设计简介

化工搅拌器的设计

摘 要

随着我国城市化和工业化的发展,搅拌器作为主要的搅拌处理设备,其搅拌和推流的效果对产品的质量有着重要影响。搅拌设备使用历史悠久,应用范围广。在化学工业、石油工业、建筑行业等传统工业中均有广泛的使用。搅拌操作看来似乎简单,但实际上,它所涉及的因素却极为复杂。搅拌器叶片在电机的驱动下旋转搅拌液体产生旋向射流,利用沿着射流表面的剪切应力来进行混合,使流体以外的液体通过摩擦产生搅拌作用,在极度混合的同时,形成体积流,应用大体积流动模式得到受控流体的搅拌推流输送。

本文介绍了小型搅拌器设计的基本思路和基本理论,分析了搅拌器的基本结构及其相关内容阐述了搅拌器的运动及其动力装置。通过对搅拌器的基本设备的描述和对其基本工作原理、作用和功能等相关文献的参考,从而对小型搅拌器的设计加以综述。

关键词:传动装置,联轴器,支承装置,电动机,减速器

the Design of Chemical Industry Agitator

Abstract

With the development of industrialization and urbanization,the agitator as major sewage treatment equipment is very important to sewage treatment for its effect of mixing and pushing the flow. The equipment of agitator have a long history and are used in most areas. meanwhile agitator are used in tradition industry such as chemistry industry,petroleum industry,architecture industry and so on. The operation of mix round looks as if simple,but actually,the ingredient it involved are very complexity. Blender’s wheel rotates and mixes liquid with the help of engine, it causes revolved efflux nozzle and mixes liquid taking advantage of shearing stress. At the same time it gives exterior liquid shearing stress,then carries exterior liquid by large volume flow.

The text introduces the basic consider way and the basic theory of small agitator design. Analyzing the basic configuration of agitator and related content, and the athletics and power equipment of agitator. Overpass describe the basic fixture of agitator and consult its basic employment principle,function and operation,thereby summarize the design of small agitator.

