设计简介

摘 要

加工中心是一种配以刀具库和自动换刀系统的高自动化、高柔性的加工设备。自动换刀系统由控制系统和换刀装置组成,PLC 控制换刀机构完成自动换刀,一次能完成多种工艺。在数控机床内,加工中心运用广泛,因此对换刀机构的设计研究是很有意义的。

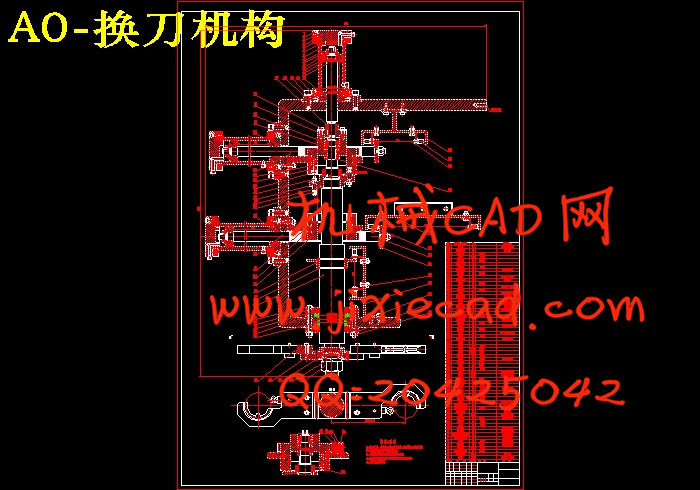

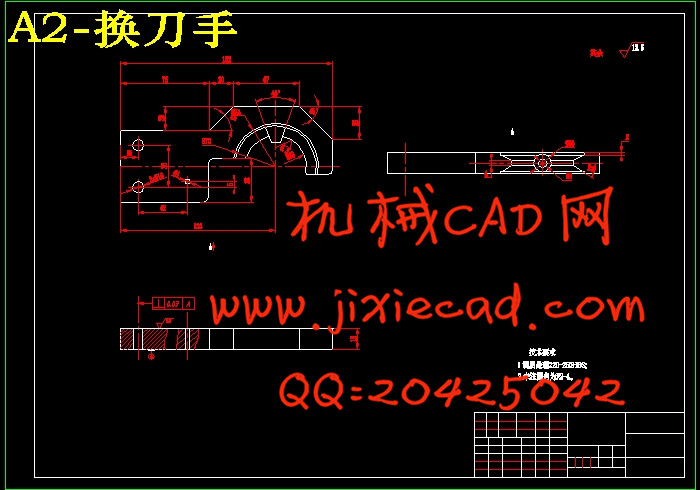

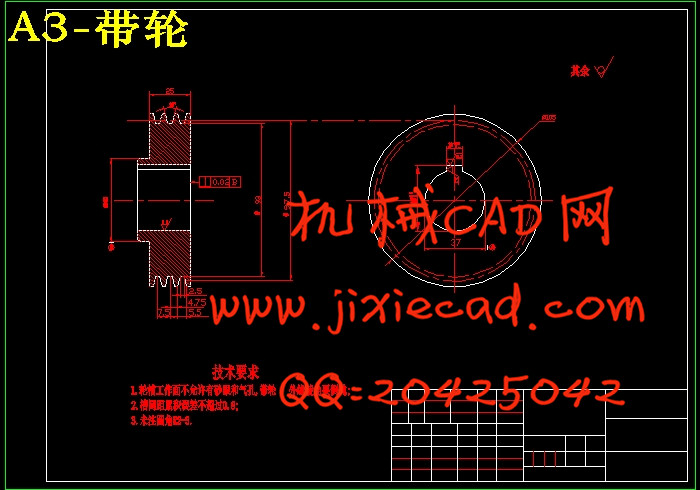

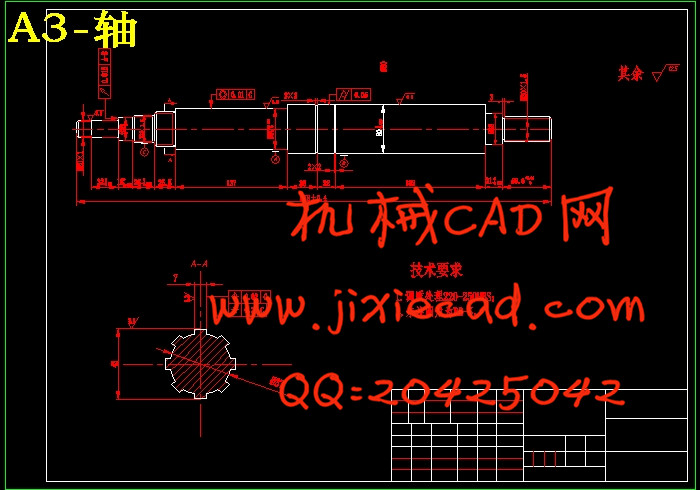

本设计主要对主轴以及换刀机构进行设计计算。根据设计要求,参考设计手册,进行了主轴的直径选取、扭矩校核和使用寿命验算等计算。为了有利于自动装卸刀具,主轴内还设计有自动夹紧装置和切屑清除装置。换刀机构采用回转式单臂双手机械手,由液压缸来完成对换刀动作的驱动。另外,本设计还研究了电气控制系统,采用

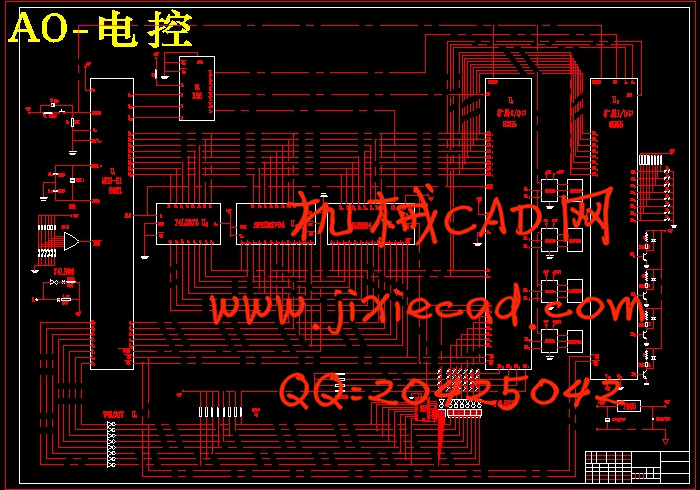

PLC 对其进行控制,合理选用了单片机并设计了电气控制线路。

本次设计自动换刀装置是数控铣加工中心的重要部件,完成和其它的部件装配后,可以有效提高切削功率以及加工效率,并能使得换刀时间缩短,提升刀具的是重复定位精度。

关键词: 加工中心;主轴;换刀装置;PLC

加工中心是一种配以刀具库和自动换刀系统的高自动化、高柔性的加工设备。自动换刀系统由控制系统和换刀装置组成,PLC 控制换刀机构完成自动换刀,一次能完成多种工艺。在数控机床内,加工中心运用广泛,因此对换刀机构的设计研究是很有意义的。

本设计主要对主轴以及换刀机构进行设计计算。根据设计要求,参考设计手册,进行了主轴的直径选取、扭矩校核和使用寿命验算等计算。为了有利于自动装卸刀具,主轴内还设计有自动夹紧装置和切屑清除装置。换刀机构采用回转式单臂双手机械手,由液压缸来完成对换刀动作的驱动。另外,本设计还研究了电气控制系统,采用

PLC 对其进行控制,合理选用了单片机并设计了电气控制线路。

本次设计自动换刀装置是数控铣加工中心的重要部件,完成和其它的部件装配后,可以有效提高切削功率以及加工效率,并能使得换刀时间缩短,提升刀具的是重复定位精度。

关键词: 加工中心;主轴;换刀装置;PLC

ABSTRACT

The machining center is a highly automated, highly flexible processing equipment with a tool magazine and automatic tool changer system. Automatic tool changer system consists of control system and tool changer. PLC makes the tool changer complete the automatic tool change.At the same time,it can complete a variety of processes. In the CNC machine tool, the processing center is widely used, so the design of the tool change is very meaningful.

