设计简介

20世纪90年代以来,数控加工技术得到迅速的普及和发展。带有换刀装置的加工中心和柔性加工系统得到获得了巨大的发展,使得加工质量和生产率得到大幅提升。本次毕业设计,完成了换刀机器人的总体结构的论证和换刀机器人末端操作器。该换刀机器人的水平方向和纵向移动由伺服电机驱动,丝杠传动,手爪的旋转由伺服电机驱动,齿轮减速器调速,电磁铁驱动手爪张合,弹簧使手爪闭合,完成手爪部分的取刀和换刀动作。本次毕业设计在研究了国内外加工中心及其自动换刀装置的基础上分析换刀机器人的要求和主要功能。本文中主要介绍了双手爪的整体结构,手腕自由度运动学参数计算,手腕电机的选择,减速器的选用,手爪的结构设计和电磁铁的选用。

关键词 换刀机器人 齿轮减速器 伺服电机 电磁铁

Abstract

20th century since the 90's, CNC machining technology is the rapid popularization and development. Machining center and flexible manufacturing systems with a tool changing was a tremendous development. It makes the processing quality and productivity to be increased dramatically. The graduation project, mainly to complete the end of the robot manipulator ATC - tool changing the structural design of claw hands.

The tool changing robot complete gripper tool changing tools and action taken, which move by the servo motor driven screw drive gripper rotary driven by the servo motor, speed reducer, solenoid-driven Zhang gripper, gripper closing spring so that, part of the completion of gripper tool changing knives and action taken. The graduation project analysis requirements and the main functions of the robot tool changing based on the research about machining center and automatic tool changing device at home and abroad .This article introduces the overall structure of claw hands, wrist kinematic parameters degrees of freedom, the choice of wrist motor, reducer selection, and the hand count and calculation of the structural design and the selection electromagnet.

Keywords tool change Robot gear reducer actuating motor

electric magnet

目 录

1 引言 1

1.1 换刀机器人概念及发展状况 1

1.2 换刀机器人未来发展趋势 3

1.3 课题研究意义 4

2 方案论证 5

2.1 技术要求 5

2.2 总体方案设计 5

2.3 总体方案确定 12

3 执行系统的设计 13

3.1 纵向移动机构 13

3.2 横向移动机构 13

3.3 垂直升降机构 13

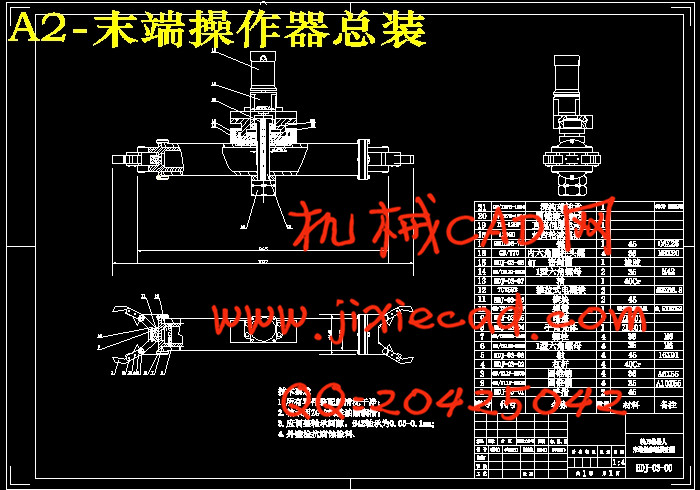

3.4 末端操作器 14

3.5 机械手爪 15

4. 末端操作器的设计 16

4.1 手部结构设计及计算 16

4.2 手部驱动方式选择及计算 18

4.3 手指的设计 19

4.4 手部转动力矩计算 20

4.5 电机及齿轮减速器的选择 23

5 联轴器的选择和转矩校核 26

5.1 联轴器的选择 26

5.2 转矩校核 27

结论 28

致谢 29

参考文献 30

关键词 换刀机器人 齿轮减速器 伺服电机 电磁铁

Abstract

20th century since the 90's, CNC machining technology is the rapid popularization and development. Machining center and flexible manufacturing systems with a tool changing was a tremendous development. It makes the processing quality and productivity to be increased dramatically. The graduation project, mainly to complete the end of the robot manipulator ATC - tool changing the structural design of claw hands.

The tool changing robot complete gripper tool changing tools and action taken, which move by the servo motor driven screw drive gripper rotary driven by the servo motor, speed reducer, solenoid-driven Zhang gripper, gripper closing spring so that, part of the completion of gripper tool changing knives and action taken. The graduation project analysis requirements and the main functions of the robot tool changing based on the research about machining center and automatic tool changing device at home and abroad .This article introduces the overall structure of claw hands, wrist kinematic parameters degrees of freedom, the choice of wrist motor, reducer selection, and the hand count and calculation of the structural design and the selection electromagnet.

