设计简介

摘 要

液压升降平台是一种多功能起重装卸机械设备。液压升降平台适用于多种场合,例如汽车维修场所升降待维修汽车时,市政维修需要高空作业时,以及流水线作业等等。液压升降机与其他一些传动方式相比,在同等功率下,液压装置相对体积小、质量轻、结构更加紧凑;在同等体积下,液压装置能产生更大的动力。

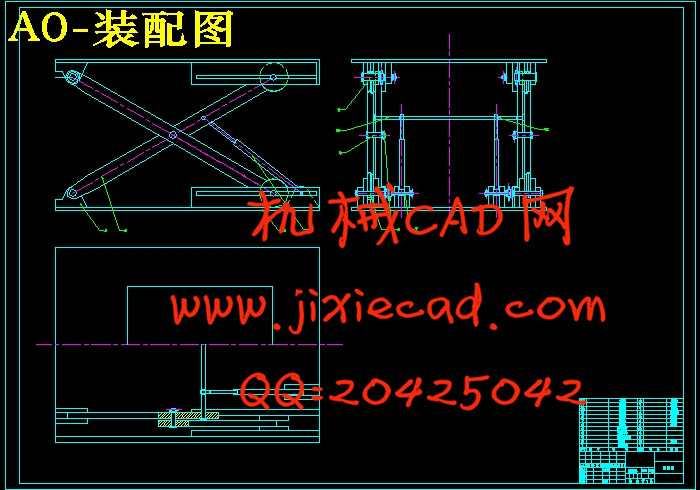

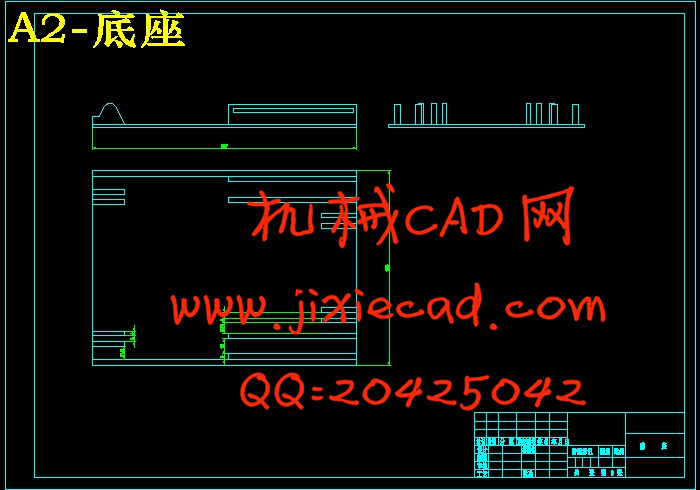

剪叉式液压升降机具有液压升降机的优点,同时,它的结构十分简单,能够承载较大载荷,工作可靠,可以便捷地实现自动控制。用作汽车维修用升降平台可以给工人师傅留下可观的空间进行汽车维修工作。剪叉式结构由两根相互交叉的支撑杆构成,两根支撑杆均为一头固定铰支连接,一头移动铰支连接。当液压缸工作时,液压缸推动支撑杆,这根支撑杆带动另外一根支撑杆运动,剪角变小,平台随之上升。如果要求降低载荷提高举升高度,则减少支撑杆长度并增加支撑杆数量可以轻松实现。

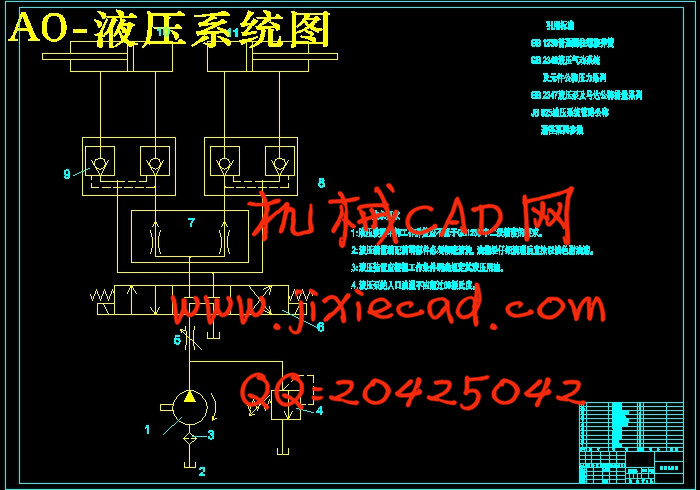

本论文即为汽车维修设计液压升降平台,所选用的液压升降平台的种类即为剪叉式液压升降平台。所选择的机械结构即为剪叉式结构。在选定机械结构后,对支撑杆件进行受力分析,进而计算液压传动系统,并根据手册选取合适液压元器件组成液压系统,最后完成支撑杆和销轴的强度校核,完成设计。

