设计简介

摘 要

面对食品工业的发展,出现了多种多样的物料形势以及多样的处理方式,其中对于食品粉料这一物料种类来说,处理要求也相当高,对新型粉料烘干杀菌设备的需求量也很大。

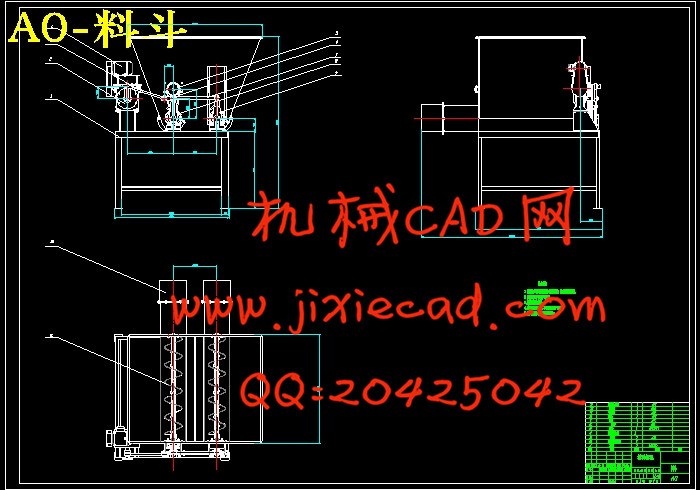

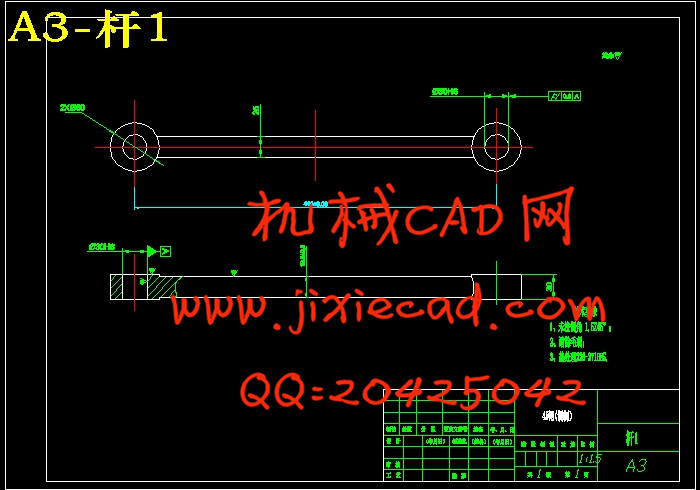

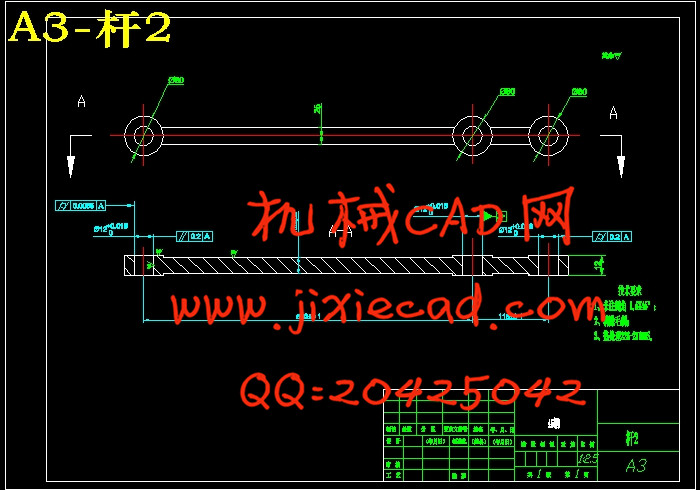

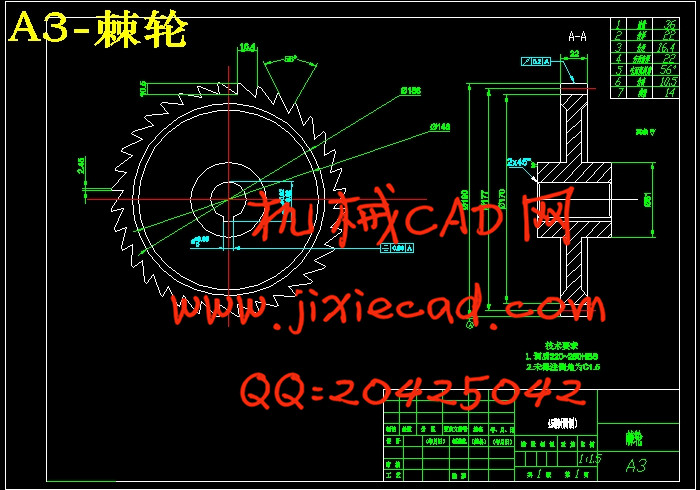

新型粉料烘干杀菌机是具有烘干和杀菌一体化的机械设备,具有处理量大,去水率的特点,本设计主要是对烘干部分结构的确定,包括烘干采用的具体方式,电机、减速机、传动结构的选型,新型粉料烘干杀菌机的工况分析也是设计的一部分,设计部分还包括滚筒的设计计算和料斗的部分结构设计。

