设计简介

摘 要

在当今大规模制造业中,企业为提高生产效率,保障产品质量,普遍重视生产过程的自动化程度,机械手作为自动化生产线上的重要成员,逐渐被企业所认同并采用。机械手的技术水平和应用程度在一定程度上反映了一个国家工业自动化的水平,目前,机械手主要承担着焊接、喷涂、搬运以及堆垛等重复性并且劳动强度极大的工作,工作方式一般采取示教再现的方式。

本文将设计一台四自由度的机械手,主要的功用就是自动换刀。首先,本文将设计机器人的底座、大臂、小臂和机械手的结构,然后选择合适的传动方式、驱动方式,搭建机器人的结构平台;在此基础上,本文将设计该机器人的控制系统,包括数据采集卡和伺服放大器的选择、反馈方式和反馈元件的选择、端子板电路的设计以及控制软件的设计,重点加强控制软件的可靠性和机器人运行过程的安全性,最终实现的目标包括:关节的伺服控制和制动问题、实时监测机器人的各个关节的运动情况、机器人的示教编程和在线修改程序、设置参考点和回参考点。

关键词:机械手,示教编程,伺服,制动

ABSTRACT

In the modern large-scale manufacturing industry, enterprises pay more attention on the automation degree of the production process in order to enhance the production efficiency, and guarantee the product quality. As an important part of the automation production line, industrial robots are gradually approved and adopted by enterprises. The technique level and the application degree of industrial robots reflect the national level of the industrial automation to some extent, currently, industrial robots mainly undertake the jops of welding, spraying, transporting and stowing etc. , which are usually done repeatedly and take high work strength, and most of these robots work in playback way.

In this paper I will design an industrial robot with four DOFs, which is used to carry material for a punch. First I will design the structure of the base, the big arm, the small arm and the end manipulator of the robot, then choose proper drive method and transmission method, building the mechanical structure of the robot. On this foundation, I will design the control system of the robot, including choosing DAQ card, servo control, feedback method and designing electric circuit of the terminal card and control software. Great attention will be paid on the reliability of the control software and the robot safety during running. The aims to realize finally include: servocontrol and brake of the joint, monitoring the movement of each joint in realtime, playback programming and modifying the program online, setting reference point and returning to reference point.

KEY WORDS: robot, playback, servocontrol, brake

目录

第1章 引言 3

1.1机械手分类…3

1.2机械手的组成 6

1.3 应用机械手的意义 9

1.4 机械手的现状 9

1.5 工业机械手在生产中的应用 12

1.6机械手的组成 13

1.7 课题要求 14

第2章机械手的结构设计 16

2.1手部结构 16

2.1.1手部设计基本要求 16

2.1.2典型的手部结构 16

2.1.3机械手手抓的设计计算 16

2.1.4 机械手手抓夹持精度的分析和计算 21

2.1.5弹簧的计算 21

2.2 系统的组成 23

2.3 总体技术方案 23

2.4腕部结构的设计 24

2.5 臂部 30

2.5.1臂部的结构形式 30

2.5.2臂部机构的导向装置 31

2.6 机械手机身的设计计算 33

2.6.1机身的整体设计 34

2.6.2机身回转机构设计的计算 35

2.6.3机身升降机构计算 38

2.6.4轴承选择分析 41

2.7 驱动方式 42

2.8 传动方式 43

2.9 制动器 45

设计小结 47

致谢 48

参考文献 49

在当今大规模制造业中,企业为提高生产效率,保障产品质量,普遍重视生产过程的自动化程度,机械手作为自动化生产线上的重要成员,逐渐被企业所认同并采用。机械手的技术水平和应用程度在一定程度上反映了一个国家工业自动化的水平,目前,机械手主要承担着焊接、喷涂、搬运以及堆垛等重复性并且劳动强度极大的工作,工作方式一般采取示教再现的方式。

