设计简介

摘要

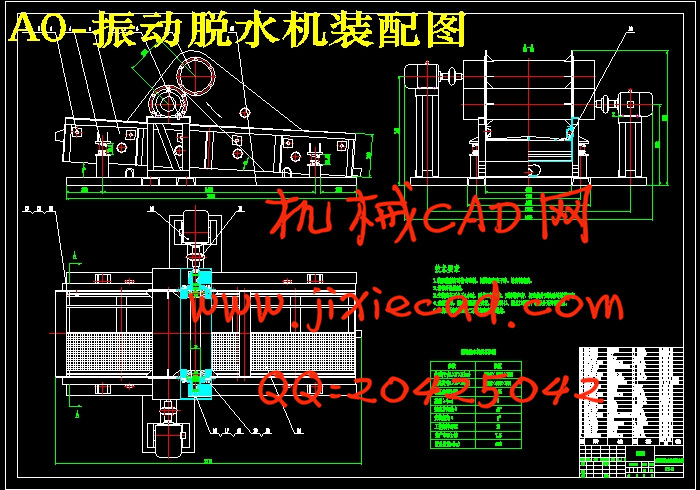

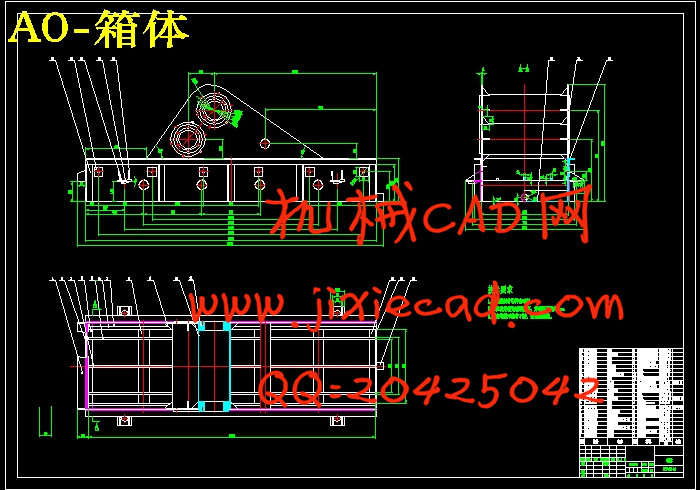

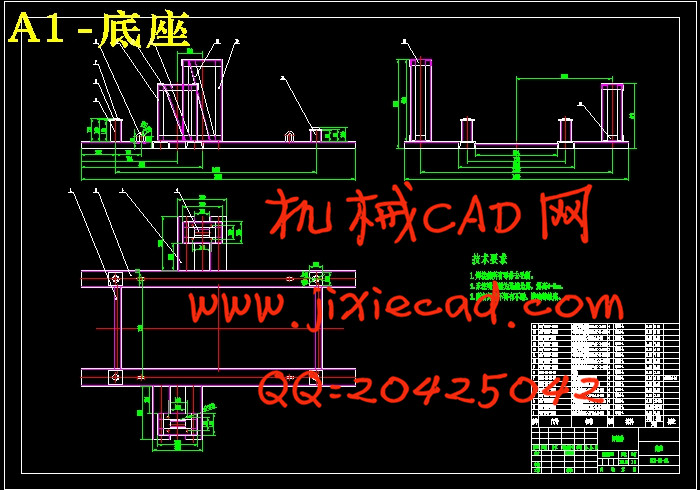

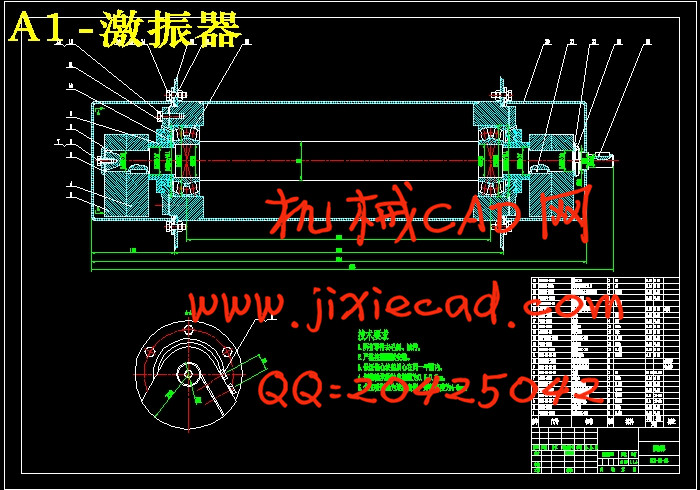

这次任务要求设计的双轴惯性式振动脱水机,由箱体、激振器、电动机、弹簧、底座、筛网等组成,采用直线振动筛进行脱水,两个激振器主轴分别由两个电机联接,两台电机主轴的旋转方向相反,物料在筛面上运动,通过激振器产生离心激振力来振动筛体,通过筛面上的小孔将物料进行筛分,其中的水分则通过筛面上的小孔筛分,经机体下面排水口流出。本次设计在原有机器的基础上进行了改进,采用双轴电机驱动取代了原来的运用齿轮传动强制同步的方式,简化了结构,减少了噪音。电机放在箱体侧面,减少了对箱体的强度要求。使用双轴可以较大距离进行安装,优化了结构。本次设计还进行了结构设计优化,参数计算,经过改进之后,生产效率得到提高,结构得到简化,降低了维修难度,提高了经济效益。关键词:振动脱水机;激振器;振动筛;

ABSTRAC

The two-axis inertial vibration dehydrator, designed for this mission, consists of a box, a vibrator, a motor, a spring, a base, a screen, and so on. It uses a linear vibrating screen for dehydration, and the main shaft of the two exciters is connected by two motors, respectively. The rotation direction of the main shaft of the two motors is opposite, the material moves on the screen surface, the vibrating body is vibrated by the centrifugal exciting force generated by the exciter, the material is screened through the holes in the screen surface, and the moisture content is screened by the small hole in the screen surface. Flow through the drain under the body. This design has been improved on the basis of the original machine, the use of two-axis motor drive instead of the original use of gear drive force with the same. The step way simplifies the structure and reduces the noise. The motor is placed on the side of the box body to reduce the intensity requirement of the box body. Using two-axis can be installed at a large distance, optimize the structure. After the improvement, the production efficiency is improved, the structure is simplified, the difficulty of maintenance is reduced, and the economic benefit is improved.

Keywords: vibratory dehydrator; vibrator; vibrating screen;

The two-axis inertial vibration dehydrator, designed for this mission, consists of a box, a vibrator, a motor, a spring, a base, a screen, and so on. It uses a linear vibrating screen for dehydration, and the main shaft of the two exciters is connected by two motors, respectively. The rotation direction of the main shaft of the two motors is opposite, the material moves on the screen surface, the vibrating body is vibrated by the centrifugal exciting force generated by the exciter, the material is screened through the holes in the screen surface, and the moisture content is screened by the small hole in the screen surface. Flow through the drain under the body. This design has been improved on the basis of the original machine, the use of two-axis motor drive instead of the original use of gear drive force with the same. The step way simplifies the structure and reduces the noise. The motor is placed on the side of the box body to reduce the intensity requirement of the box body. Using two-axis can be installed at a large distance, optimize the structure. After the improvement, the production efficiency is improved, the structure is simplified, the difficulty of maintenance is reduced, and the economic benefit is improved.

Keywords: vibratory dehydrator; vibrator; vibrating screen;