通过对新型粉料烘干杀菌机的结构的设计,在利用solidworks辅助工具实现实体建模并作分析,证明设计的可行性,并优化设计内容,运用CAD完成的零件图为零件的加工提供了可行性。

关键词 机械结构设计;粉料烘干;结构选型

Abstract

In the face of the development of the food industry, there have been a wide variety of materials and a variety of processing methods, which for the food powder material type, the processing requirements are quite high, the new powder drying sterilization equipment demand Too big

The new powder drying and sterilizing machine is a mechanical equipment with drying and sterilization integration. It has the characteristics of large capacity and water removal rate. The design is mainly to determine the structure of drying, including the concrete way of drying, Motor, reducer, transmission structure selection, the new powder drying sterilization machine conditions analysis is part of the design part of the design also includes the design of the drum and hopper part of the structural design.

Through the design of the structure of the new powder drying and sterilizing machine, the solidworks aids are used to realize the solid modeling and analysis, and the feasibility of the design is proved and the design content is optimized. The parts of the parts are completed by CAD feasibility.

Key words Mechanical design;Powder drying;Structural selection

目录

1. 绪论 1

1.1 课题研究的应用价值 1

1.2 目前研究的概况和发展趋势 1

2. 方案的比较与选择 2

2.1 带式烘干机组成及工作原理及优缺点 2

2.2 塔式烘干机优缺点 3

2.3 箱式烘干机工作原理及优缺点 5

2.4 滚筒烘干机原理及优缺点 6

2.5 烘干部分选型的确定 7

2.6 传动机构的选择 7

3. 方案的总体设计 10

3.1 新型粉料烘干杀菌机预想简图 10

3.2 新型粉料烘干杀菌机工作原理 10

3.3 工况分析 11

4. 滚筒设计 12

4.1 物料吸热计算 12

4.2 计算有效加热面积 12

4.3 滚筒参数的确定 13

5. 电机选型 14

6. 减速机的选型 16

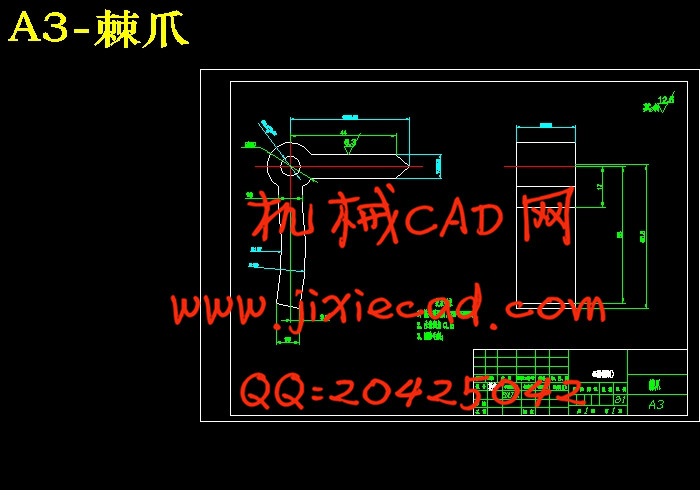

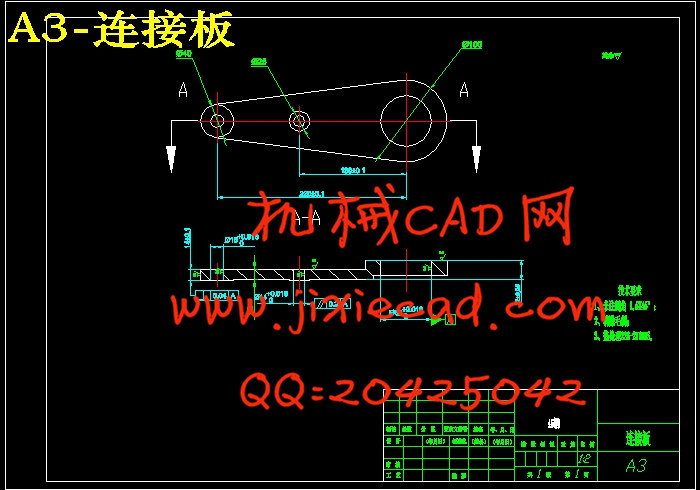

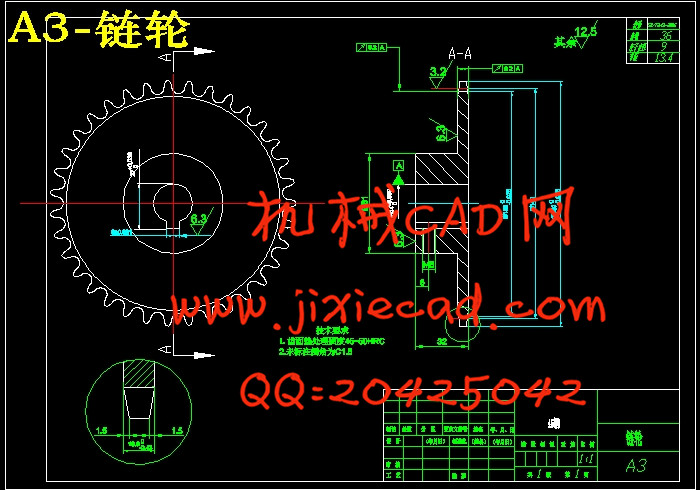

7. 链传动设计 18

7.1 链传动特点 18

7.2 链传动参数的计算 19

8.滚轮部装计算 23

9. 料斗螺旋式送料结构设计与计算 26

10. 总结 28

参考文献 31

致 谢 32

面对食品工业的发展,出现了多种多样的物料形势以及多样的处理方式,其中对于食品粉料这一物料种类来说,处理要求也相当高,对新型粉料烘干杀菌设备的需求量也很大。