本文将设计一台四自由度的机械手,主要的功用就是自动换刀。首先,本文将设计机器人的底座、大臂、小臂和机械手的结构,然后选择合适的传动方式、驱动方式,搭建机器人的结构平台;在此基础上,本文将设计该机器人的控制系统,包括数据采集卡和伺服放大器的选择、反馈方式和反馈元件的选择、端子板电路的设计以及控制软件的设计,重点加强控制软件的可靠性和机器人运行过程的安全性,最终实现的目标包括:关节的伺服控制和制动问题、实时监测机器人的各个关节的运动情况、机器人的示教编程和在线修改程序、设置参考点和回参考点。

关键词:机械手,示教编程,伺服,制动

ABSTRACT

In the modern large-scale manufacturing industry, enterprises pay more attention on the automation degree of the production process in order to enhance the production efficiency, and guarantee the product quality. As an important part of the automation production line, industrial robots are gradually approved and adopted by enterprises. The technique level and the application degree of industrial robots reflect the national level of the industrial automation to some extent, currently, industrial robots mainly undertake the jops of welding, spraying, transporting and stowing etc. , which are usually done repeatedly and take high work strength, and most of these robots work in playback way.

In this paper I will design an industrial robot with four DOFs, which is used to carry material for a punch. First I will design the structure of the base, the big arm, the small arm and the end manipulator of the robot, then choose proper drive method and transmission method, building the mechanical structure of the robot. On this foundation, I will design the control system of the robot, including choosing DAQ card, servo control, feedback method and designing electric circuit of the terminal card and control software. Great attention will be paid on the reliability of the control software and the robot safety during running. The aims to realize finally include: servocontrol and brake of the joint, monitoring the movement of each joint in realtime, playback programming and modifying the program online, setting reference point and returning to reference point.

KEY WORDS: robot, playback, servocontrol, brake

目录

第1章 引言 3

1.1机械手分类…3

1.2机械手的组成 6

1.3 应用机械手的意义 9

1.4 机械手的现状 9

1.5 工业机械手在生产中的应用 12

1.6机械手的组成 13

1.7 课题要求 14

第2章机械手的结构设计 16

2.1手部结构 16

2.1.1手部设计基本要求 16

2.1.2典型的手部结构 16

2.1.3机械手手抓的设计计算 16

2.1.4 机械手手抓夹持精度的分析和计算 21

2.1.5弹簧的计算 21

2.2 系统的组成 23

2.3 总体技术方案 23

2.4腕部结构的设计 24

2.5 臂部 30

2.5.1臂部的结构形式 30

2.5.2臂部机构的导向装置 31

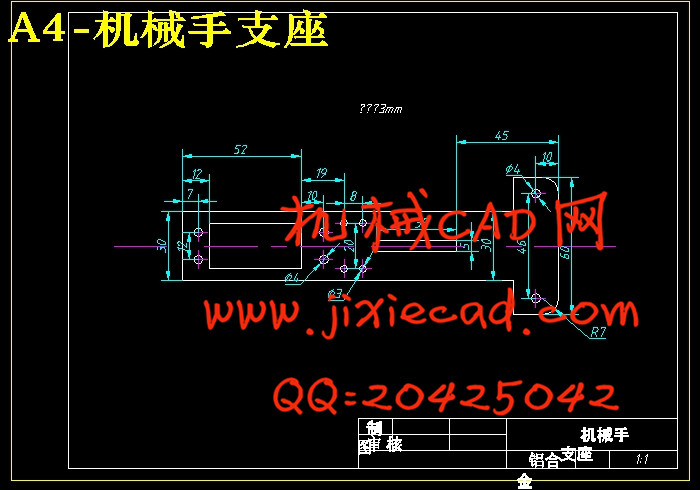

2.6 机械手机身的设计计算 33

2.6.1机身的整体设计 34

2.6.2机身回转机构设计的计算 35

2.6.3机身升降机构计算 38

2.6.4轴承选择分析 41

2.7 驱动方式 42

2.8 传动方式 43

2.9 制动器 45

设计小结 47

致谢 48

参考文献 49