Key word: Gearing,Join shaft ware,Bearing device,Electromotor,Reducer

目 录

1 绪论…………………………………………………………………………………………………… 1

1.1搅拌器的概述…………………………………………………………………………………...1

1.1.1搅拌器的应用范围……………………………………………………….……………1

1.1.2搅拌器的工作原理……………………………………………………………………1

1.1.3化工反应器中的搅拌设备…………………………………………………………1

1.2化工搅拌器的适应条件和构造……………………………………………………………2

1.2.1化工搅拌器的适应条件………………………………………………………………2

1.2.2化工搅拌器的构造……………………………………………………………………2

1.3课题的目的、意义、国内外现状……………………………………………………………..3

1.3.1课题的目的、意义……………………………………………………………………3

1.3.2搅拌器的发展史及现状 …………………………………………………………3

1.3.3搅拌器的主要类型及其发展概况…………………………………………………4

1.3.4结语………………………………………………………………………………………9

1.4本课题的设计思路…………………………………………………………………………10

2 搅拌容器的设计 …………………………………………………………………………………10

2.1搅拌容器的设计探讨………………………………………………………………………11

2.1搅拌容器的设计探讨………………………………………………………………………11

2.2搅拌容器的设计计算……………………………………………………...………………12

2.2.1确定筒体的几何参数………………………………………………………………12

2.2.2封头的设计……………………………………………………….…………………14

3 传动装置的选择和搅拌器的设计………………………………………………………………16

3.1搅拌器的选型…………………………………………………………………………….…16

3.2搅拌器功率的计算……………………………………………………………..………16

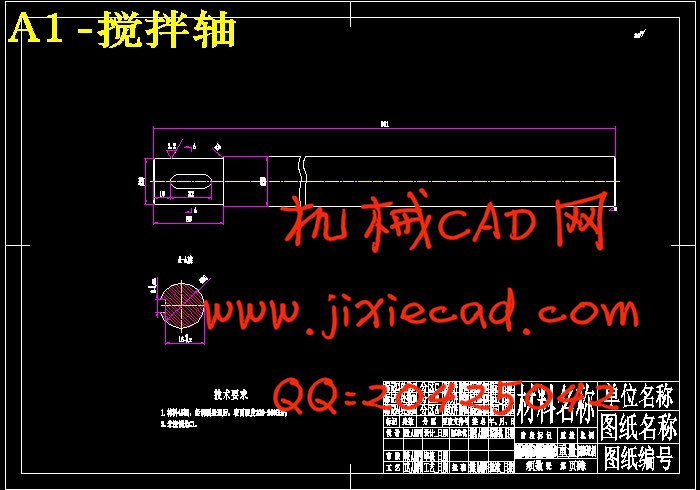

3.3搅拌轴的结构及材料………………………………………………………………………17

3.3.1轴的结构………………………………………………………………………………17

3.3.2轴的材料………………………………………………………………………………17

3.3.3搅拌轴的计算………………………………………………………………………17

3.3.4搅拌轴的形位公差和表面粗糙度要求…………………………………………19

3.4搅拌器及传动装置等的设计及计算………………………………………………..…….19