新型粉料烘干杀菌机是具有烘干和杀菌一体化的机械设备,具有处理量大,去水率的特点,本设计主要是对烘干部分结构的确定,包括烘干采用的具体方式,电机、减速机、传动结构的选型,新型粉料烘干杀菌机的工况分析也是设计的一部分,设计部分还包括滚筒的设计计算和料斗的部分结构设计。

通过对新型粉料烘干杀菌机的结构的设计,在利用solidworks辅助工具实现实体建模并作分析,证明设计的可行性,并优化设计内容,运用CAD完成的零件图为零件的加工提供了可行性。

关键词 机械结构设计;粉料烘干;结构选型

Abstract

In the face of the development of the food industry, there have been a wide variety of materials and a variety of processing methods, which for the food powder material type, the processing requirements are quite high, the new powder drying sterilization equipment demand Too big

The new powder drying and sterilizing machine is a mechanical equipment with drying and sterilization integration. It has the characteristics of large capacity and water removal rate. The design is mainly to determine the structure of drying, including the concrete way of drying, Motor, reducer, transmission structure selection, the new powder drying sterilization machine conditions analysis is part of the design part of the design also includes the design of the drum and hopper part of the structural design.

Through the design of the structure of the new powder drying and sterilizing machine, the solidworks aids are used to realize the solid modeling and analysis, and the feasibility of the design is proved and the design content is optimized. The parts of the parts are completed by CAD feasibility.

Key words Mechanical design;Powder drying;Structural selection

目录

1. 绪论 1

1.1 课题研究的应用价值 1

1.2 目前研究的概况和发展趋势 1

2. 方案的比较与选择 2

2.1 带式烘干机组成及工作原理及优缺点 2

2.2 塔式烘干机优缺点 3

2.3 箱式烘干机工作原理及优缺点 5

2.4 滚筒烘干机原理及优缺点 6

2.5 烘干部分选型的确定 7

2.6 传动机构的选择 7

3. 方案的总体设计 10

3.1 新型粉料烘干杀菌机预想简图 10

3.2 新型粉料烘干杀菌机工作原理 10

3.3 工况分析 11

4. 滚筒设计 12

4.1 物料吸热计算 12

4.2 计算有效加热面积 12

4.3 滚筒参数的确定 13

5. 电机选型 14

6. 减速机的选型 16

7. 链传动设计 18

7.1 链传动特点 18

7.2 链传动参数的计算 19

8.滚轮部装计算 23

9. 料斗螺旋式送料结构设计与计算 26

10. 总结 28

参考文献 31

致 谢 32