The paper designs and calculates the spindle and tool change mechanism. According to the design requirements, refer to the design manual, the diameter of the spindle is selected, the torque of the spindle is checked and the life of the spindle is checked. In order to facilitate to load and unload tool automatically,the spindle is also designed with automatic clamping device and chip removal device. The tool changer adopts a rotary single-arm, two-handed manipulator, and the hydraulic cylinder is used to complete the driving of the tool change. In addition, the design also the electrical control system which controlled by PLC.What's more,it selects single chip reasonably and designes the electrical control circuit.

Automatic tool changer is an important part of CNC milling machining center. After the completion of assembly with other parts, it can effectively improve the cutting power and processing efficiency. It can also shorten the time of changing tools and raise the repeatability of the tool.

Key words: Machine Center ; Principle axis ;Tool Changer;PLC

The machining center is a highly automated, highly flexible processing equipment with a tool magazine and automatic tool changer system. Automatic tool changer system consists of control system and tool changer. PLC makes the tool changer complete the automatic tool change.At the same time,it can complete a variety of processes. In the CNC machine tool, the processing center is widely used, so the design of the tool change is very meaningful.

The paper designs and calculates the spindle and tool change mechanism. According to the design requirements, refer to the design manual, the diameter of the spindle is selected, the torque of the spindle is checked and the life of the spindle is checked. In order to facilitate to load and unload tool automatically,the spindle is also designed with automatic clamping device and chip removal device. The tool changer adopts a rotary single-arm, two-handed manipulator, and the hydraulic cylinder is used to complete the driving of the tool change. In addition, the design also the electrical control system which controlled by PLC.What's more,it selects single chip reasonably and designes the electrical control circuit.

Automatic tool changer is an important part of CNC milling machining center. After the completion of assembly with other parts, it can effectively improve the cutting power and processing efficiency. It can also shorten the time of changing tools and raise the repeatability of the tool.

Key words: Machine Center ; Principle axis ;Tool Changer;PLC

| 目 | 录 | ||

| 摘要 | .................................................... | 错误!未定义书签。 | |

| ABSTRACT ................................................ | 错误!未定义书签。 | ||

| 1. 绪论 | ................................................. | 错误!未定义书签。 | |

| 1.1 | 数控机床的概述 ........................................................................ | 错误!未定义书签。 | |

| 1.2 | 数控机床的特点 .......................................................................................................... | 1 | |

| 1.3 | 加工中心的原理 .......................................................................................................... | 2 | |

| 1.4 | 数控技术的现状和发展趋势 ...................................................................................... | 3 | |

| 1.5 | 本设计研究内容 .......................................................................................................... | 4 | |

| 2. 加工中心换刀机构方案设计 .............................................. | 5 | ||

| 3.主轴及换刀机构的设计计算 .............................................. | 7 | ||

| 3.1 | 主轴的性能分析 .......................................................................................................... | 7 | |

| 3.2 | 刀具自动装卸及切屑清除装置 .................................................................................. | 7 | |

| 3.3 | 主轴准停装置 .............................................................................................................. | 8 | |

| 3.4 | 主轴部分零件的设计计算 .......................................................................................... | 8 | |

| 3.5 | 换刀机构的设计 ........................................................................................................ | 13 | |

| 3.6 | 液压缸的计算 ............................................................................................................ | 15 | |

| 4. 加工中心硬件的选择设计 ............................................... | 19 | ||

| 4.1 CPU 的选择 ............................................................................................................... | 19 | ||

| 4.2 | 程序存储器和数据存储器的扩展 ............................................................................ | 19 | |

| 4.3 | I/O 接口的扩展 .......................................................................................................... | 19 | |

| 4.4 | 步进电机驱动器的选择 ............................................................................................ | 20 | |

| 4.5 | 液压缸的控制 ............................................................................................................ | 21 | |

| 5. | 结 | 论 .............................................................. | 22 |

| 参 考 文 献 ............................................................. | 23 | ||

| 致 | 谢 ................................................................ | 24 | |