3.4.1搅拌器的选择………………………………………………………………………19

3.4.2电动机的选型………………………………………………………………………19

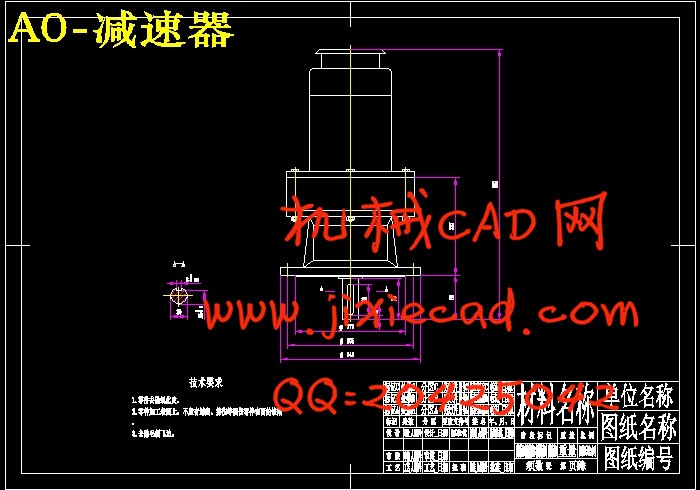

3.4.3减速器的选型…………………………………………………………………………20

3.4.4轴承的选择……………………………………………………………………………20

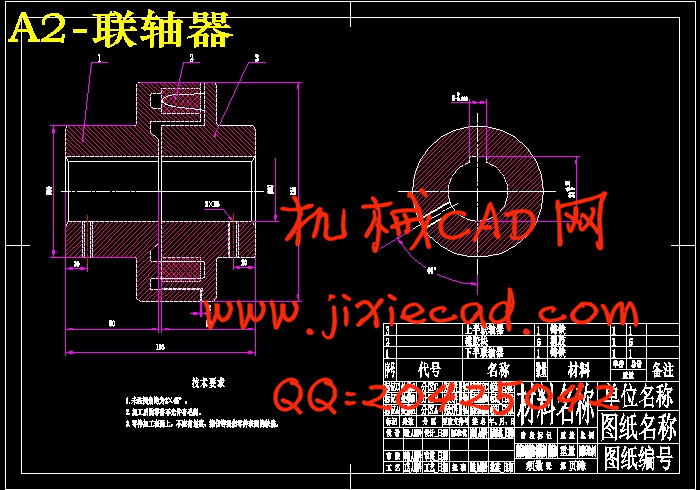

3.4.5联轴器的选择…………………………………………………………………………21

3.5传动装置的机架……………………………………………………………………………22

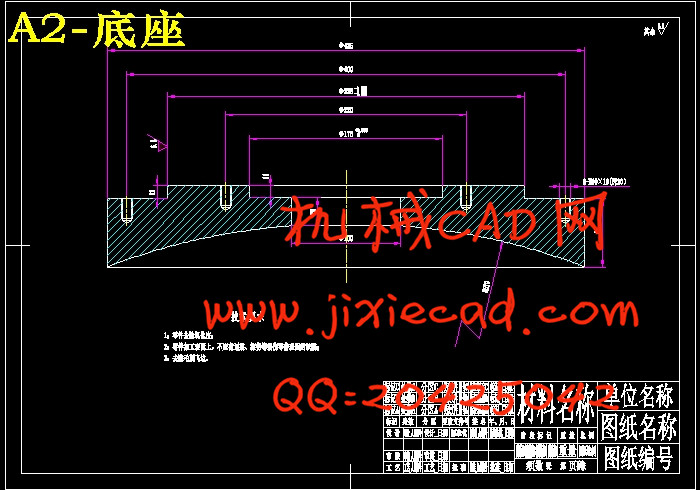

3.6底座的设计……………………………………………………………………………………23

3.7搅拌器的轴封装置…………………………………………………………………………24

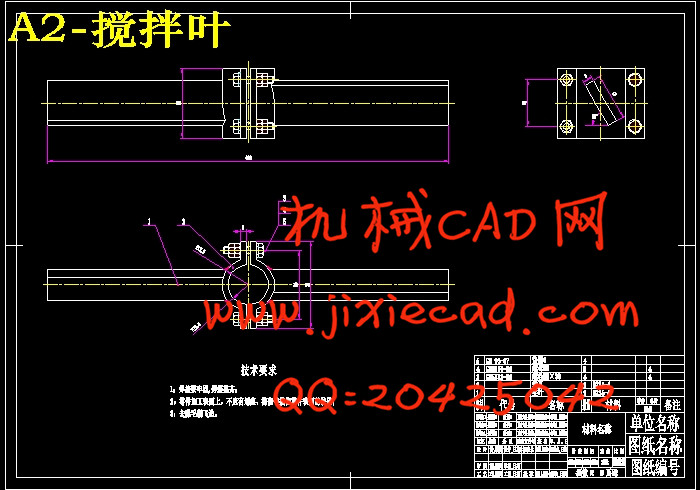

3.8搅拌器桨叶的设计…………………………………………………………………………26

3.8.1搅拌器桨叶的选型………………………………………………………………….26

3.8.2搅拌桨叶的直径设计……………………………………………………….……….27

3.9搅拌器的接管口支座的结构设计………………………………………………………..27

3.9.1液体进料管……………………………………………………………………………28

3.9.2液体出料管……………………………………………………………………………28

3.9.3仪表接管口……………………………………………………………………………29

3.9.4法兰的选择…………………………………………………………………………29

3.9.5设备支座的选择……………………………………………………………………30

结论………………………………………………………………………………………………………32

致谢……………………………………………………………………………………………………..33

参考文献…………………………………………………………………………………………………34

摘 要

随着我国城市化和工业化的发展,搅拌器作为主要的搅拌处理设备,其搅拌和推流的效果对产品的质量有着重要影响。搅拌设备使用历史悠久,应用范围广。在化学工业、石油工业、建筑行业等传统工业中均有广泛的使用。搅拌操作看来似乎简单,但实际上,它所涉及的因素却极为复杂。搅拌器叶片在电机的驱动下旋转搅拌液体产生旋向射流,利用沿着射流表面的剪切应力来进行混合,使流体以外的液体通过摩擦产生搅拌作用,在极度混合的同时,形成体积流,应用大体积流动模式得到受控流体的搅拌推流输送。

本文介绍了小型搅拌器设计的基本思路和基本理论,分析了搅拌器的基本结构及其相关内容阐述了搅拌器的运动及其动力装置。通过对搅拌器的基本设备的描述和对其基本工作原理、作用和功能等相关文献的参考,从而对小型搅拌器的设计加以综述。