关键词:液压;升降平台;剪叉式;机械结构设计;强度校核;

剪叉式液压升降机具有液压升降机的优点,同时,它的结构十分简单,能够承载较大载荷,工作可靠,可以便捷地实现自动控制。用作汽车维修用升降平台可以给工人师傅留下可观的空间进行汽车维修工作。剪叉式结构由两根相互交叉的支撑杆构成,两根支撑杆均为一头固定铰支连接,一头移动铰支连接。当液压缸工作时,液压缸推动支撑杆,这根支撑杆带动另外一根支撑杆运动,剪角变小,平台随之上升。如果要求降低载荷提高举升高度,则减少支撑杆长度并增加支撑杆数量可以轻松实现。

本论文即为汽车维修设计液压升降平台,所选用的液压升降平台的种类即为剪叉式液压升降平台。所选择的机械结构即为剪叉式结构。在选定机械结构后,对支撑杆件进行受力分析,进而计算液压传动系统,并根据手册选取合适液压元器件组成液压系统,最后完成支撑杆和销轴的强度校核,完成设计。

关键词:液压;升降平台;剪叉式;机械结构设计;强度校核;

ABSTRACT

Hydraulic lifting platform is a multi-function lifting handling machinery and equipment. Hydraulic lifting platform for a variety of occasions, such as car repair places to be upgraded to repair the car, the municipal maintenance needs high-altitude operations, as well as pipeline operations and so on. Compared with other transmission methods, the hydraulic device is relatively small in volume, light in weight and compact in structure. Under the same volume, the hydraulic device can produce more power.

Scissor hydraulic lift has the advantages of hydraulic lift, at the same time, its structure is very simple, able to carry a larger load, reliable, you can easily achieve automatic control. Used as a vehicle maintenance platform can be left to the workers master considerable space for vehicle maintenance work. The scissor-shaped structure consists of two interlocking support rods, each of which is a fixed hinge connection and a hinged connection. When the hydraulic cylinder work, the hydraulic cylinder to promote the support rod, the support rod driven by another support rod movement, cut angle becomes smaller, the platform will rise. If the load is required to increase the lift height, reducing the length of the support bar and increasing the number of support bars can be easily achieved.

This paper is designed for hydraulic maintenance platform for hydraulic maintenance, the type of hydraulic lifting platform used is scissor hydraulic lift platform. The selected mechanical structure is the scissor structure. After selecting the mechanical structure, the support bar is subjected to the force analysis, and then the hydraulic drive system is calculated. According to the manual, the hydraulic system is selected according to the manual, and finally the strength of the support rod and the pin is checked to complete the design.

Key Words:Hydraulic; Lifting platform; Scissors;Mechanical design;Strength Check;

Hydraulic lifting platform is a multi-function lifting handling machinery and equipment. Hydraulic lifting platform for a variety of occasions, such as car repair places to be upgraded to repair the car, the municipal maintenance needs high-altitude operations, as well as pipeline operations and so on. Compared with other transmission methods, the hydraulic device is relatively small in volume, light in weight and compact in structure. Under the same volume, the hydraulic device can produce more power.

Scissor hydraulic lift has the advantages of hydraulic lift, at the same time, its structure is very simple, able to carry a larger load, reliable, you can easily achieve automatic control. Used as a vehicle maintenance platform can be left to the workers master considerable space for vehicle maintenance work. The scissor-shaped structure consists of two interlocking support rods, each of which is a fixed hinge connection and a hinged connection. When the hydraulic cylinder work, the hydraulic cylinder to promote the support rod, the support rod driven by another support rod movement, cut angle becomes smaller, the platform will rise. If the load is required to increase the lift height, reducing the length of the support bar and increasing the number of support bars can be easily achieved.

This paper is designed for hydraulic maintenance platform for hydraulic maintenance, the type of hydraulic lifting platform used is scissor hydraulic lift platform. The selected mechanical structure is the scissor structure. After selecting the mechanical structure, the support bar is subjected to the force analysis, and then the hydraulic drive system is calculated. According to the manual, the hydraulic system is selected according to the manual, and finally the strength of the support rod and the pin is checked to complete the design.

Key Words:Hydraulic; Lifting platform; Scissors;Mechanical design;Strength Check;