Keywords tool change Robot gear reducer actuating motor

electric magnet

目 录

1 引言 1

1.1 换刀机器人概念及发展状况 1

1.2 换刀机器人未来发展趋势 3

1.3 课题研究意义 4

2 方案论证 5

2.1 技术要求 5

2.2 总体方案设计 5

2.3 总体方案确定 12

3 执行系统的设计 13

3.1 纵向移动机构 13

3.2 横向移动机构 13

3.3 垂直升降机构 13

3.4 末端操作器 14

3.5 机械手爪 15

4. 末端操作器的设计 16

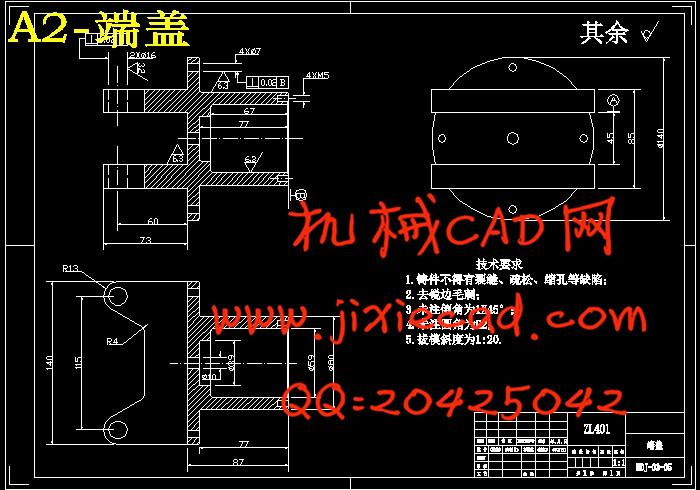

4.1 手部结构设计及计算 16

4.2 手部驱动方式选择及计算 18

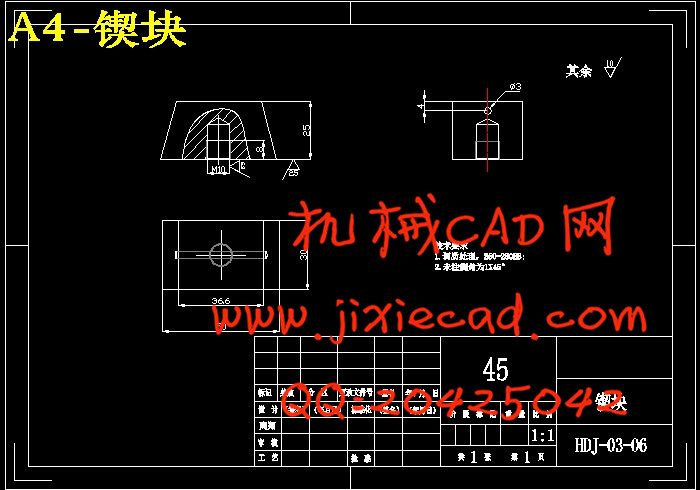

4.3 手指的设计 19

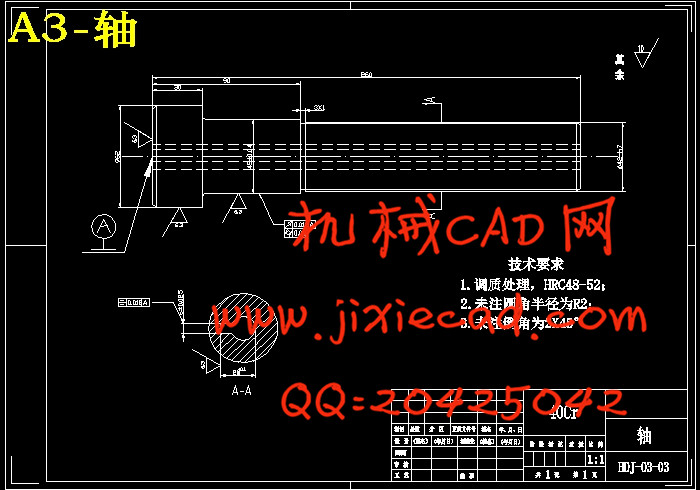

4.4 手部转动力矩计算 20

4.5 电机及齿轮减速器的选择 23

5 联轴器的选择和转矩校核 26

5.1 联轴器的选择 26

5.2 转矩校核 27

结论 28

致谢 29

参考文献 30