关键词:传动装置,联轴器,支承装置,电动机,减速器

the Design of Chemical Industry Agitator

Abstract

With the development of industrialization and urbanization,the agitator as major sewage treatment equipment is very important to sewage treatment for its effect of mixing and pushing the flow. The equipment of agitator have a long history and are used in most areas. meanwhile agitator are used in tradition industry such as chemistry industry,petroleum industry,architecture industry and so on. The operation of mix round looks as if simple,but actually,the ingredient it involved are very complexity. Blender’s wheel rotates and mixes liquid with the help of engine, it causes revolved efflux nozzle and mixes liquid taking advantage of shearing stress. At the same time it gives exterior liquid shearing stress,then carries exterior liquid by large volume flow.

The text introduces the basic consider way and the basic theory of small agitator design. Analyzing the basic configuration of agitator and related content, and the athletics and power equipment of agitator. Overpass describe the basic fixture of agitator and consult its basic employment principle,function and operation,thereby summarize the design of small agitator.

Key word: Gearing,Join shaft ware,Bearing device,Electromotor,Reducer

目 录

1 绪论…………………………………………………………………………………………………… 1

1.1搅拌器的概述…………………………………………………………………………………...1

1.1.1搅拌器的应用范围……………………………………………………….……………1

1.1.2搅拌器的工作原理……………………………………………………………………1

1.1.3化工反应器中的搅拌设备…………………………………………………………1

1.2化工搅拌器的适应条件和构造……………………………………………………………2

1.2.1化工搅拌器的适应条件………………………………………………………………2

1.2.2化工搅拌器的构造……………………………………………………………………2

1.3课题的目的、意义、国内外现状……………………………………………………………..3

1.3.1课题的目的、意义……………………………………………………………………3

1.3.2搅拌器的发展史及现状 …………………………………………………………3

1.3.3搅拌器的主要类型及其发展概况…………………………………………………4

1.3.4结语………………………………………………………………………………………9

1.4本课题的设计思路…………………………………………………………………………10

2 搅拌容器的设计 …………………………………………………………………………………10

2.2搅拌容器的设计计算……………………………………………………...………………12

2.2.1确定筒体的几何参数………………………………………………………………12

2.2.2封头的设计……………………………………………………….…………………14

3 传动装置的选择和搅拌器的设计………………………………………………………………16

3.1搅拌器的选型…………………………………………………………………………….…16

3.2搅拌器功率的计算……………………………………………………………..………16

3.3搅拌轴的结构及材料………………………………………………………………………17

3.3.1轴的结构………………………………………………………………………………17

3.3.2轴的材料………………………………………………………………………………17

3.3.3搅拌轴的计算………………………………………………………………………17

3.3.4搅拌轴的形位公差和表面粗糙度要求…………………………………………19

3.4搅拌器及传动装置等的设计及计算………………………………………………..…….19

3.4.1搅拌器的选择………………………………………………………………………19

3.4.2电动机的选型………………………………………………………………………19

3.4.3减速器的选型…………………………………………………………………………20

3.4.4轴承的选择……………………………………………………………………………20

3.4.5联轴器的选择…………………………………………………………………………21

3.5传动装置的机架……………………………………………………………………………22

3.6底座的设计……………………………………………………………………………………23

3.7搅拌器的轴封装置…………………………………………………………………………24

3.8搅拌器桨叶的设计…………………………………………………………………………26

3.8.1搅拌器桨叶的选型………………………………………………………………….26

3.8.2搅拌桨叶的直径设计……………………………………………………….……….27

3.9搅拌器的接管口支座的结构设计………………………………………………………..27

3.9.1液体进料管……………………………………………………………………………28

3.9.2液体出料管……………………………………………………………………………28

3.9.3仪表接管口……………………………………………………………………………29

3.9.4法兰的选择…………………………………………………………………………29

3.9.5设备支座的选择……………………………………………………………………30

结论………………………………………………………………………………………………………32

致谢……………………………………………………………………………………………………..33

参考文献…………………………………………………………………………………………………34