可行性方案。对机床进行了整体工作原理的设计和分析,其中传动机构是设计的重点内容。主要可以分为两大类,第一是主轴传动部分,第二是砂轮空间运动部分。通过中间的设计连接件,将两部分有机结合起来,组成齿轮倒角机。对机床在工作情况下进行受力分析,设计出传动方案,并对其传动件进行设计、计算。最后对其外形与导轨进行了设计,得出了较合理的设计方案,使齿轮磨棱倒角方便快捷。解决了大型齿轮磨棱效率低、工时长的问题,设计的倒角机有较为广阔的使用前景。

关键词:齿轮加工;磨棱倒角;机床设计;传动系统;磨削

齿轮作为机械领域重要的传动零件,应用于各个领域,其加工制造一直受到人们的重视。随着科学技术的发展,人们对齿轮的加工要求越来越高,齿轮加工后的去翻边毛刺已成为齿轮加工的必要工序。齿轮翻边毛刺的去除对其外观、传动精度、再加工和装配等都有很大的提高。并且能够降低机械传动产生的噪音,提高齿轮配合精度,从而提高齿轮的可靠性、寿命和润滑效果。

本文对齿轮磨棱倒角技术进行了分析,并提出了齿轮倒角机的可行性方案。对机床进行了整体工作原理的设计和分析,其中传动机构是设计的重点内容。主要可以分为两大类,第一是主轴传动部分,第二是砂轮空间运动部分。通过中间的设计连接件,将两部分有机结合起来,组成齿轮倒角机。对机床在工作情况下进行受力分析,设计出传动方案,并对其传动件进行设计、计算。最后对其外形与导轨进行了设计,得出了较合理的设计方案,使齿轮磨棱倒角方便快捷。解决了大型齿轮磨棱效率低、工时长的问题,设计的倒角机有较为广阔的使用前景。

关键词:齿轮加工;磨棱倒角;机床设计;传动系统;磨削

ABSTRACT

Gear as the mechanical field important mechanical parts, the processing and manufacturing has been the subject of much attention. With the development of science and technology, gear processing requirements of increasingly high, gear processing to turn over burr has become a necessary step in gear machining. Gear burr removal flanging on the appearance, transmission accuracy, processing and assembly are improved greatly. And can reduce the mechanical noise, thereby improving the gear reliability, service life and lubricating effect.

The gear chamfering technology are analyzed, and puts forward the feasible scheme of gear chamfering machine. The working principle of the machine design and analysis. The machine in the condition of force analysis, design of transmission scheme, and the transmission part design, calculation. The more reasonable design scheme, solved large gear chamfering low efficiency, long working hours, the design of edge grinding machine has a broad application prospect.

Key Words:gear processing;Edge grinding and chamfering;machine tool design;driving system; grinding

Gear as the mechanical field important mechanical parts, the processing and manufacturing has been the subject of much attention. With the development of science and technology, gear processing requirements of increasingly high, gear processing to turn over burr has become a necessary step in gear machining. Gear burr removal flanging on the appearance, transmission accuracy, processing and assembly are improved greatly. And can reduce the mechanical noise, thereby improving the gear reliability, service life and lubricating effect.

The gear chamfering technology are analyzed, and puts forward the feasible scheme of gear chamfering machine. The working principle of the machine design and analysis. The machine in the condition of force analysis, design of transmission scheme, and the transmission part design, calculation. The more reasonable design scheme, solved large gear chamfering low efficiency, long working hours, the design of edge grinding machine has a broad application prospect.

Key Words:gear processing;Edge grinding and chamfering;machine tool design;driving system; grinding

目 录

摘 要 I

ABSTRACT II

1 绪论 1

1.1设计齿轮倒角机的出发点 1

1.2齿轮倒角机相关历史 1

1.3重点内容解析 2

2 齿轮倒角机的总体机构设计 3

2.1设计参数 3

2.2设计传动方案 3

3 齿轮旋转台设计 5

3.1动力源设计 5

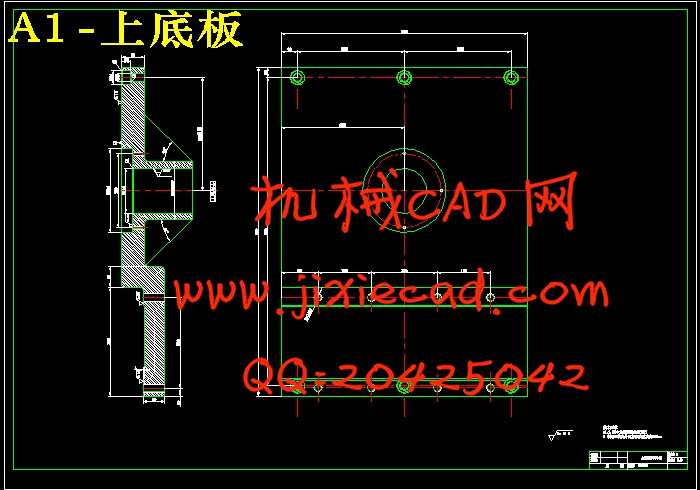

3.2工作台设计 22

4 齿轮倒角机的导轨设计 25

4.1主要卧式导轨设计 25

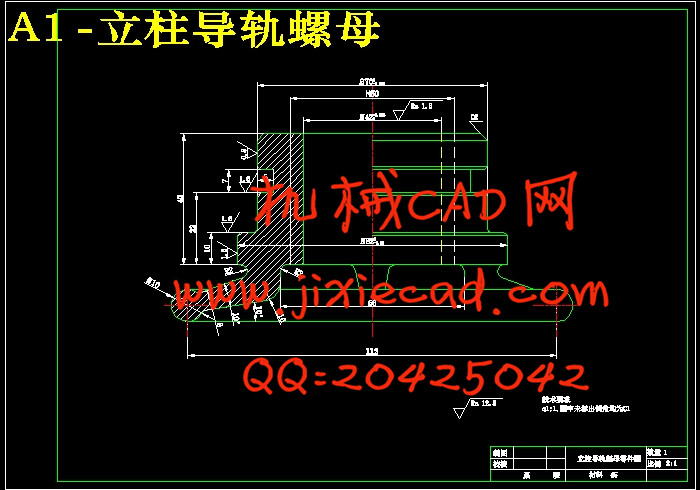

4.2立柱导轨的设计 26

5 结论 28

参考文献 30

致 谢 31