目录

第1章 绪论 1

1.1 课题的提出和意义 1

1.2 振动机械的组成和分类 1

1.3 国内研究状况 1

1.4发展方向 2

1.5课题研究的主要内容和理论基础及应用工具 2

第2章 设计方案的确定 3

2.1工作原理及总体方案的提出 3

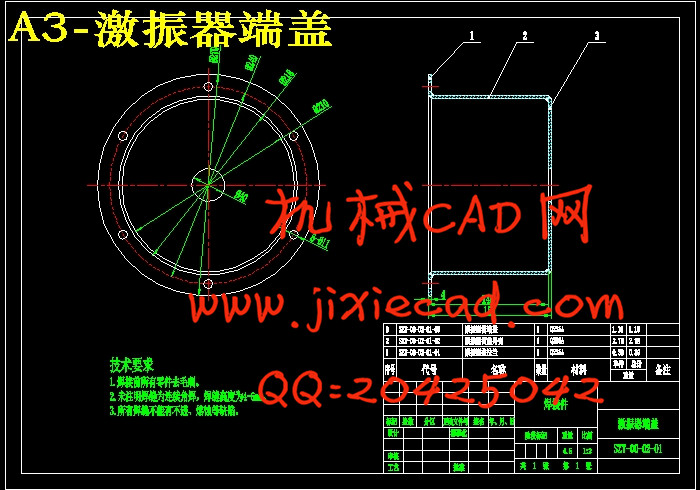

2.2激振器的选择 4

2.3箱体结构设计 5

2.4电机的布置 5

2.5传动方式 7

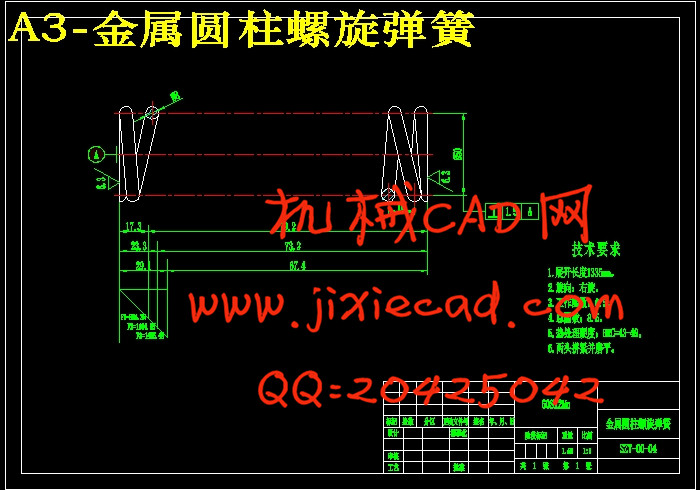

2.6弹性元件的选择 8

第3章 动力学分析及参数计算 9

3.1动力学分析 9

3.2 设计基本参数 11

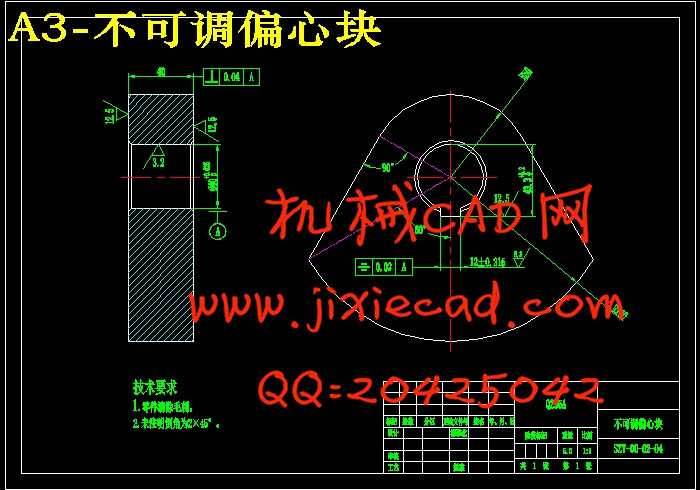

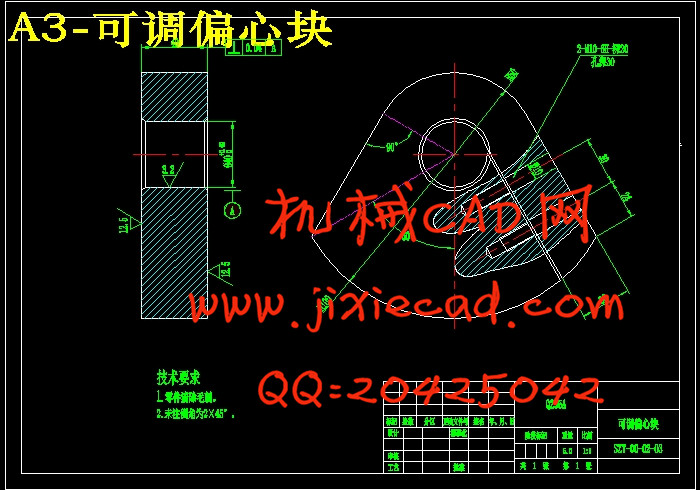

3.3激振器的计算 12

3.5电机的选择 18

3.6质量的计算 18

3.7 弹簧的设计计算 23

第4章 强度校核 27

4.1轴的强度校核 27

4.2轴承校核 34

4.3键的强度计算 35

第 5 章 安装与检修 37

5.1 安装要求 37

5.2 维护与检修 37

第 6 章 经济性分析 38

参考文献 39